Polyester-containing waste textile decolorization process capable of realizing solvent circulation

A technology for recycling waste textiles and solvents. It is applied in textiles and papermaking, solvent treatment, textile material treatment, etc. It can solve the problems of easy environmental pollution, high polarity and easy volatility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

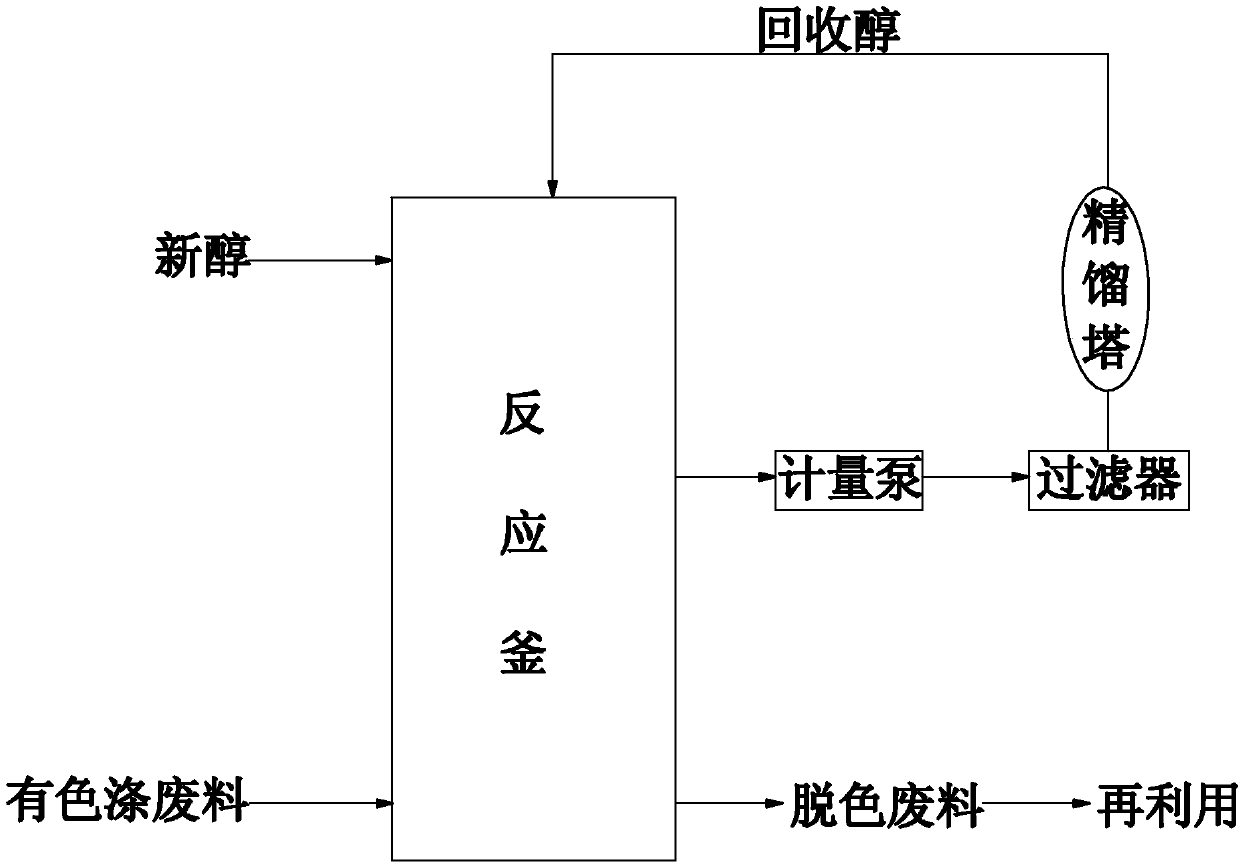

Method used

Image

Examples

Embodiment 1

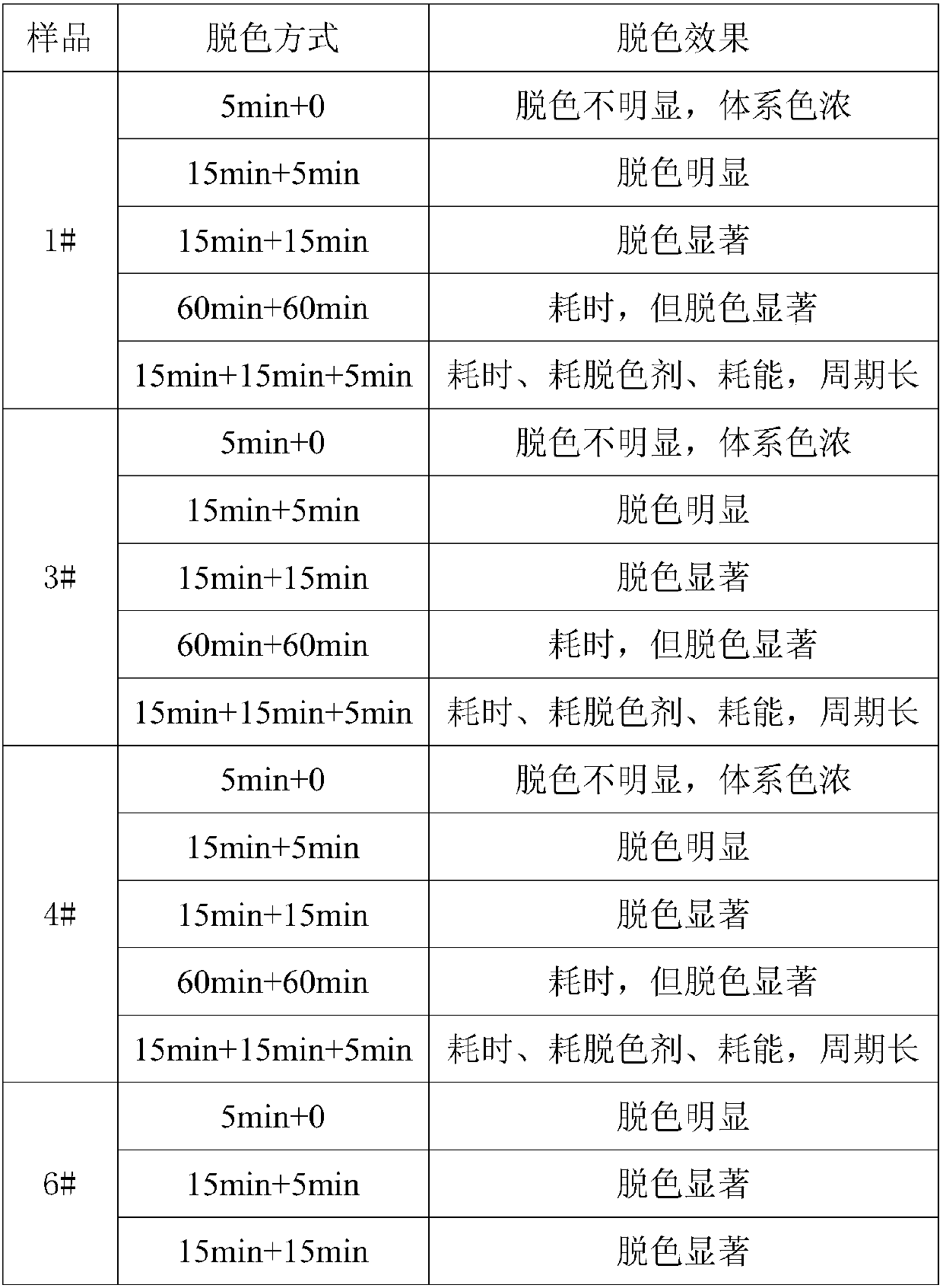

[0020] Taking the colored polyester waste cloth as the processing object, the alcohol elution decolorization process provided by the application is described in detail; wherein the inelastic black pure polyester is used as the 1# sample; the elastic and textured black polyester