A regenerated water manufacturing device and method based on electrolysis and double-membrane technology

A technology for manufacturing devices and reclaimed water, applied in chemical instruments and methods, biological water/sewage treatment, water/sewage treatment, etc. Total COD emissions and odor elimination effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

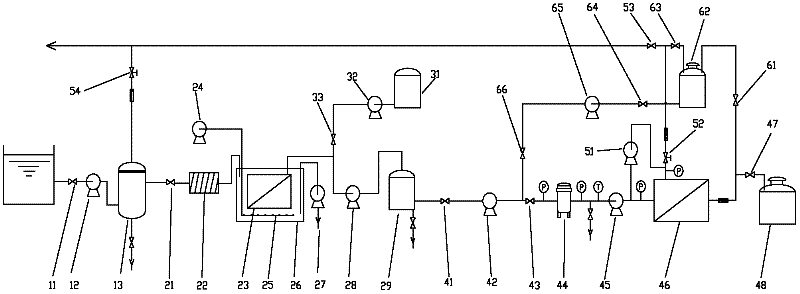

Image

Examples

Embodiment 1

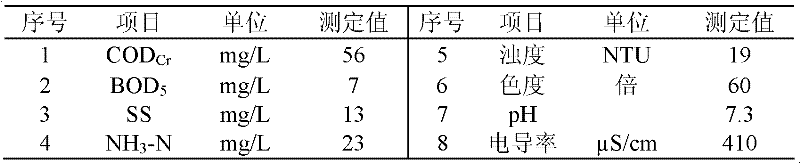

[0046] Deep purification regeneration and recycling project of 500 tons / day sewage.

[0047] The water quality of the sewage is shown in Table 2.

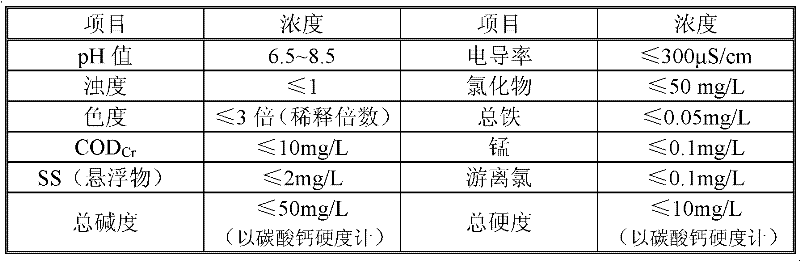

[0048] Table 2 Water quality of sewage

[0049]

[0050] Step 1, electrolysis: start the water supply pump 12, and the sewage 3 The / h flow rate enters the electrolysis machine 13 through the stop valve 11 for electrolysis. The working voltage of the electrolysis is 12V, the voltage between the two poles is 3.5-8.0V, and the current density is 130mA / cm 2 , under the action of current, strong oxidizing substances such as nascent chlorine [Cl], hydroxyl [OH] and nascent oxygen [O] produced by electrolysis can not only kill plankton and bacteria in sewage, but also make The macromolecules in the sewage are opened or chain broken, so that the macromolecules that are difficult to biodegrade are decomposed into small molecules, increasing the BOD 5 / COD Cr Ratio, improve the biodegradability of sewage; at the same time, oxidize a...

Embodiment 2

[0060] The deep purification regeneration and recycling project of 3000 tons / day sewage.

[0061] The water quality of the sewage is shown in Table 5.

[0062] Table 5 Water quality of sewage

[0063]

[0064] Step 1, electrolysis: start the water supply pump 12, and the sewage is 3 The / h flow rate enters the electrolysis machine 13 through the stop valve 11 for electrolysis. The working voltage of the electrolysis is 48V, the voltage between the two electrodes is 5.5-8.0V, and the current density is 190mA / cm 2 , under the action of current, strong oxidizing substances such as nascent chlorine [Cl], hydroxyl [OH] and nascent oxygen [O] produced by electrolysis can not only kill plankton and bacteria in sewage, but also make The macromolecules in the sewage are opened or chain broken, so that the macromolecules that are difficult to biodegrade are decomposed into small molecules, increasing the BOD 5 / COD Cr Ratio, improve the biodegradability of sewage; at the same ti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com