Temperature control system

a temperature control and temperature technology, applied in the field of temperature control systems, can solve the problems of unstable control and unstable amount of generated vapor, and achieve the effects of avoiding complex structure and enlargement of equipment, high accuracy and precision, and uniform temperature in the refrigerant drum

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example

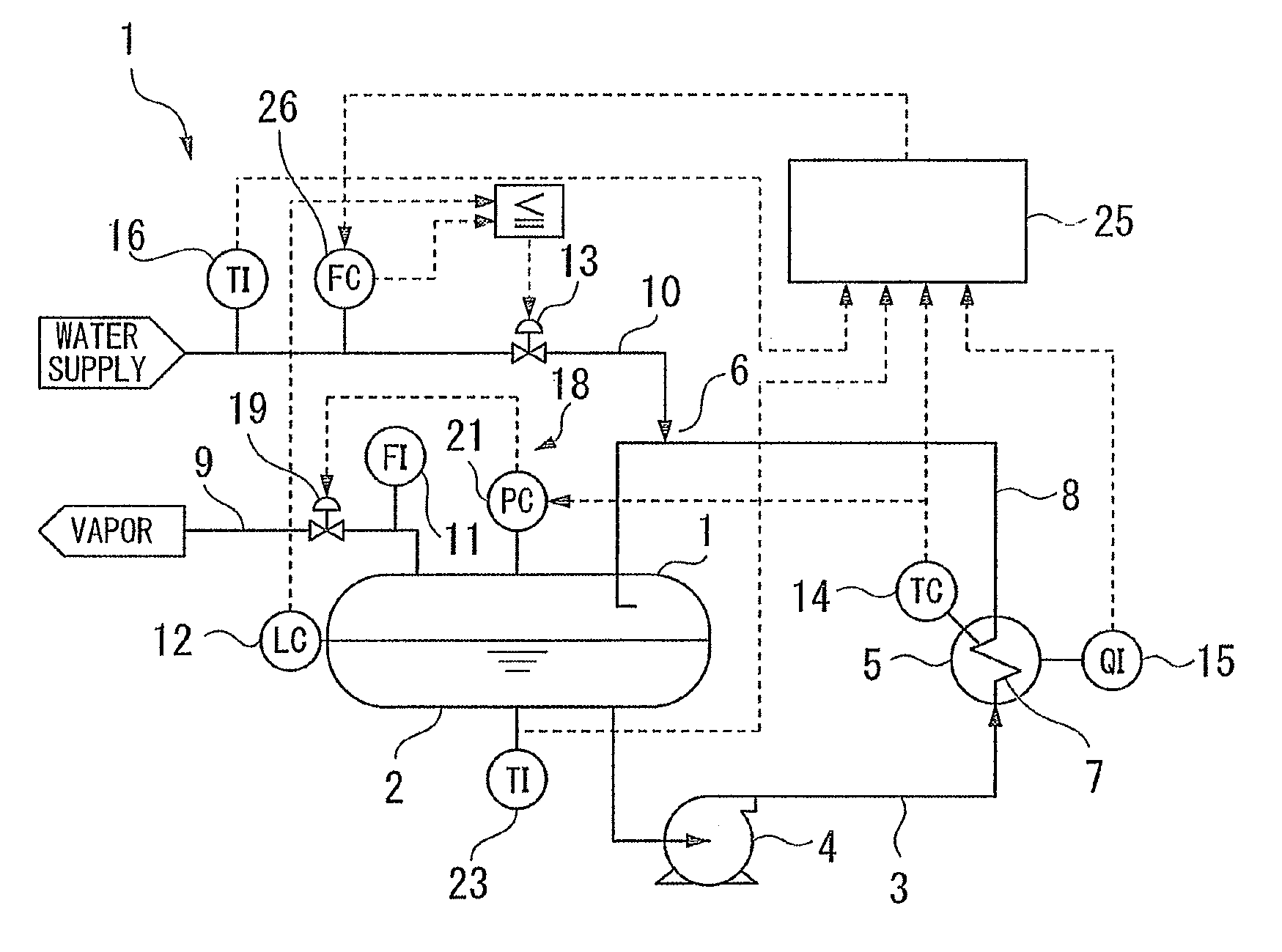

[0094]Next is a description of an example of the temperature control system 1 according to an embodiment of the present invention.

