Patents

Literature

53results about How to "To achieve the purpose of decolorization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A regenerated water manufacturing device and method based on electrolysis and double-membrane technology

InactiveCN102260013AImprove water qualityTo achieve the purpose of cleaner productionWater/sewage treatmentMultistage water/sewage treatmentWater basedWater quality

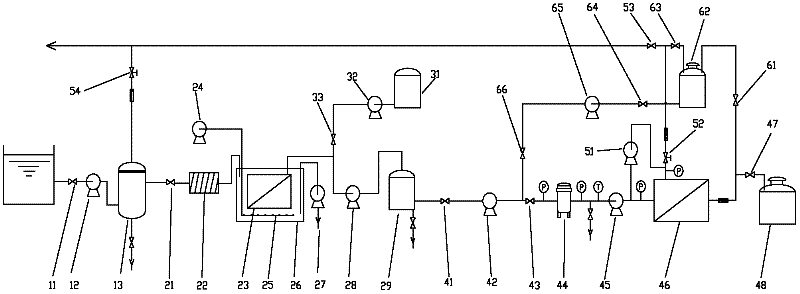

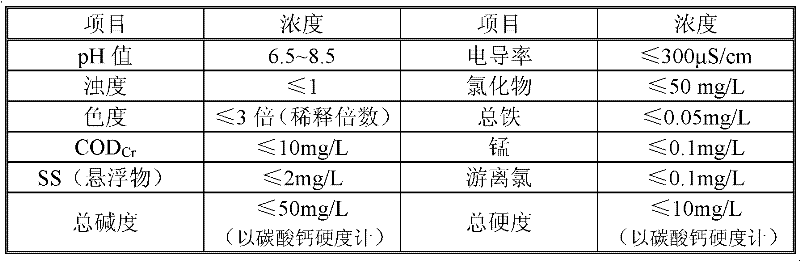

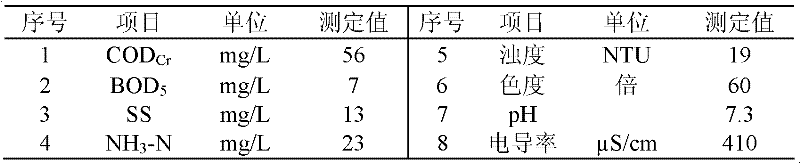

Provided is an apparatus for producing reclaimed water based on electrolysis and double membrane technologies. The apparatus is disposed with an electrolysis system, an MBR system and a reverse osmosis system. Further provided is a method for producing reclaimed water using the apparatus, comprising the following steps: retrieving biochemical sewage through a water pump (12) and inputting the biochemical sewage into an electrolysis apparatus (13) of the electrolysis system to be electrolyzed, then enabling the sewage to enter an MBR reaction tank (26) through a grid (22) to obtain primary reclaimed water, pumping the primary reclaimed water into the reverse osmosis system with a high pressure pump (45) to separate dialysis water and concentrated water, enabling the dialysis water to enter a reclaimed water storage tank (48) to obtain ultrapure reclaimed water, enabling a part of the concentrated water to flow back for cyclic membrane filtering and separation, enabling a part of the concentrated water to flow back to enter an electrolysis procedure for cyclic use, and discharging the rest part of the concentrated water.

Owner:BOYING XIAMEN SCI & TECH

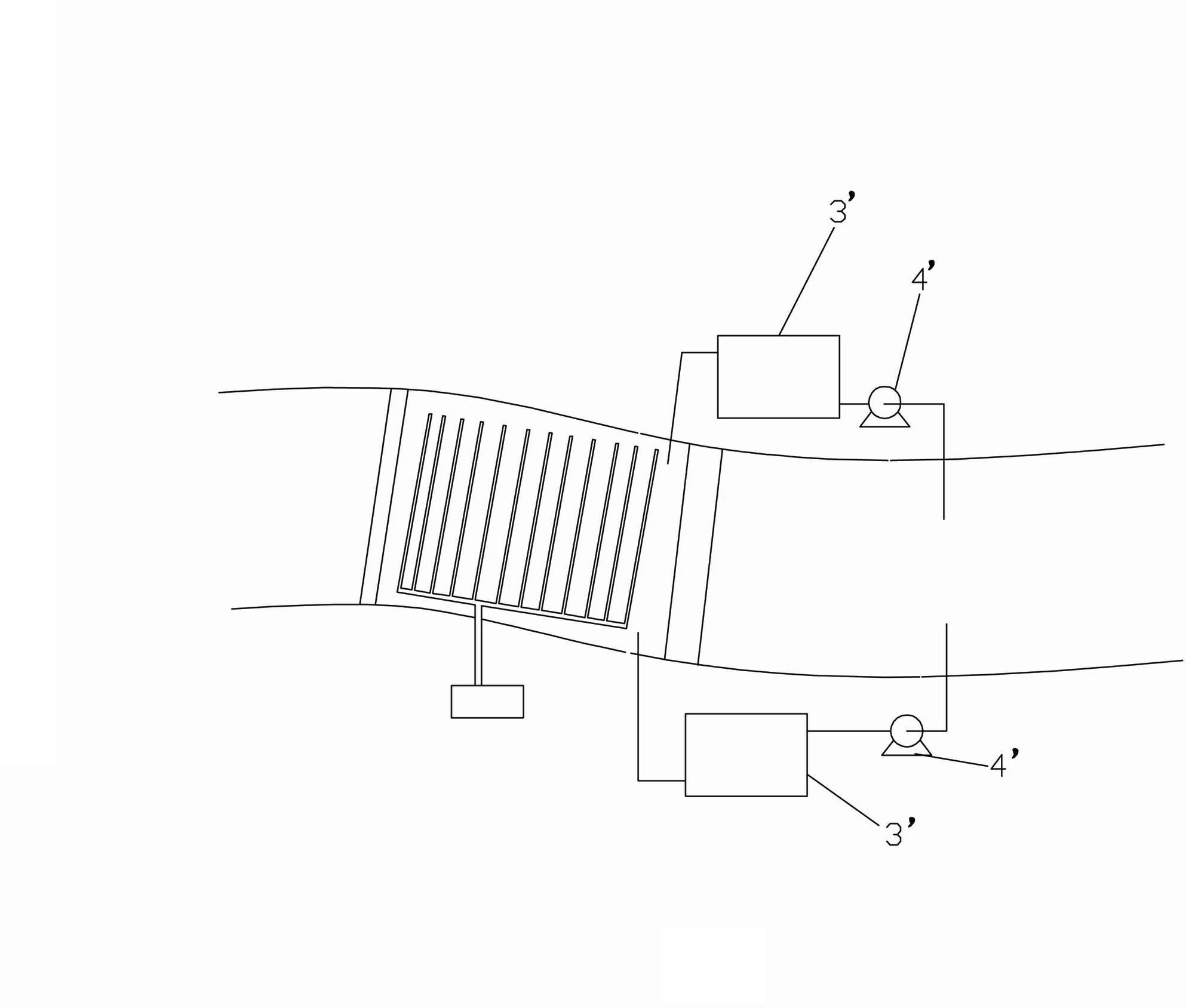

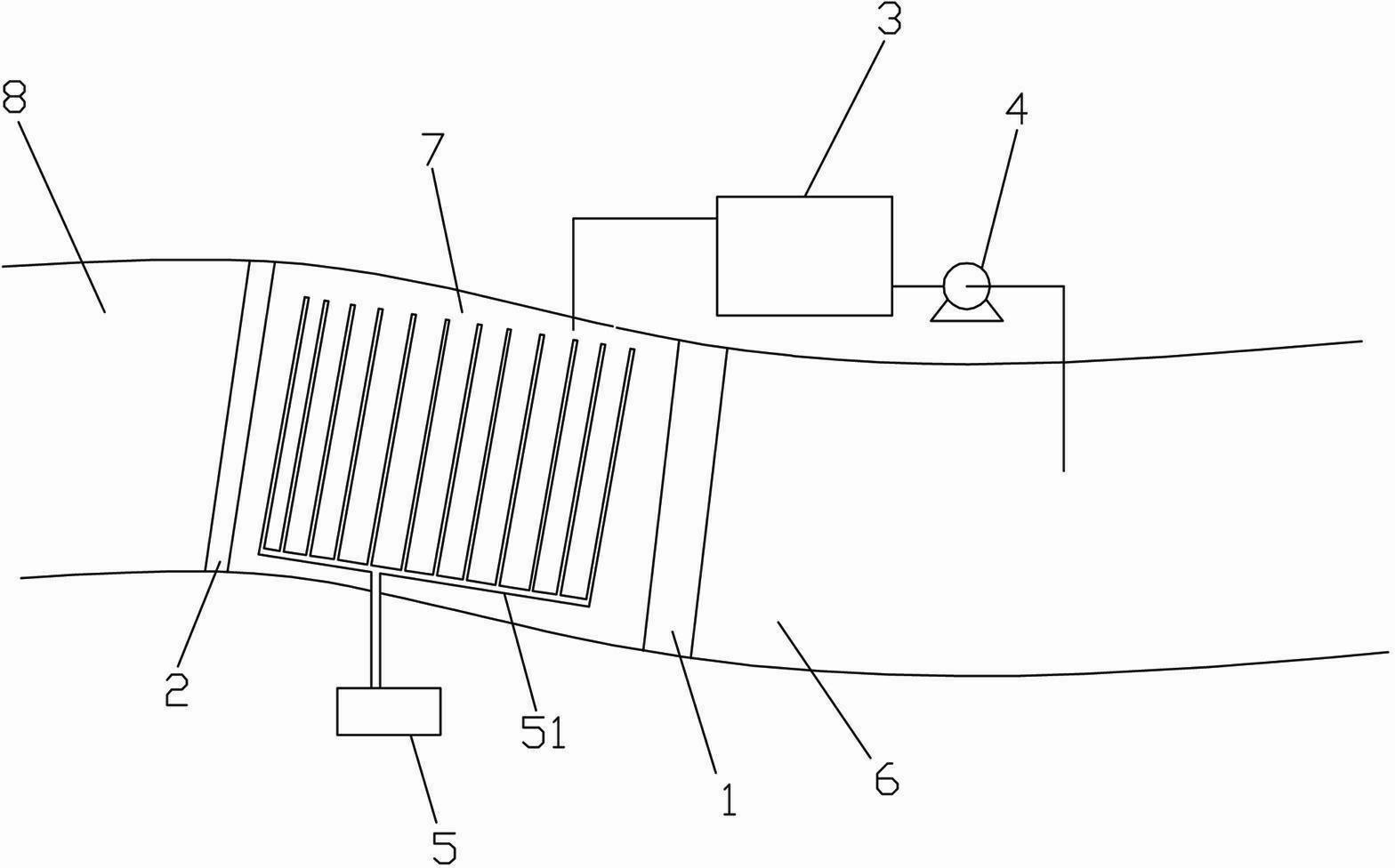

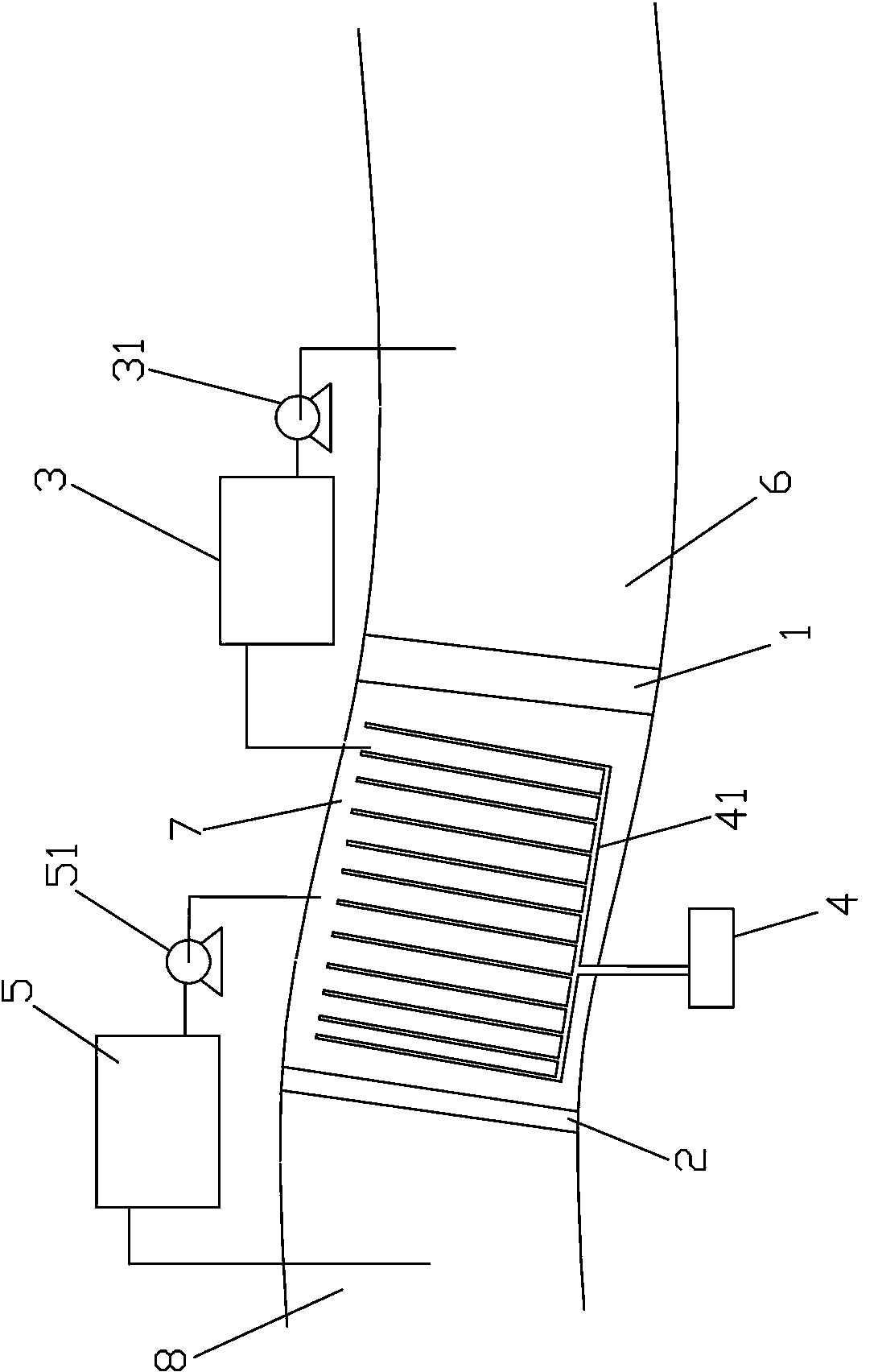

Eutrophicated river water quality purifying method and purifying device thereof

InactiveCN102633395AReduce CODEliminate odorWater treatment compoundsSpecific water treatment objectivesElectrolysisEutrophication

