Dissolved gas sampling apparatus and method used in transformer oil gas-chromatography on-line analysis

A sampling device and technology for transformer oil, which are applied to the direct sampling and sampling method and the device used, and the field of gas chromatography sample pretreatment and sampling, which can solve the problems of increasing the cost of the device and the complexity of the operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

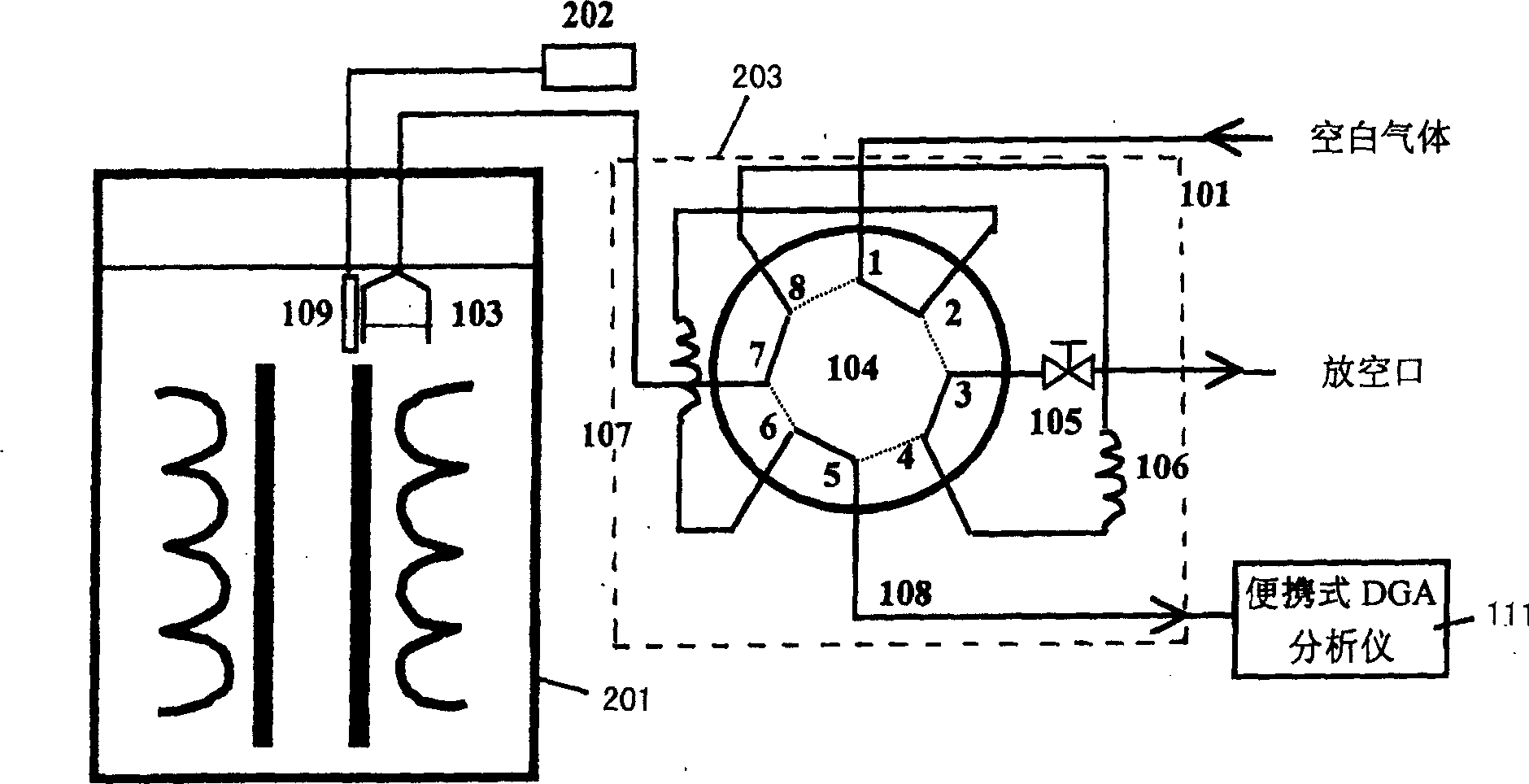

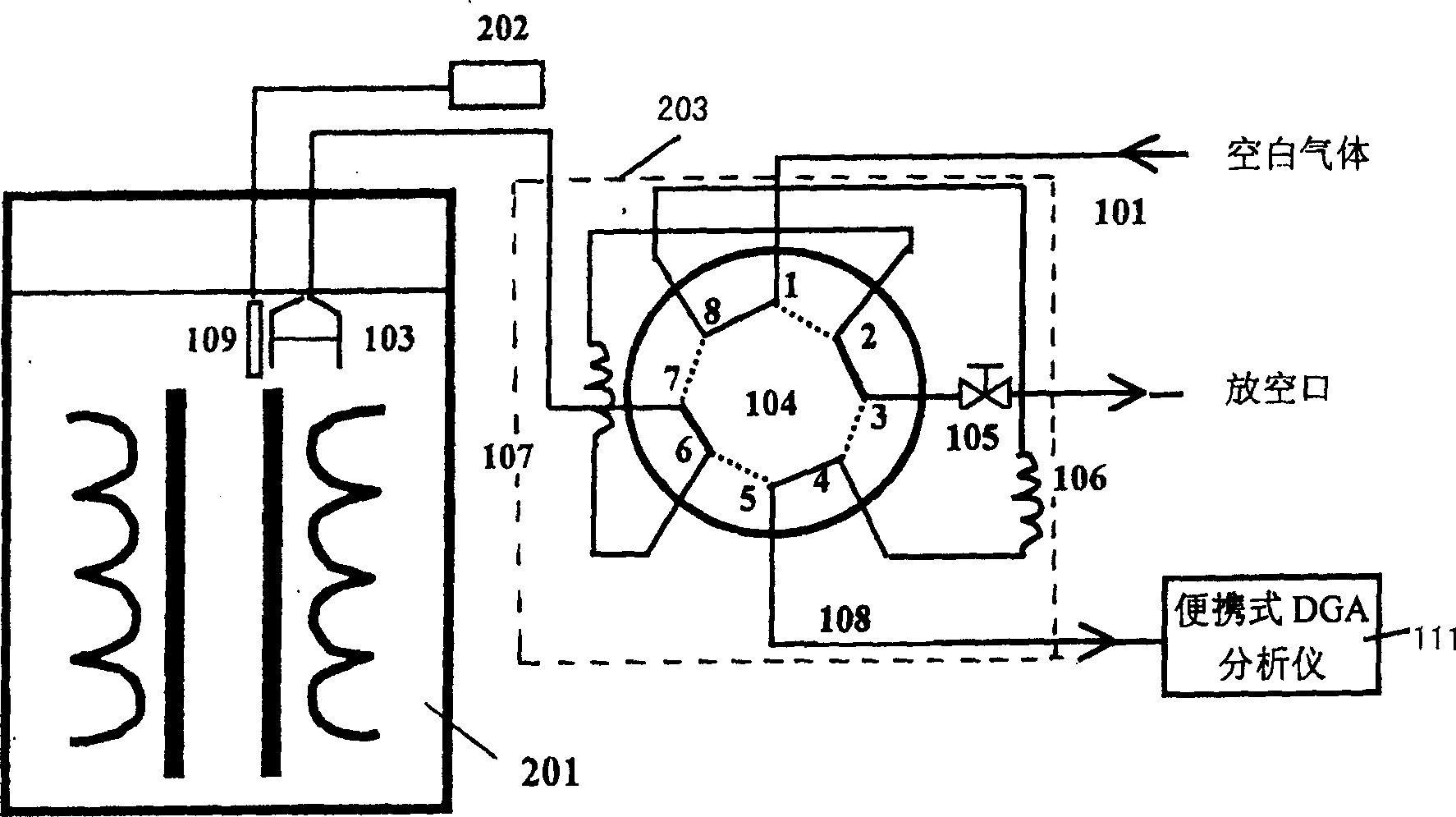

[0043] Embodiment 1: see Fig. 1, blank gas 101 adopts high-purity helium or hydrogen (purity is more than 99.999%), is controlled in 0.1-0.2Mpa scope with pressure-stabilizing valve, is connected in 1 " position of eight-way valve 104, The sample quantitative tube 107 adopts a 3mm I.D.×141.5cm stainless steel tube, 10mL, and is connected with the 2″ and 6″ positions of the eight-way valve 104. The blank gas quantitative tube 106 adopts a 3mm I.D.×283cm stainless steel tube, 20mL, and is connected with the eight-way valve 104. The 4″ and 8″ positions are connected, the 7″ position is connected to the sampling probe 103 through a 1 / 16″ stainless steel tube or quartz capillary tube with an inner diameter of 0.3-0.8mm, and the 3″ position is the vent port, connected to the two-way stop valve 105, 5 The "position" is connected to the micro-oil Dissolved Gas Analyzer (DGA) (2100 SAT type) 111 inlet by quartz capillary 108, and micro-TCD detects. Sampling probe 103 is cylindrical and ...

Embodiment 2

[0044] Embodiment 2: other conditions are the same as embodiment 1. See Fig. 1, the 5 " position of eight-way valve 104 links to each other with the six-way valve of U.S. Varian3800 gas chromatograph through internal diameter 0.2mm, long 300cm quartz capillary 108, FID detects. Sampling probe 103 is a bell jar shape, and volume is 50mL. Realize The simulated on-line analysis of dissolved gas in oil in transformer 201 achieves good separation of 5ppm hydrocarbon gas. The chromatogram is as follows Figure 4 shown. The detection concentration of acetylene can reach 0.1ppm, meeting the requirements of the national standard GB7252-2001.