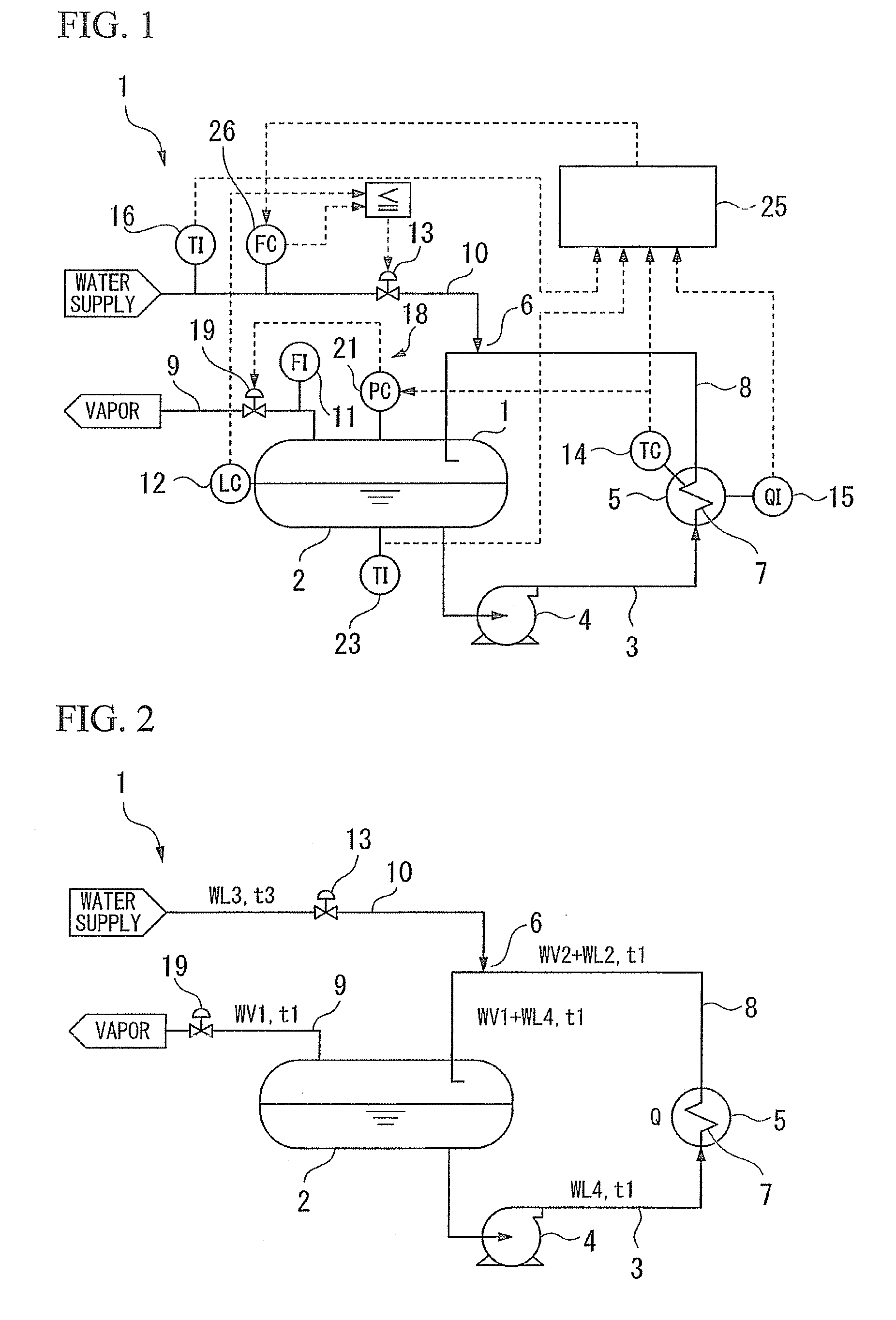

[0095]First, in FIG. 2, it is assumed that the temperature inside the steam drum 2, the respective water temperatures t1 of the water to be supplied at the flow rates WL4 and WL2 via the supply line 3, and the temperature t1 of vapor at the flow rates WV1 and WV2 are all a saturation temperature of 195° C. It is also assumed that the water temperature t3 of the makeup water in the amount of WL3 is 110° C.

[0096]Moreover, it is assumed that

[0097]reaction heat Q=8000000 kcal / h

[0098]evaporative latent heat of water r=470 kcal / kg (physical property (constant))

[0099]specific heat Cp of water=1 kcal / kg / ° C. (physical property (constant))

[0100]pressure in steam drum=1.3 MPaG

[0101]circulation amount WL4 of water supply pump 4=68000 kg / h.

[0102]Under the above conditions, the control unit 25 of the temperature control system 1 determines the amount of makeup water W...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com