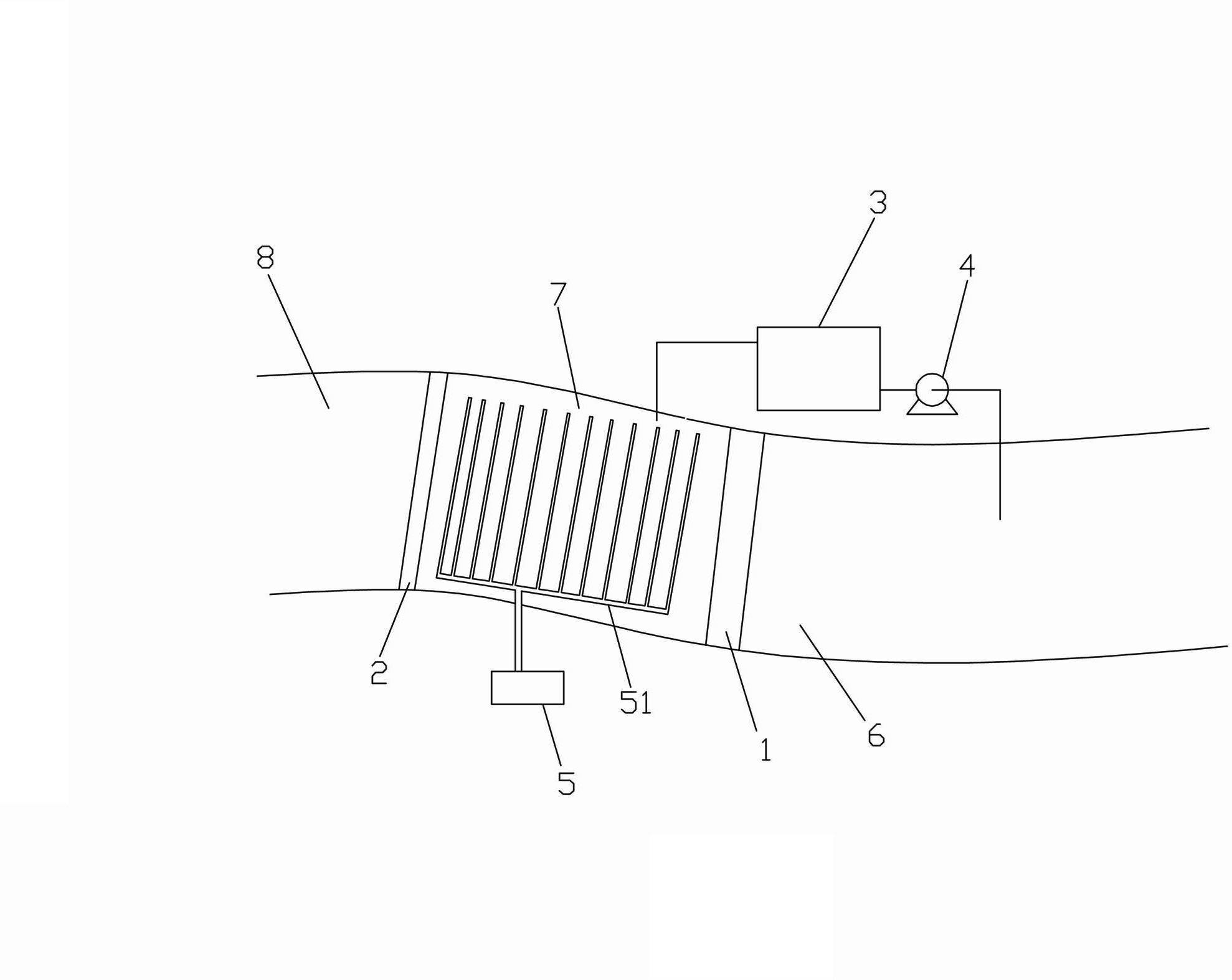

The invention discloses an eutrophicated river water quality purifying method. The method comprises the following steps of: intercepting eutrophicated river into upstream, midstream and downstream parts; then conveying water of the upper part into an electrolyzing machine to be electrolyzed; then, discharging the electrolyzed water into the midstream part to be subjected to aeration treatment at the midstream part; and finally, flowing the water subjected to the aeration treatment to the downstream part. The eutrophicated river water quality purifying method adopts a method for firstly electrolyzing and secondly aerating, and can effectively inhibit the growth of algae in the water and an anaerobic reaction of a water body; an organic matter is decomposed, and total nitrogen, total phosphorus and chromaticity in the water are reduced and the odor is removed, so as to improve the river water quality and recover a water ecological system in a shorter time. The invention further discloses a river water quality purifying device, comprising a rubber dam, a water pump, the electrolyzing machine and an aeration device. The river water quality purifying device can be directly mounted in a river to directly purify river water; and the river does not need to be specially leaded to a pre-set structure to be treated, and the river water quality purifying device nearly does not change an environment, so that the influences to a natural environment are smaller.

Owner:BOYING XIAMEN SCI & TECH

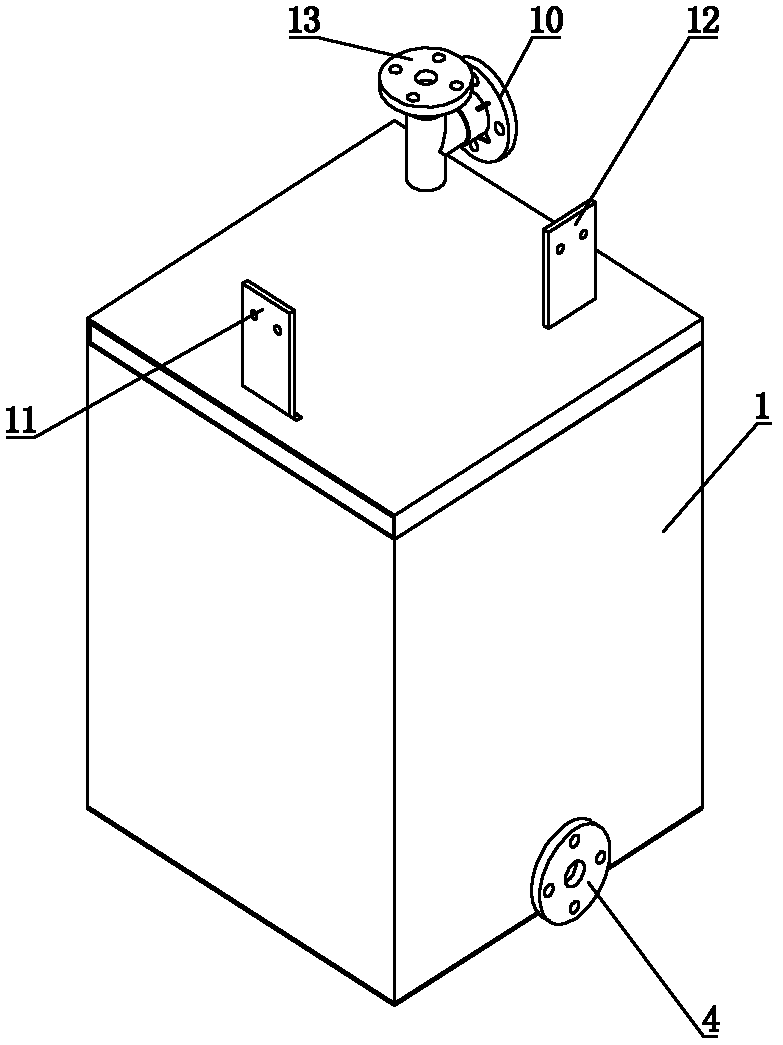

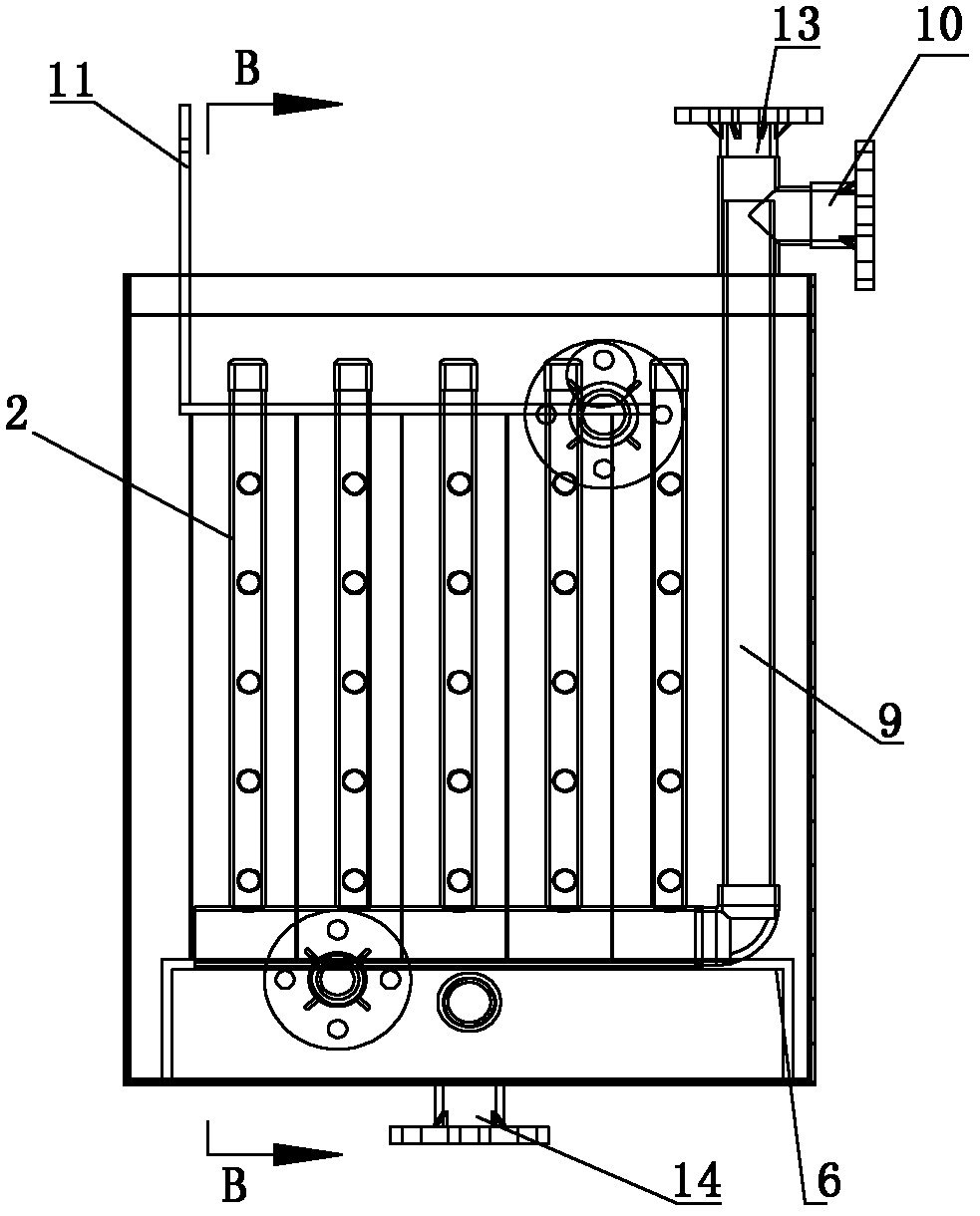

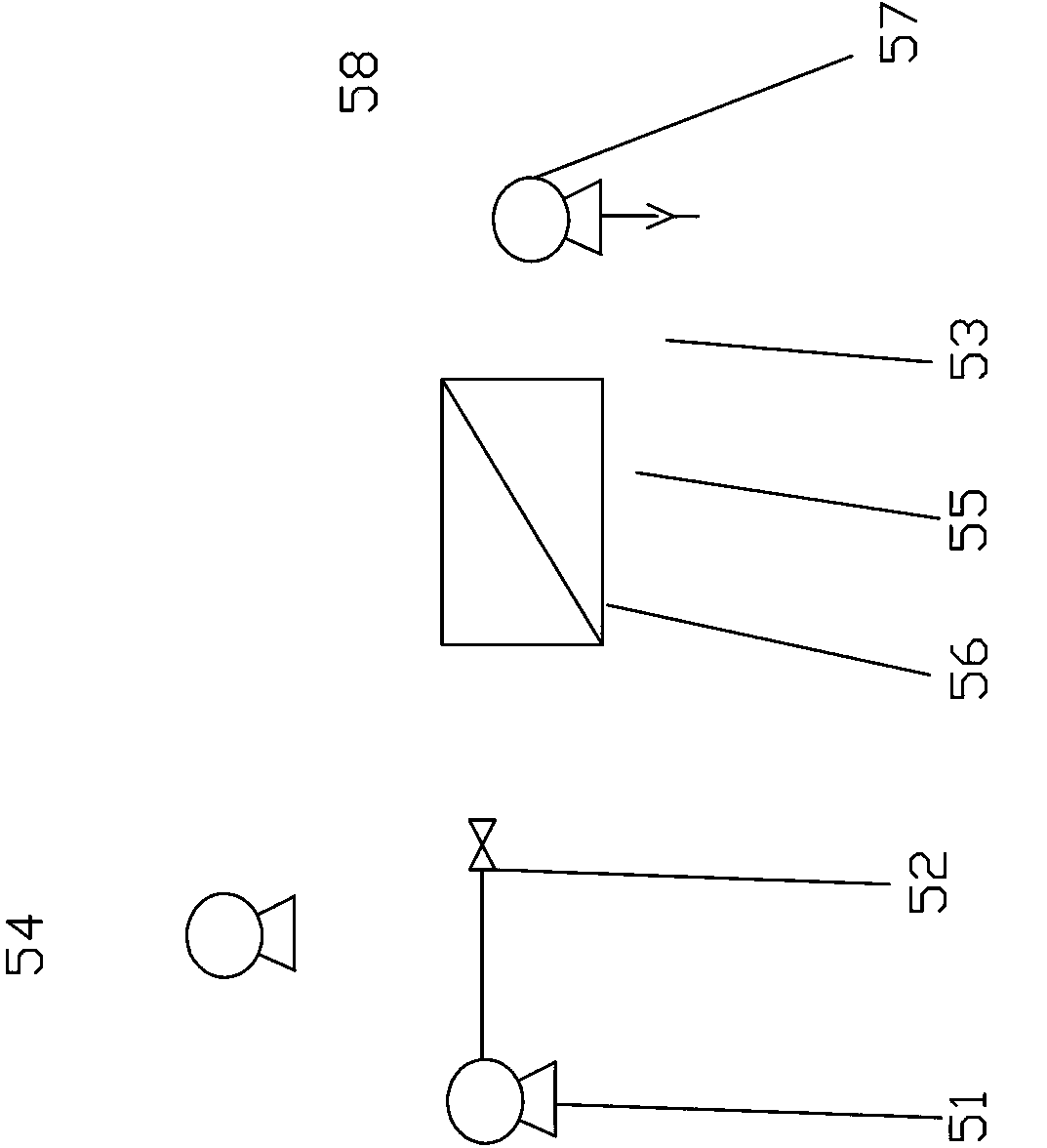

Electrolysis unit with membrane filtration function

InactiveCN102633324AIncrease B/C valueImproved biodegradabilityDispersed particle separationWater/sewage treatment by flotationWater pipeMembrane configuration

The invention discloses an electrolysis unit with a membrane filtration function and relates to an electrolysis unit. The electrolysis unit is provided with a shell and an electrode set, wherein a water inlet and an air inlet are arranged on the bottom part of the shell, and the water inlet is connected with a water inlet pipeline through a pipeline; the air inlet is connected with an aerating apparatus through a pipeline; an overflow opening and a drain outlet are respectively arranged on the upper part and the lower part of the shell, and the overflow opening and the drain outlet are connected with an external blow-off line through pipelines; the electrode set is provided with a bracket, a cathode, an anode and a water outlet; the electrode set is fixed on the shell through the bracket,the cathode is a metal membrane component with filtering and separating functions, and the anode is one of metal anode, alloy anode, carbon anode and titanium anode, and the like; and a connecting plate connected with a power supply is arranged on one end of the cathode, an anode binding post and a cathode binding post are arranged on the connecting plate, a filtration water collecting pipe and afiltration back wash pipe are arranged on the other end of the cathode, the filtration water collecting pipe is connected with a water suction pump, and the filtration back wash pipe is sequentially connected with a back wash pump and a chemical feed pipe. The electrolysis unit integrates electrolysis and membrane filtration functions.

