Test method for iron ore powder sintering assimilation flux amount and speed

A test method and technology of iron ore powder, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve problems such as needing improvement in accuracy, complex measurement methods, and single reference data, so as to achieve true and reliable data, low experimental cost, and easy operation Effects with ease of control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

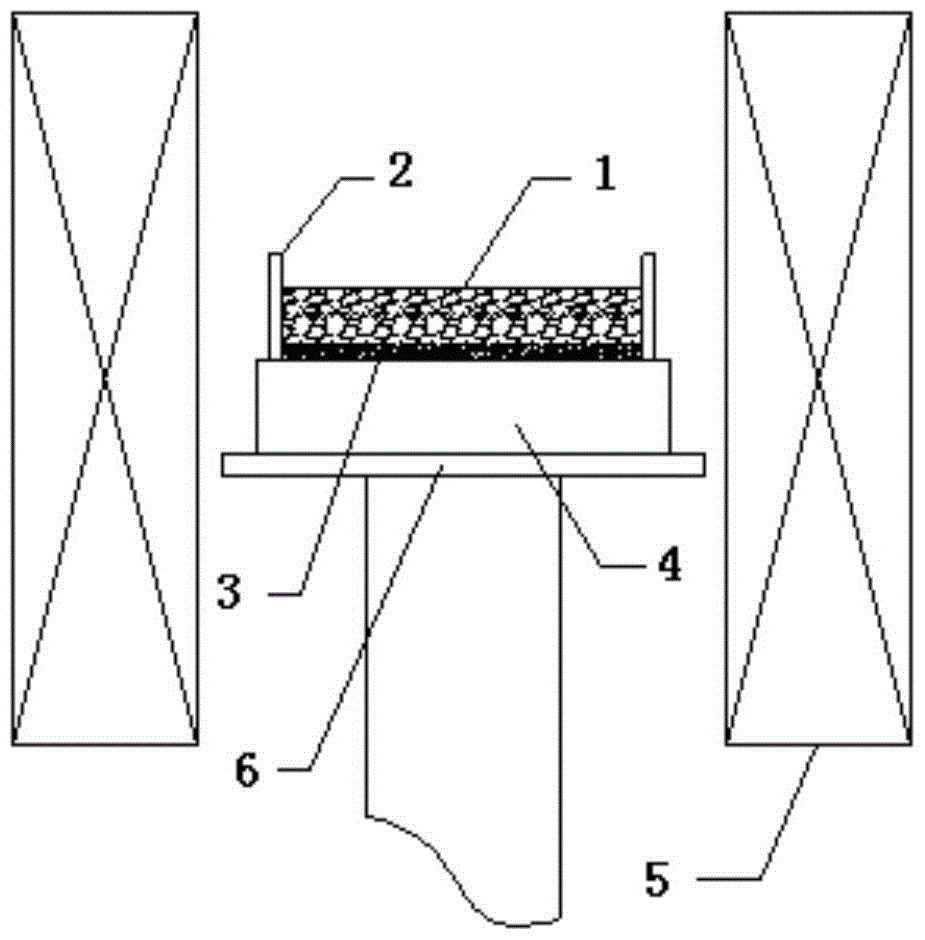

Image

Examples

Embodiment Construction

[0032] The present invention takes iron ore powder A and iron ore powder B contained in a certain iron ore powder for production as an example, and tests the assimilation amount of each particle size and the CaO consumption speed of assimilation. Step (1) and (2) of the two test methods are the same:

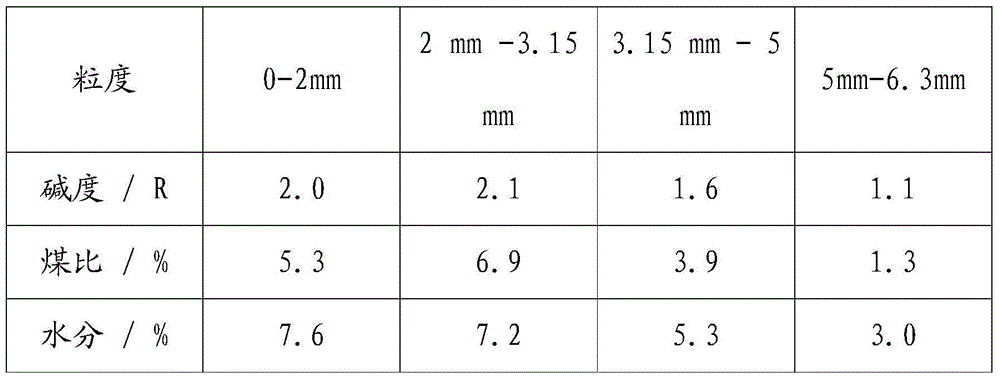

[0033] (1) First test the alkalinity R, coal mixing ratio and water content of the 4 particle sizes of 0-2mm, 2mm-3.15mm, 3.15mm-5mm and 5mm-6.3mm iron ore powder for production, see the table 1.

[0034] Table 1 produces the flux, fuel and moisture of each particle size of the mixed mineral powder

[0035]

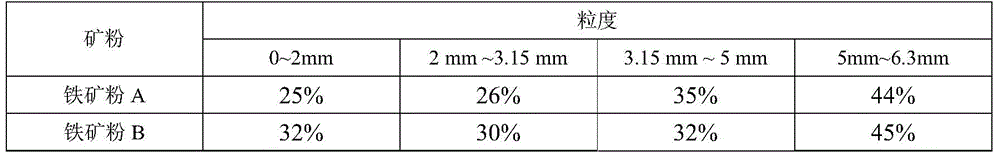

[0036](2) According to the alkalinity R and coal ratio of the above test particle size, prepare four kinds of iron ore powder A and iron ore powder B respectively 0-2mm, 2mm-3.15mm, 3.15mm-5mm and 5mm-6.3mm. Alkalinity R, Coal Ratio and Moisture of Grade Size.

[0037] (1) Test of the assimilation amount of iron ore powder in each particle size:

[0038] (3) Weigh 50...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com