Patents

Literature

88results about How to "Reduce operating conditions" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

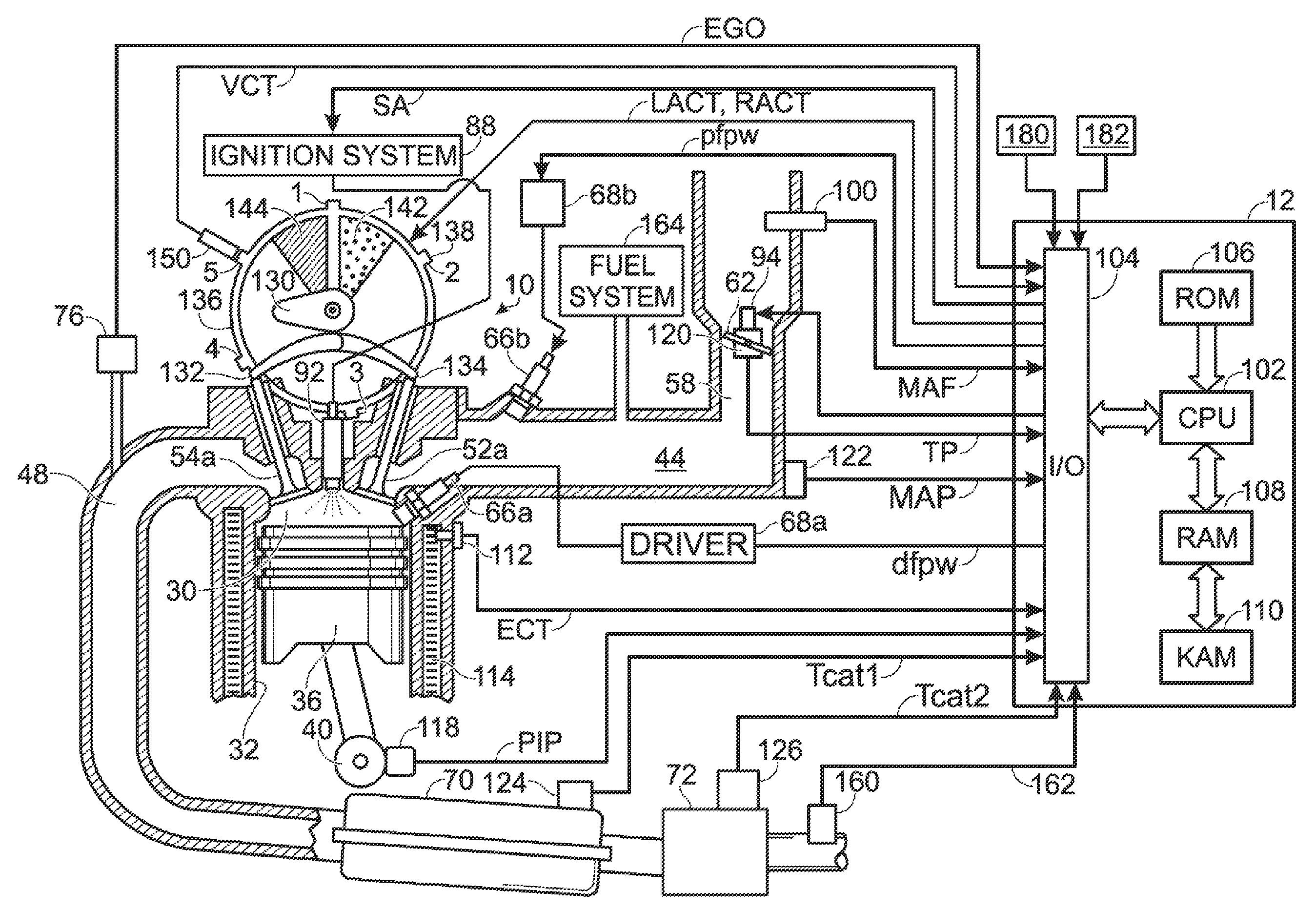

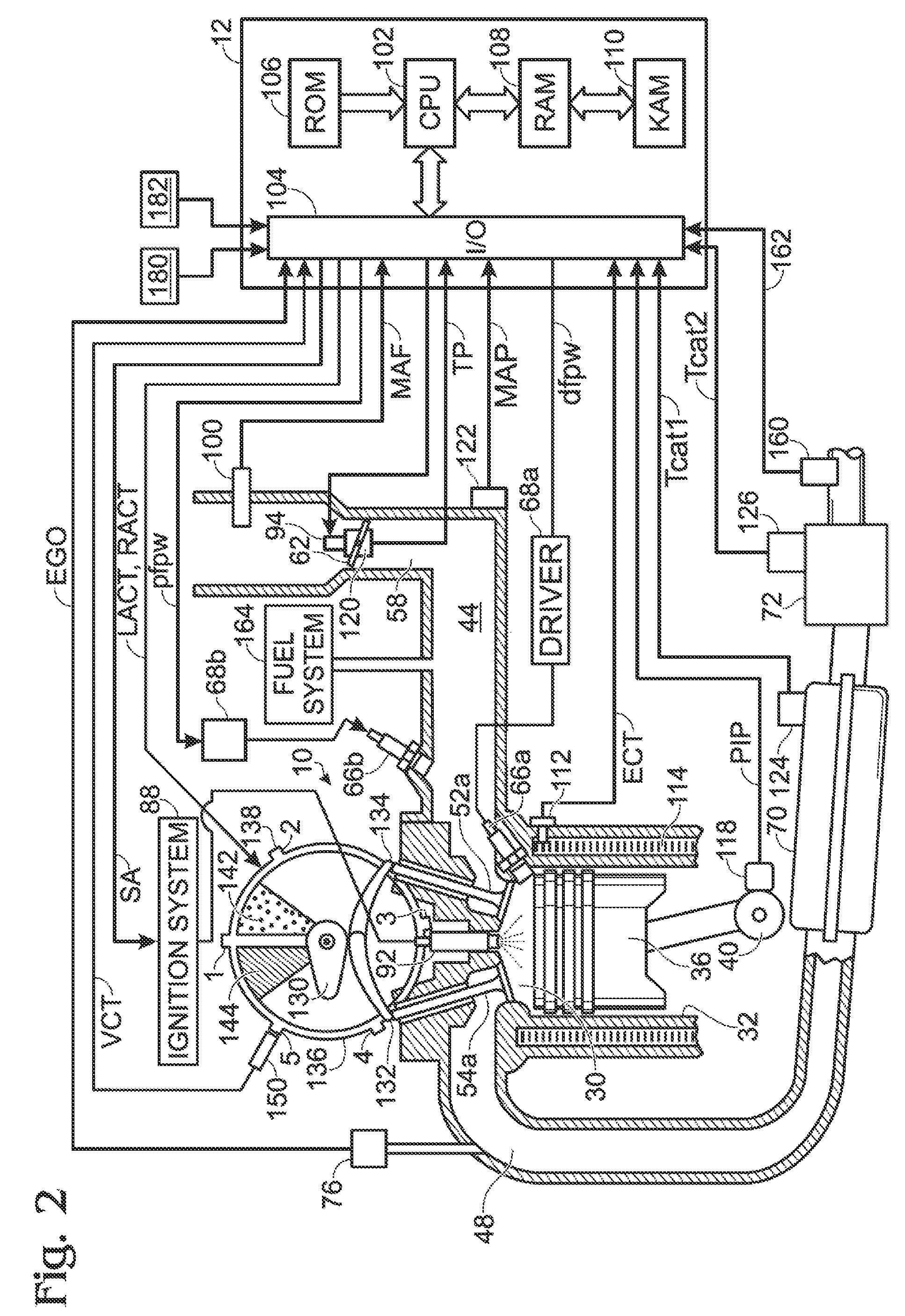

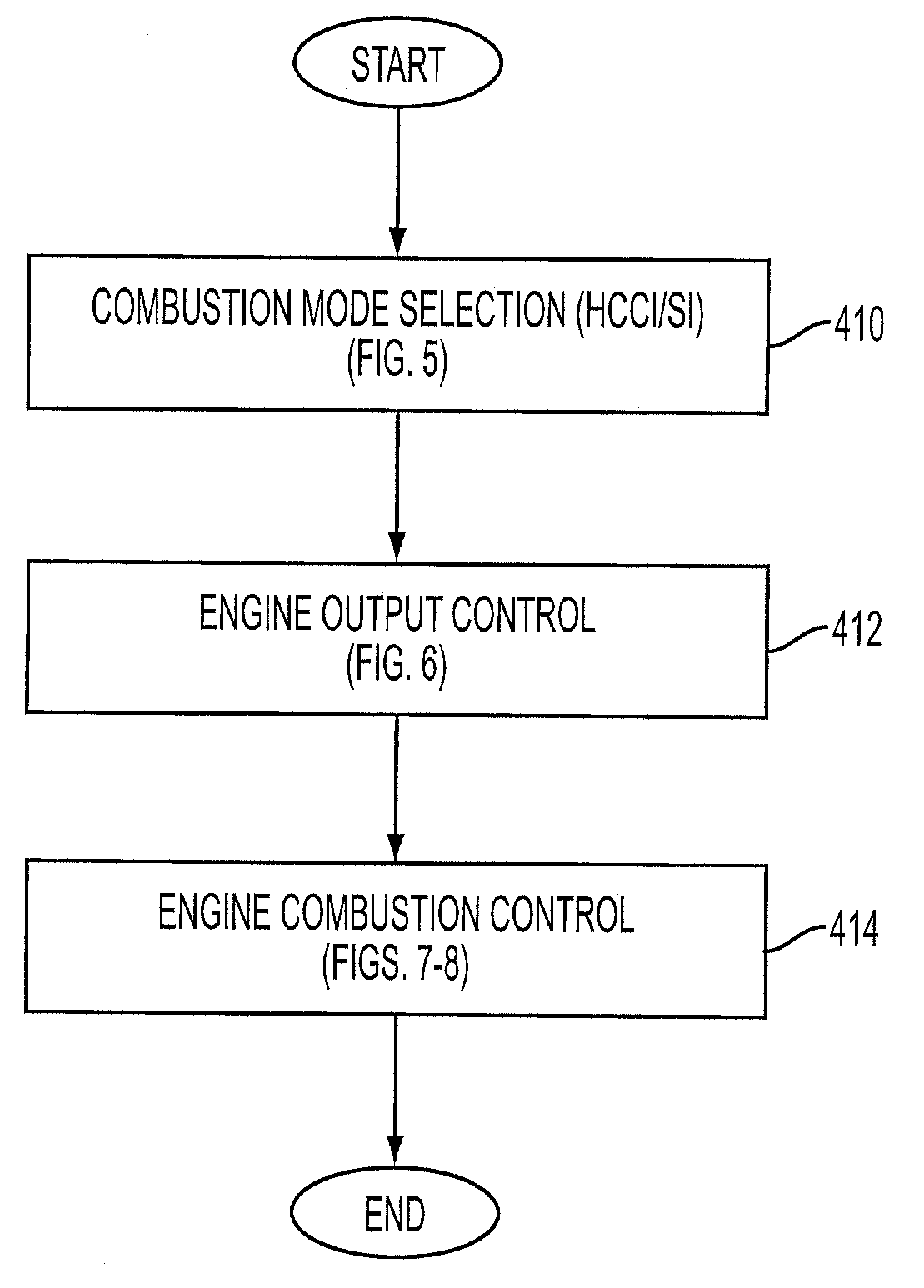

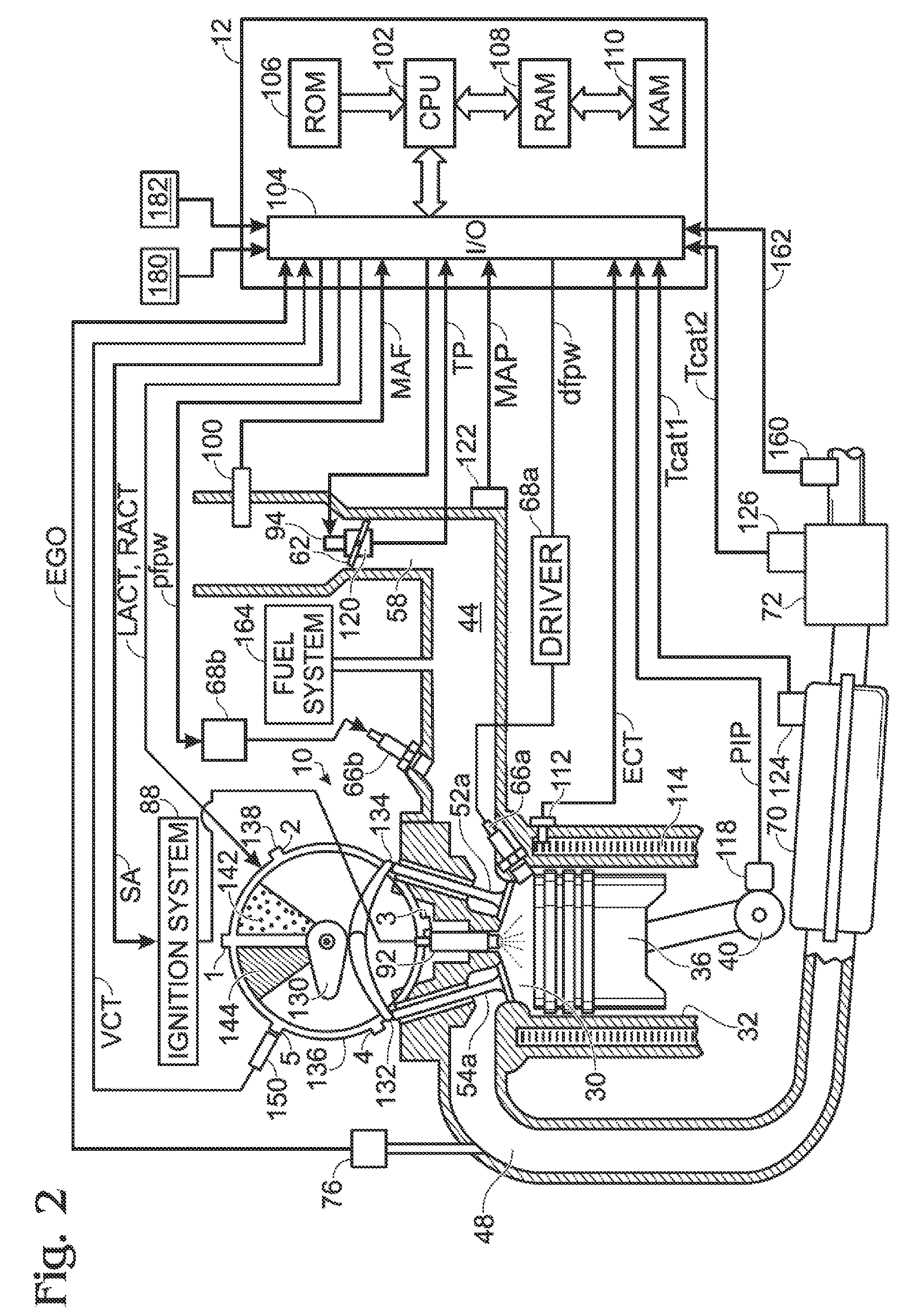

Multiple Combustion Mode Engine Using Direct Alcohol Injection

ActiveUS20080127933A1Improve operation and transient performanceDesign range be expandAnalogue computers for vehiclesElectrical controlAutomotive engineeringSpark-ignition engine

A method of operating an engine, comprising of performing homogeneous charge compression ignition combustion during a first operating condition, and performing spark ignition combustion during a second operating condition, where an amount of directly injected alcohol in at least one of said homogeneous charge compression ignition combustion and said spark ignition combustion is varied in response to at least an operating parameter.