Owner:BOYING XIAMEN SCI & TECH

Nano-catalysis, electrolysis, flocculation and air-floatation device

InactiveCN102936072AEliminate pollutionReduce turbidityMultistage water/sewage treatmentWater/sewage treatment using germicide/oligodynamic-processFlocculationSlag

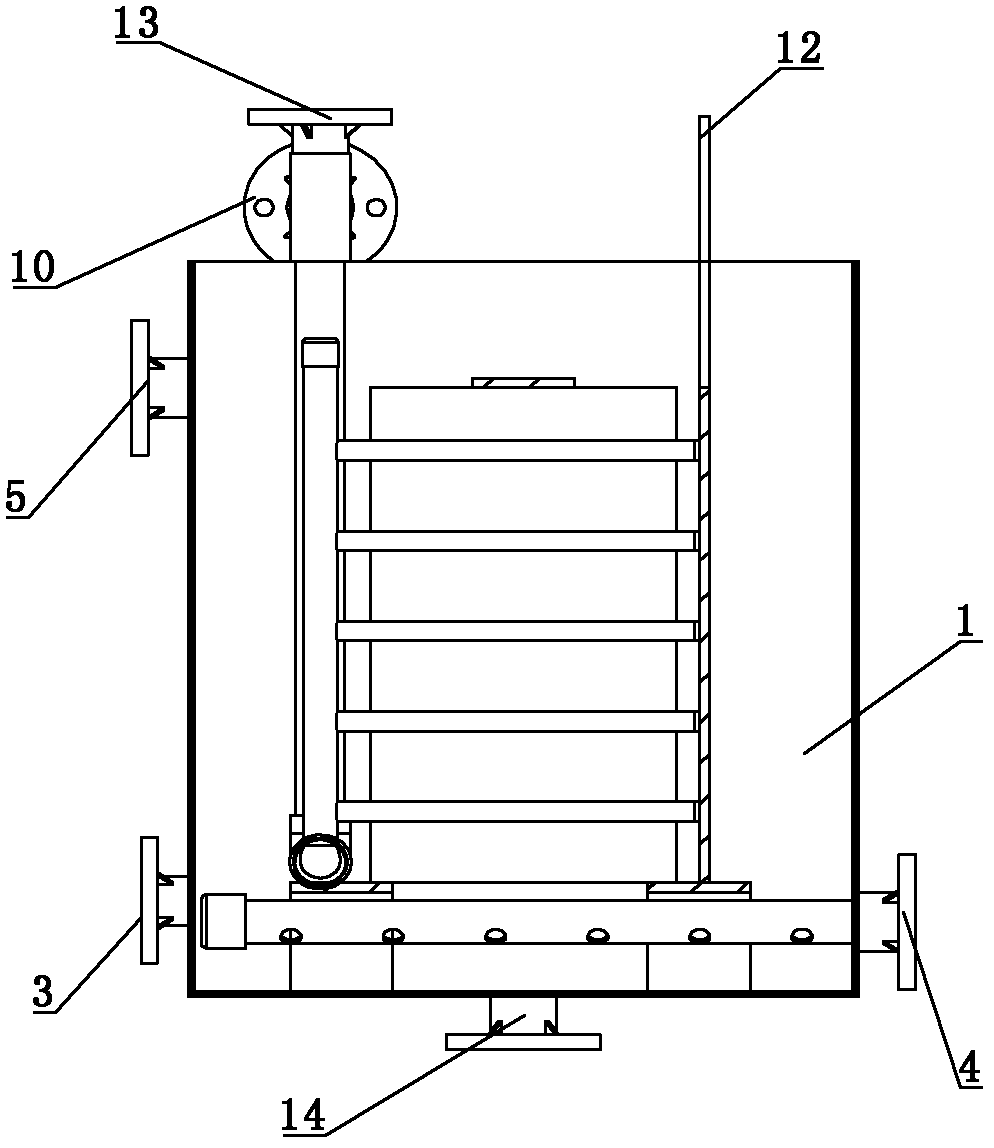

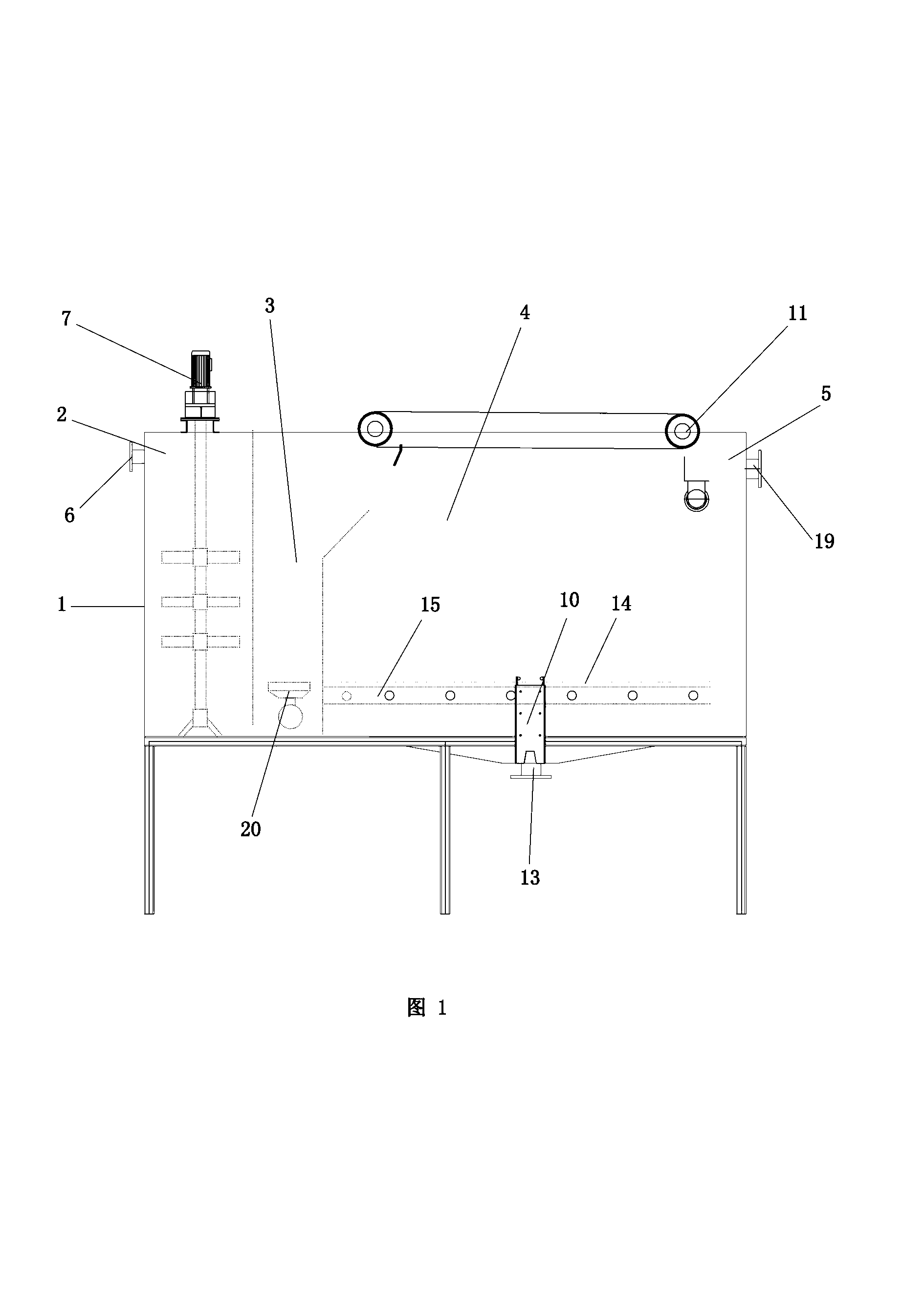

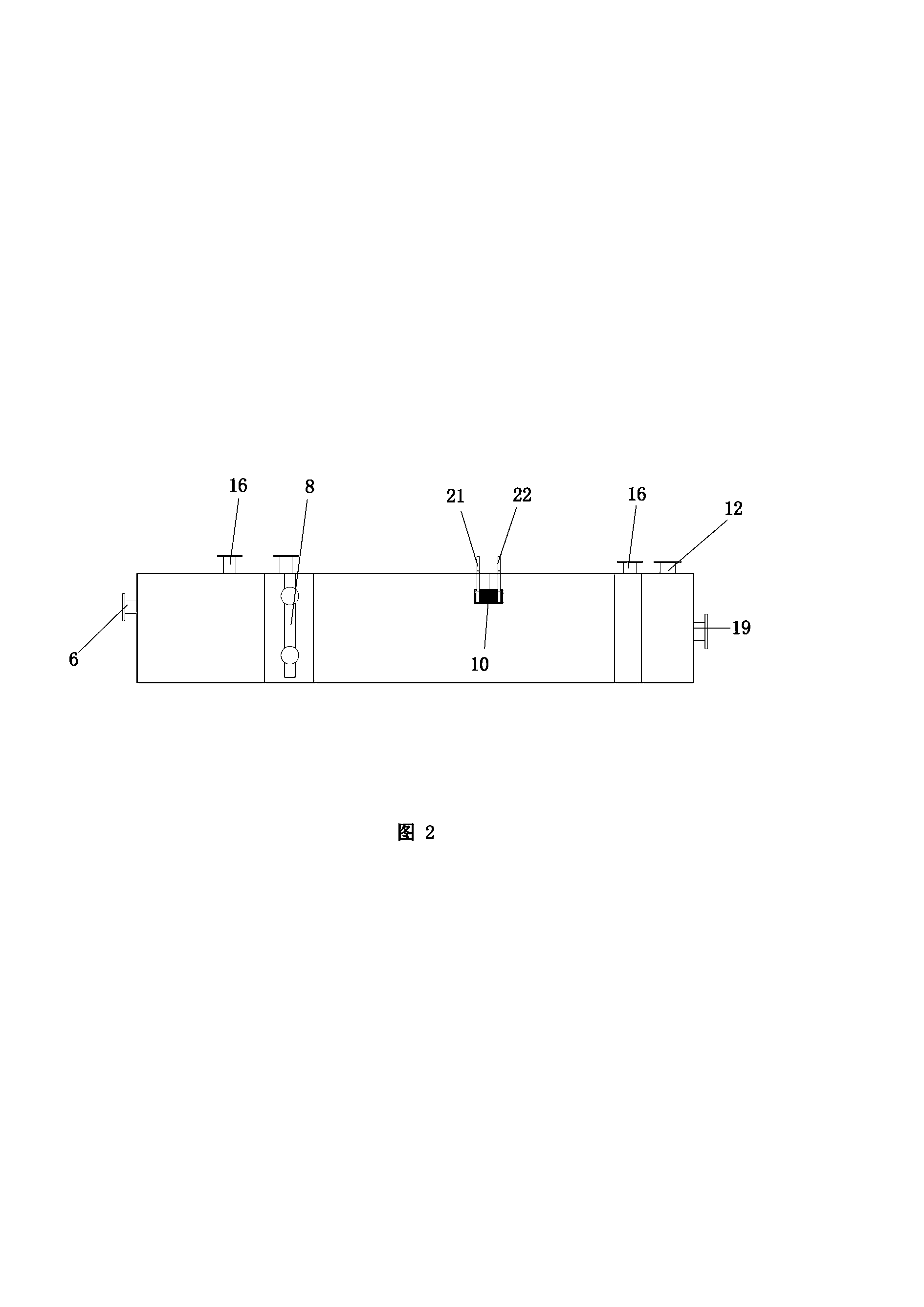

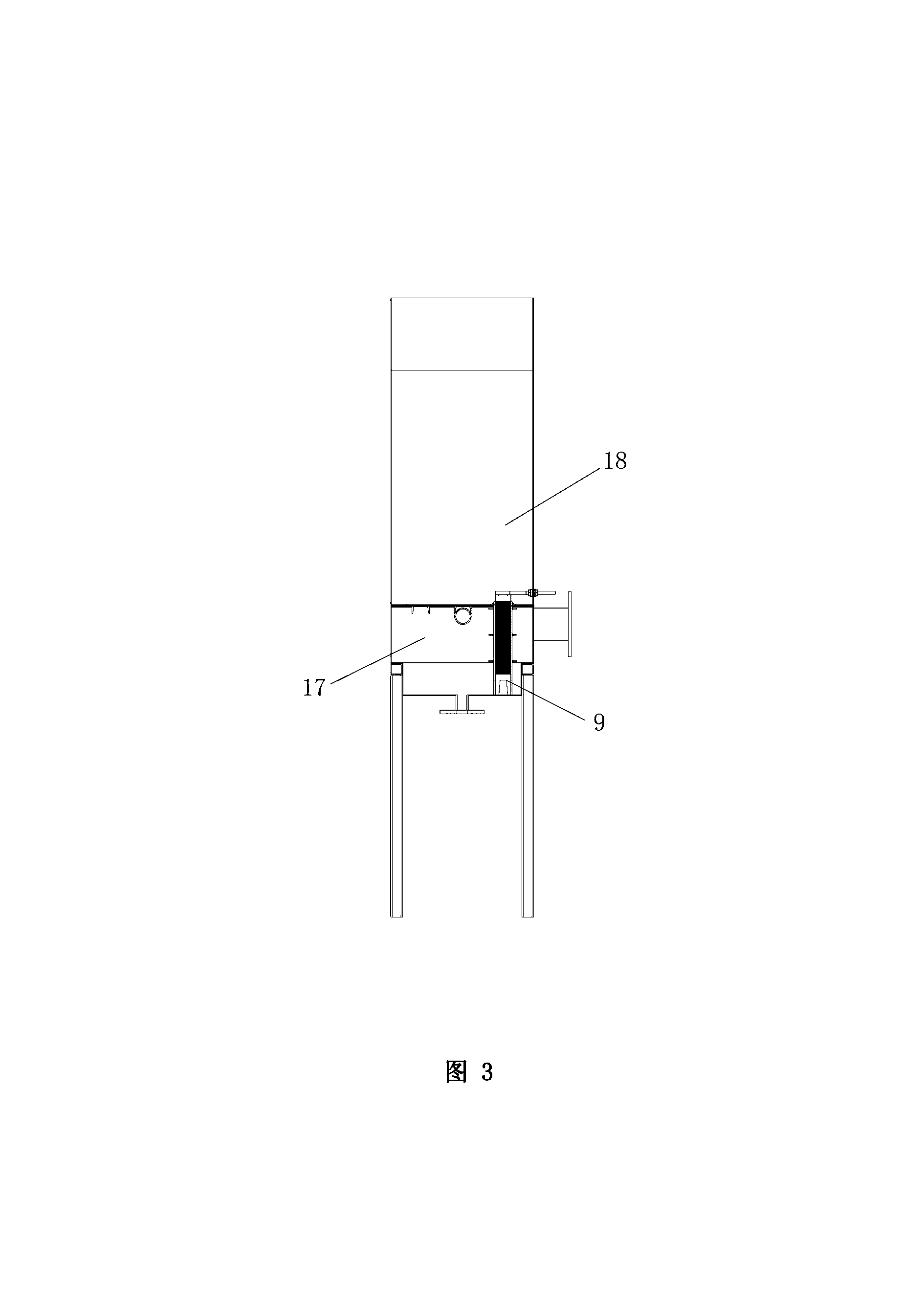

The invention provides a nano-catalysis, electrolysis, flocculation and air-floatation device. A coagulative precipitation tank, a primary air-floatation tank, an electrolytic air-floatation tank and a slag-discharging tank are arranged in a housing of the device, wherein the top of the coagulative precipitation tank is provided with a water inlet and a mixer; the bottom of the coagulative precipitation tank is communicated with the primary air-floatation tank; a side sewage-draining outlet is connected with a sewage-draining pipe; a dissolved gas release pipe is arranged at the edge of the primary air-floatation tank; the sewage-draining outlet is connected with the sewage-draining pipe; the upper portion of the inner side of the primary air-floatation tank is communicated with the electrolytic air-floatation tank; the electrolytic air-floatation tank is divided into an upper layer and a lower layer by an upper-lower separator plate; a slag-scraping device is arranged in an upper gas-liquid separation chamber; an electrolytic cell is mounted between the upper layer and the lower layer of the electrolytic air-floatation tank; the bottom of the electrolytic cell is fixed on the inner bottom of the casing; the top of the electrolytic cell is open and horizontal with the top of the upper-lower separator plate; an electrode is installed in the electrolytic cell; and an interval between an anode and a cathode of the electrode serves as a water passage. The device integrates multiple functions of electrolysis, flocculation precipitation, air-floatation and the like together, has high automation degree, sewage-discharging efficiency and low running cost, and is convenient for operation and maintenance.

Owner:BOYING XIAMEN SCI & TECH

Ferric aluminum silicon composite carbon-based electrode and application thereof in decoloration of wastewater

ActiveCN102126771ATo achieve the purpose of decolorizationSimple preparation processWater/sewage treatment by oxidationPerchloric acidHydroxyl radical

The invention discloses a ferric aluminum silicon composite carbon-based electrode and application thereof in decoloration of wastewater. A preparation method for the ferric aluminum silicon composite carbon-based electrode comprises the following steps of: mixing aqueous solution of tetraethyl orthosilicate, ferric perchlorate and aluminum choride and ethanol to obtain mixed solution; putting a carbon-based material into the mixed solution, stirring, heating to 75 to 85 DEG C, and adding ammonia water, so that iron, silicon and aluminum are deposited on the carbon-based material; and after performing a heat-preserving reaction completely, taking the carbon-based material out, drying for the first time, washing, and drying again to obtain the ferric aluminum silicon composite carbon-basedelectrode. The ferric aluminum silicon composite carbon-based electrode is used as a cathode of an electro-Fenton system, so a Fenton reagent can be provided continuously at the cathode and performs a Fenton reaction with hydrogen peroxide effectively to generate hydroxyl free radicals with high oxidability to oxidize organic matters in the wastewater, and the decoloration effect of the wastewater is desirable. The electrode has a simple preparation process, is low in cost, has low requirement on using environment and can be used under the condition of neutral pH, and the catalytic efficiencyis far higher than that of ferric oxides s.

