Decoloring method of pharmaceutical raw material grade camellia seed oil

A technology of Camellia oleifera seed oil and Camellia oleifera seed crude oil, which is applied in chemical instruments and methods, fat oil/fat refining, and other chemical processes, can solve the problem that the adsorbent cannot meet the decolorization requirements, and achieve good decolorization effect and easy access to raw materials , the effect of strong adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

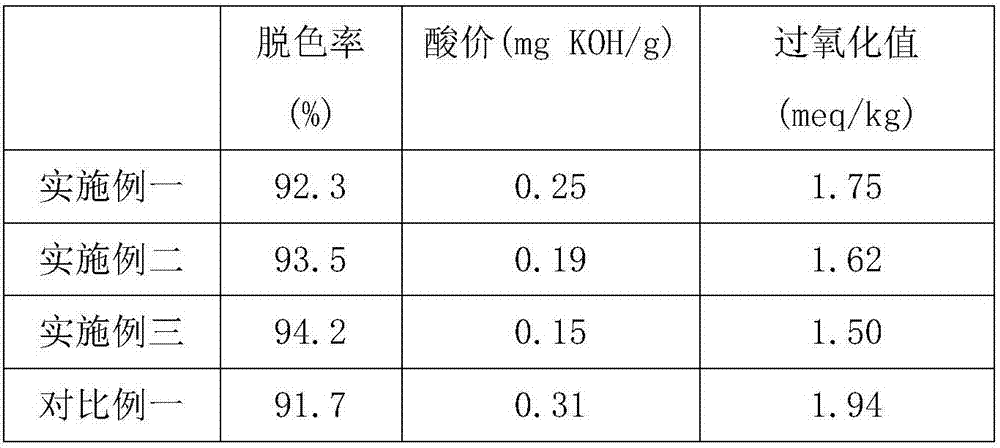

Examples

Embodiment 1

[0016] A method for decolorizing medicinal raw material grade Camellia oleifera seed oil, comprising the following steps:

[0017] A. The preparation of the decolorizing agent comprises the following steps: (1) mixing clay and 8% hydrochloric acid with a mass concentration of 8% hydrochloric acid in a ratio of 1:3 in mass to volume ratio g / mL, shaking and mixing in a water bath at 80° C. for 3 hours, suction filtration, and filter cake Wash with deionized water until the pH value of the filtrate is 7, dry, pulverize, and pass through a 200-mesh sieve to obtain activated clay; (2) Take activated clay and deionized water in a mass ratio of 1:3 under magnetic stirring at 80°C Mix to make a suspension, add 3% cetyltrimethylamine by mass of activated clay, mix evenly, then add a certain amount of NaOH solution with a mass concentration of 1% to adjust the pH of the system to 11, and stir for 3 hours , suction filtration, the filter cake was washed with 95% ethanol, dried, pulverize...

Embodiment 2

[0020] A method for decolorizing medicinal raw material grade Camellia oleifera seed oil, comprising the following steps:

[0021] A, the preparation of decolorizing agent, comprise the following steps: (1) the preparation of activated clay: clay and mass concentration 10% hydrochloric acid are by mass volume ratio 1: 3, 80 ℃ of water bath oscillation reaction 3h, suction filtration, filter cake uses deionized water Wash until the pH value of the filtrate is 7, dry, pulverize, and pass through a 200-mesh sieve to obtain activated clay; (2) modified activated clay: take activated clay and add deionized water in a mass ratio of 1:3 and stir magnetically at 80°C Mix at low temperature to make a suspension, add 4% cetyl trimethylamine of activated clay, adjust the pH of the system to 11, stir thoroughly for 3 hours, filter with suction, wash the filter cake with 95% ethanol, dry, and pulverize , through a 200-mesh sieve to obtain modified activated clay; (3) Preparation of carboni...

Embodiment 3

[0024] A method for decolorizing medicinal raw material grade Camellia oleifera seed oil, comprising the following steps:

[0025] A, the preparation of decolorizing agent, comprise the following steps: (1) the preparation of activated clay: clay and mass concentration 10% hydrochloric acid are by mass volume ratio 1: 3, 80 ℃ of water bath oscillation reaction 3h, suction filtration, filter cake uses deionized water Wash until the pH value of the filtrate is 7, dry, pulverize, and pass through a 200-mesh sieve to obtain activated clay; (2) modified activated clay: take activated clay in a mass ratio of 1:3 and mix it with deionized water at 80°C under magnetic stirring Make a suspension, add 5% cetyl trimethylamine by mass of activated clay and mix, adjust the pH of the system to 11 with NaOH solution after mixing evenly, stir and react for 3 hours, suction filter, filter cake with 95% Washing with ethanol, drying, pulverizing, and passing through a 200-mesh sieve to obtain mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com