Positive pressure foam fire extinguishing system based on two-phase flow drive and foam generation method

A foam fire extinguishing and foam generation technology, applied in fire rescue and other directions, can solve the problems of uneven mixing of driving medium and foam mixture, inability to continuously provide a large amount of compressed gas in time, and local temperature reduction, etc., to achieve uniform size and reduce temperature drop. , strengthen the effect of mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

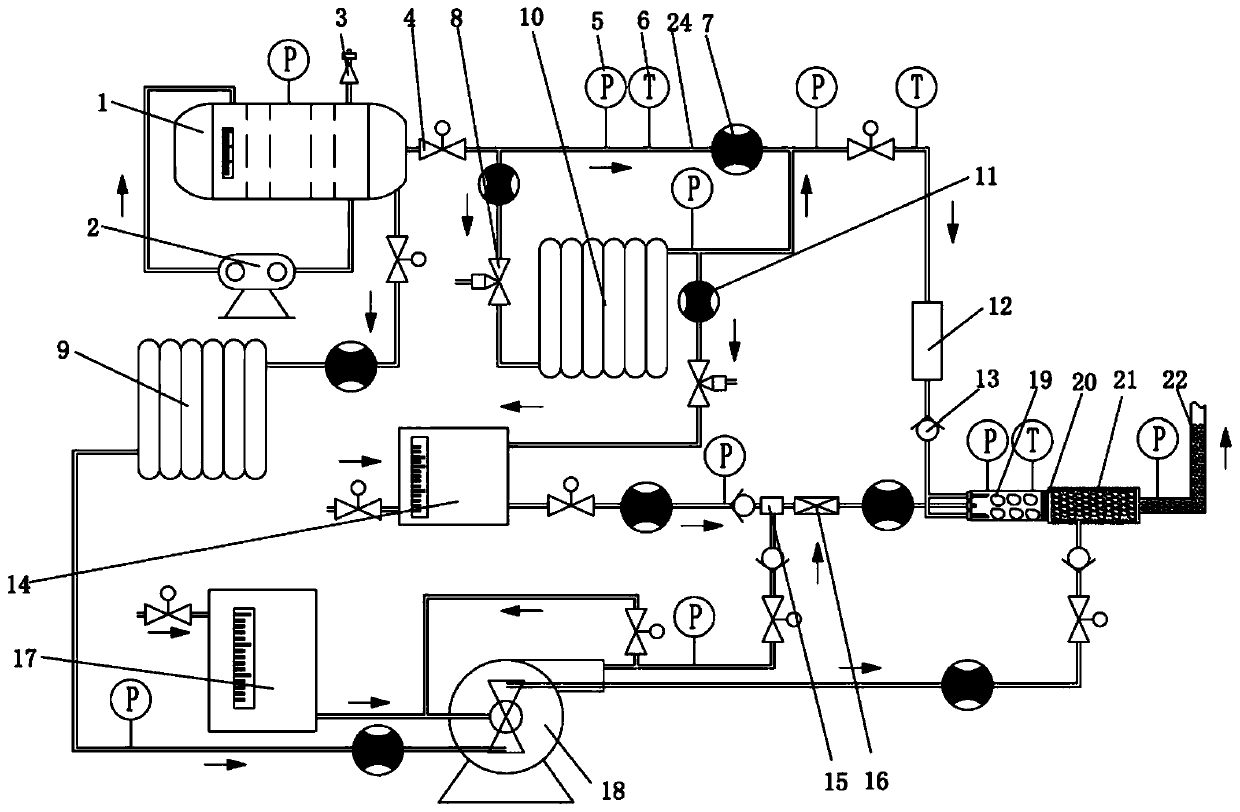

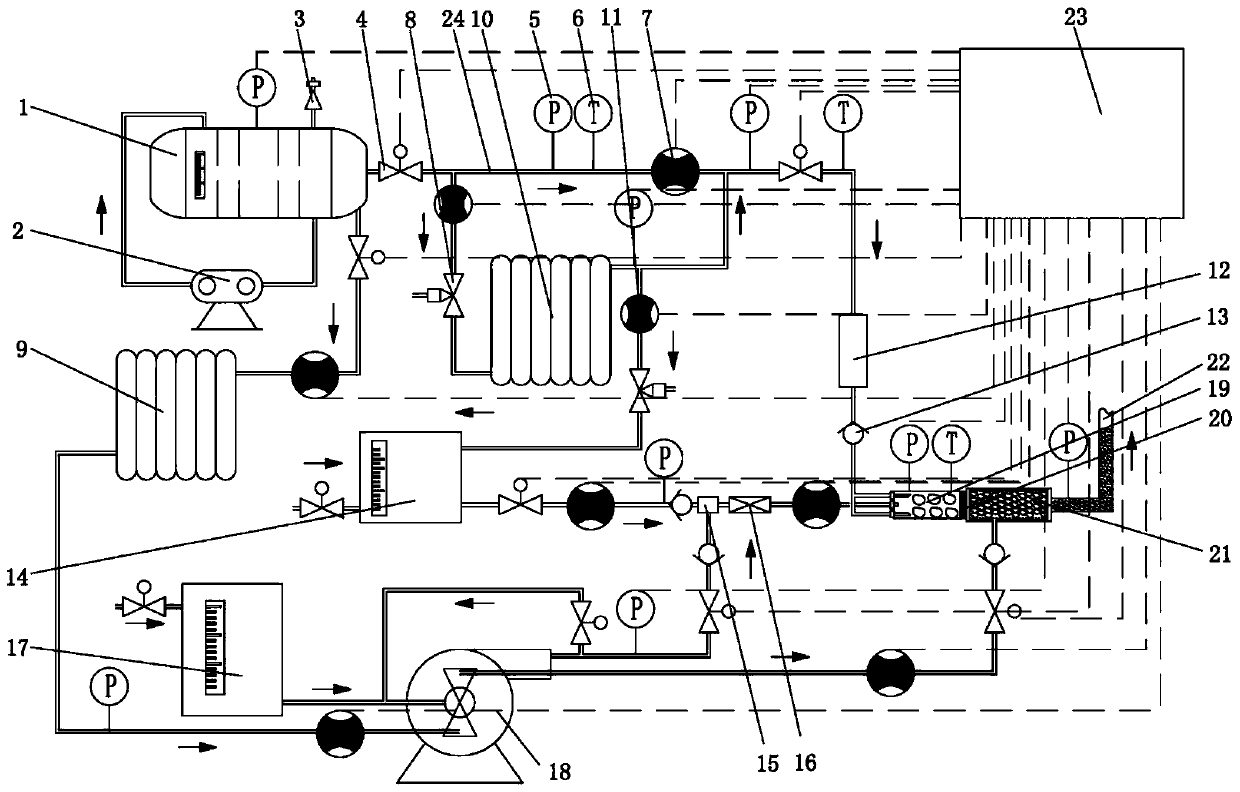

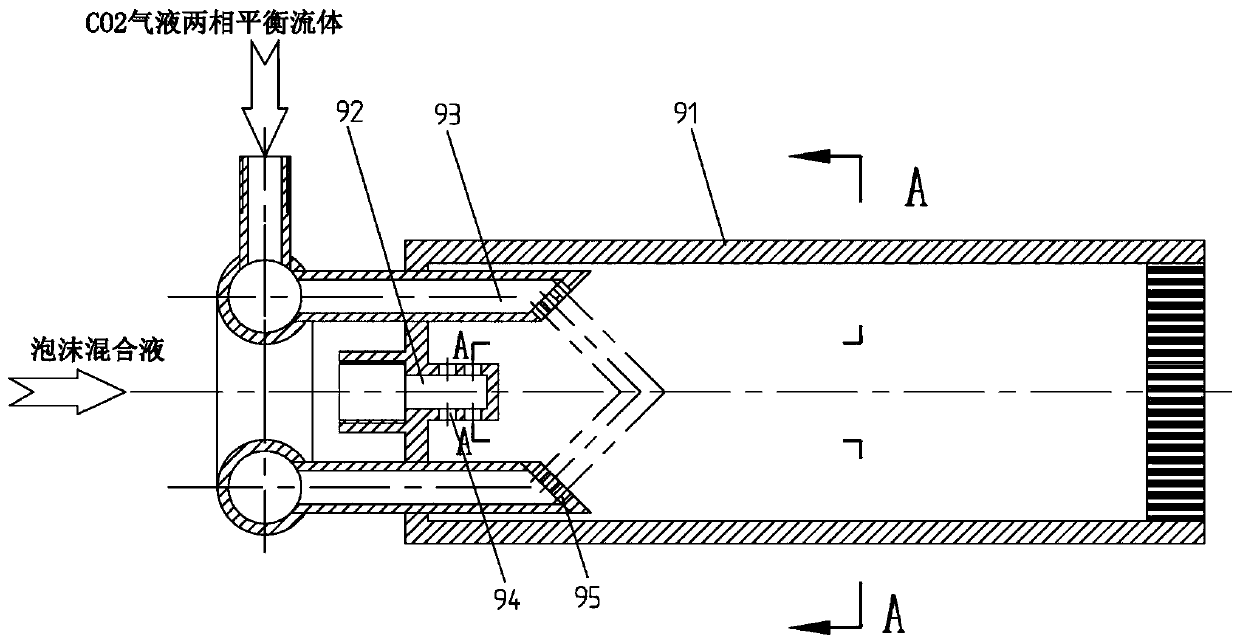

[0033] The invention provides a method and a system for generating foam by mixing a gas-liquid two-phase equilibrium flow and a foaming substance. In the system, CO 2 The foam mixture is mixed twice, the first time is in the first foam generation room CO 2 The gas-liquid two-phase equilibrium flow is mixed with the foam mixture, and the mixing method is porous axial rotating jet mixing; the second time is in the second foam generation chamber, the gaseous CO 2 Secondary mixing with the foam after primary foaming, the mixing method is porous horizontal jet mixing; the pressure in the first foam generation chamber is relatively high, and the pressure in the second foam generation chamber is low. Through this secondary mixing method, the system produces The size of the foam is more uniform, and the control and adjustment of the expansion ratio is more flexible and convenient. The CO proposed by the present invention 2 The gas-liquid two-phase equilibrium flow is used as the gas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com