Owner:GUANGDONG INST OF ECO ENVIRONMENT & SOIL SCI

Process for removing organic matter, iron and silicon dioxide in sodium aluminate solution

PendingCN107416877AImprove removal efficiencyGood decolorization effectAluminates/aluminium-oxide/aluminium-hydroxide purificationAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationDisplacement reactionsSodium aluminate

The invention discloses a process for removing an organic matter, iron and silicon dioxide in a sodium aluminate solution. The process comprises the following steps: heating sodium aluminate circulating mother liquor to 80 to 90 DEG C, adding calcium oxide into the sodium aluminate circulating mother liquor for adsorption displacement reaction, the calcium oxide being obtained by calcining or precipitating pure limestones and calcining and crushing obtained calcium carbonate, performing stirring in an open state after addition to separate out the organic matter sodium humate in the solution in form of calcium salt, simultaneously reacting the calcium oxide with sodium aluminate in the solution to generate fine calcium aluminate particles with large surface areas, performing solid-liquid separation after reaction, filtering and separating small particles suspended in the solution after reaction, regulating the temperature of the solution to 45 to 55 DEG C, and adding 3 to 6 volume percent of hydrogen peroxide to further decolorize the solution, the treated mother liquor being used for preparing refined liquor. An operating flow is simple, no additional equipment is required, and the process is high in organic matter removal efficiency and low in cost, and has good impurity removal and decolorization effects and a broad application prospect.

Owner:ZIBO LINJIA ALUMINUM IND TECH CO LTD

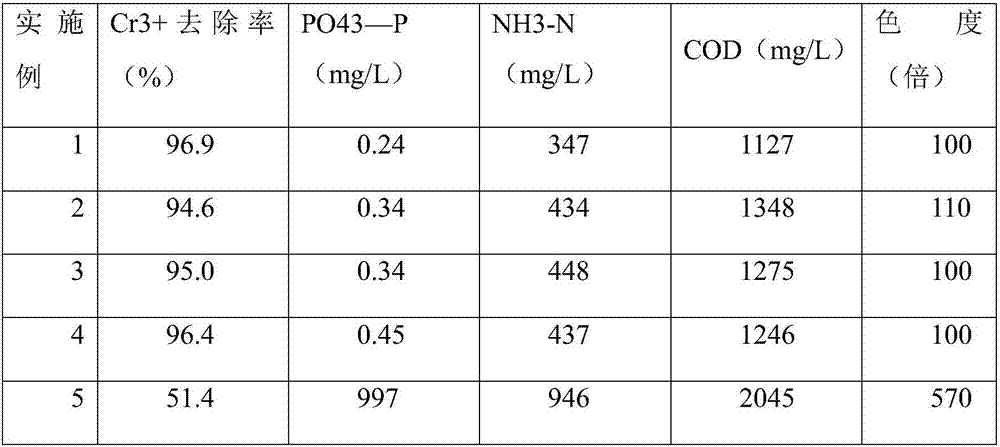

Leather wastewater treatment method

InactiveCN107986570AEfficient removalReduce chromaWater/sewage treatment by irradiationWater treatment compoundsChemical oxygen demandPhosphate

The invention discloses a leather wastewater treatment method and relates to the field of leather production. The leather wastewater treatment method comprises the following steps: filtering leather wastewater; adjusting the wastewater until the pH (Potential of Hydrogen) to be 3; adding a Fenton reagent and de-coloring; irradiating by an ultraviolet lamp to react; adding a Ca(OH)2 solution and removing lower-layer sediment; adding a chemical agent and removing phosphate sediment; adjusting the wastewater until the pH is greater than or equal to 11 and the temperature to be 80 DEG C; carryingout alkaline hydrolysis reaction at room temperature; adjusting the pH until the pH is greater than or equal to 11 and adjusting the temperature to be 50 DEG C, and then carrying out deamination; adding a flocculation precipitation agent into the leather wastewater to enable the leather wastewater to form a solid-liquid layered state; separating supernatant and lower-layer red solid substances ofthe precipitated wastewater; finally, carrying out biochemical treatment on the treated leather wastewater. By adopting the leather wastewater treatment method, COD (Chemical Oxygen Demand) can be effectively removed and the chroma of the wastewater can be effectively reduced.

Owner:苏州天亦辰针织有限公司

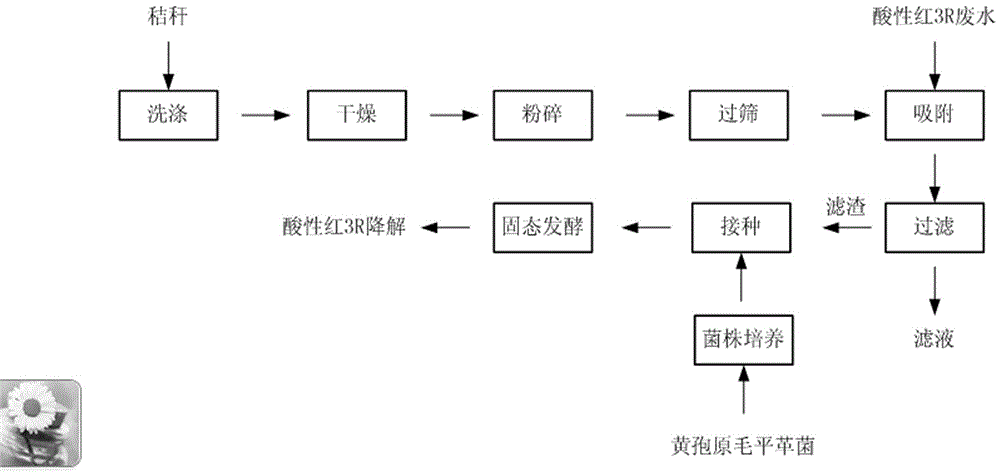

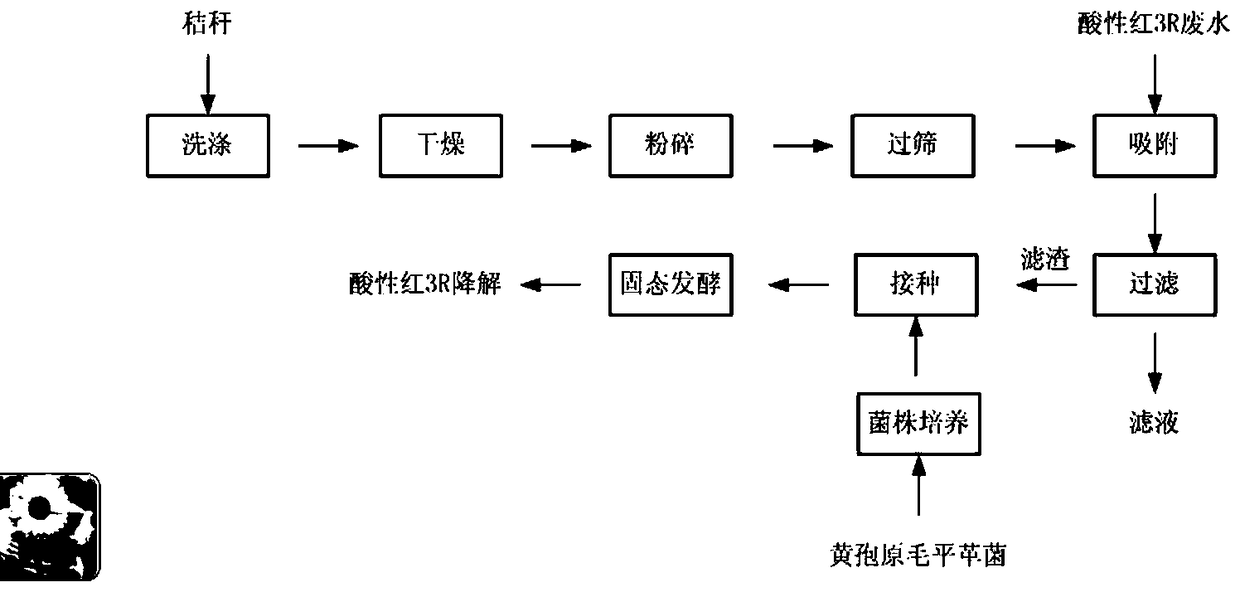

Method for removing acid red 3R by straw adsorption coupled fungus fermentation

ActiveCN105621652AEliminate Harmful PollutionLow costFungiWater contaminantsFiltrationChrysosporium species

The invention discloses a method for removing acid red 3R by straw adsorption coupled fungus fermentation, belonging to the technical field of industrial wastewater treatment. The method comprises the following main steps: pretreating straws, adsorbing dyes, culturing Phanerochaete chrysosporium and carrying out solid state fermentation. The crop straws with abundant sources and low cost are used as a biological adsorbent to adsorb and remove acid red 3R in wastewater. After the straws adsorb the acid red 3R, filtration is carried out, the Phanerochaete chrysosporium is inoculated into the filter residues, and the solid state fermentation is carried out, so that the acid red 3R is degraded in the fermentation process. The method is based on straw adsorption and fungus solid state fermentation, removes the acid red 3R in the water body, eliminates the harmful pollution of the acid red 3R on the environment, and has the advantages of simple process, low cost, environment friendliness, wide prospects and the like.

Owner:NANYANG INST OF TECH

Method for treating DSD acid oxidized waste water using electrolytic process

The invention provides an electrolysis method to treat the sewage oxidized by DSD acid. Wherein, with NaCl, Na2SO4 or original salt in sewage as conducting medium, adjusting the plate height of electrolytic bath as 25~35cm and the work current as 30~50A; leading the diluted sewage into the bath to position of 4~8cm of plate; electrifying and electrolyzing the sewage for 2. 5~3. 5h with O2 or Cl2 on anode and H2 on cathode; using the oxidation of NaClO and reduction of H2 to destroy the dye molecular structure and decolor. This invention can desalinate and decolor at one time to let the sewage come up to discharge standard.

Owner:UNIV OF SCI & TECH BEIJING

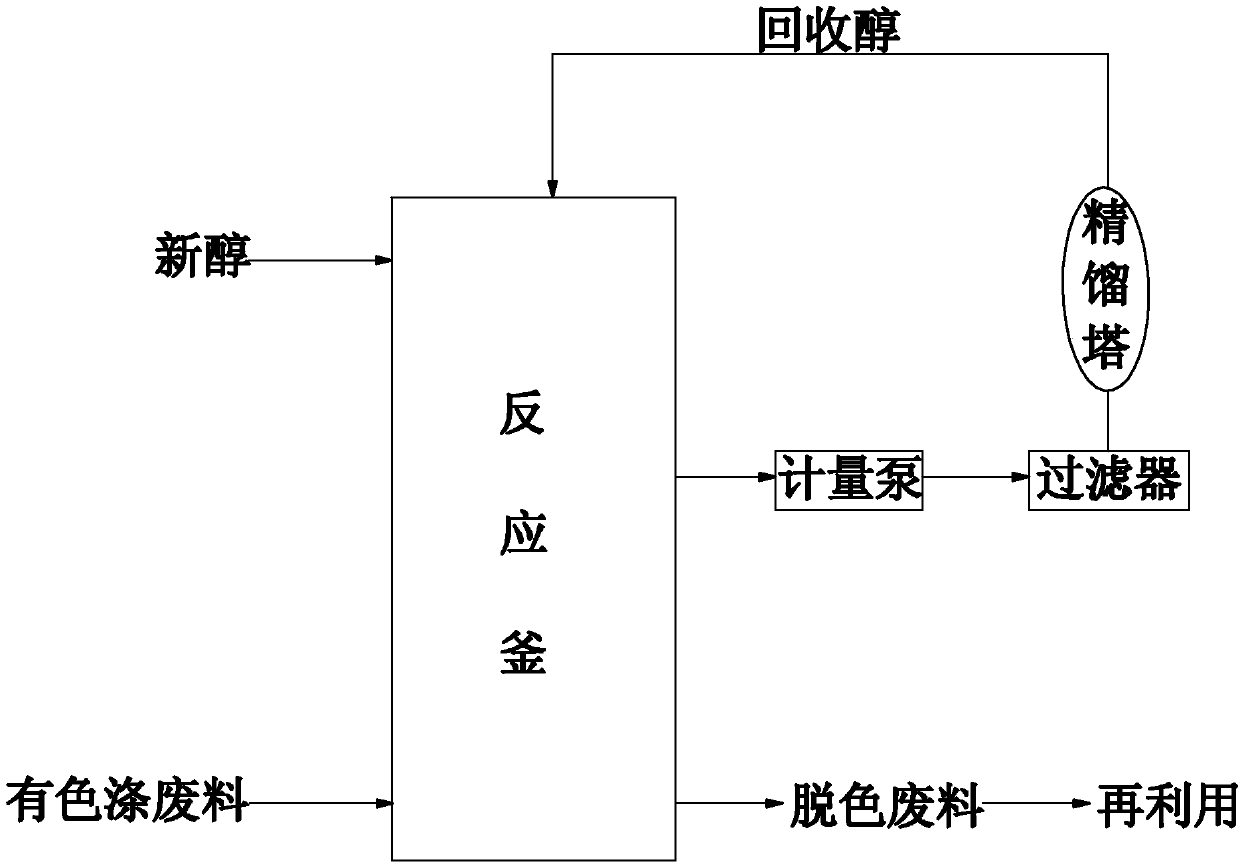

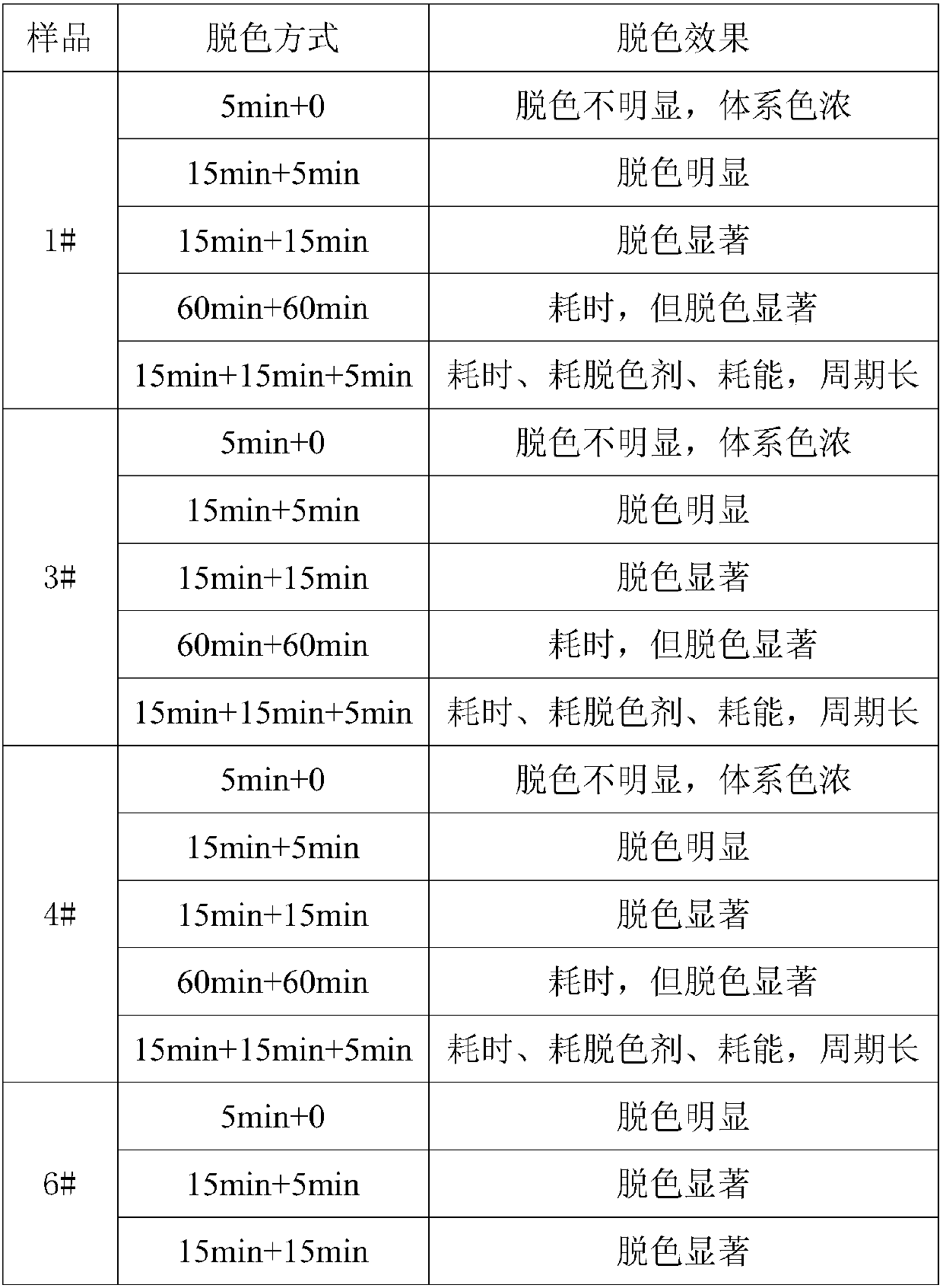

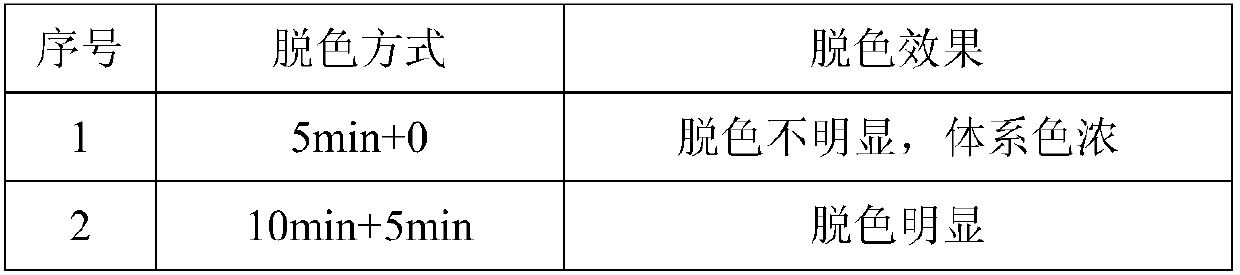

Polyester-containing waste textile decolorization process capable of realizing solvent circulation

