Micro-electrolysis treatment technology for chemical waste water

A technology for treating process and chemical wastewater, which is applied in water/sewage treatment, natural water treatment, water treatment parameter control, etc. Instability, improved biodegradability, effect of increasing biodegradability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

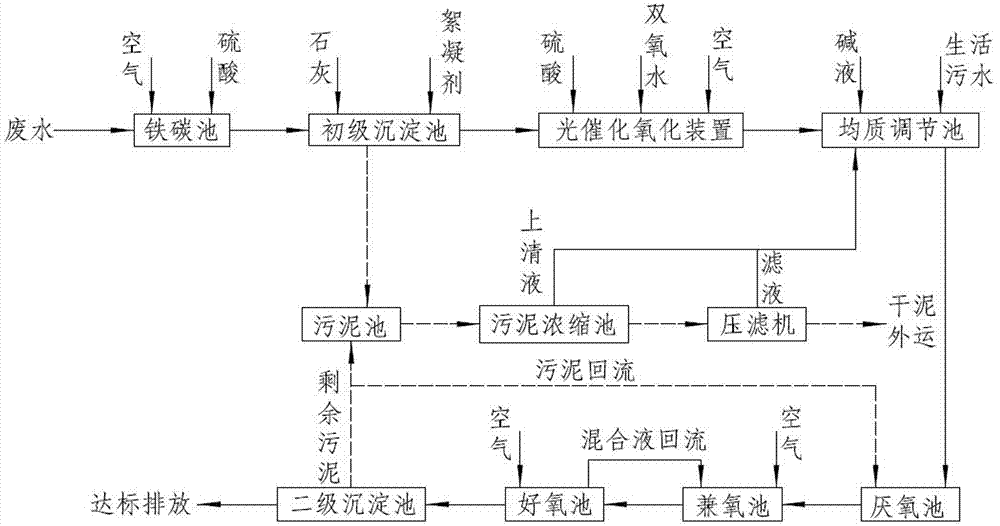

[0039] Such as figure 1 Shown, a kind of micro-electrolysis treatment process of chemical waste water is carried out according to the following steps:

[0040] (1) Wastewater pretreatment:

[0041] A. Micro-electrolysis treatment: After the wastewater from each workshop is collected, it is pumped into the iron-carbon pool, the float-type liquid level controller controls the water inlet switch, the electromagnetic flowmeter controls the water inlet, and at the same time, concentrated sulfuric acid is added to adjust the pH value to about 3. Monitoring is carried out through an industrial online PH meter, air is supplied by a Roots blower, aeration is performed through a PPR perforated aeration device, and iron-carbon micro-electrolysis is carried out. The residence time of wastewater in the iron-carbon pool is about 2 hours;

[0042] B. Primary sedimentation: The effluent from the iron-carbon pool is lifted by the pump to the primary sedimentation tank. In the primary sedime...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com