containing 95% product is the 2# sample, Elastic and fluffy black products containing 90% polyester are 3# samples; cool-color plush fabrics containing 85% polyester are products of 4# samples; bright-color series plush cloth containing 80% polyester are 5# samples; non-elastic light The color pure polyester is used as the 6# sample; the elastic light-colored product containing 75% polyester is used as the 7# sample.

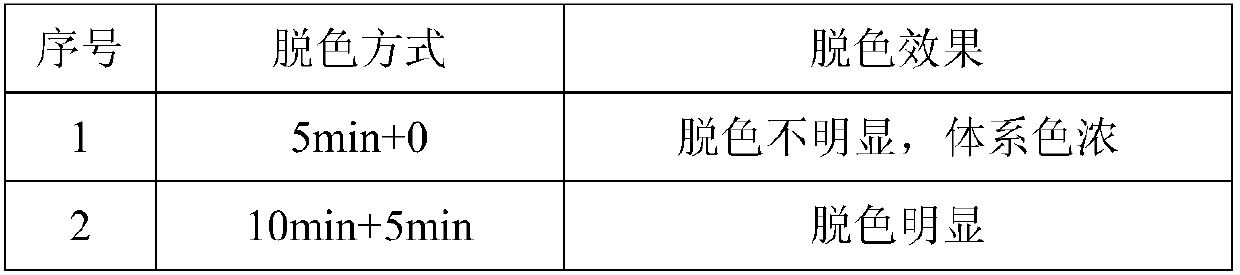

[0021] ①Decolorization method:

[0022] Two samples of elastic black pure polyester and non-elastic light-colored pure polyester were used for decolorization in different ways. The mass ratio of waste cloth to solvent was 1:40, and the decolorization temperature was 180°C. See Table 1 for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com