InactiveCN107587362AEnable recyclingRealize cyclic decolorization processSolvent-treatmentDyeing processFiberPolyester

The present invention relates to a polyester-containing waste textile decolorization process capable of realizing solvent circulation, and belongs to the technical field of solvent or fiber regeneration. Waste cloth to be processed is placed in a reaction kettle, meanwhile a solvent alcohol is added, after decolorization, the discolored waste cloth is reused, and the solvent in the reaction kettleis recovered through alcohol recovery, and put back to the reaction kettle to continue to finish washing and decolorization, and the mass ratio of the waste cloth and the solvent is 1: (1-50). The decolorization is carried out twice. The decolorization temperature is 100-250 DEG C, and the decolorization time is (5-90) min + (0-60) min. The polyester-containing waste textile decolorization process is applied to the recycling of polyester products, and has the advantages of low energy consumption, short cycle and less pollution and the like.

Owner:ZHEJIANG LUYU ENVIRONMENTAL PROTECTION

Method for removing slag before solvent extraction in process of producing industrial-grade phosphoric acid by wet-process phosphoric acid

The invention discloses a method for removing the slag before solvent extraction in the process of producing industrial-grade phosphoric acid by wet-process phosphoric acid. The method comprises the following steps of: procedures of solid-liquid separation and fine filtration, i.e., continuously conveying concentrated phosphoric acid slurry, which needs to be pretreated by desulfurization, defluorination and decolorization before extraction and purification of the phosphoric acid by an organic solvent and has 8-10% solid content, to a centrifugal machine, carrying out solid-liquid separation at a rotating speed of 1800-2500r / min, controlling the solid content in clear solution to be in 1%, and conveying solid slag into the next procedure for retreatment; and conveying the clear solution into fine filtration equipment for fine filtration, enabling the solid content in the clear solution to be less than 0.2%, and conveying refined acid to the organic extraction and purification procedures. The method adopts the two procedures of solid-liquid separation and fine filtration to enable the solid content in the treated acid slurry to be reduced below 0.2%, and be conductive to the obtainment of high-quality and high-added-value phosphoric acid products. The method has the advantages that the process is simple, the working is stable and reliable, solid slag in acid liquor can be effectively treated, simultaneously the purposes of desulfurization, defluorination and decolorization can be achieved, and the favorable conditions are created for extracting and purifying the phosphoric acid by the organic solvent.

Owner:KUNMING CHUAN JINNUO CHEM IND

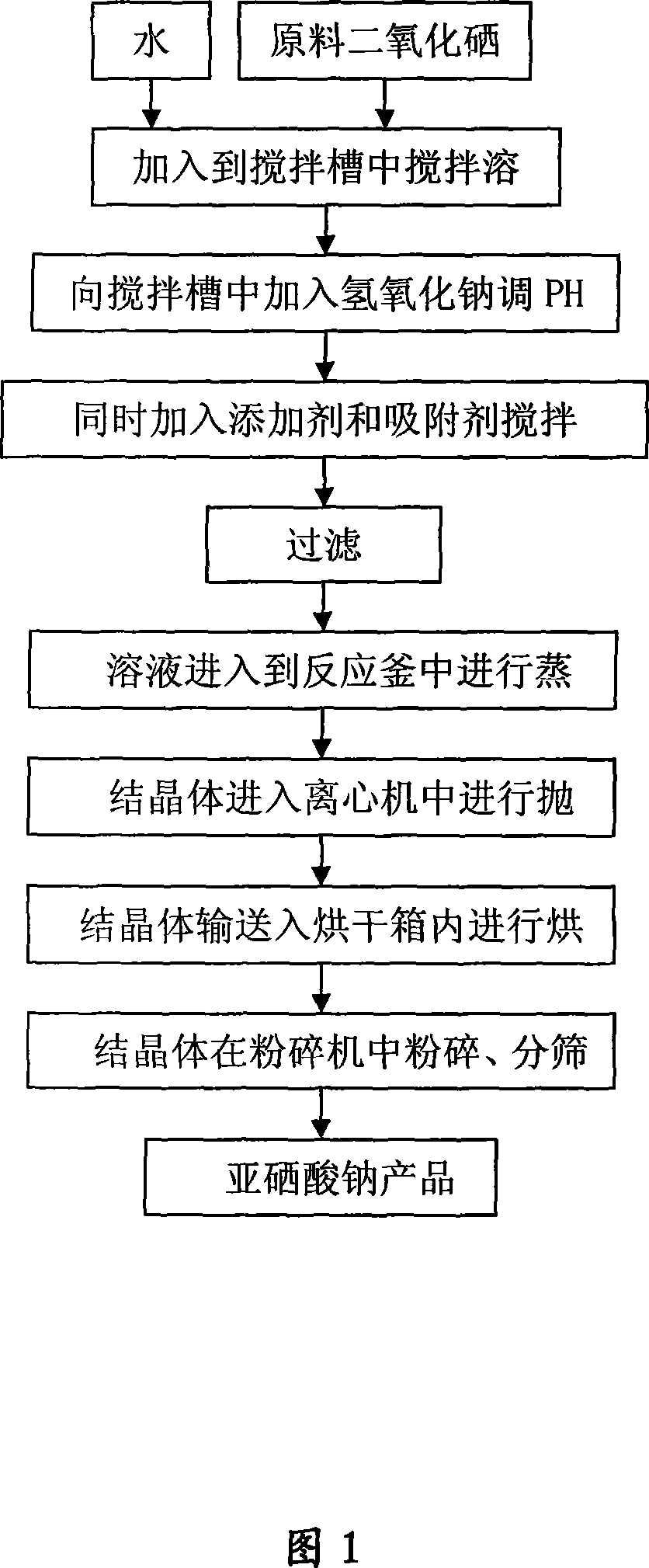

Process for producing sodium selenite

InactiveCN101104520ALess investmentEfficient preparation processSelenium/tellurium compundsSodium/potassium compoundsSelenious AcidSodium Biselenite

The present invention relates to a production technology of sodium selenite. The invention comprises the following steps: 1. a proper amount of selenium dioxide is dissolved in water to form selenious acid solution; 2. sodium hydroxide is added to the selenious acid solution and the pH value is adjusted to 7 to 14; 3, a proper amount of additive and adsorbent is added; 4, filtration, evaporation and crystallization; 5, heating, drying, crushing and screening; 6, finished sodium selenite product. The sodium selenite production technology of the invention has the advantages of simple production technology, less production equipment investment, as well as simple and convenient operation, and is a highly efficient and energy-saving sodium selenite preparation technology.

Owner:FIRST RARE MATERIALS CO LTD

Cold pad-batch pre-treatment method for cotton textile

InactiveCN103556449AImprove wettabilityAccelerated alkaline hydrolysisBleaching apparatusVegetal fibresWater useBatch processing

The invention relates to a cold pad-batch pre-treatment method for a cotton textile and belongs to a spinning and printing pre-treatment process technology. According to the cold pad-batch pre-treatment method, a method for changing a cold pad-batch process path of the cotton textile and preparing alkali liquid and bleaching liquid in the cold pad-batch process of the cotton textile is adopted; the cotton textile is sequentially padded by the alkali liquid formed by mixing a high-ratio alcohol organic solvent with sodium hydroxide, and the bleaching liquid formed by mixing the high-ratio alcohol organic solvent with hydrogen peroxide, and then the cotton textile is subjected to pad-batch pre-treatment so as to reduce the water use amount to the greatest extent and improve a treatment effect. The method is simple in process and good in treatment effect and has the characteristics of good capillary effect, high whiteness, good quality, high softness and good glossiness; favorable conditions are created for subsequent dyeing processing and the use amount of water and chemical reagents is reduced; the alcohol organic solvent is recycled so that the burden of sewage treatment of enterprises is reduced greatly; the cold pad-batch pre-treatment method for the cotton textile is a clean production process meeting the environmental requirements and has very high social and economic benefits.

Owner:WUHAN TEXTILE UNIV

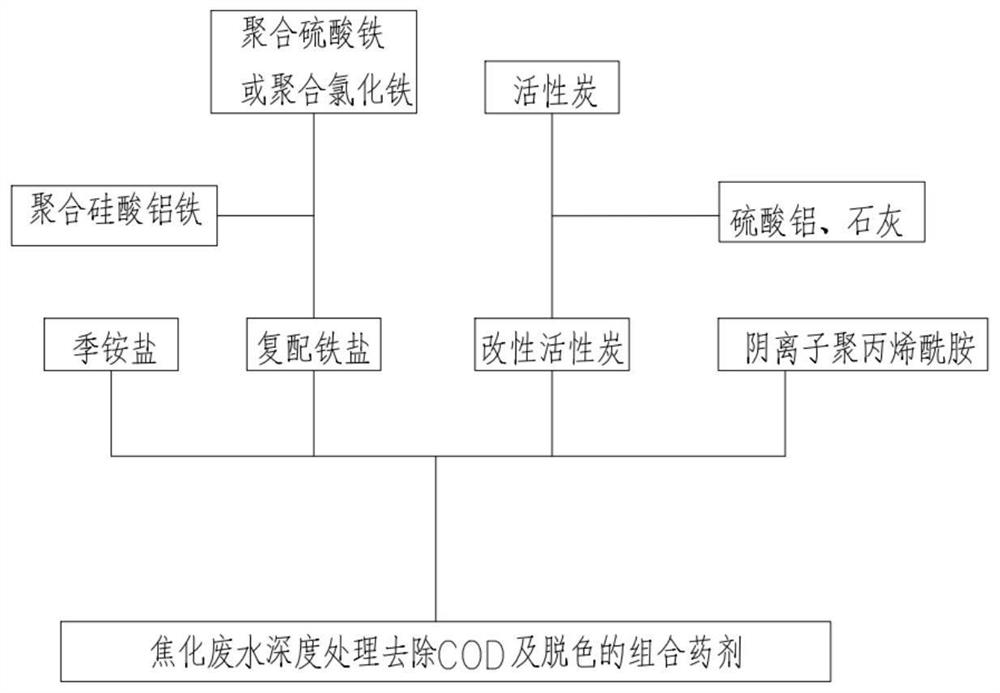

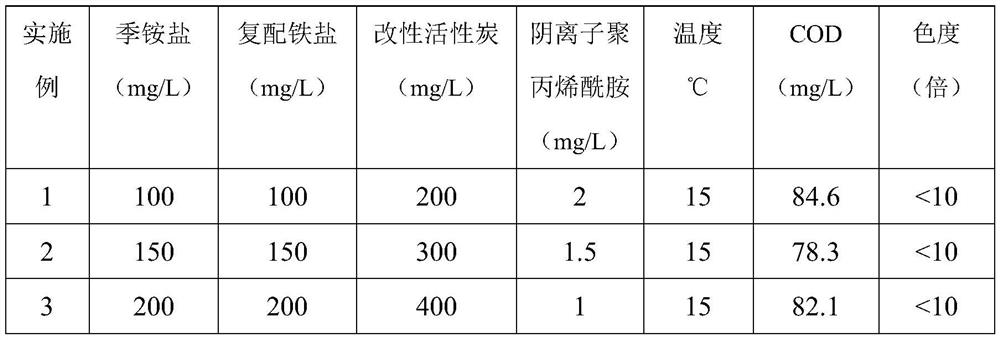

Combined reagent applied to deep treatment of coking wastewater to remove COD and discolor, and application thereof

InactiveCN111807490ATo achieve the purpose of decolorizationFast flocculationWater/sewage treatment by flocculation/precipitationWater/sewage treatment by sorptionIron sulfateEngineering

The invention discloses a combined reagent applied to deep treatment of coking wastewater to remove COD and discolor, and application thereof. The reagent comprises, by weight, 100-200 parts of quaternary ammonium salt, 100-200 parts of compound ferric salt, 200-400 parts of modified activated carbon and 1-2 parts of anionic polyacrylamide. The compound ferric salt is prepared from 700-900 parts of polyferric sulfate or polyferric chloride and 100-300 parts of polyaluminum ferric silicate; and the modified activated carbon comprises 7-8 parts of activated carbon, 1-1.5 parts of aluminum sulfate and 0.5-1 part of lime. A quaternary ammonium salt stock solution and the compound ferric salt are respectively prepared into 10% solutions, a 5% solution is prepared from the modified activated carbon, preparing a 0.01% solution is prepared from the anionic polyacrylamide, the solutions are added into coking wastewater which is subjected to biochemical treatment in a coking plant and has COD of300-500 mg / L and chromaticity of 150-250 times, reinforced composite coagulation is carried out, and it is detected that the COD of effluent of the coking wastewater is less than 100 mg / L, thereby reaching the indirect discharge standard of the coking industry. And the effluent chromaticity is less than 20 times. Under the synergistic action of adsorption and enhanced flocculation, the combined reagent has the advantages of high COD removal efficiency, favorable precipitation effect and low operating cost, and can be widely suitable for advanced wastewater treatment of coking plants of different scales.

Owner:众意环保科技(大连)有限公司

Decoloration ink

The invention discloses decoloration ink which comprises the following components in percentage by weight: 86-93 percent of water, 2-8 percent of thyme phenolphthalein, 3-5 percent of sodium hydroxide and 1-5 percent of NaCl. In the invention, by utilizing the characteristic that the thyme phenolphthalein is blue in an alkaline environment with a pH value of 9-12, after the ink is sprayed on a clothing material or paper, water is absorbed by fibers to ensure that the pH value of the ink becomes smaller until reaching a neutral environment, and then the ink changes from blue to colorless so as to achieve the purpose of decoloration.

