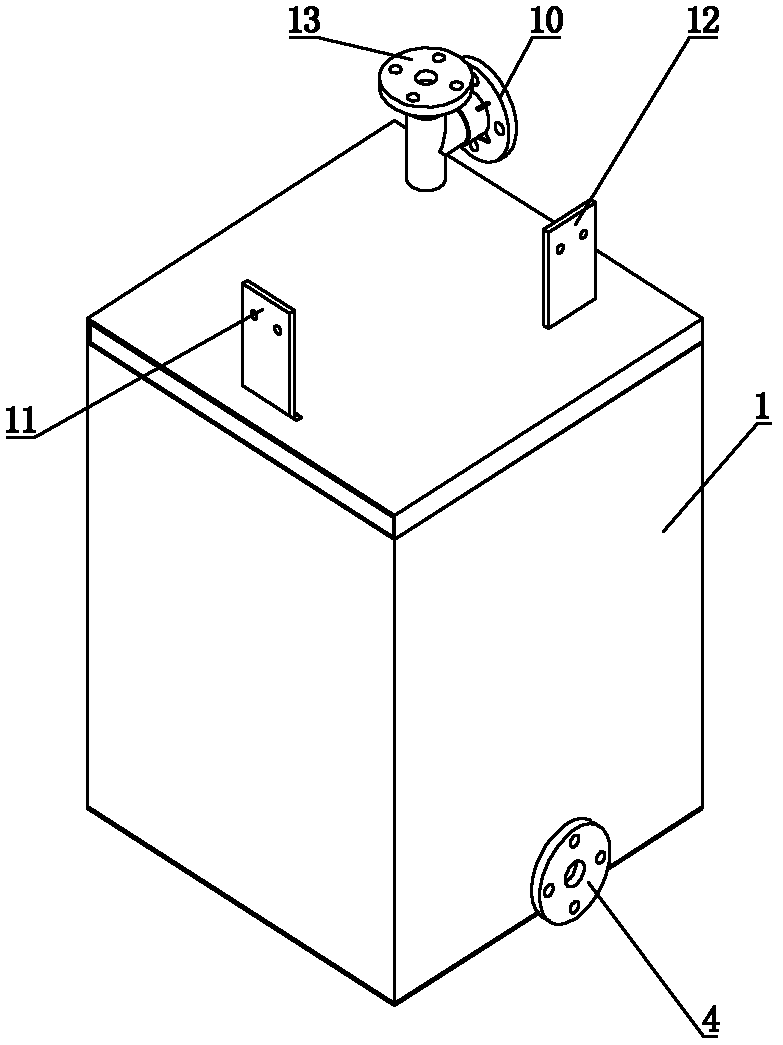

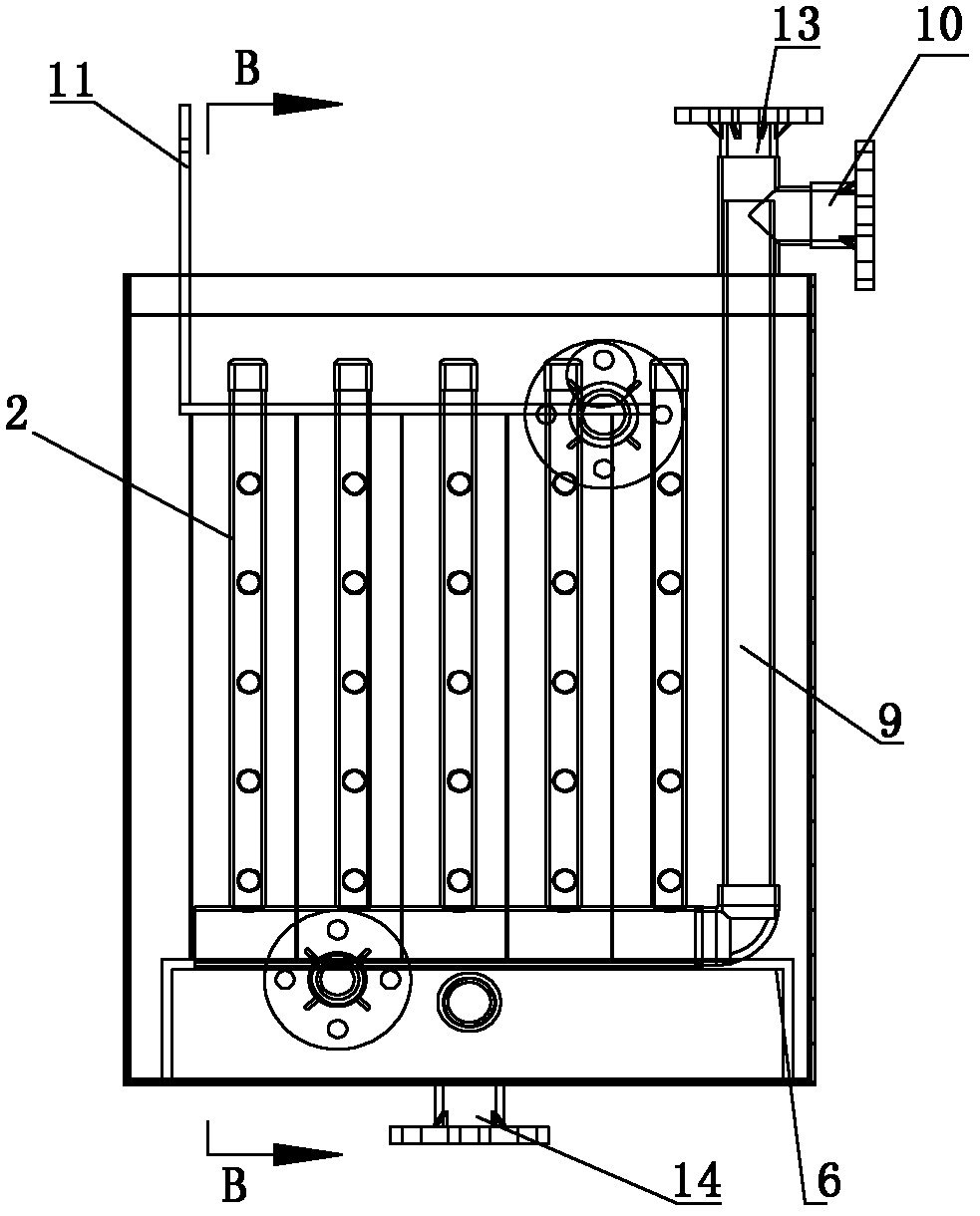

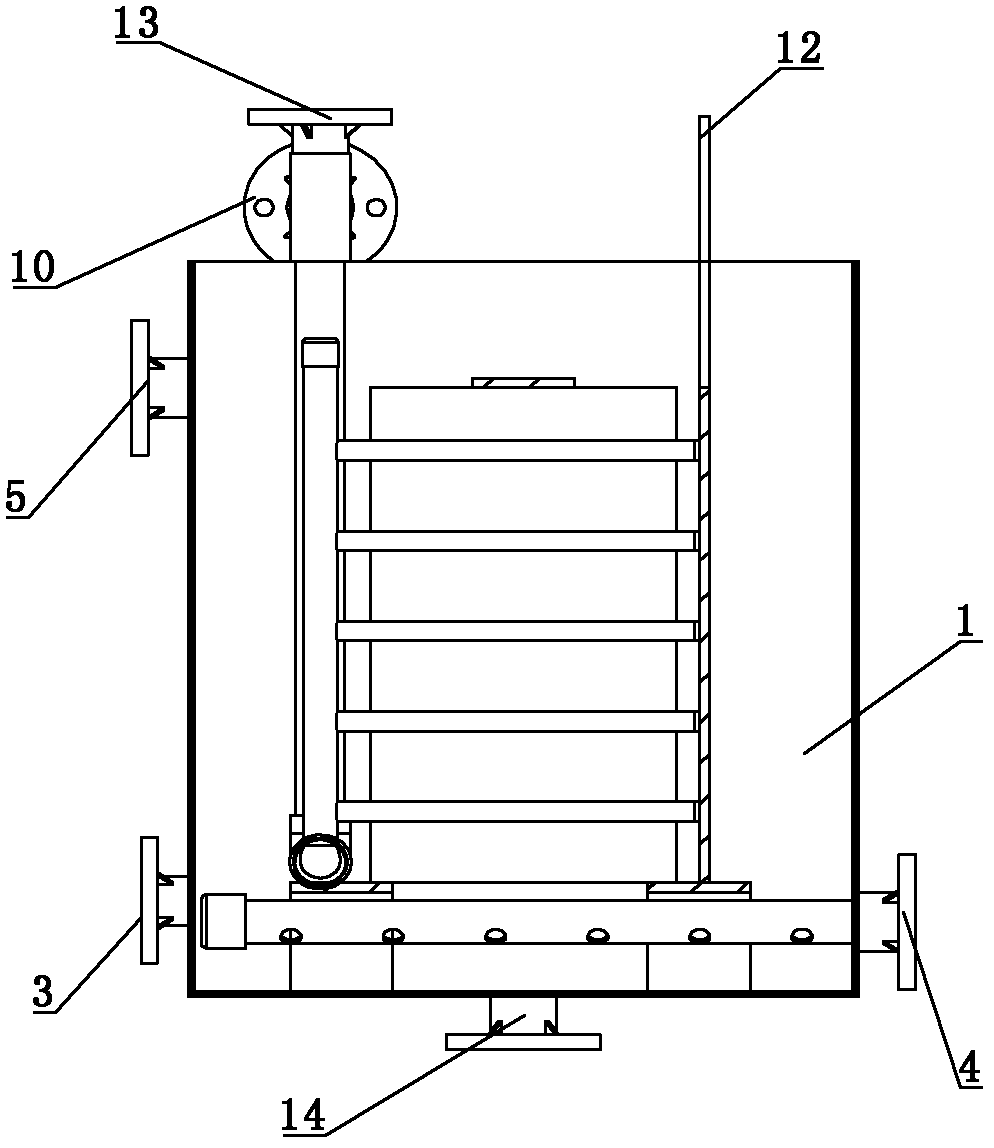

Electrolysis unit with membrane filtration function

An electrolysis device and membrane filtration technology, applied in water/sludge/sewage treatment, flotation water/sewage treatment, water/sewage treatment, etc., can solve the problems of poor treatment effect, low working voltage, high current density, etc. , to achieve the effect of improving water quality conditions, increasing B/C value, and preventing biological pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Embodiment 1 is to the processing effect of printing and dyeing advanced treatment waste water:

[0044] The printing and dyeing advanced treatment wastewater in the secondary sedimentation tank that has undergone biochemical treatment is pumped into the electrolysis device with membrane filtration function for electrolysis through the water pump. The voltage between the two electrodes is 1-18V, and the current density is 1-300mA / cm 2 , keep the residence time of wastewater in the electrolysis device at 1-5 minutes, and control the electricity consumption of wastewater electrolysis at 0.01-0.2 degrees / m 3 . The effects before and after treatment are shown in Tables 1-4.

[0045] Table 1 Water quality of printing and dyeing wastewater after biochemical treatment

[0046] serial number

project

measured value

serial number

project

measured value

1

pH

7.1

5

12

2

SS(mg / ...

Embodiment 2

[0053] Embodiment 2 is to the processing effect of tannery advanced treatment waste water:

[0054] Pump the biochemically treated secondary sedimentation tank tannery advanced treatment wastewater into the electrolysis device with membrane filtration function for electrolysis, the voltage between the two electrodes is 1-18V, and the current density is 1-300mA / cm 2 , keep the residence time of wastewater in the electrolysis device at 1-5 minutes, and control the electricity consumption of wastewater electrolysis at 0.01-0.2 degrees / m 3 . The effects before and after treatment are shown in Tables 5-8.

[0055] Table 5 Water quality of tannery wastewater after biochemical treatment

[0056] serial number

project

measured value

serial number

project

measured value

1

pH

7.2

5

3.2

2

SS(mg / L)

25

6

BOD 5 (mg / L)

18

3

Turbidity (NTU)

16 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com