Method for saving energy and producing more propylene in absorption-stabilization system by catalytic cracking

An absorption stabilization system and catalytic cracking technology, applied in catalytic cracking, cracking, chemical industry, etc., can solve problems such as gasoline yield decline, liquefied gas loss, and device control and adjustment difficulties, and achieve the effect of reducing the total load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

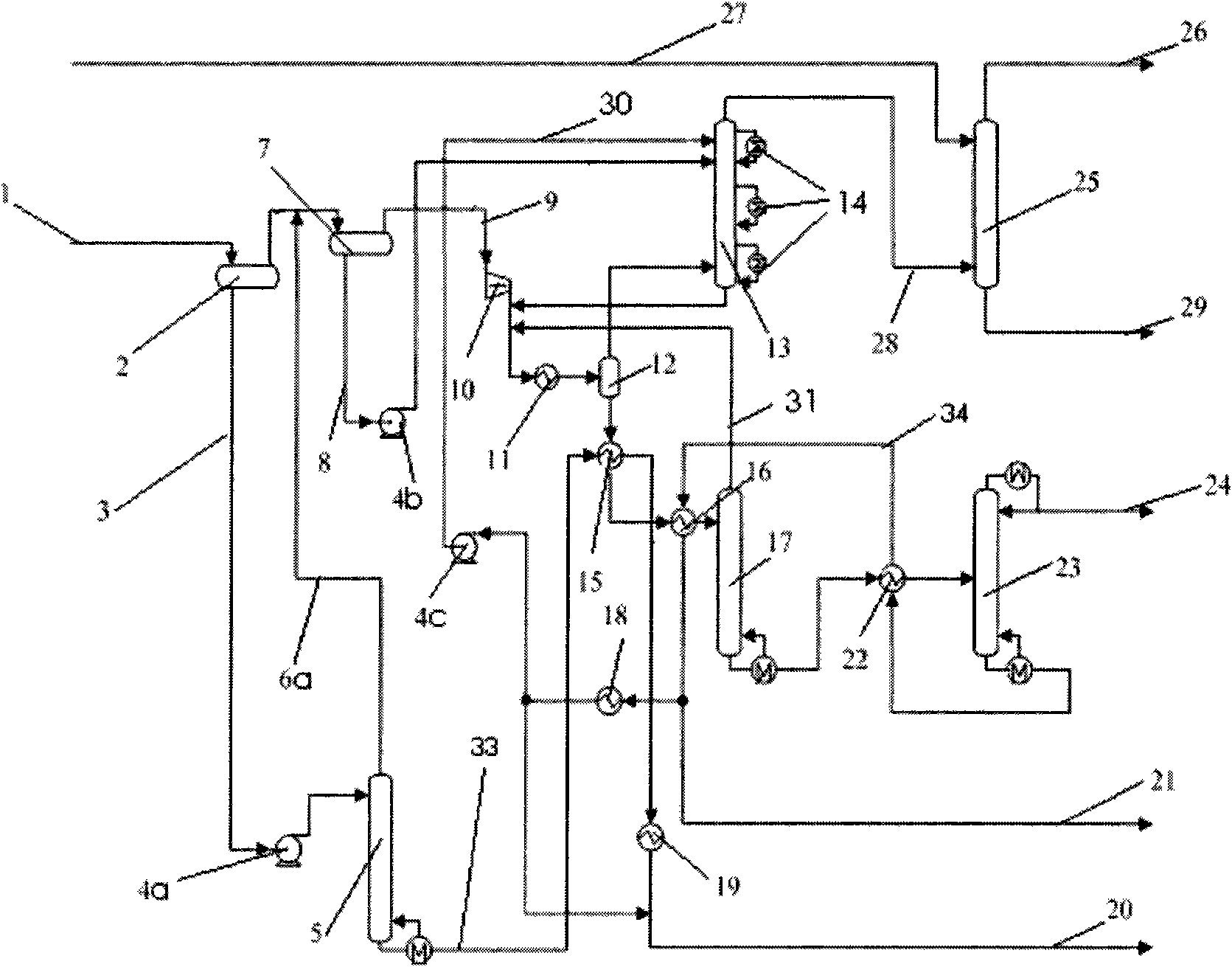

[0023] Example 1: Energy-saving and productive propylene process desorption tower T302 hot feed scheme

[0024] Taking an oil refinery with a catalytic processing capacity of 0.4Mt / a as an example for simulation, its rich gas flow rate is 8000kg / h, the flow rate of light gasoline is 7000kg / h, and the flow rate of heavy gasoline is 4000kg / h. The heavy gasoline separated by the heavy gasoline separator V201A enters the top of the absorption stabilization system after being pressurized and cooled, and the newly added desorption tower T305, the desorption tower T305 separates the heavy gasoline into the top desorption tower rich in C1~C4 components under low pressure operation. Stable gasoline with aspirated and low olefin content. The rich gas separated from the light gasoline separator V201B is pressurized, mixed with the saturated absorption oil at the bottom of the absorption tower T301 and the desorbed gas at the top of the desorption tower T302, cooled to 30°C-45°C, and then...

