Method for preparing high-purity esomeprazole magnesium

A high-purity technology of esomeprazole magnesium, applied in organic chemistry methods, organic chemistry, etc., can solve problems such as unfavorable products, difficulty in mass production, and product deterioration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

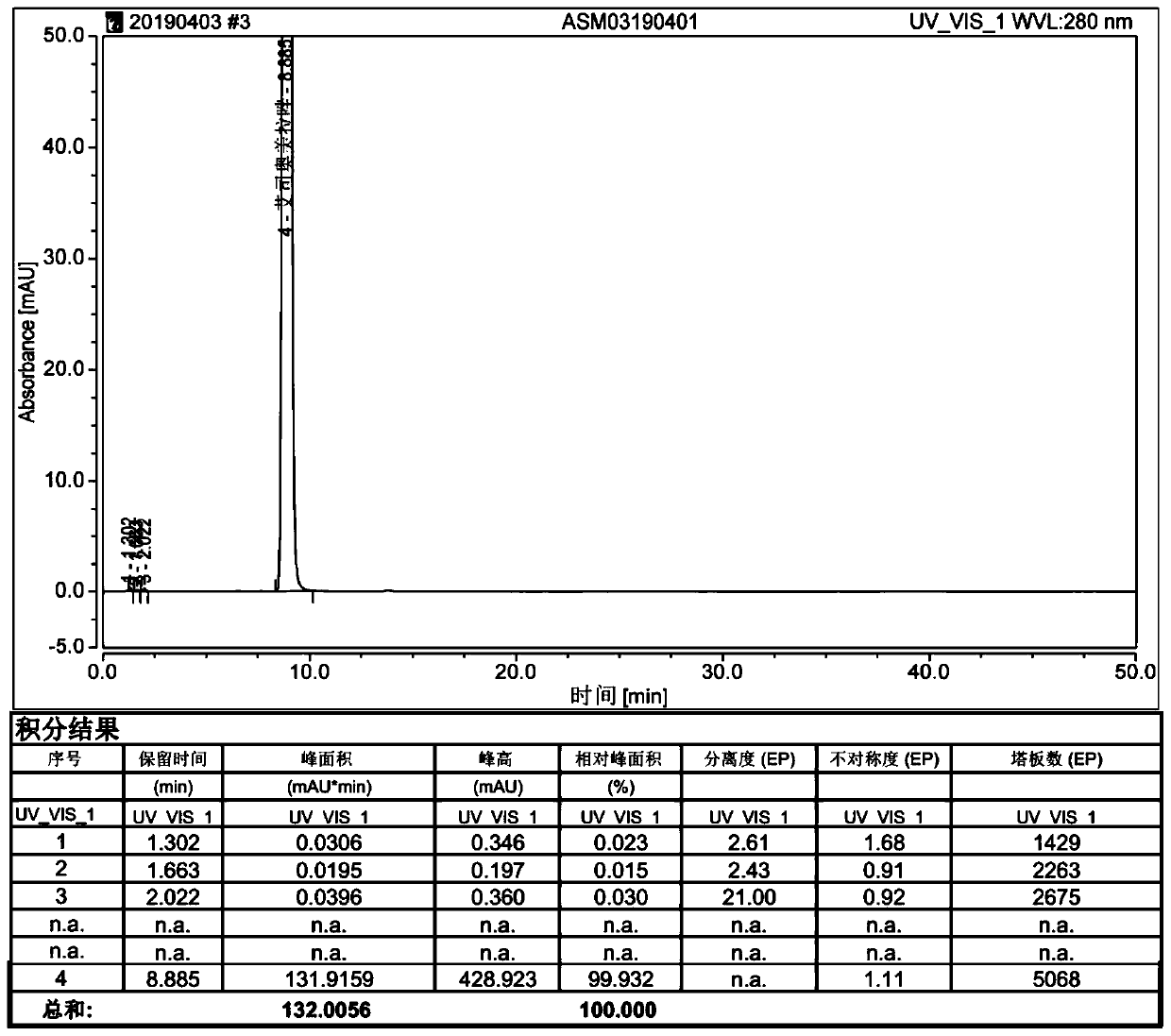

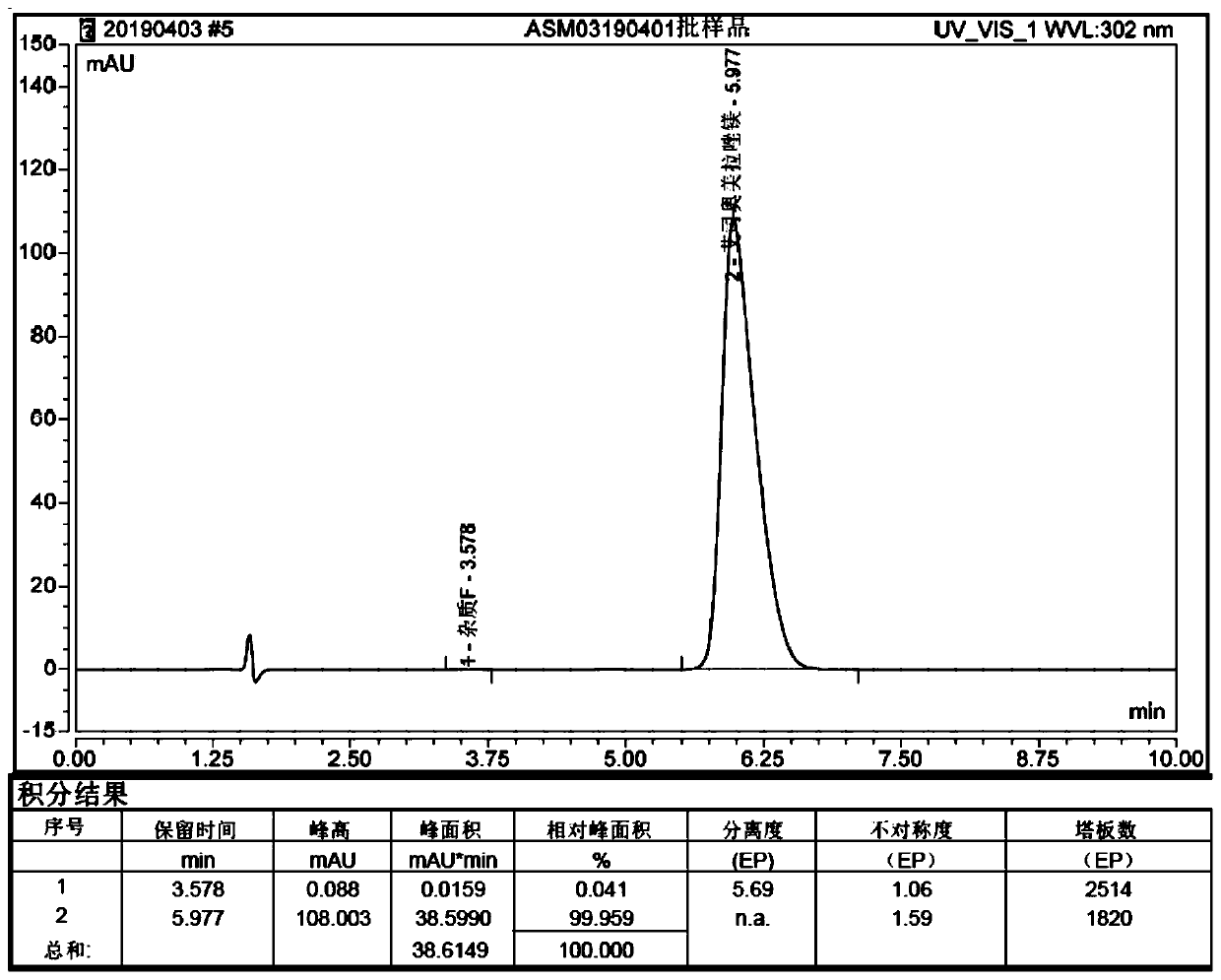

Embodiment 1

[0036] Preparation of sodium salt: Weigh 10g (55.48mmol) 2-mercapto-5-methoxybenzimidazole and add it to 100ml 5% sodium hydroxide aqueous solution, stir to dissolve. Take 12.5g (56.28mmol) of 2-chloromethyl-3,5-dimethyl-4-methoxypyridine hydrochloride and dissolve it in 120ml of dichloromethane, add it dropwise, heat up to reflux, keep at reflux for 1 hour, Sample TLC. After the reaction was completed, the liquid was separated, the organic phase was washed with 50 ml of purified water, the liquid was separated, the organic phase was dried with 10 g of anhydrous sodium sulfate, and filtered.

[0037] Transfer the organic phase into a 500ml three-necked flask, raise the temperature to slight reflux, add 3.8g diethyl tartrate, stir well, then add 2.6g isopropyl titanate dropwise, and