A pretreatment system and treatment method for high-concentration wastewater from chemical synthesis and pharmaceuticals

A technology of chemical synthesis and pretreatment, applied in chemical instruments and methods, water/sewage treatment, water/sewage multi-stage treatment, etc., can solve the problems of high energy consumption and high pretreatment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

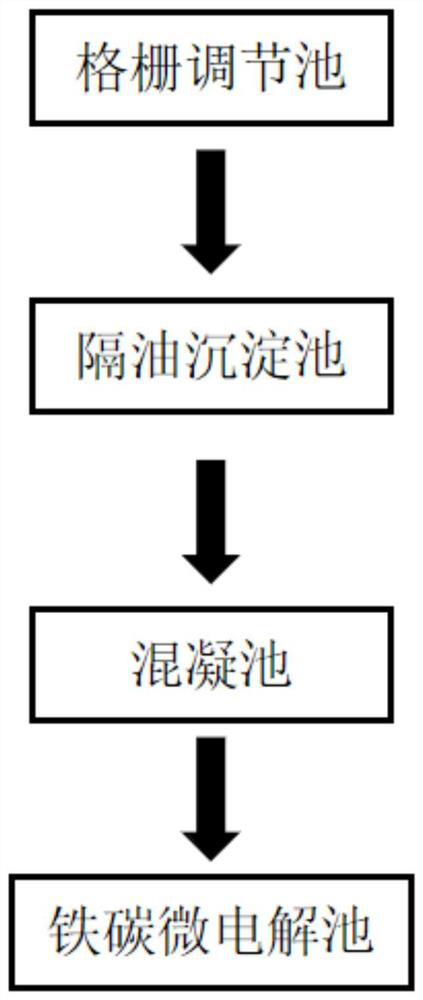

Method used

Image

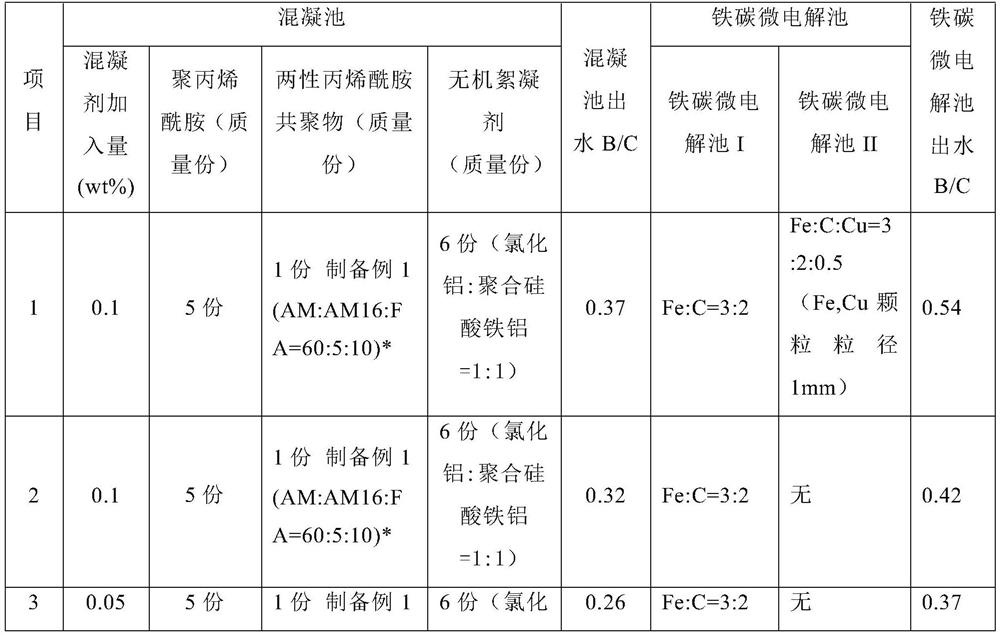

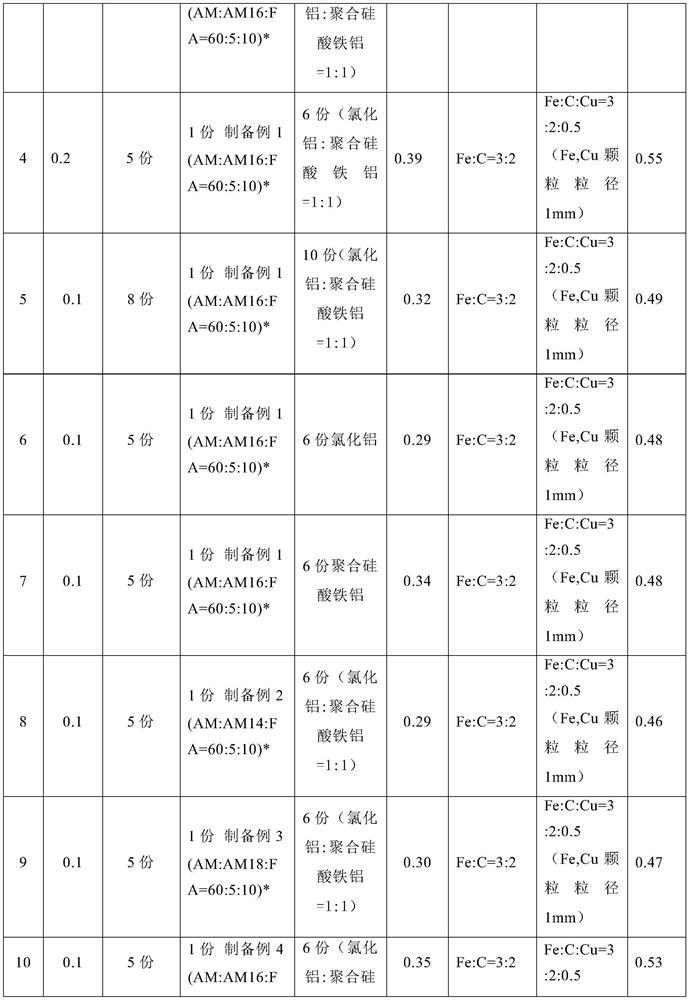

Examples

preparation example 1

[0033] Preparation Example 1 Use petroleum ether as the continuous phase, and use Tween 60: Span 40 = 1:1 as a composite emulsifier to prepare the oil phase. According to the mass ratio of acrylamide (AM): dimethylhexadecyl (2-methyl Acrylamidopropyl) ammonium bromide (AM16):fumaric acid (FA)=60:5:10 disperses the monomer in water, the total mass concentration of the monomer is controlled at 40wt%, and the aqueous phase is prepared.

[0034] Under stirring, under nitrogen, the water phase is slowly added to the oil phase, the volume ratio of the oil phase and the water phase is 1.7:1, the temperature is raised to 50 ° C, and then 0.7 wt% of the total monomer mass is added. According to the aqueous solution of the composite initiator of ammonium sulfate with a mass ratio of 1:2, heat preservation and react for 6h, cool to room temperature and discharge to obtain a solution of the copolymer, break the emulsion with ethanol, and wash with a solvent with acetone / ethanol volume rati...

preparation example 2

[0037] Other conditions and steps are the same as in Preparation Example 1, except that dimethyltetradecyl (2-methacrylamidopropyl) ammonium bromide (AM14) is used to replace dimethylhexadecyl (2-methyl Acrylamidopropyl) ammonium bromide (AM16).

preparation example 3

[0039] Other conditions and steps are the same as in Preparation Example 1, except that dimethyloctadecyl (2-methacrylamidopropyl) ammonium bromide (AM18) is used to replace dimethylhexadecyl (2-methyl Acrylamidopropyl) ammonium bromide (AM16).

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com