Owner:陶运祥

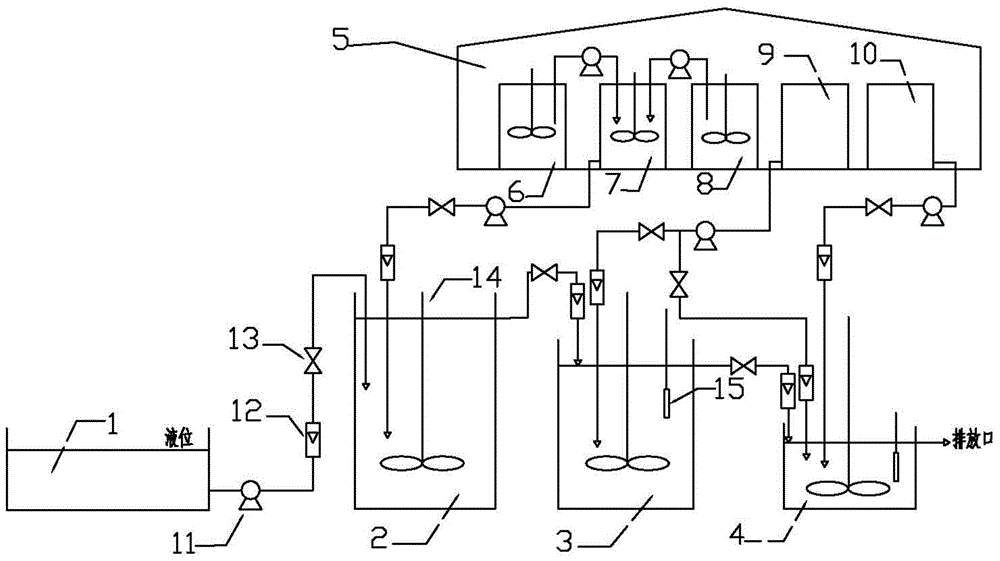

Decoloration method and system for electroplating wastewater

ActiveCN104098170AReduce the amount of medicine usedShort reaction timeWaste water treatment from metallurgical processWater/sewage treatment by reductionChemistryResist

The invention belongs to the field of wastewater treatment, and particularly discloses a decoloration method and system for electroplating wastewater. According to the method, a certain quantity of strong reducing agent systems NaBH4 / NaHSO3 at certain proportions is added into final settlement tank effluent with a pH (potential of hydrogen) value of 7 in the electroplating wastewater, the mixture is uniformly stirred to stabilize the pH, a dilute sulphuric acid solution is added to adjust the pH to 7.0-8.0, wastewater containing resist salt is treated to be transparent and colorless in 1-10 minutes, and color reversion phenomenon is not caused during natural placement or after oxidizing agents such as sodium hypochlorite and the like are added. The treatment system based on the decoloration method for electroplating wastewater comprises a preparation chamber, a NO.1 reaction tank, a NO.2 reaction tank, a pH adjusting tank and the like, wherein the preparation chamber comprises a NaBH4 solution (containing 10%-40% of NaOH) preparation bucket, a NaHSO3 solution preparation bucket, a reaction system preparation bucket, a sulfuric acid storage bucket and a liquid caustic soda storage bucket. The method and the system have the characteristics of high electroplating wastewater decoloration efficiency, low probability of color reversion and the like.

Owner:ZHEJIANG HI TECH ENVIRONMENTAL TECH

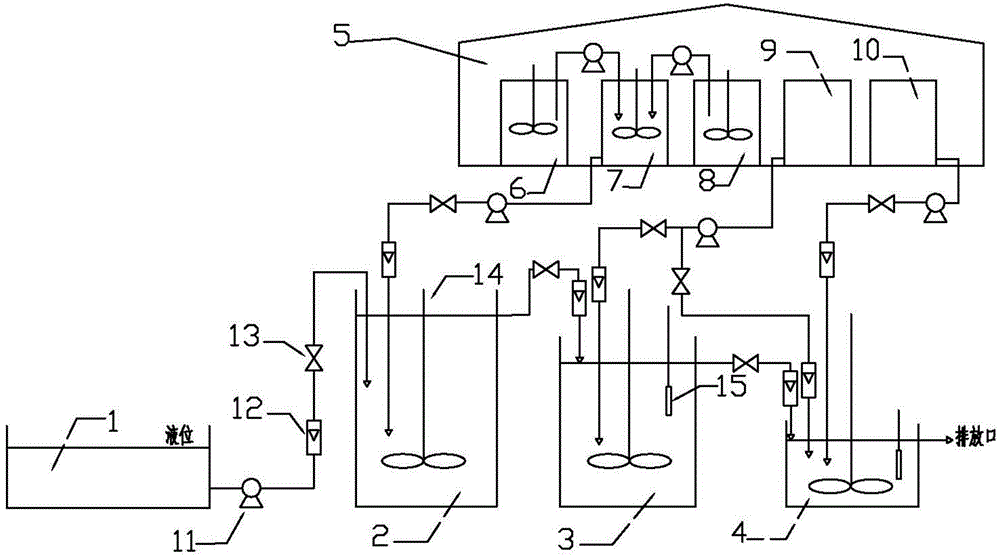

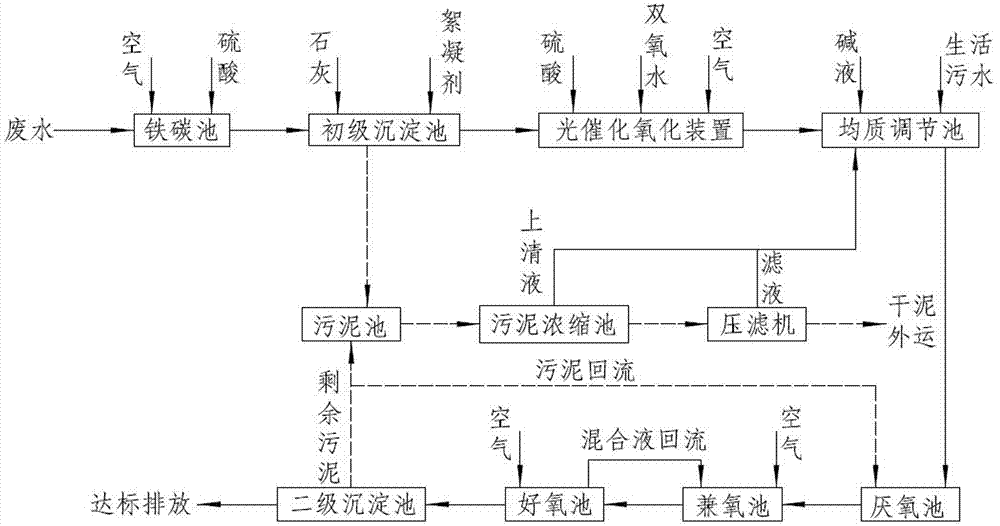

Micro-electrolysis treatment technology for chemical waste water

PendingCN107324619ATo achieve the purpose of decolorizationImprove biodegradabilityWater treatment parameter controlTreatment with aerobic and anaerobic processesPhoto catalyticSludge

The invention belongs to the field of chemical waste water treatment, in particular to a micro-electrolysis treatment technology for chemical waste water. The method comprises the five steps of pretreatment of the waste water, homogenizing treatment of the waste water, biochemical treatment, precipitation and discharge and sludge treatment. According to the micro-electrolysis treatment technology for the chemical waste water, before the biochemical treatment of the waste water, the pretreatment steps of micro-electrolysis, coagulation precipitation, photo-catalytic oxidation and the like are conducted, wherein chromophoric groups and auxochrome groups in the waste water are removed through the micro-electrolysis treatment to achieve a discoloration purpose, so that compositions of the waste water are converted to be likely to occur biochemical reactions, and the biodegradability is greatly improved. Through the coagulation precipitation treatment, Fe(OH)2 and Fe(OH)3 are generated and precipitated with nascent-state Fe<2+> and Fe<3+> in alkaline environment; in cooperation with a flocculant PAM, original suspended solids, colloid, oil and the like and partial water-soluble organic matter in the waste water are gathered, adsorbed and condensed in order to be separated and precipitated from the waste water. Through the adoption of the photo-catalytic oxidation, the removal rate of the organic matter in the waste water reaches 40% or above, the B / C is increased to 0.4 or above, and favorable conditions are created for the subsequent biochemical treatment.

Owner:云南今业生态建设集团有限公司

Novel textile product dyeing and finishing process

The invention relates to a novel textile product dyeing and finishing process, which comprises: preparing a boiling-bleaching liquid, and treating a cotton knitted product, wherein a low temperature scouring-bleaching aid composition, hydrogen peroxide, caustic soda, a stabilizer and an anti-wrinkle agent into water to prepare the boiling-bleaching liquid; adjusting the pH value of the boiling-bleaching liquid to 7, taking out the bamboo cotton blended fabric, placing the bamboo cotton blended fabric and a dyeing liquid into a dyeing machine, and carrying out slow color fixing; adding a cleaning liquid into the dyeing machine, and washing for 25-30 min at a temperature of 55-70 DEG C, wherein the cleaning liquid contains 5-7 g / L of sodium dithionite and 1.5-3 g / L of caustic soda; and placing the cleaned and reduced bamboo cotton blended fabric into a glacial acetic acid bath, heating to a temperature of 60-65 DEG C, carrying out thermal insulation for 10-15 min, completely neutralizing the residual alkali on the cloth surface, discharging the water, adjusting the PH value to 7-8, adding water, adding soaping enzyme at a room temperature, heating to a temperature of 85-90 DEG C, carrying out thermal insulation for 10-15 min, discharging the liquid, adding water, and carrying out water washing at a room temperature. According to the present invention, with the process, the produced fabric has characteristics of flat surface, uniform color, and high color fastness.