Owner:FORD GLOBAL TECH LLC +1

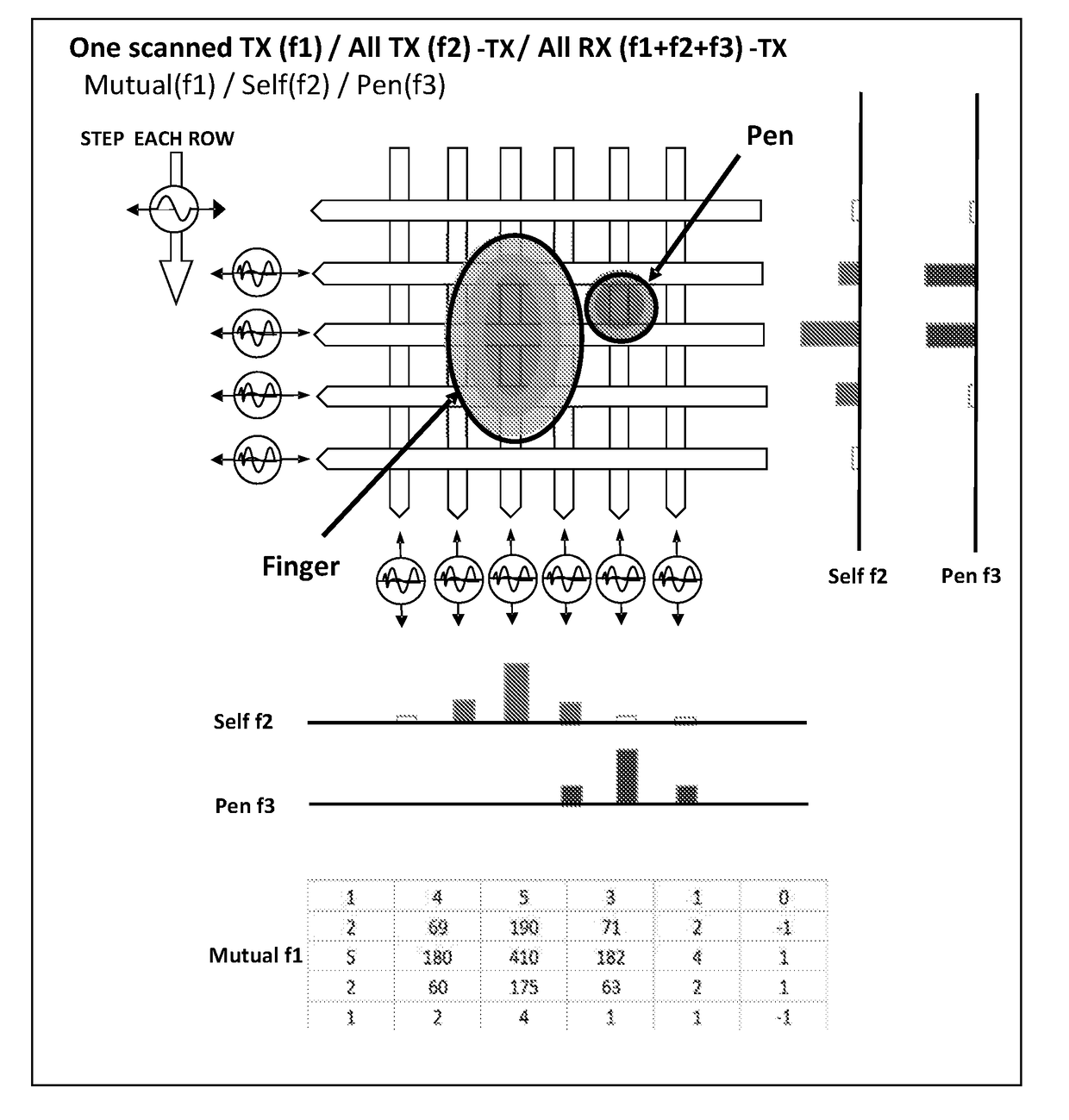

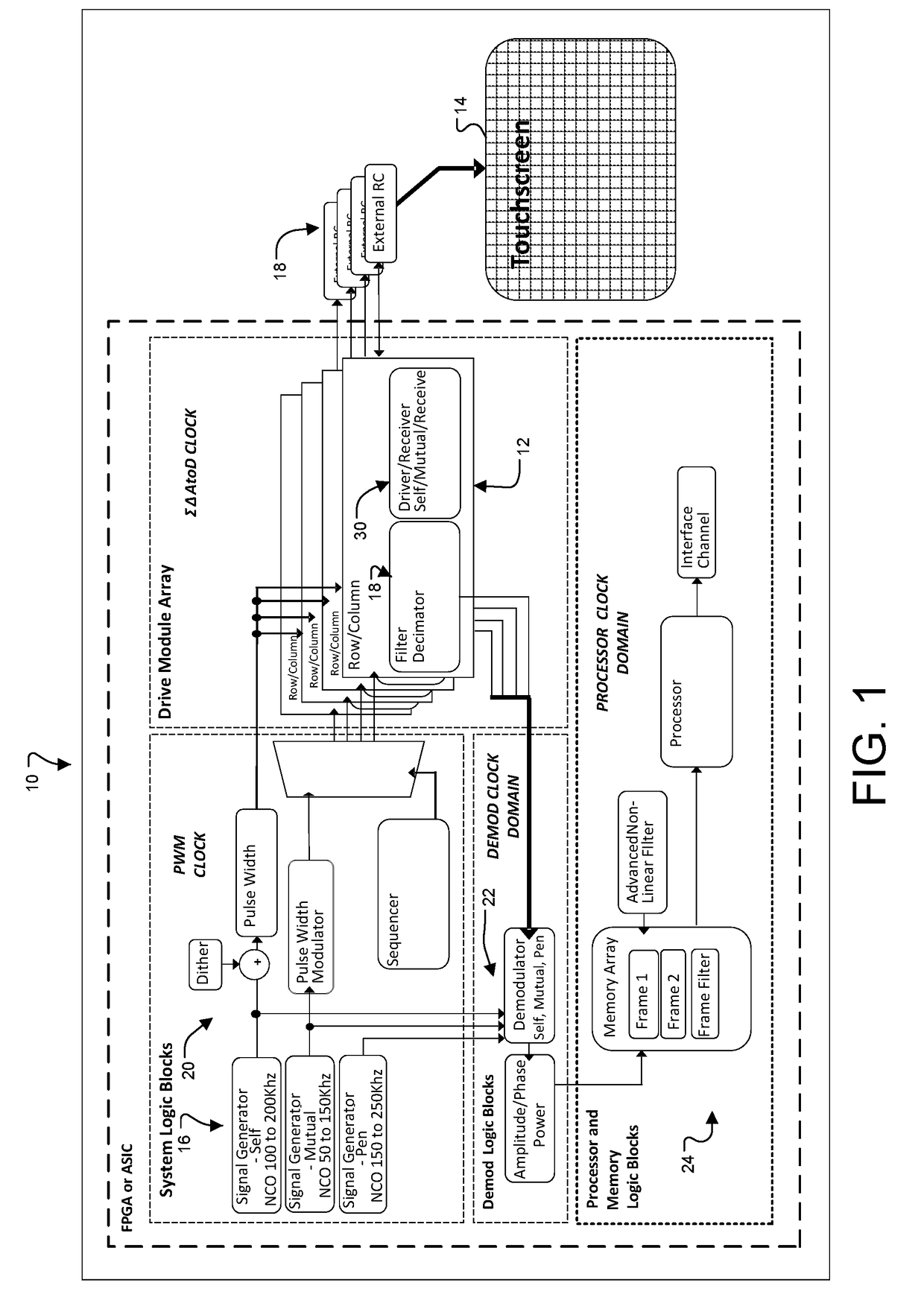

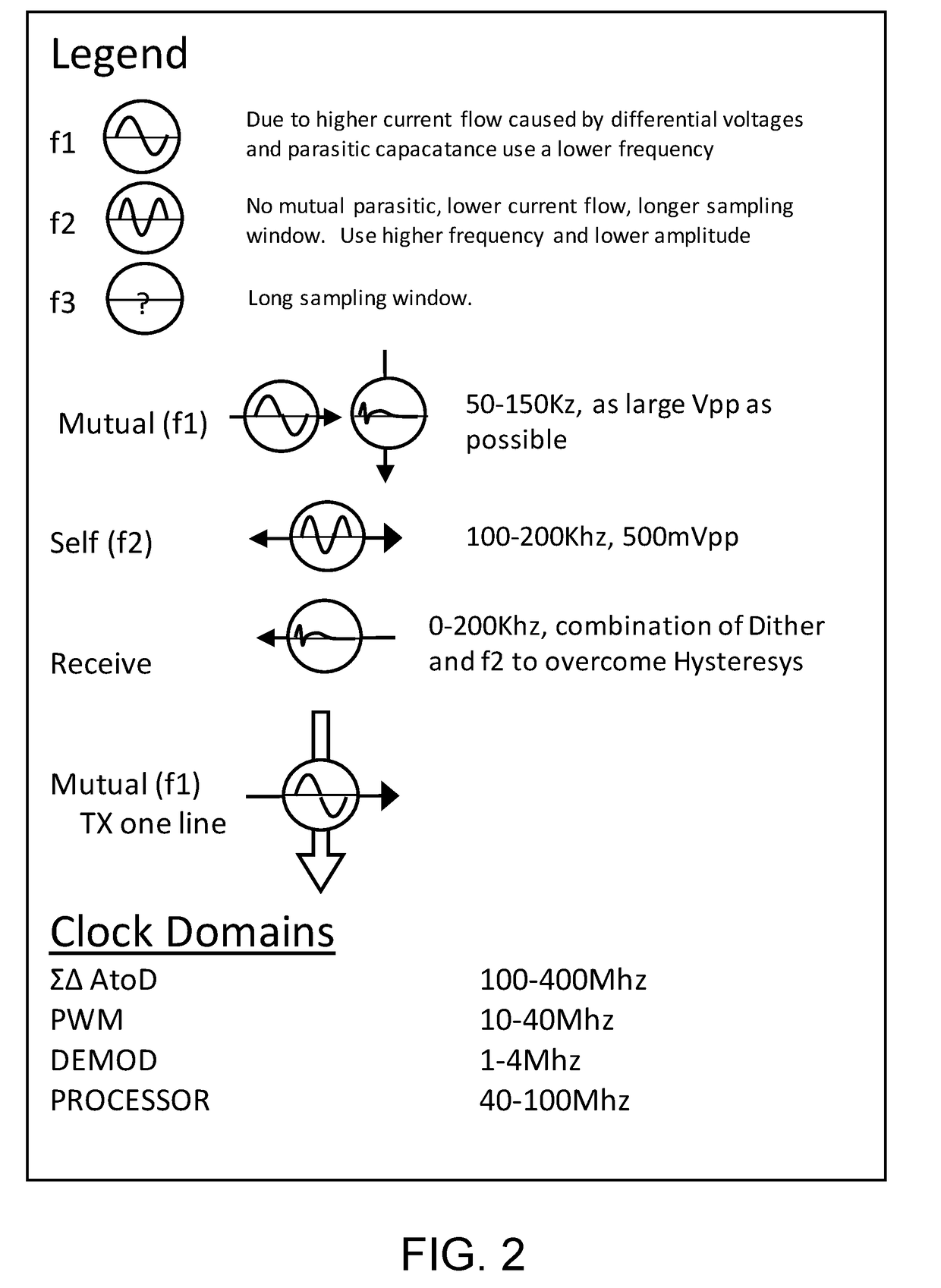

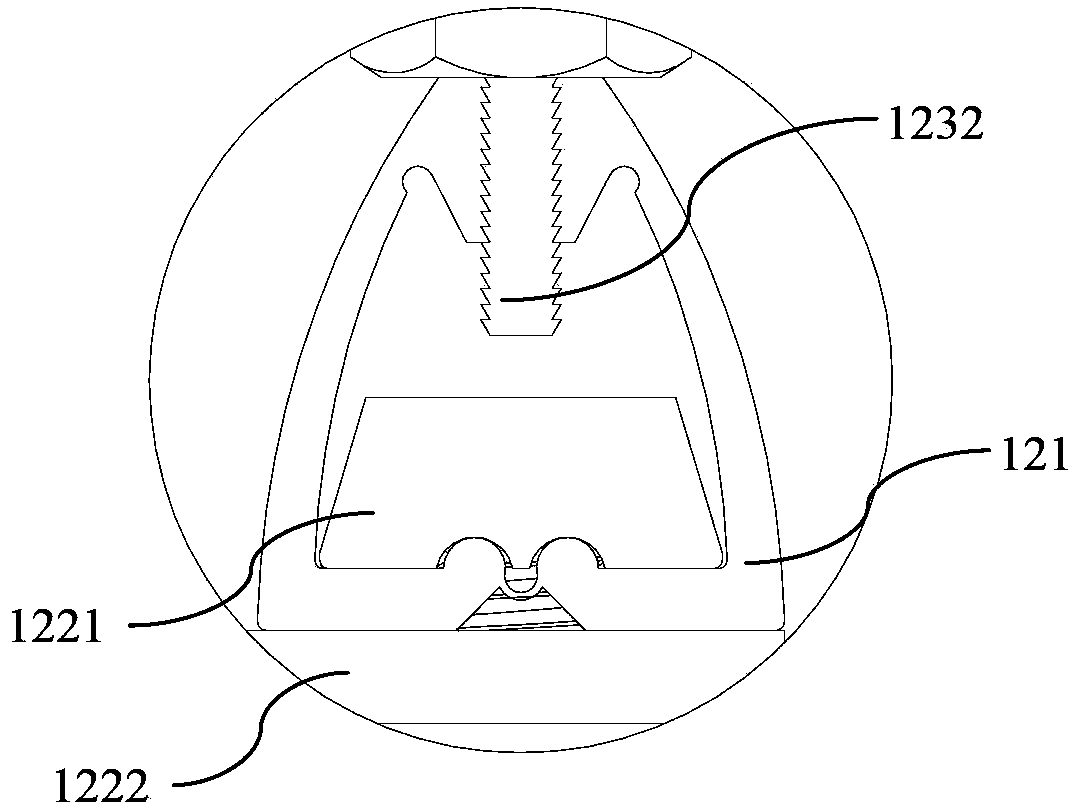

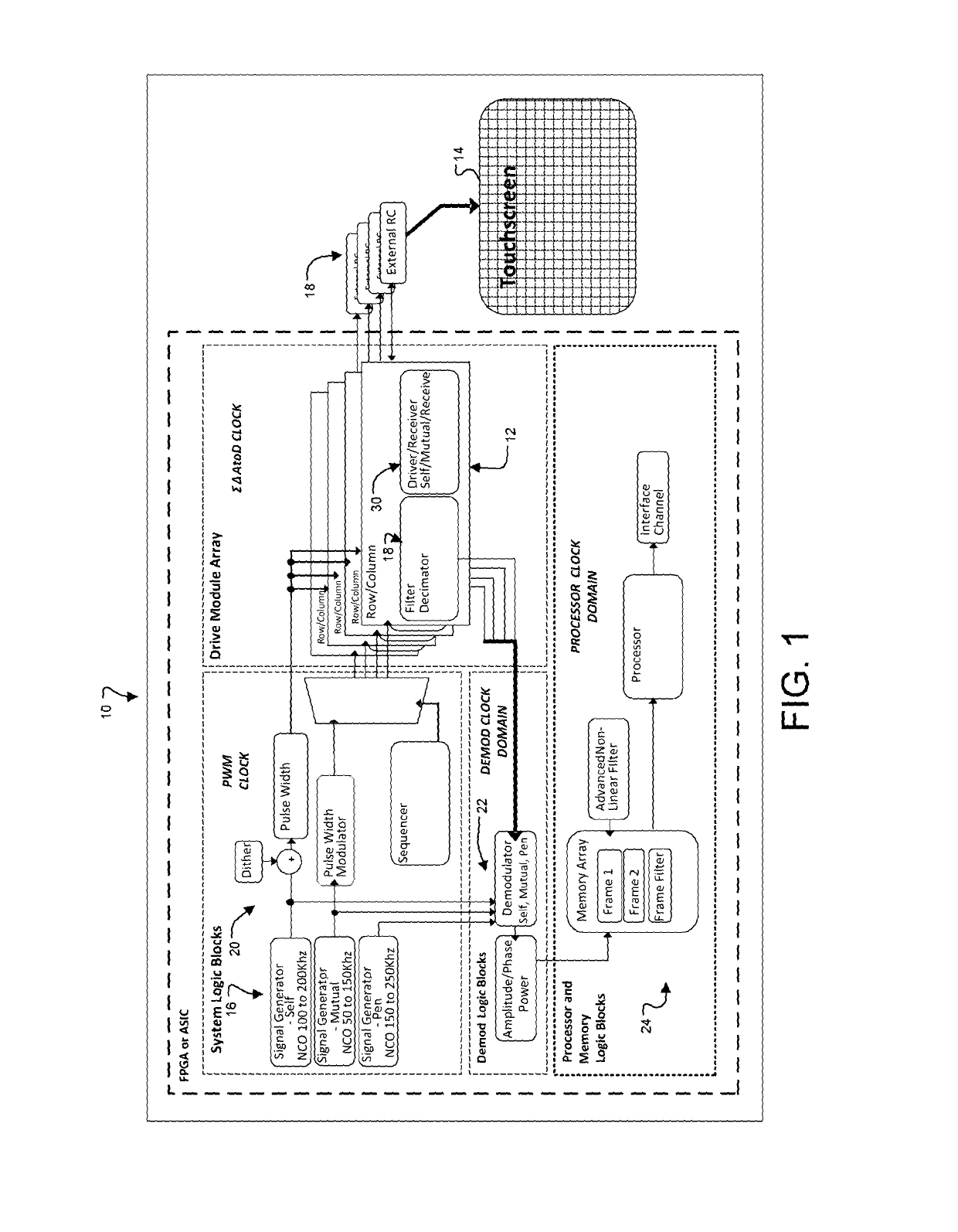

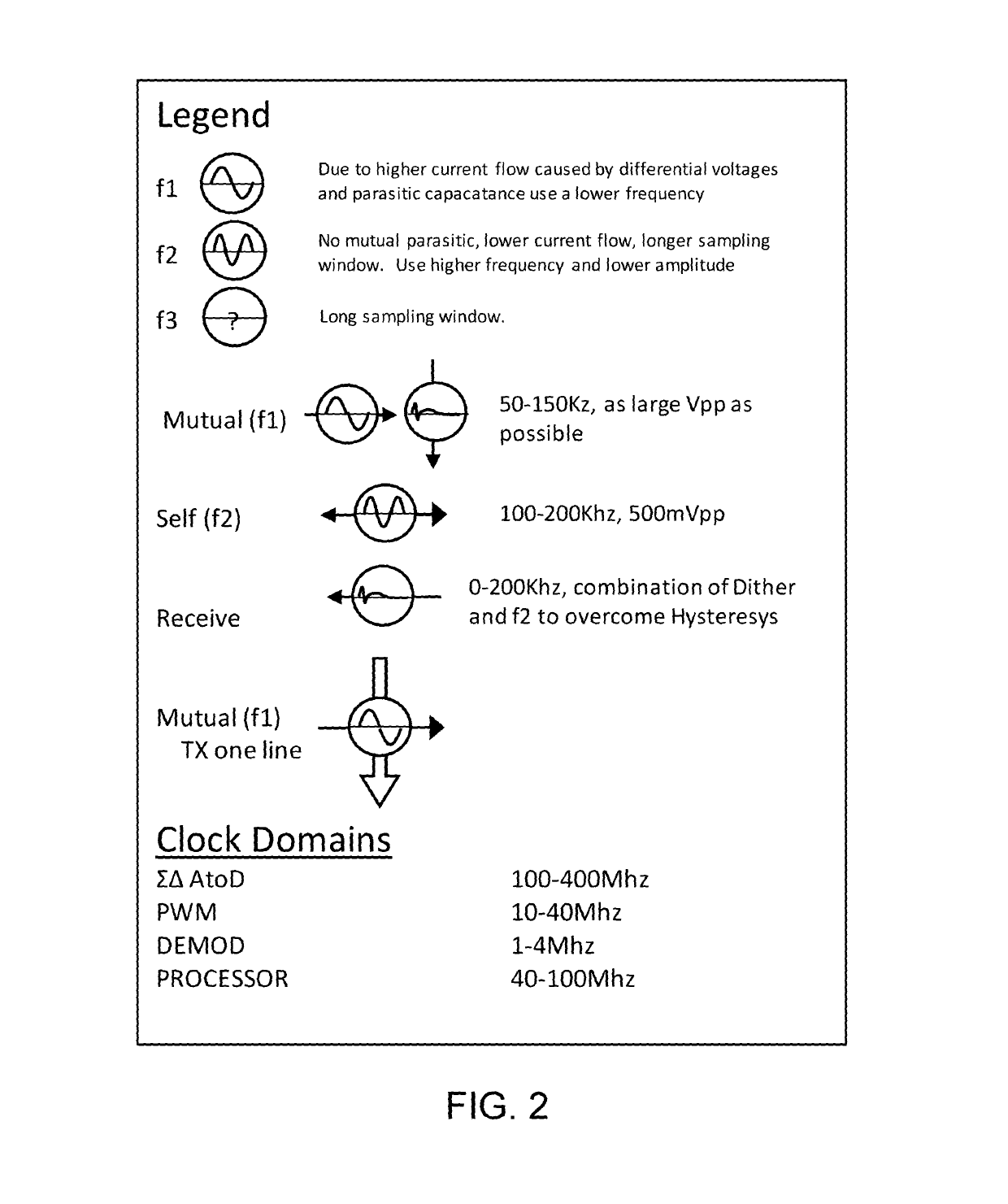

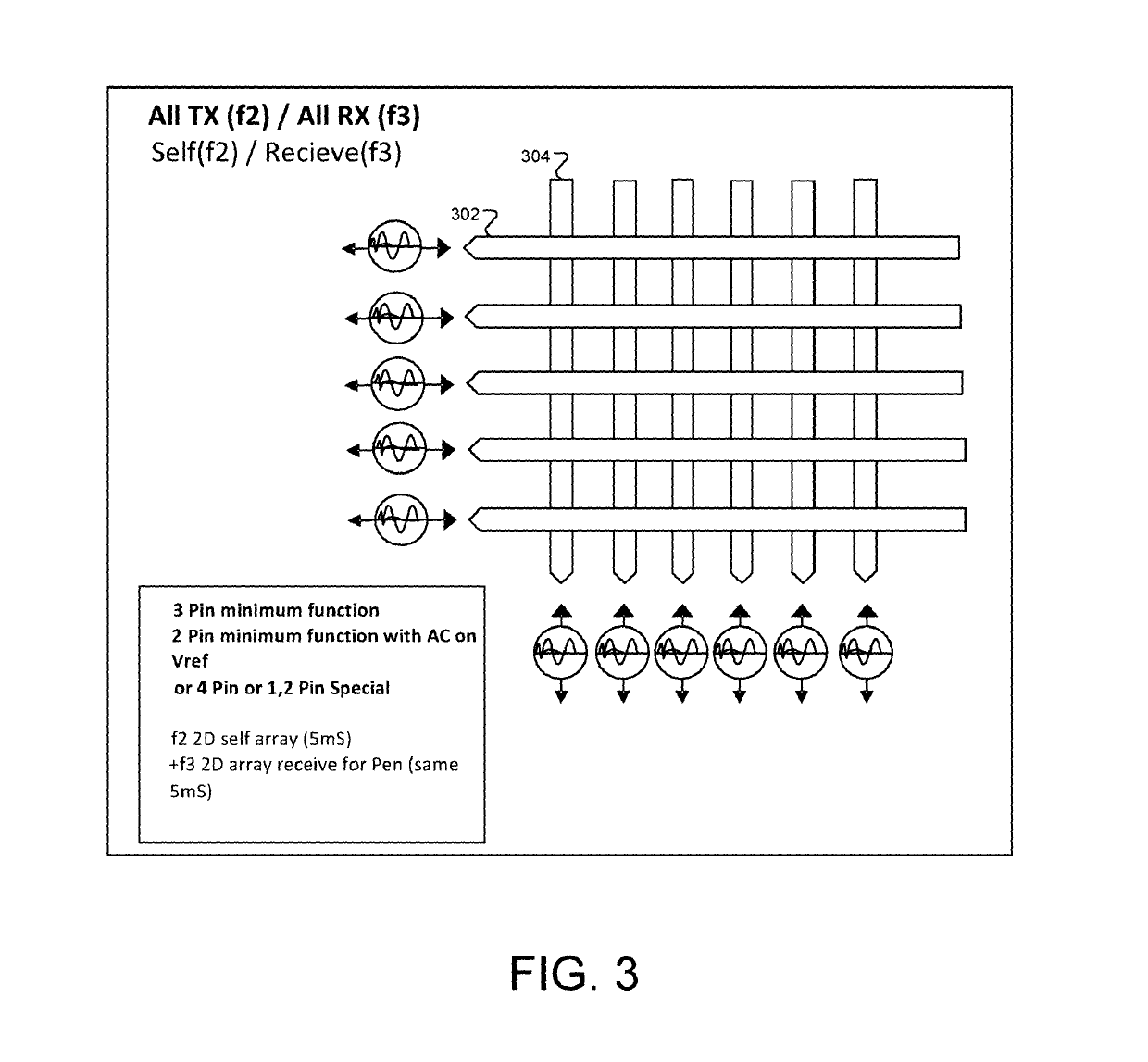

Pen system with internal pressure tilt rotation

