Gas-liquid-liquid equilibrium data measurement device

A measuring device, gas-liquid technology, applied in the direction of laboratory equipment, investigation stage/state change, chemical instruments and methods, etc., can solve problems such as non-equilibrium vaporization, no phase separator, and blank gas-liquid-liquid balance kettle, etc., to achieve Accelerate the mass transfer process, the experimental operation is simple, the effect of accurate measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

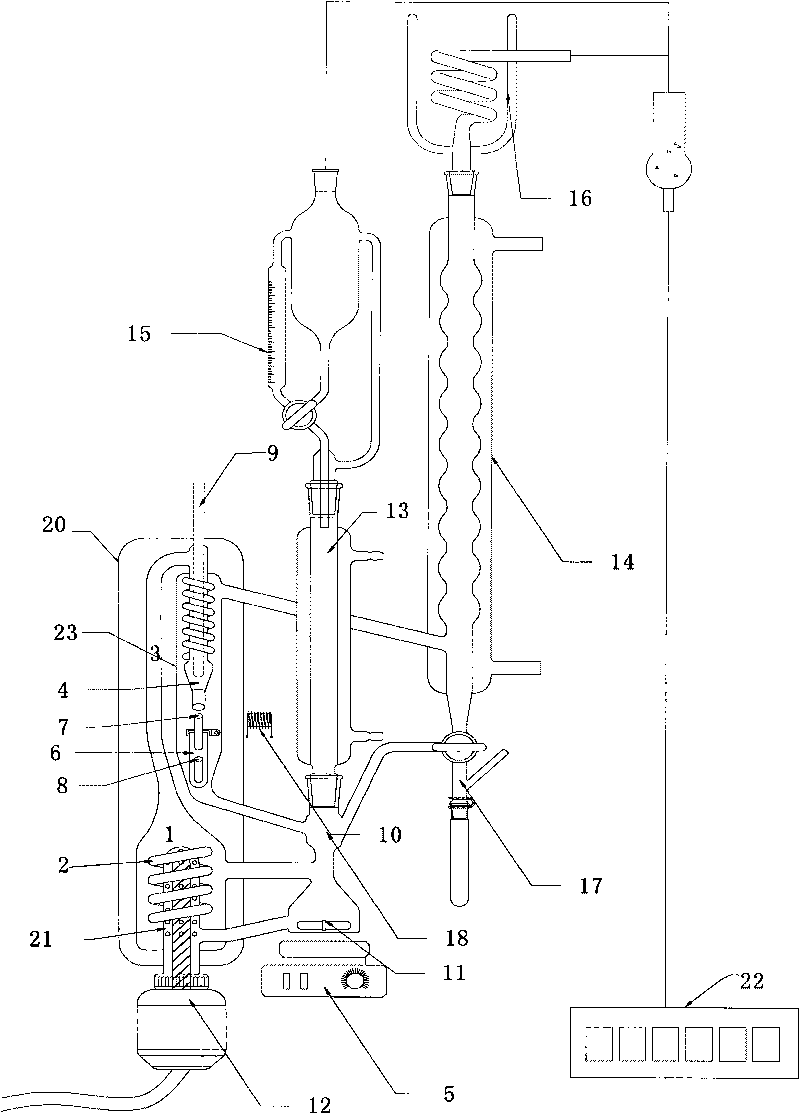

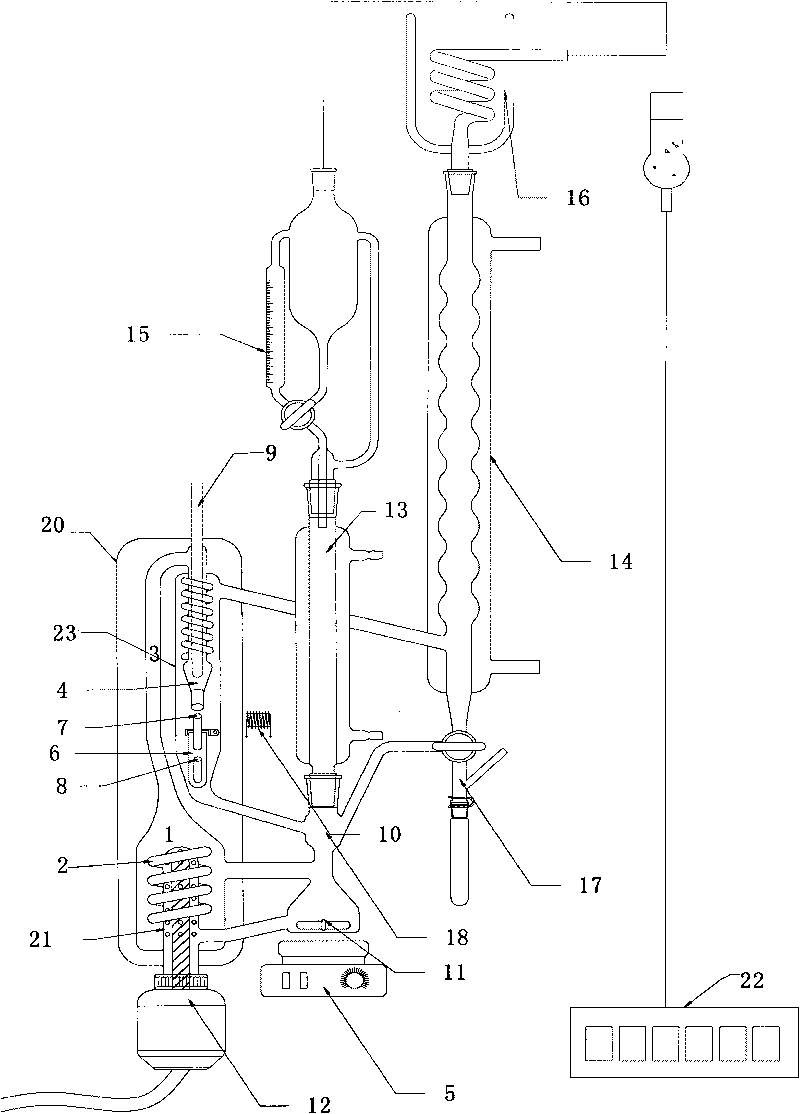

[0017] figure 1 It is a structural schematic diagram of an embodiment of a three-cycle gas-liquid balance kettle. In this embodiment, the balance kettle is made of heat-resistant glass. Structurally, the balance kettle is mainly composed of a heating kettle 1, a heater 2, a Cottrell pump 3, a gas-liquid nozzle 4 with a balance column effect, a gas-liquid separation chamber 23, a liquid-liquid phase separation pipe 6, an electromagnet 18, The mixer 10, the stirring chamber 11, the disperser 21, the ultrasonic homogenizer 12, the inner silver-plated vacuum insulation jacket 20 and the gas phase condenser tube 14 are composed of some auxiliary devices, a secondary condenser 16, a quantitative feed Hopper 15, a drying tube 19 and a pressure control system 22. All valves are PTFE glass valves, and all connections are standard ground. Before the experiment, the non-equilibrium gas-phase condensing tube 13 was packed into the grinding port above the mixer 10, and then the feed fun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com