Method for optimizing experimental fuel proportioning based on thermogravimetric analysis and gas-liquid dual-phase calculation

A technology of thermogravimetric analysis and phase calculation, which can be used in engine testing, weighing by removing certain components, testing of machine/structural components, etc., to solve problems such as the overall volatility gap, and to achieve improved calculation accuracy and good performance. Universal applicability, simple and reliable test method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

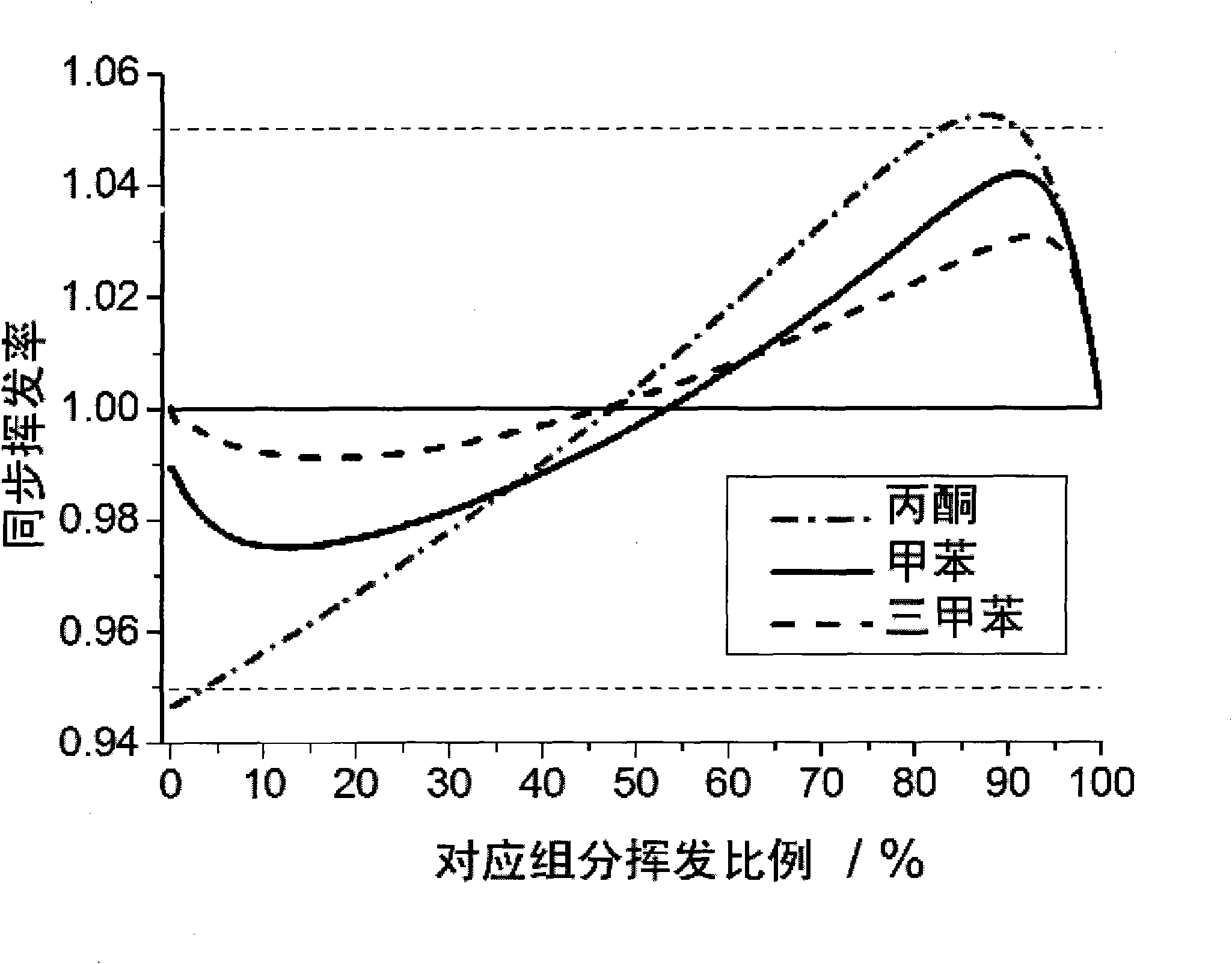

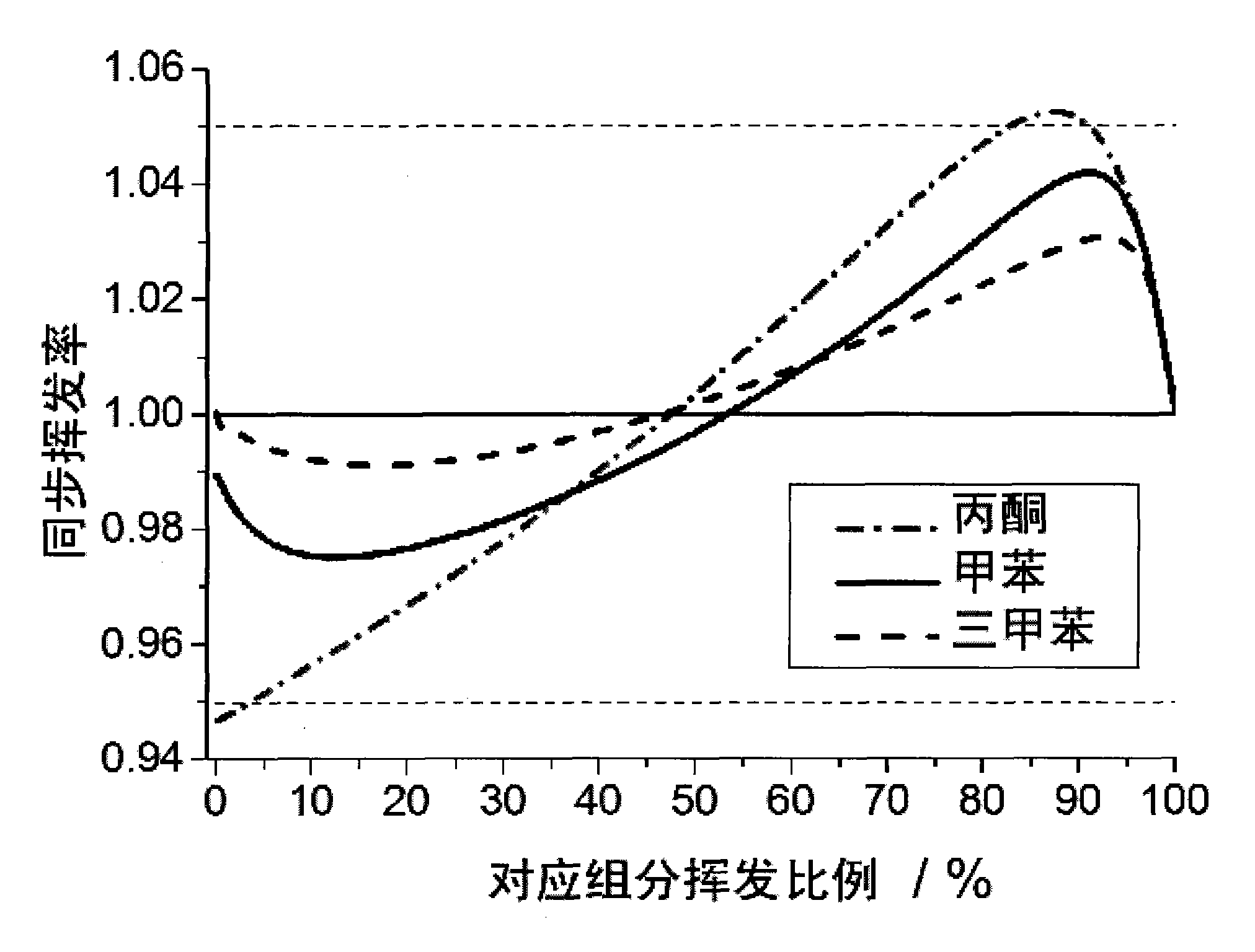

[0024] The preparation method of the present invention can simultaneously solve the similarity problem of volatilization between special fuel oil and real fuel oil and the problem of synchronous volatilization of tracers in the mixed gas test of internal combustion engine laser-induced fluorescence method, and can match corresponding components for different tracers to realize Distinguish the volatilization of different light and heavy components in multi-component fuel oil, improve the accuracy of laser-induced fluorescence method experiment and expand the multi-component measurement capability of laser-induced fluorescence method.

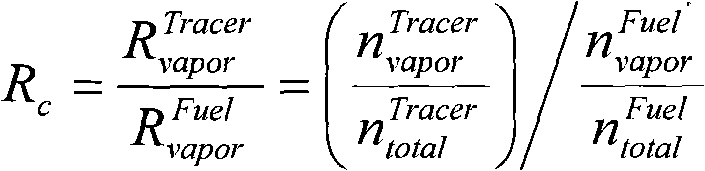

[0025] The preparation method of the present invention firstly prepares the sample fuel oil, and then obtains the target fuel oil, adopts the measures of thermogravimetric analysis and gas-liquid equilibrium calc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com