Decoloration method and system for electroplating wastewater

A technology for electroplating wastewater and wastewater, applied in metallurgical wastewater treatment, reduced water/sewage treatment, etc., can solve the problems of large dosage of chemicals, yellowing of effluent, and difficulty in decolorization, etc. land area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

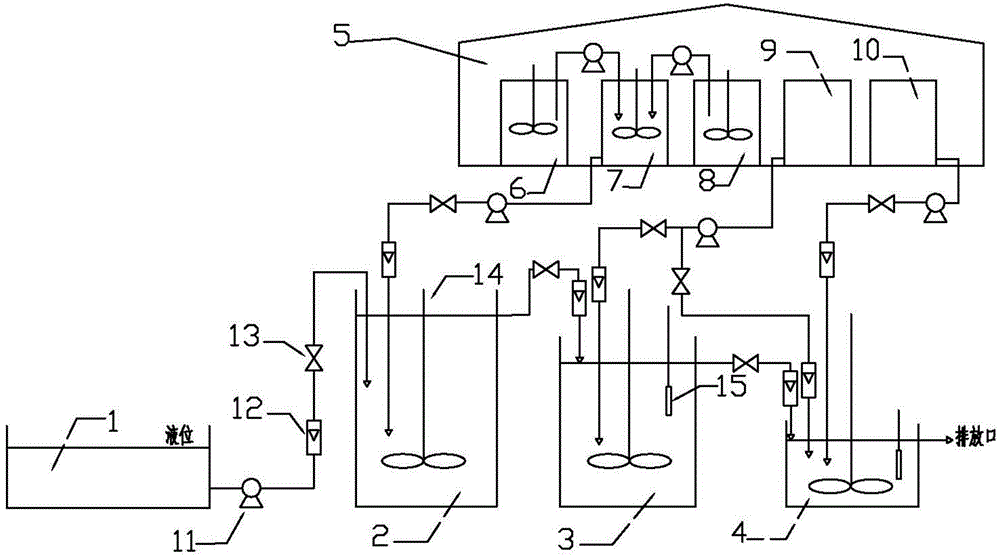

[0026] Such as figure 1 As shown, first prepare 20% sodium hydroxide aqueous solution in 1# dispensing barrel 6 of dispensing room 5. After sodium hydroxide is completely dissolved and cooled, NaBH is added 4 Configured to contain 10% NaBH 4 Solution; configure 5% NaHSO in 3# dispensing barrel 8 3 Aqueous solution; 2# dispensing barrel 7 is NaBH 4 / NaHSO 3 The reduction system is composed of 6 medicines and 8 medicines mixed according to the volume ratio of 1:50, and is prepared for immediate use. The medicine storage barrel 9 contains 20% dilute sulfuric acid; the medicine storage barrel 10 contains 30% liquid caustic soda solution. The yellow electroplating wastewater in the pre-treatment tank 1 (chromaticity is about 300 times) is pumped into 1# reaction tank 2 through the peristaltic pump 11. The flowmeter 12 and valve 13 are used to control the water inflow, and the agent in 7 is passed into 2 at the same time , Keep the ratio of the medicine to the inlet water flow at 1:1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com