Embodiment 2

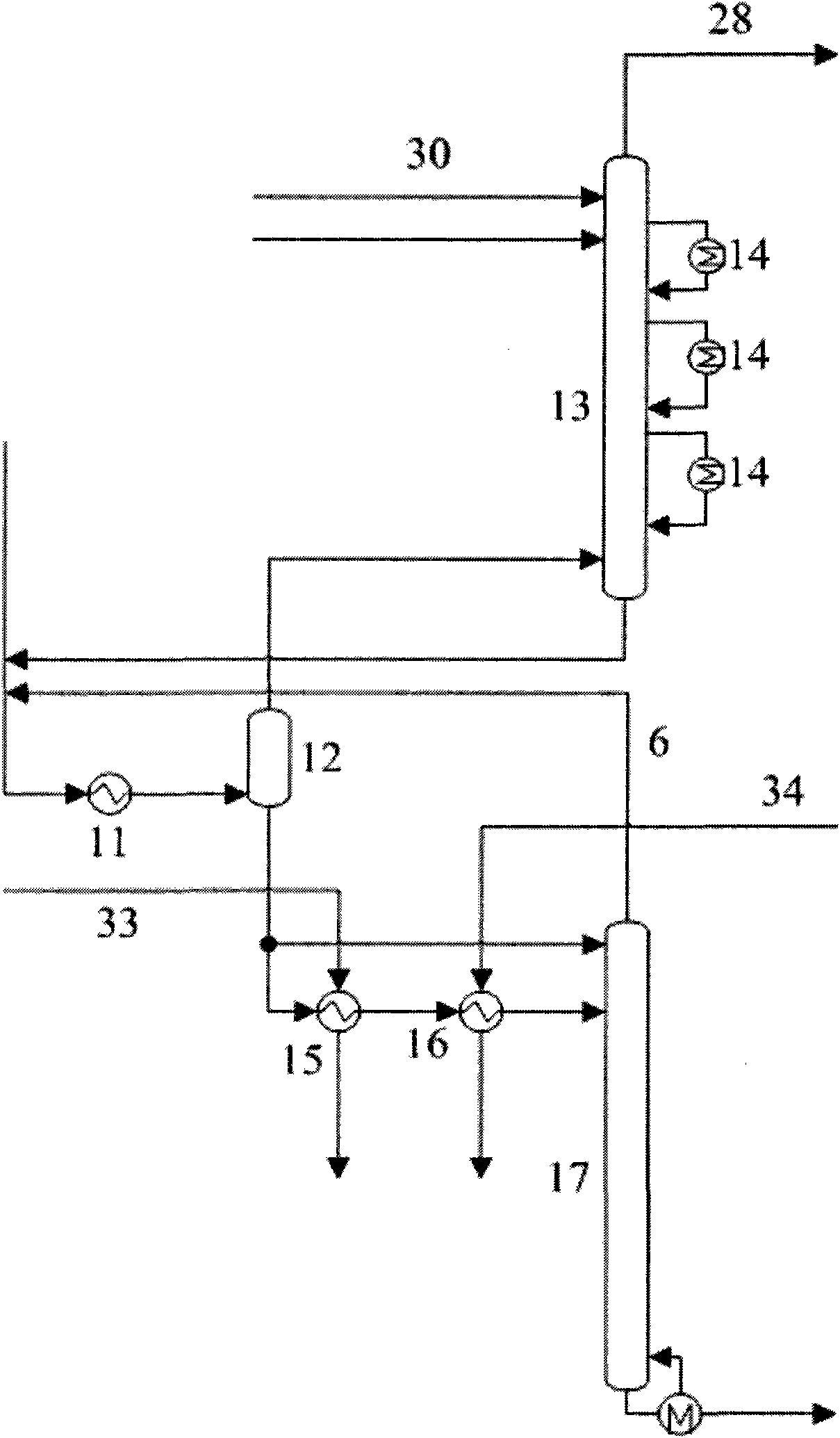

[0026] Example 2: Energy-saving and productive propylene process desorption tower T302 double-strand feeding scheme

[0027] Divide the liquid phase of the vapor-liquid balance tank of the desorption tower T302 hot feed process into two streams, one as cold feed into the top of the desorption tower T302, and the other hot feed into the upper part of the desorption tower T302; for effective use and stability The heat of gasoline, the hot stream first passes through the heat exchanger E301 and the stable gasoline at the bottom of the desorption tower T305 to exchange heat to 35°C-50°C, and then heats up to 50°C-90°C after heat exchange through the heat exchanger E302. This example is the improvement of Example 1, except the above-mentioned improved part, all the other technological processes are the same as Example 1.