Owner:RUGAO XIAYUAN SCI & TECH ESTABLISH A BUSINESS SERVICES CO LTD

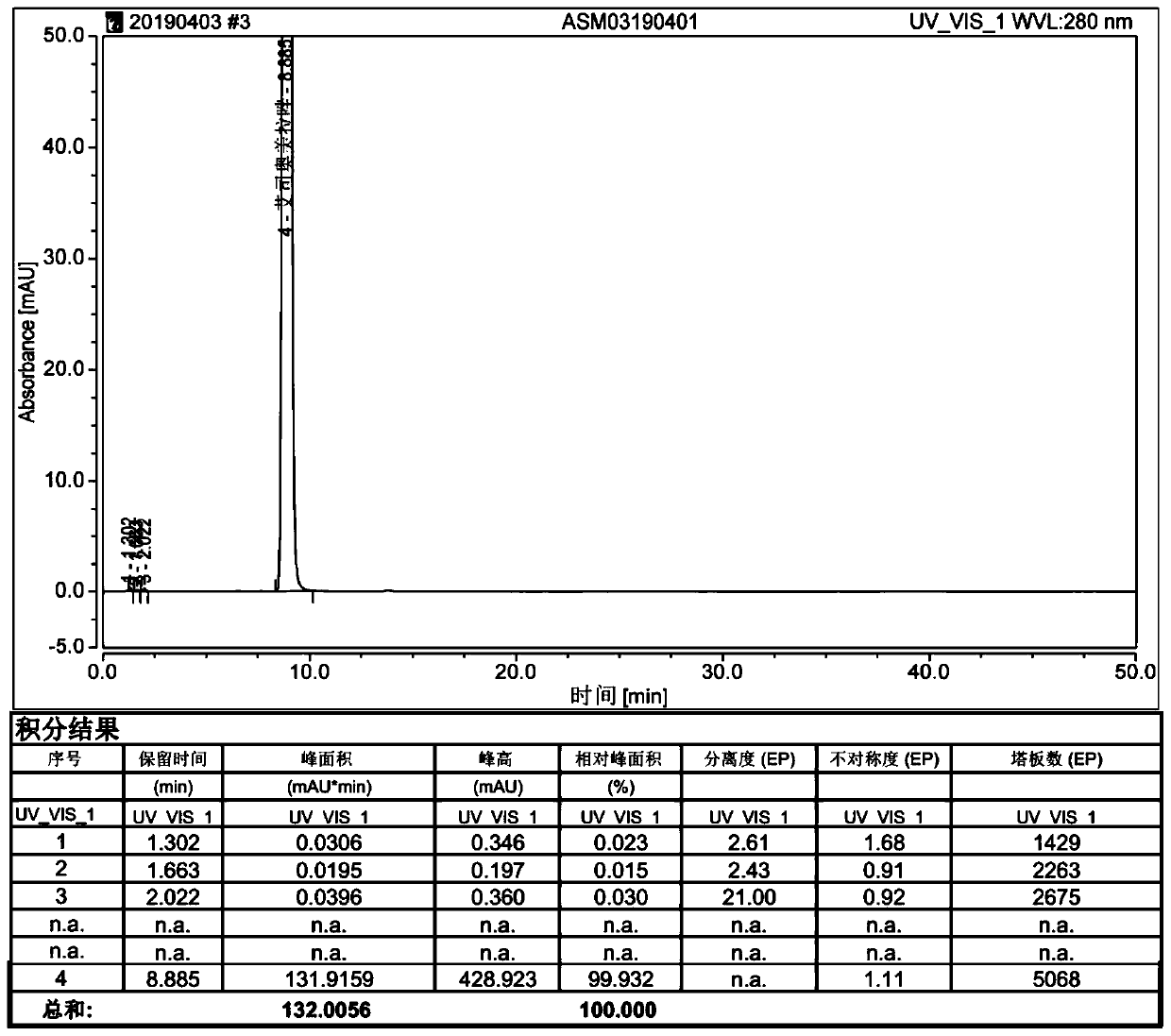

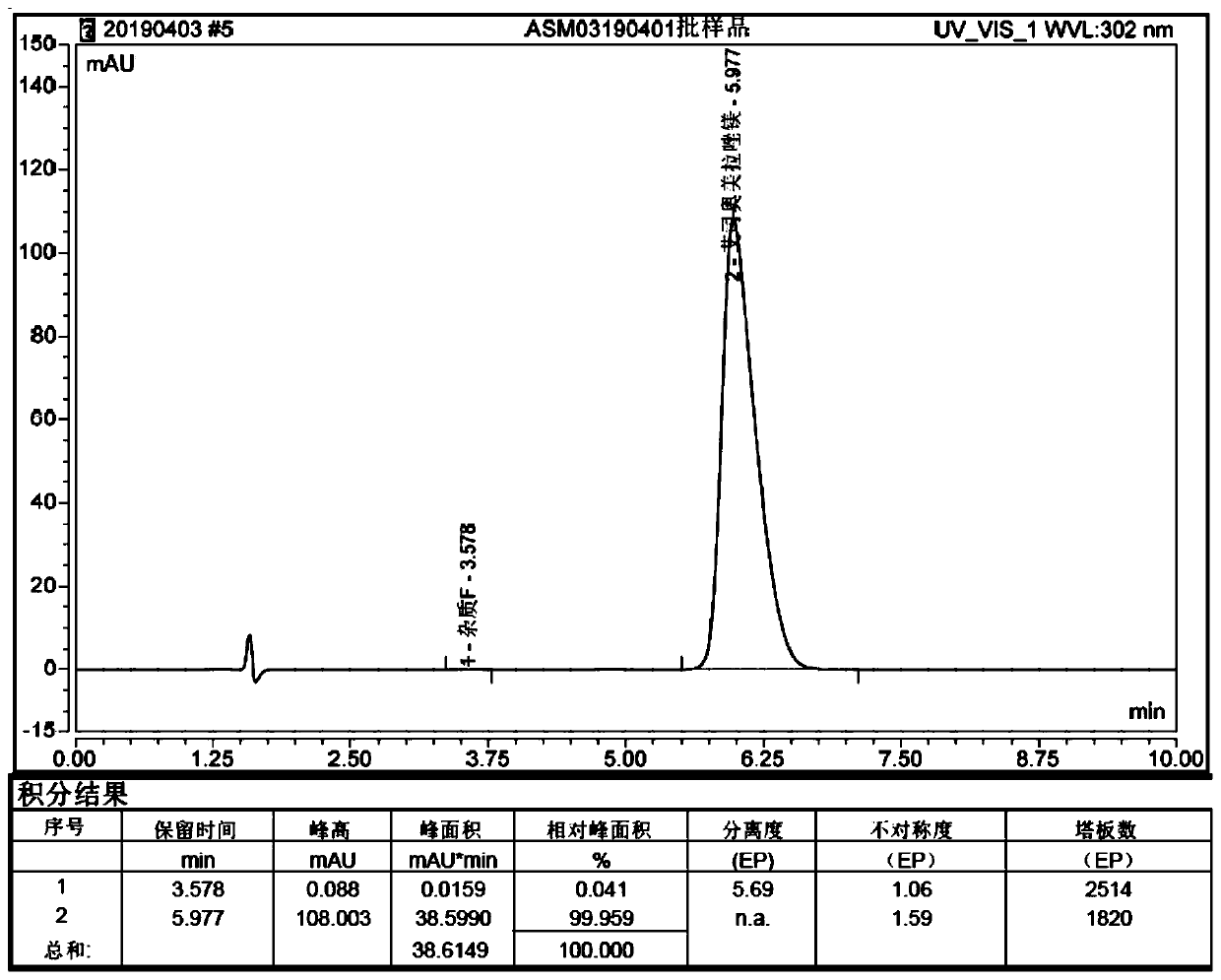

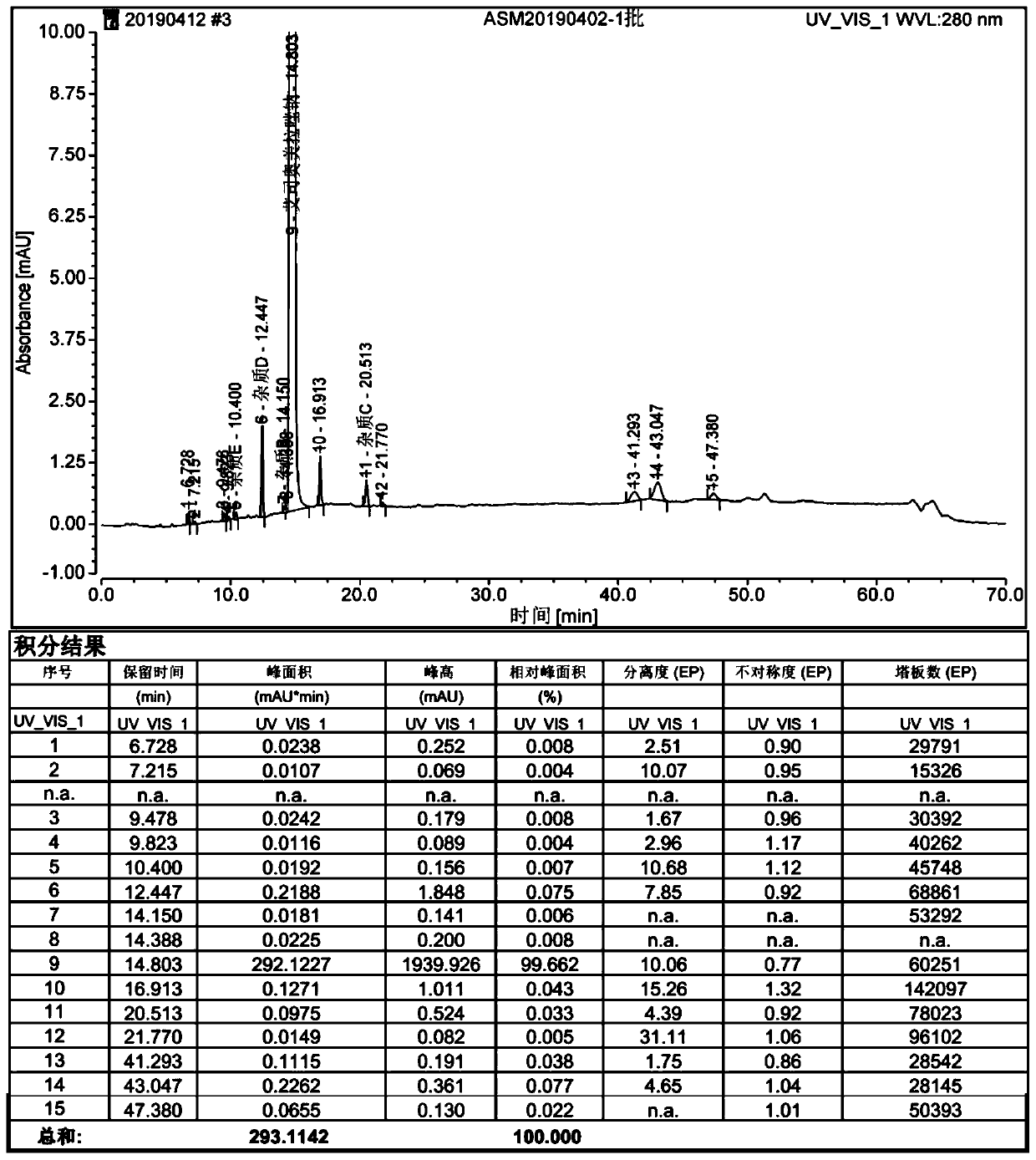

Method for preparing high-purity esomeprazole magnesium

ActiveCN110305108ATo achieve the purpose of decolorizationOrganic chemistry methodsAqueous acetoneFiltration

The invention relates to a method for preparing high-purity esomeprazole magnesium. The method comprises the following steps: mixing omeprazole sulfide, diethyl tartrate and titanium isopropoxide, adding diisopropylethylamine, performing stirring, dropping cumene hydroperoxide, and performing separation so as to obtain an oil substance; adding a strong base, performing stirring, adding the strongbase time by time, performing extraction and washing, performing TLC (thin-layer chromatography) monitoring, and stopping adding the strong base when trace points are generally vanished; performing cooling, crystal separation, filtration and leaching so as to obtain an esomeprazole salt; dissolving the esomeprazole salt with water, reducing the temperature to 20 DEG C or less, adjusting the pH value, dropping a magnesium sulfate heptahydrate solution, and after dropping, performing stirring, filtration, leaching and drying so as to obtain a crude product of esomeprazole; dissolving the crude product of the esomeprazole with methanol, performing decoloring with activated carbon, performing filtration, concentration and secondary dissolution, adding an acetone solution, and performing stirring, suction filtration and drying, so as to obtain the esomeprazole magnesium. The product prepared by using the method is high in purity, high in yield and small in impurity.

Owner:湖南协创药品开发有限公司

A method for removing acid red 3r by straw adsorption coupled with fungal fermentation

ActiveCN105621652BTo achieve the purpose of decolorizationEliminate Harmful PollutionFungiWater contaminantsFiltrationChrysosporium species

Owner:NANYANG INST OF TECH

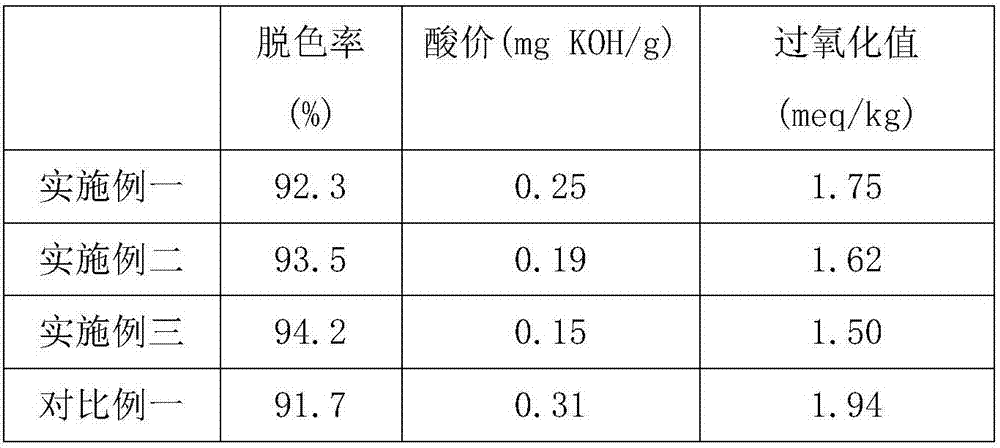

Decoloring method of pharmaceutical raw material grade camellia seed oil

InactiveCN107022412AIncrease layer spacingHigh decolorization rateOther chemical processesFatty-oils/fats refiningCamellia oleiferaAbsorption capacity

The invention belongs to the technical field of grease refining, specifically provides a decoloring method of pharmaceutical raw material grade camellia seed oil. The method comprises the following steps: adding crude camellia seed oil after degumming and alkali refining in a decoloring tower, heating and warming to a certain temperature, adding self-made mixed decoloring agent, performing vacuum decoloring and drying, sufficiently decoloring and drying under a certain rotating speed, cooling to less than 50 DEG C, filtering, centrifuging and separating the filtrate to obtain the decolored grease. The decoloring method disclosed by the invention utilizes a feature that the modified activated clay is strong in capacity of absorbing the pigment in the oil, and utilizes the feature that the carbonized soybean hull ash has strong absorption capacity to the residual phospholipid, peroxide and free fatty acid; the decoloring speed is fast and the decoloring effect is good.

Owner:安徽山美生物科技有限公司

Reversible temperature-sensitive color-changing neutral ink

InactiveCN109694617AFix bugs that cannot be fixedAvoid the potential risks of using organic nitrogen and sulfur compoundsInksPreservativeBenzotriazole

The invention discloses a reversible temperature-sensitive color-changing neutral ink, which comprises, by mass, 30-50 parts of a reversible temperature-sensitive color-changing microcapsule pigment paste, 10-20 parts of a water-soluble organic humectant, 0.1-1.0 part of iodopropynyl butyl carbamate (IPBC) as a preservative, and 0.1-1.0 part of benzotriazole as an anti-rust agent. According to thepresent invention, the reversible temperature-sensitive color-changing neutral ink has the pH value of 7-9, is safely and reliably used, and can achieve color developing and color eliminating effectat a certain phase transition temperature so as to achieve the purpose of writing modification.

Owner:金文华

A method and system for decolorizing electroplating wastewater

ActiveCN104098170BReduce usageShort stayWaste water treatment from metallurgical processWater/sewage treatment by reductionSodium chlorateProcess engineering

Owner:ZHEJIANG HI TECH ENVIRONMENTAL TECH

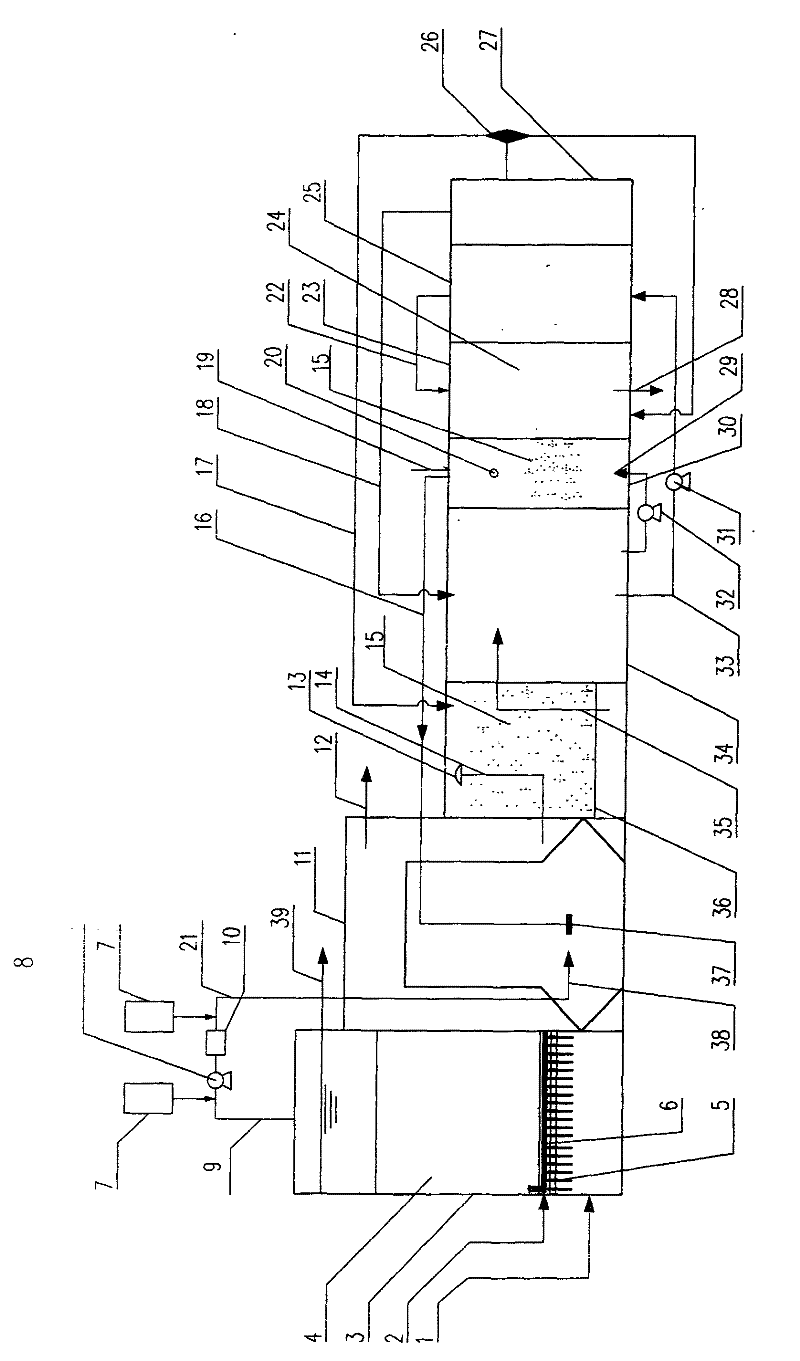

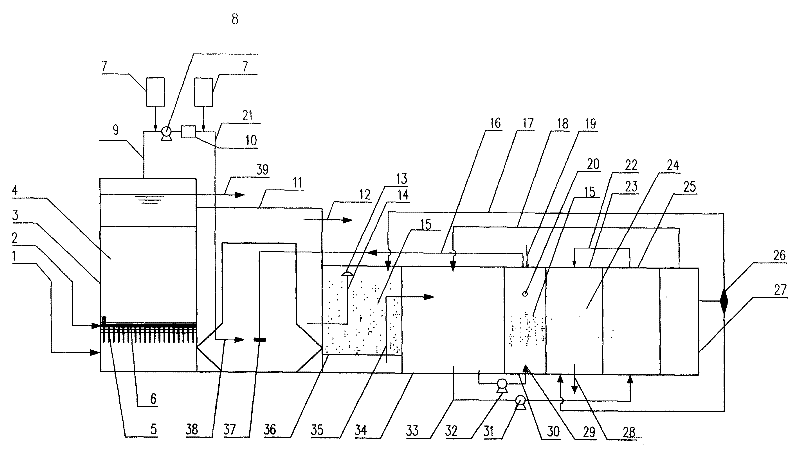

Advanced treatment and reuse integrated equipment for textile dyeing and finishing wastewater

InactiveCN102198998AGood effectGood denitrification functionMultistage water/sewage treatmentWaste water treatment from textile industryOzone generatorActivated carbon

The invention discloses advanced treatment and reuse integrated equipment for textile dyeing and finishing wastewater. The equipment comprises an aerated biofiltration cavity (3), an air floatation cavity (11), an ozone reaction cavity (36), a middle water tank (34), a dissolved air chamber (30), an activated carbon cavity (23), a filtration cavity (25) and an ozone generator (27) which are arranged in a box body in parallel in sequence; the aerated biofiltration cavity (3) and the air floatation cavity (11) are connected by a pipeline; the air floatation cavity (11) and the ozone reaction cavity (36) are connected by a pipeline; the ozone reaction cavity (36) and the middle water tank (34) are connected by a pipeline; the middle water tank (34) and the dissolved air chamber (30) are connected with the filtration cavity (25) and the ozone generator (27) by pipelines; the air floatation cavity (11) and the dissolved air chamber (30) are connected by a pipeline; and the activated carbon cavity (23) and the filtration cavity (25) are connected by a pipeline. The equipment has ingenious design and compact and reasonable internal layout, occupation area is reduced and the manufacture and maintenance costs are reduced.

