A combined treatment method for high-concentration acrylic acid and ester wastewater

A treatment method, acrylic acid technology, applied in multi-stage water treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. Metabolic rate, the effect of reducing effluent turbidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

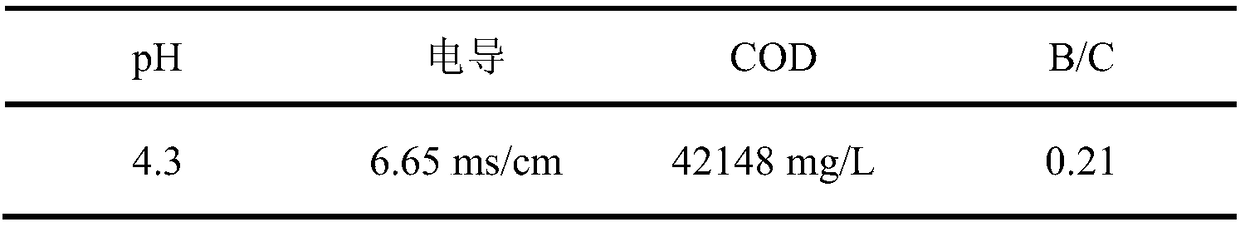

[0024] Acrylic acid and ester wastewater from an enterprise, the water quality is shown in Table 1.

[0025] Table 1 Water quality of acrylic acid and ester wastewater

[0026]

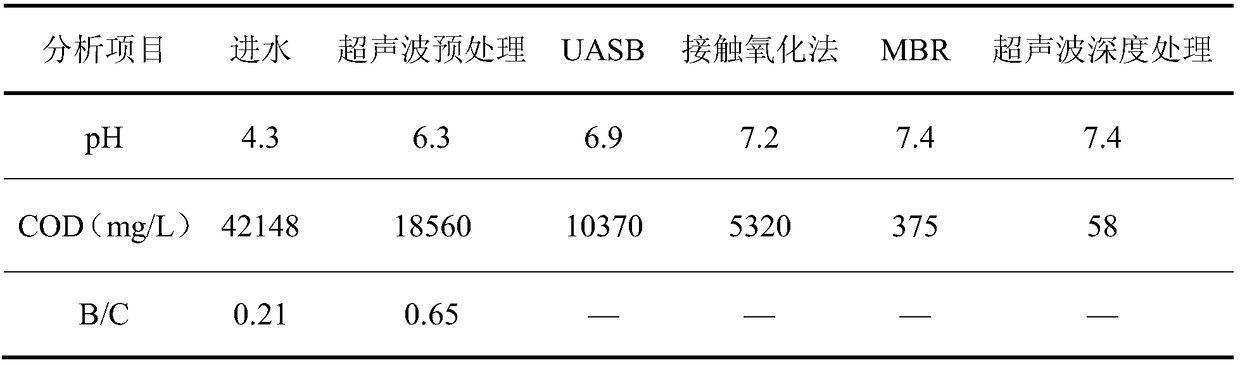

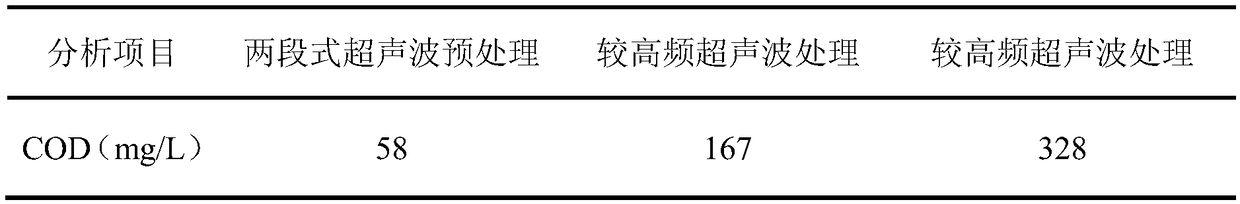

[0027] The above-mentioned waste water is first pretreated by ultrasonic method. The procedure of ultrasonic pretreatment is: first stage, frequency 300KHz, temperature 35°C, reaction for 1h; second stage, frequency 50KHz, room temperature, reaction for 30min. After ultrasonic pretreatment, the B / C value of wastewater increased from 0.21 to 0.65, greatly reducing the pressure of biological treatment. Ultrasonic pretreatment effluent is treated by anaerobic method, and the anaerobic method adopts UASB process (organic content of granular sludge VSS 45-60g / L, particle size 0.5-3.5mm), and the residence time is 24h. The anaerobic effluent is treated with two-stage aerobic treatment. The first-stage aerobic method adopts the contact oxidation method with a residence time of 24 hours; the second-stage ...

Embodiment 2

[0037] Acrylic acid and ester wastewater from a certain enterprise, the water quality is shown in Table 5.

[0038] Table 5 Water quality of acrylic acid and ester wastewater

[0039]

[0040] The above-mentioned waste water is first pretreated by ultrasonic method. The procedure of ultrasonic pretreatment is: first stage, frequency 400KHz, temperature 40°C, reaction for 1.5h; second stage, frequency 200KHz, room temperature, reaction for 1h. After ultrasonic pretreatment, the B / C value of wastewater increased from 0.18 to 0.70, which enhanced the biodegradability of wastewater and facilitated further treatment by biological methods. The ultrasonic pretreatment effluent is treated by anaerobic method, and the anaerobic method adopts EGSB process (granular sludge organic matter content VSS 35-55g / L, particle size 0.5-4.0mm), and the residence time is 48h. The anaerobic effluent is treated with two-stage aerobic treatment. The first-stage aerobic method adopts the SBR method...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com