stir for 0.5h. Cool down to 10±2°C, add 1.2g of N,N`-diisopropylethylamine, stir to dissolve, add dropwise 4.8g of cumene hydroperoxide, react for 2 hours, sample for TLC, quench with water after t...

Embodiment 2

[0040] Preparation of sodium salt: Weigh 10g (55.48mmol) 2-mercapto-5-methoxybenzimidazole and add it to 100ml 5% sodium hydroxide aqueous solution, stir to dissolve. Take 12.5g (56.28mmol) of 2-chloromethyl-3,5-dimethyl-4-methoxypyridine hydrochloride and dissolve it in 120ml of toluene, add dropwise, heat up to reflux, keep at reflux for 1 hour, and sample for TLC . After the reaction was completed, the organic phase was washed with 50ml of purified water, the liquid was separated, and the organic phase was dried with 10g of anhydrous sodium sulfate and filtered. The organic phase was transferred into a 500ml three-necked flask, and after the temperature was raised to 55°C, 3.8g of diethyl tartrate was added, stirred well, then 2.6g of isopropyl titanate was added dropwise, and stirred for 0.5h. Cool down to 10±2°C, add 1.2g of N,N`-diisopropylethylamine, stir to dissolve, add dropwise 4.8g of cumene hydroperoxide, react for 2 hours, sample for TLC, quench with water after ...

