Advanced treatment and reuse integrated equipment for textile dyeing and finishing wastewater

A technology for advanced treatment and textile dyeing and finishing, applied in textile industry wastewater treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve secondary pollution, incomplete elimination of organic pollutants, waste accumulation and other problems, to achieve the effect of reducing infrastructure and maintenance costs, good denitrification function, and low respiration rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

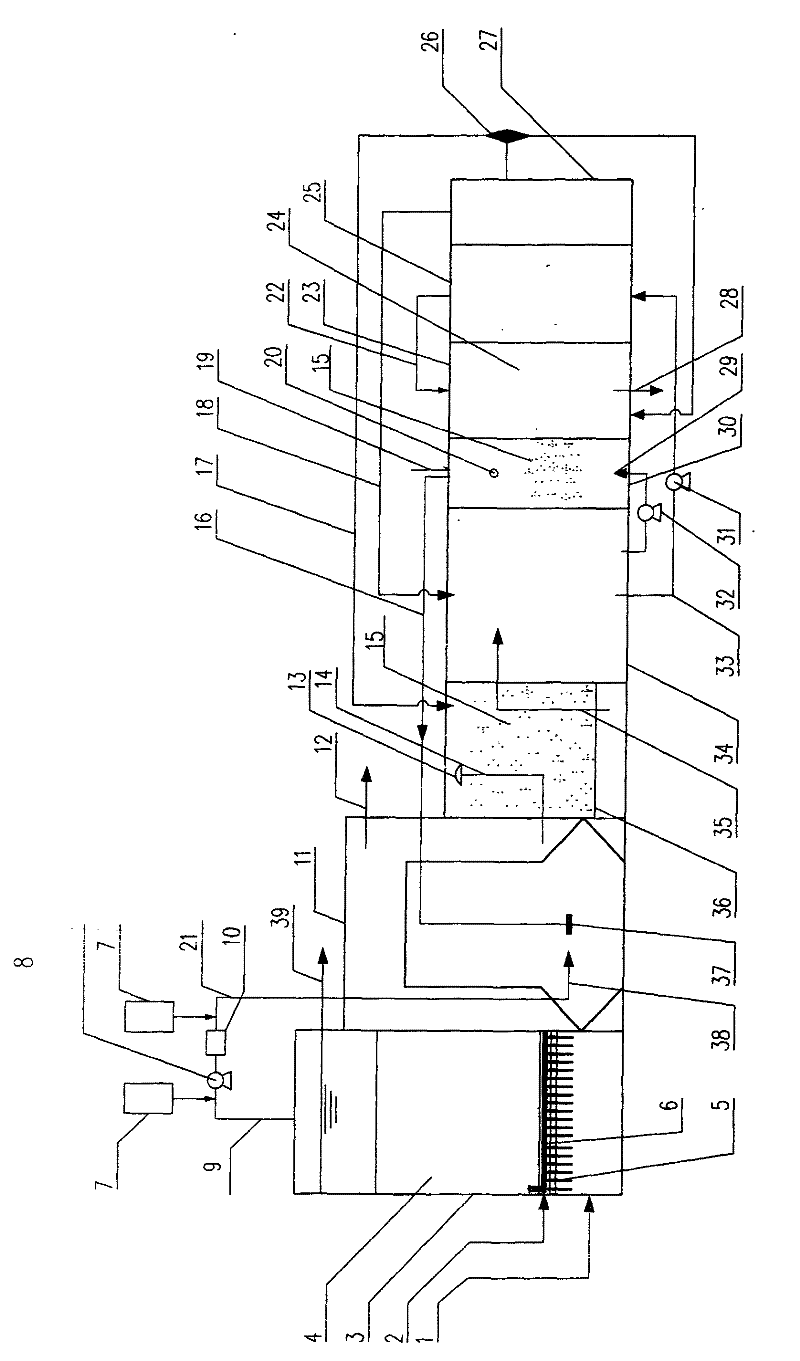

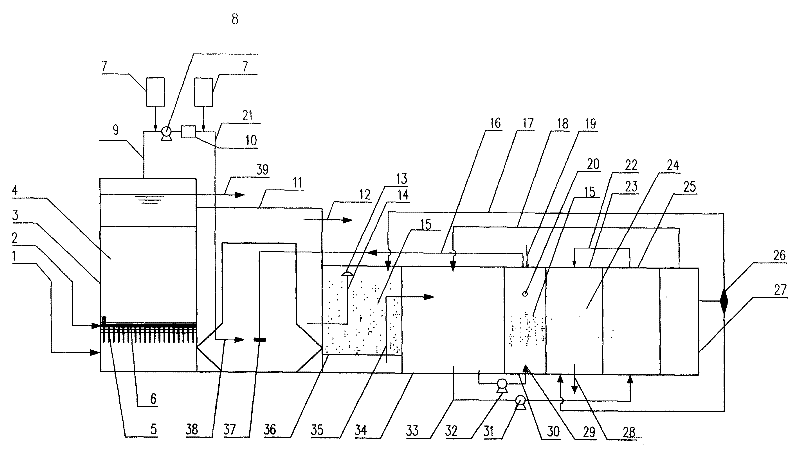

[0013] The integrated equipment for advanced treatment and reuse of textile dyeing and finishing wastewater of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0014] figure 1 The integrated equipment for advanced treatment and reuse of textile dyeing and finishing wastewater is composed of biological aeration filter chamber 3, air flotation chamber 11, ozone reaction chamber 36, intermediate water tank 34, dissolved air chamber 30, activated carbon chamber 23, filter chamber 25, Ozone generator 27 is composed of biological aeration filter chamber 3, air flotation chamber 11, ozone reaction chamber 36, intermediate water tank 34, dissolved air chamber 30, activated carbon chamber 23, filter chamber 25, and ozone generator 27 are placed side by side in sequence. In the box, the aerated biological filter chamber 3 is connected to the air flotation chamber 11 through pipelines, the air flotation chamber 11 is connected to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com