Leather wastewater treatment method

A technology of leather wastewater and treatment method, which is applied in animal processing wastewater treatment, water/sewage treatment, special compound water treatment, etc., can solve the problems of substandard chroma and difficult biodegradation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

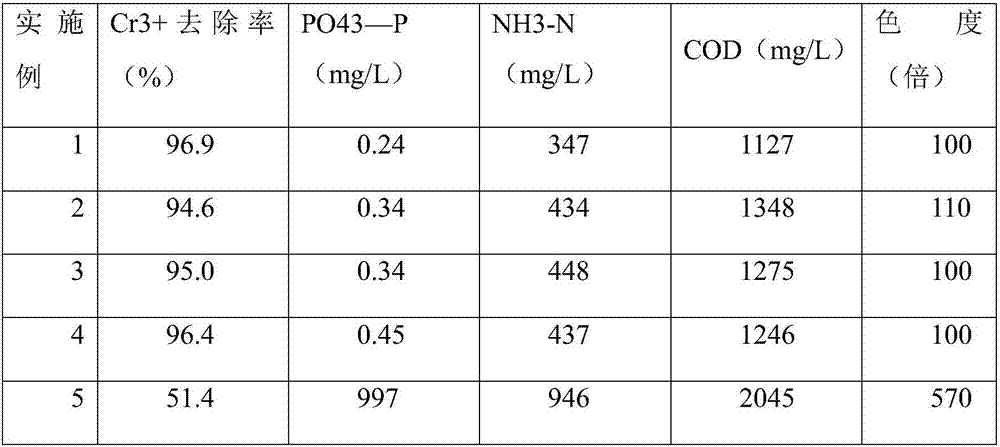

Examples

Embodiment 1

[0026] A method for treating leather wastewater, comprising the steps of:

[0027] a, get leather waste water 1000kg, first carry out the filtration of solid particulate matter to leather waste water, first filter through filter screen, then pass through the secondary filtration of macroporous adsorption resin, remove solid particle and part organic solvent in leather waste water;

[0028] b. Add sulfuric acid to the filtered leather waste water, adjust the pH value to PH=3, then add Fenton's reagent to carry out decolorization treatment, including 10kg of 30% H 2 o 2 React with ferrous sulfate under the irradiation of ultraviolet lamp while stirring, and the ultraviolet lamp is kept 10cm away from the liquid level of leather wastewater;

[0029] c. Add 10% Ca(OH) to the leather wastewater after decolorization treatment 2 solution to remove the lower precipitate;

[0030] d. Put the filtered leather waste water in the reactor for chemical precipitation and dephosphorization...

Embodiment 2

[0036] A leather wastewater treatment method, the difference between this embodiment and embodiment 1 is that the pH value in step c is 10.

Embodiment 3

[0038] A leather wastewater treatment method, the difference between this embodiment and embodiment 1 and embodiment 2 is that the pH value in step d is 11.

PUM

| Property | Measurement | Unit |

|---|---|---|

| decolorization rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com