Embodiment 3

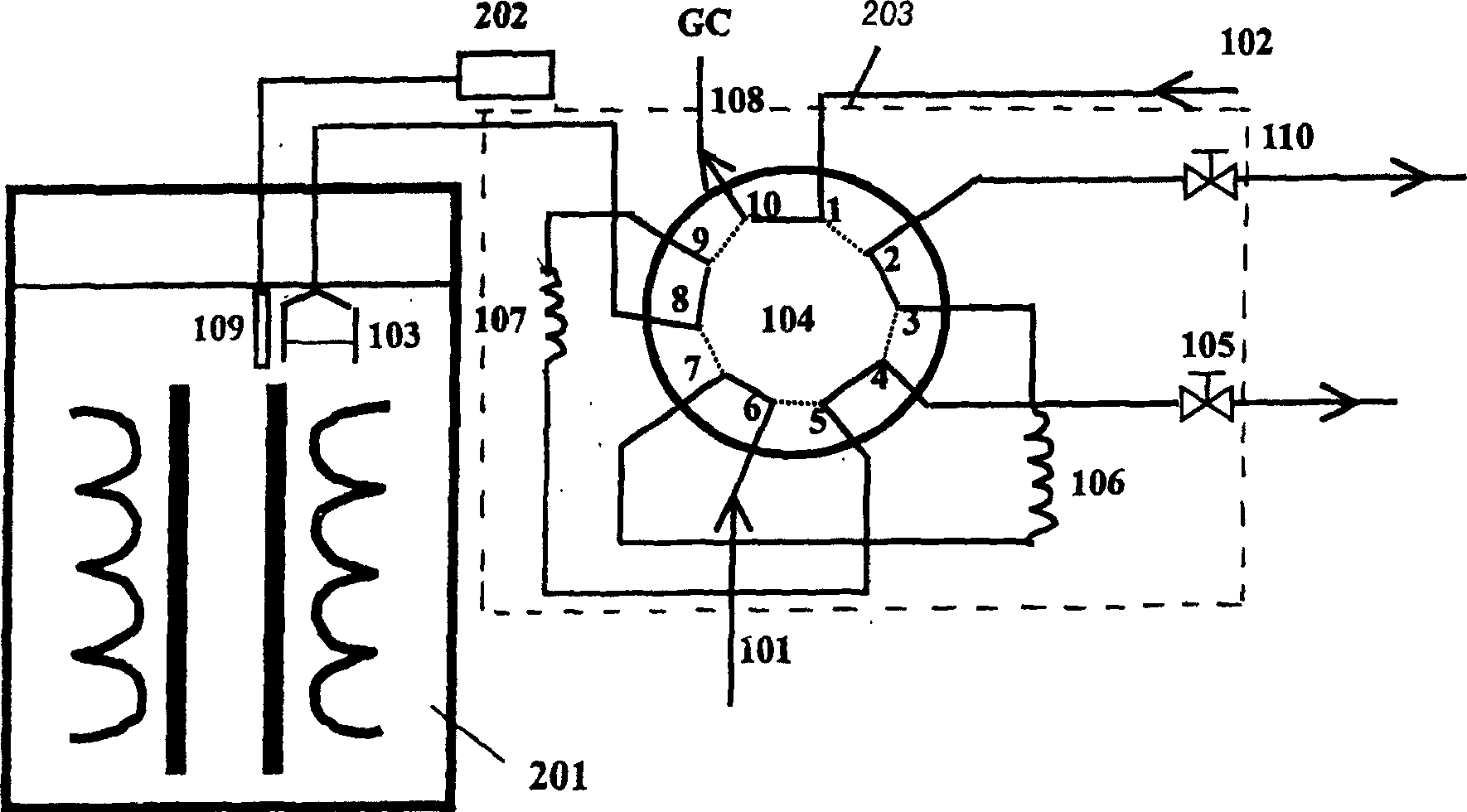

[0045] Embodiment 3: see Fig. 2, blank gas 101 is connected in the 6 " position of ten-way valve 104a, and gas chromatography carrier gas 102 adopts high-purity helium, hydrogen or nitrogen (purity is more than 99.999%), regulates carrying with pressure regulator valve The flow rate of the gas 102 is the stable flow rate under the best separation conditions, connected to the 1″ position of the ten-way valve 104a, and the 2″ position is adjusted through the needle valve 110 to be consistent with the flow rate of the carrier gas 102, and the sample quantitative tube 107 adopts a 0.8mm I.D. ×16cm stainless steel tube, 80 μL, connected to the 5″ and 9″ positions of the ten-way valve 104a, the blank gas metering tube 106 is a 3mm I.D.×283cm stainless steel tube, 20mL, connected to the 3″ and 7″ positions of the ten-way valve 104a, The 8" position is connected to the sampling probe 103 through a 1 / 16" stainless steel tube or quartz capillary tube with an inner diameter of 0.3-0.8mm, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com