Owner:李斌 +2

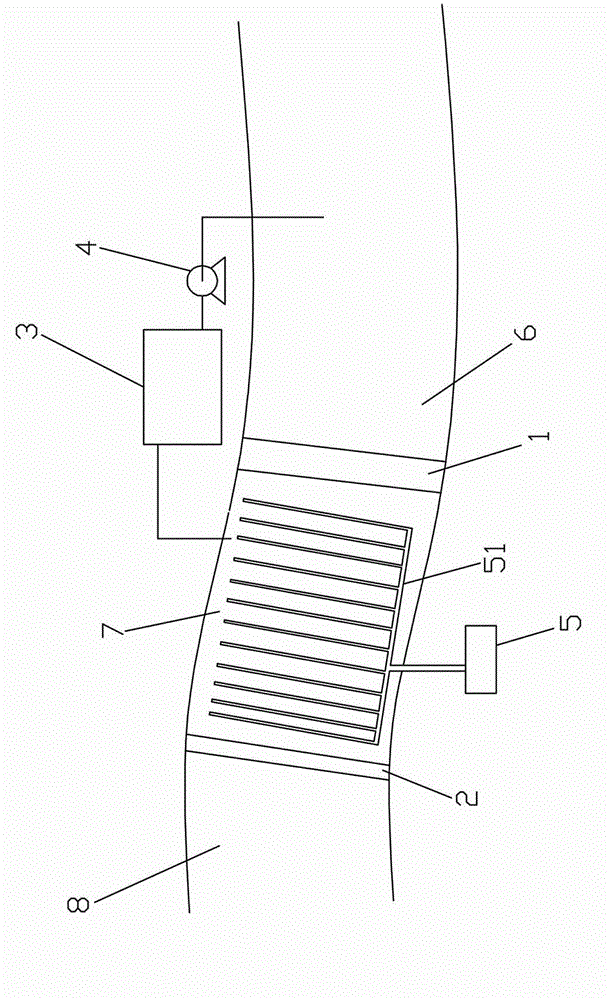

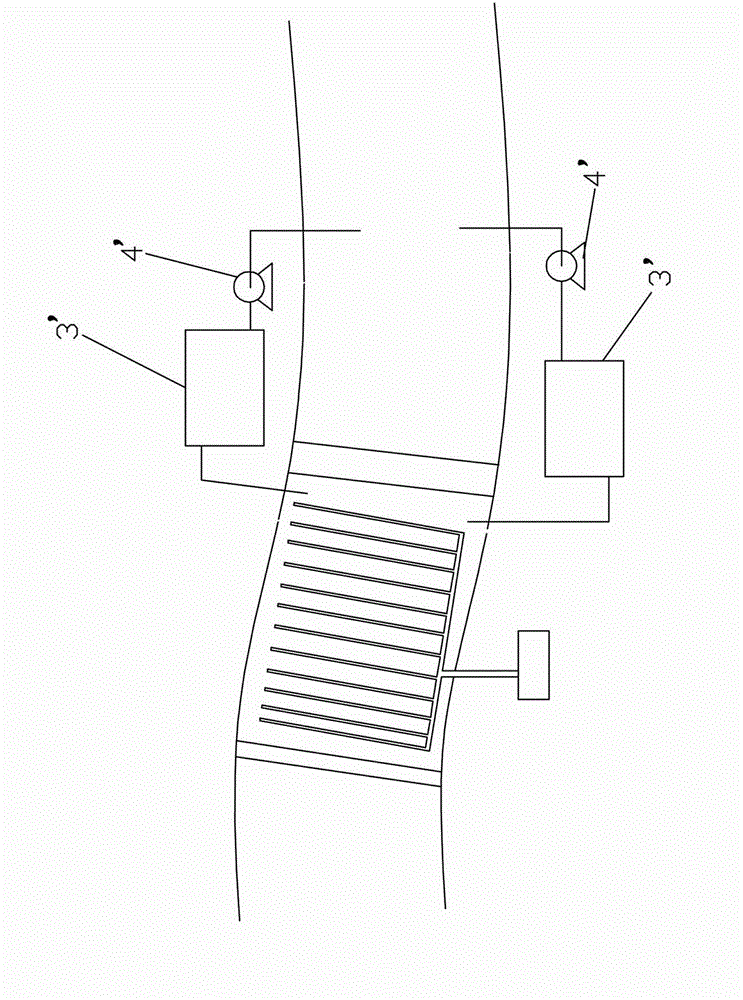

Eutrophicated river water quality purifying method

InactiveCN102633395BReduce CODEliminate odorWater treatment compoundsSpecific water treatment objectivesPurification methodsElectrolysis

Disclosed is a water quality purification method for a eutrophicated river, comprising the follow steps: first, blocking a eutrophicated river and forming an upstream part, a midstream part, and a downstream part; then entering the water in the upstream part into an electrolysis machine for electrolysis; discharging the electrolyzed water into the midstream part, and performing aeration treatment; lastly, letting the aerated water flow into the downstream part. By using a method of an electrolysis process and an aeration process in sequence, the algae growth in the water and the anaerobic reactions in the water body are effectively inhibited, organic matters are decomposed, the total nitrogen, total phosphorus, and color of the water are lowered, odors are eliminated, river water quality is improved within a relatively short period, and the water ecological system is restored. Also disclosed is a river water quality purification device, comprising a rubber dam, a pump, an electrolysis machine, and an aeration device. The device can be directly installed in the river and can directly purify river water without the need to guide the river into a pre-set structure for treatment. The present invention makes almost no change to the environment, and therefore has a relatively small impact on the natural environment.

Owner:BOYING XIAMEN SCI & TECH

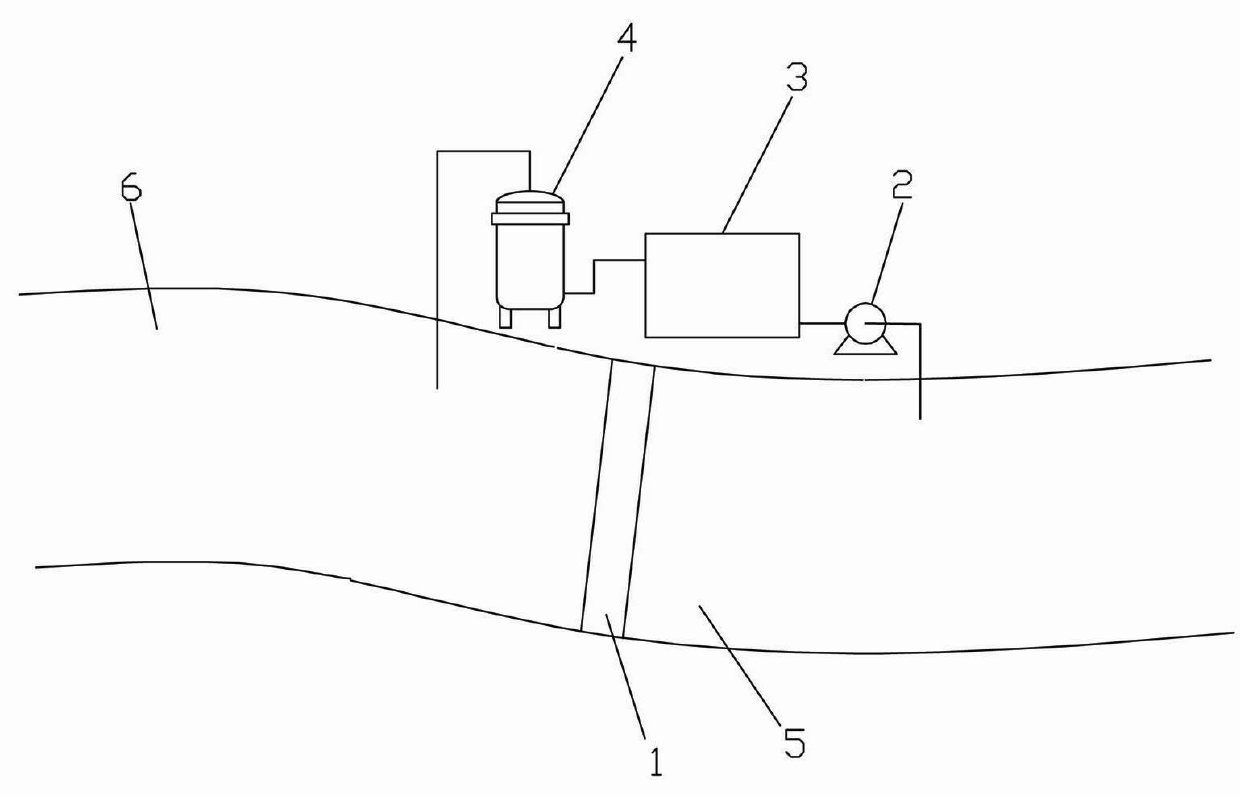

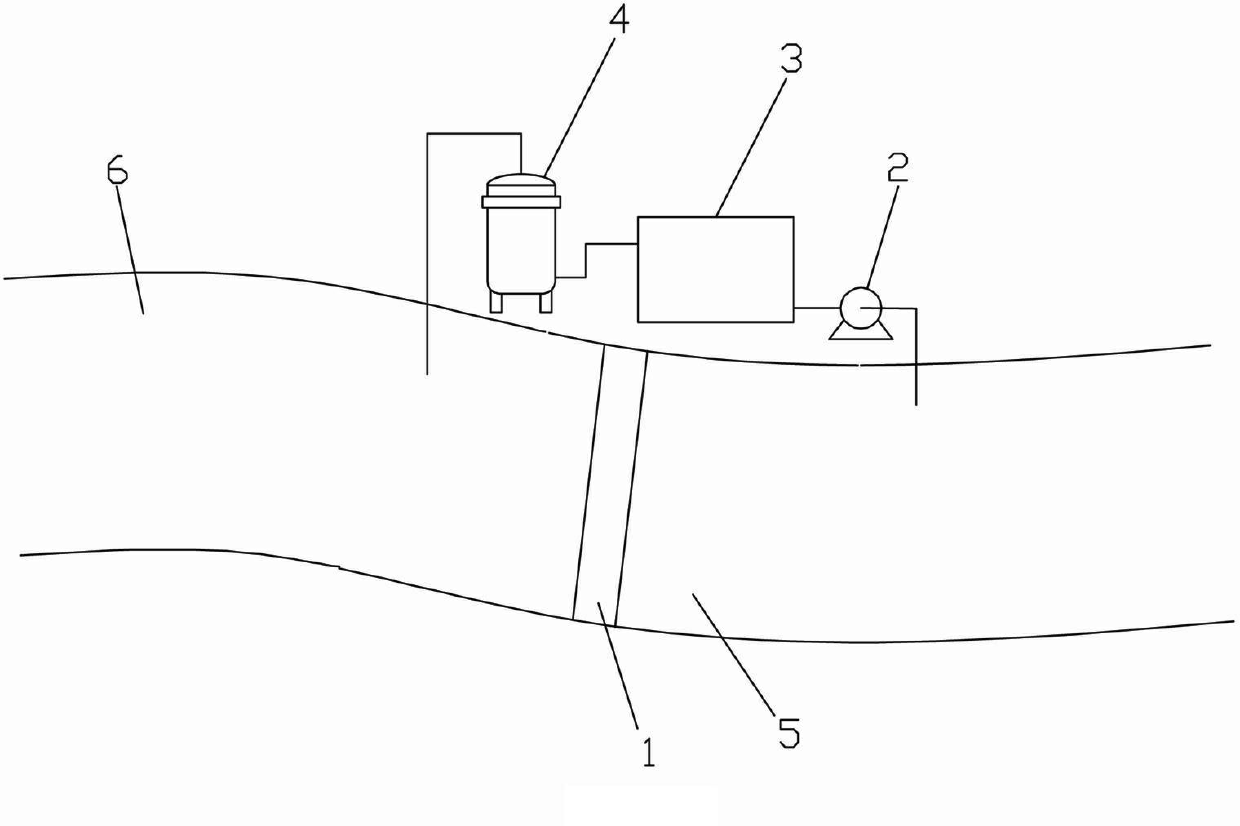

Method and device for purifying seriously eutrophic river water

InactiveCN102627377BReduce chromaEliminate odorMultistage water/sewage treatmentElectrolysisPurification methods

The invention discloses a method for purifying seriously eutrophic river water. The method mainly comprises three steps of electrolyzing, aerating and treating by a membrane bioreactor (MBR). According to the method, the pollution problems of the seriously eutrophic river can be effectively solved, the water quality of the river is improved in shorter time, so that a water ecology system is recovered, and the healthy sustainable development of a river ecology system is achieved. The invention further discloses a device for purifying the seriously eutrophic river water, which is matched with the purification method. The device comprises a dam, an electrolysis machine, an aerating device and a membrane bioreactor. According to the invention, the landscape can be combined and directly installed along the bank of the river, and the environment is hardly changed, so that the influence about the natural environment is less; in addition, the device has a simpler structure and lower production cost, and is suitable for large-scale popularization and application.

Owner:BOYING XIAMEN SCI & TECH

Purification method and purification device of eutrophic river

InactiveCN102633391AEliminate odorReduce chromaWater/sewage treatment bu osmosis/dialysisMultistage water/sewage treatmentPurification methodsElectrolysis

The invention discloses a purification method of a eutrophic river. The method comprises the following steps: firstly intercepting a eutrophic river into an upstream part and a downstream part; subsequently, sending water in the upstream part into an electrolysis machine for electrolysis; and discharging filtered water into the downstream part after being filtered. According to the invention, an electrolysis treatment method is adopted, thereby effectively restraining growth of algae in the river, decomposing organic matters, reducing total nitrogen, total phosphorus and chromaticity, eliminating odor, and finally improving water quality of the river within short time so that an ecological system is recovered. The invention further discloses a water quality purification device which mainly comprises a dam, a water pump, the electrolysis machine and a filter. The device can be directly operated at river banks to directly purify river water, is not required for specially introducing the river to a preset building for treatment, has barely change on the environment, thus having smaller influence on the natural environment; and in addition, the structure is simpler, and the production cost is lower, thus being suitable for large-scale popularization and application.

Owner:BOYING XIAMEN SCI & TECH

Extraction method of ground beeltle polysaccharide

The invention discloses an extraction method of a ground beeltle polysaccharide, wherein the extraction method comprises the specific steps: crushing ground beeltle into a coarse powder, carrying outultrasonic defatting, filtering, drying the filter residue, and crushing to prepare a defatted ground beeltle powder; soaking the defatted ground beeltle powder in water, treating with an ultrasonic and microwave extraction instrument, centrifuging, concentrating the supernatant, dialysing, carrying out ethanol precipitation, centrifuging, removing proteins by a repeated freeze thawing method anda Sevage method, dialysing the supernatant, concentrating, and freeze-drying, to obtain ground beeltle polysaccharide; loading a chromatographic column with NKA-9 macroporous adsorption resin, treating a ground beeltle polysaccharide solution, collecting an eluate, concentrating, drying, and thus obtaining the ground beeltle polysaccharide. The extraction method is simple and feasible, the extraction rate is fast, the extraction rate and purity of the polysaccharide are high, the amount of water and a solvent can be reduced, the original structure and activity of the polysaccharide can be preserved, the energy consumption is reduced, and the method is more suitable for development direction of industrialized production.

Owner:海盐县凌特生物科技有限公司

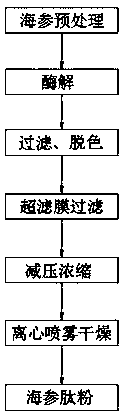

Method for decolorizing sea cucumber peptide powder by membrane filtration technology

InactiveCN109628540AReduce Maillard reactionTo achieve the purpose of decolorizationPeptide preparation methodsFermentationMaillard reactionUltrafiltration

The invention belongs to the technical field of physical engineering, in particular to a method for decolorizing sea cucumber peptide powder by a membrane filtration technology. The method includes the following steps of sea cucumber pretreatment, enzymolysis, filtration, decolorization, ultrafiltration membrane filtration, decompression concentration, spray drying and the like. By enzymolysis, filtration, decolorization, ultrafiltration membrane filtration and the other steps, the maillard reaction in the production process of the sea cucumber peptide powder can be effectively reduced, some pigment molecules are intercepted, and thus the purpose of decolorizing sea cucumber peptide powder is achieved.

Owner:WEIHAI YUWANG GRP MARINE BIOLOGICAL ENGCO

Method for soybean oil decoloring by beta-carotene-15,15'-monooxygenase

InactiveCN105296144AEasy to separateQuality impactFatty-oils/fats refiningBeta-CaroteneMonooxygenase

The invention aims at providing a method for soybean oil decoloring by beta-carotene-15,15'-monooxygenase. According to the method, firstly, beta-carotene-15,15'-monooxygenase is extracted from the chicken intestine mucous membrane; a detection result shows that the protein concentration of extracts is 5.87mg / mL; the decolorization ratio of the third-class soybean oil is used as the index for studying the effect of the beta-carotene-15,15'-monooxygenase on the beta-carotene in the three-class soybean oil under the conditions of different enzyme extraction liquid adding quantity, sodium cholate concentration, reaction time and stirring speed. The result proves that when the beta-carotene-15,15'-monooxygenase is used for decoloring the three-class soybean oil, the finally obtained decoloring rate of the enzyme process decoloring is 32.74 percent.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com