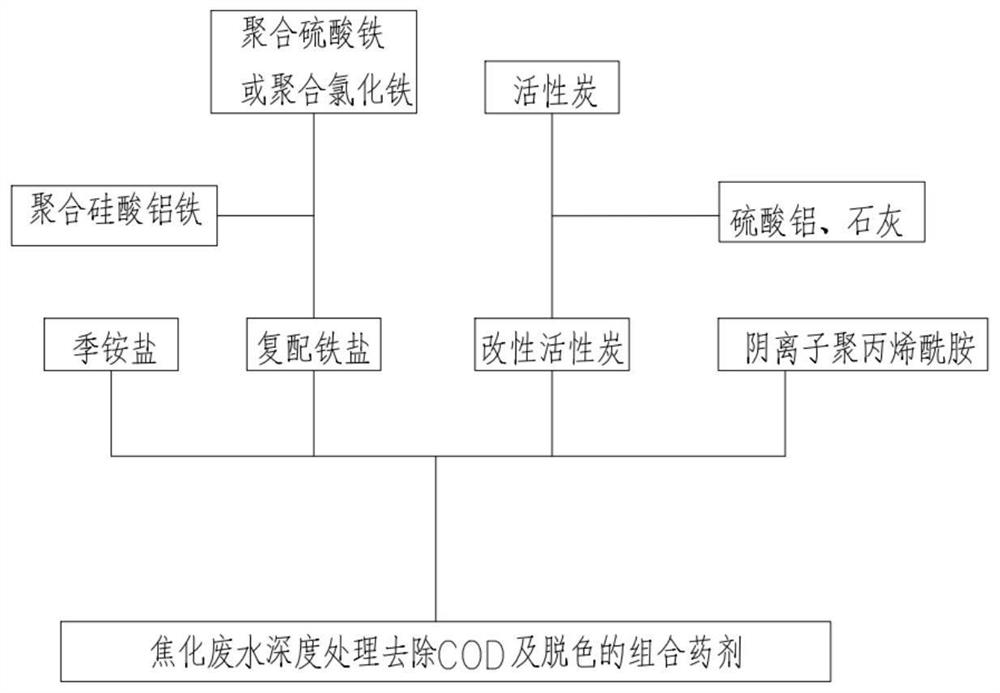

Combined reagent applied to deep treatment of coking wastewater to remove COD and discolor, and application thereof

A technology for coking wastewater and advanced treatment, which is applied in water/sewage treatment, adsorbed water/sewage treatment, water/sludge/sewage treatment, etc. Influence, troublesome operation and management, etc., to achieve the effect of improving COD removal rate and chroma removal rate, improving chemical phosphorus removal effect, and good adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

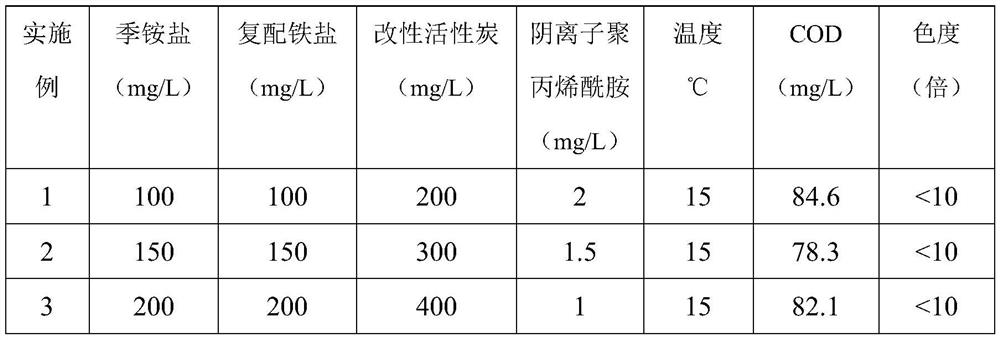

Embodiment 1

[0026] The steps for preparing a combined agent for advanced treatment of coking wastewater to remove COD and decolor are as follows:

[0027] First purchase industrial grade calcium oxide, powder activated carbon, aluminum sulfate, polymeric ferric sulfate, polymeric aluminum ferric silicate, quaternary ammonium salt, and anionic polyacrylamide.

[0028] A combined agent suitable for the advanced treatment of coking wastewater to remove COD and decolorize. Firstly, measure 700 parts of polyferric sulfate and 300 parts of polyaluminum ferric silicate and mix to make a compound iron salt; secondly, place 80g of activated carbon in a container , Add water and stir (according to the activated carbon to water mass ratio of 3:5), adjust into a uniform paste; add 10g aluminum sulfate and 10g lime successively, stir for 30 minutes, and dry at 100℃ until the moisture is less than 5%. Then use a ball mill to grind to 200-300 mesh, and obtain modified activated carbon after sieving.

[0029] ...

Embodiment 2

[0031] A combined agent suitable for the advanced treatment of coking wastewater to remove COD and decolorize. Firstly, measure 800 parts of polyferric chloride and 200 parts of polyaluminum ferric silicate and mix them to make a compound iron salt; secondly, place 75g of activated carbon in a container Add water and stir (according to the mass ratio of activated carbon to water: 3:5) to make a uniform paste; add 13g aluminum sulfate and 8g lime in sequence, stir for 30 minutes, and dry at 100℃ until the moisture is less than 5% , Then use a ball mill to grind to 200-300 meshes, and then obtain modified activated carbon after sieving.

[0032] Weigh 10 g of compound iron salt, 5 g of modified activated carbon, and 0.1 g of anionic polyacrylamide, respectively add water to prepare 10%, 5%, and 0.1% solutions (wt%) for later use. The quaternary ammonium salt is used directly without preparation. Measure quaternary ammonium salt: compound iron salt: modified activated carbon: polyac...

Embodiment 3

[0034] A combined agent suitable for the advanced treatment of coking wastewater to remove COD and decolorize. Firstly, measure 900 parts of polyferric chloride and 100 parts of polyaluminum ferric silicate to make a compound iron salt; secondly, place 70g of activated carbon in a container Add water and stir (according to the mass ratio of activated carbon to water: 3:5) to make a uniform paste; add 15g aluminum sulfate and 5g lime successively, stir for 30 minutes, and dry at 100℃ until the moisture is less than 5% , Then use a ball mill to grind to 200-300 meshes, and then obtain modified activated carbon after sieving.

[0035] Weigh 10 g of compound iron salt, 5 g of modified activated carbon, and 0.1 g of anionic polyacrylamide, respectively add water to prepare 10%, 5%, and 0.1% solutions (wt%) for later use. The quaternary ammonium salt is used directly without preparation. Measure quaternary ammonium salt: compound iron salt: modified activated carbon: polyacrylamide=200...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com