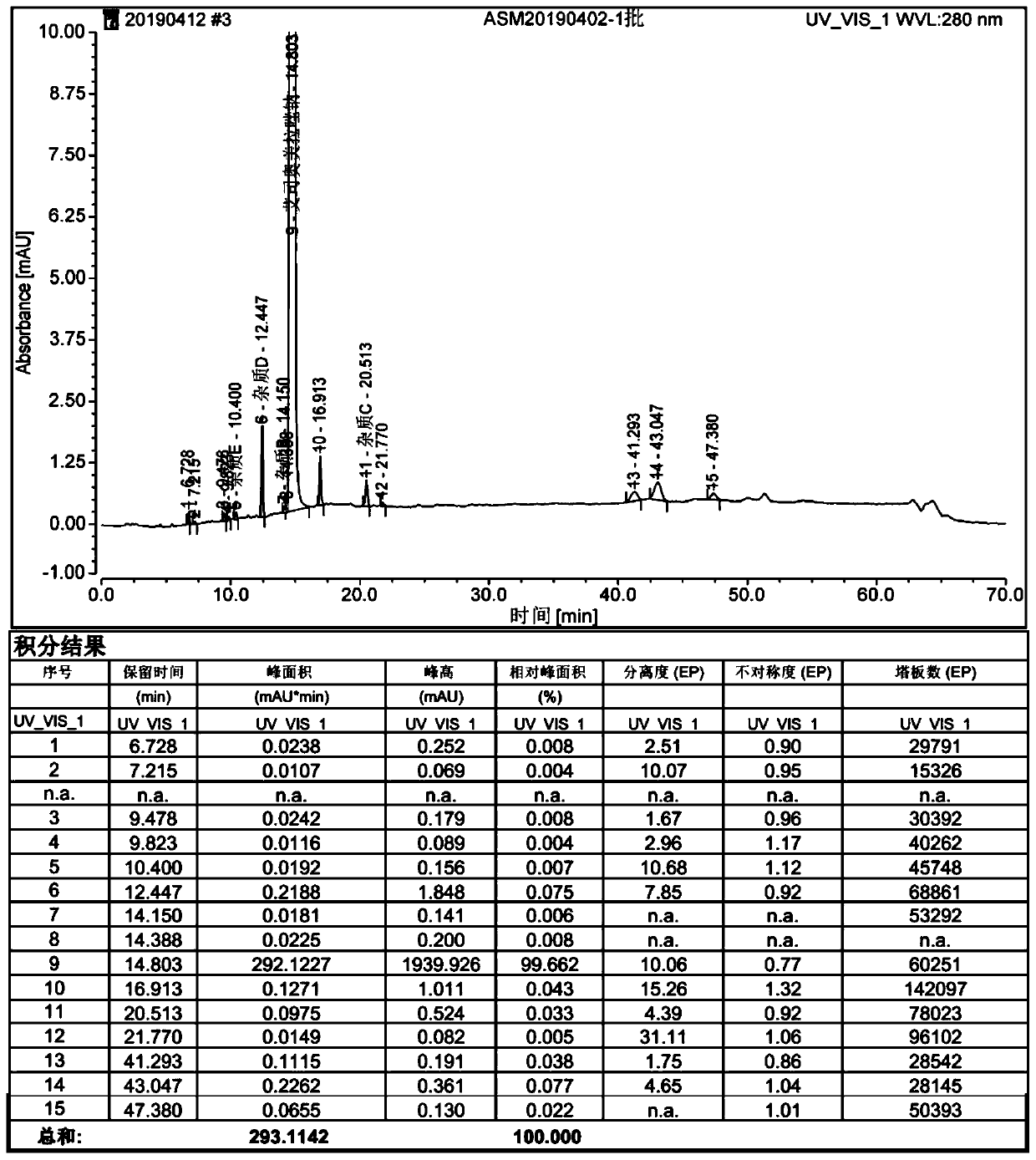

Embodiment 3

[0044] Preparation of sodium salt: Weigh 10g of 2-mercapto-5-methoxybenzimidazole and add it to 100ml of 5% potassium hydroxide aqueous solution, stir and dissolve. Take 12.5g of 2-chloromethyl-3,5-dimethyl-4-methoxypyridine hydrochloride and dissolve it in 120ml of toluene, add dropwise, heat up to reflux, keep at reflux for 1 hour, and take a sample for TLC. After the reaction was completed, the organic phase was washed with 50 ml of purified water, and the liquid was separated. The organic phase was dried with 10 g of anhydrous sodium sulfate and filtered.

[0045] Transfer the organic phase into a 500ml three-necked flask, raise the temperature to slight reflux, add 3.8g diethyl tartrate, stir well, then add 2.6g isopropyl titanate dropwise, and stir for 0.5h. Cool down to 10±2°C, add 1.2g of N,N`-diisopropylethylamine, stir to dissolve, add dropwise 4.8g of cumene hydroperoxide, react for 2 hours, sample for TLC, finish the reaction with 5% sodium bicarbonate Quench, sep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com