Embodiment 3

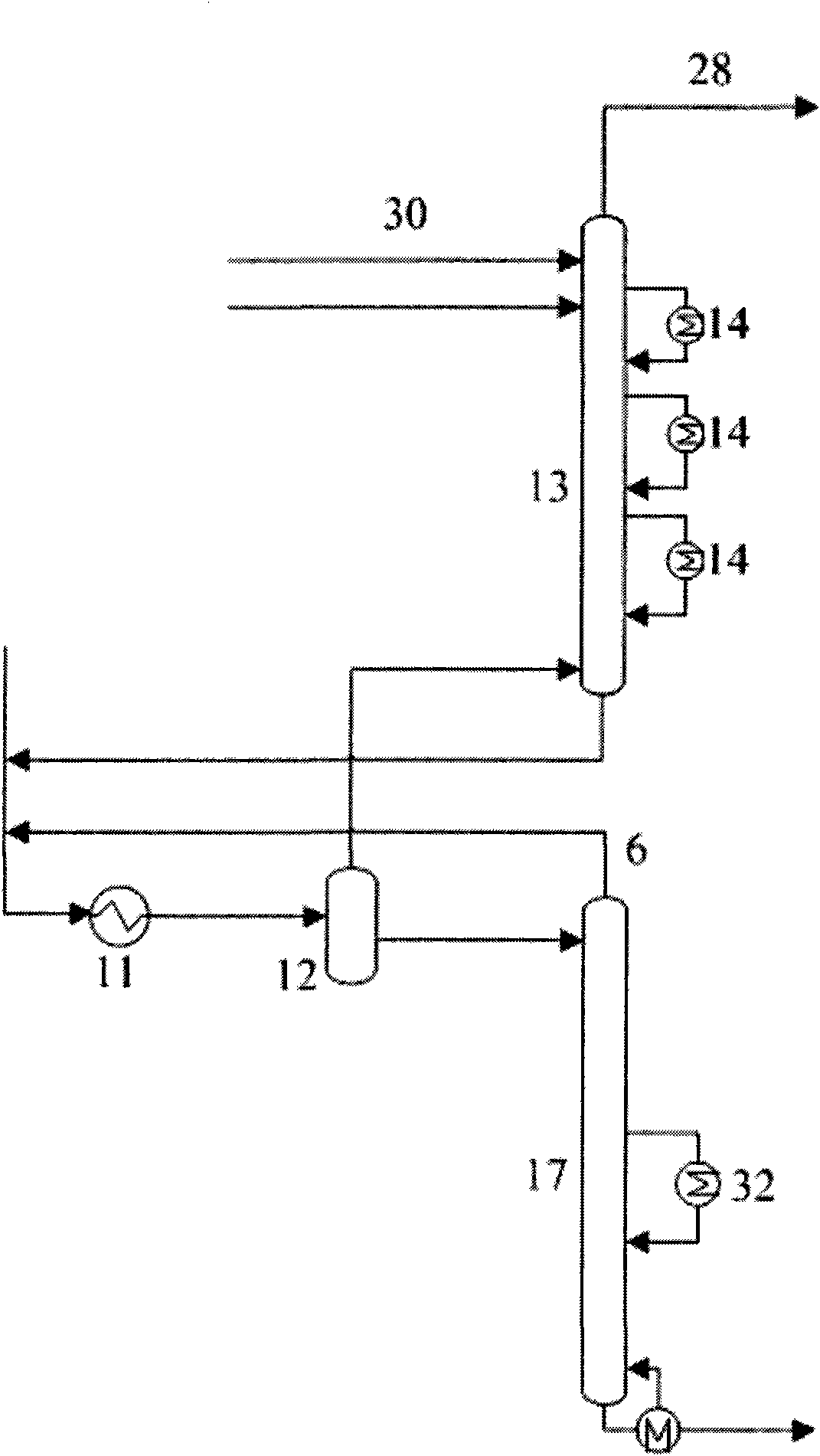

[0028] Example 3: Energy-saving and productive propylene process desorption tower T302 intermediate reboiler scheme

[0029] The heat exchanger E301 and the heat exchanger E302 in the hot feed process of the desorption tower T302 are canceled, and the liquid phase of the vapor-liquid balance tank directly enters the top of the desorption tower T302; and an intermediate reboiler (32) is set in the lower part of the desorption tower T302, Its return temperature is 70°C to 110°C. The heat for the intermediate reboiler comes from stabilizing gasoline. This example is the improvement of Example 1, except the above-mentioned improved part, all the other technological processes are the same as Example 1.

[0030] Under the same feed and product specifications, the treatment effects of Example 1, Example 2 and Example 3 are compared with the treatment effects of the conventional thermal feed process of the double-tower flow process. The comparison results of the four processes are as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com