ActiveUS20170242502A1Function increaseReduce operating conditionsInput/output processes for data processingInternal pressureMulti axis

A pen apparatus with a pressure sensitive tip mechanism that internally generates pressure, tilt, and / or barrel rotation through the use of a multi-axis measurement scheme with simultaneous transmit, receive, and sensing driver capability operable in conjunction with a receiving system or in a relative stand-alone manner. Signaling schemes are provided for operating the pen apparatus to achieve improved function. Systems and methods are provided for operating a pen, and for operating a pen with a touch sensor system. Drive / receive circuitry and methods of driving and receiving sensor electrode signals are provided that allow digital I / O pins to be used to interface with touch sensor electrodes. This circuitry may be operated in modes to sense various combinations of signals coupled within a pen, or from outside of a pen.

Owner:SIGMASENSE LLC

Multiple combustion mode engine using direct alcohol injection

ActiveUS7461628B2Improve efficiencyReduce the production of nitrogen oxidesAnalogue computers for vehiclesElectrical controlHomogeneous charge compression ignitionAlcohol

A method of operating an engine, comprising of performing homogeneous charge compression ignition combustion during a first operating condition, and performing spark ignition combustion during a second operating condition, where an amount of directly injected alcohol in at least one of said homogeneous charge compression ignition combustion and said spark ignition combustion is varied in response to at least an operating parameter.

Owner:FORD GLOBAL TECH LLC +1

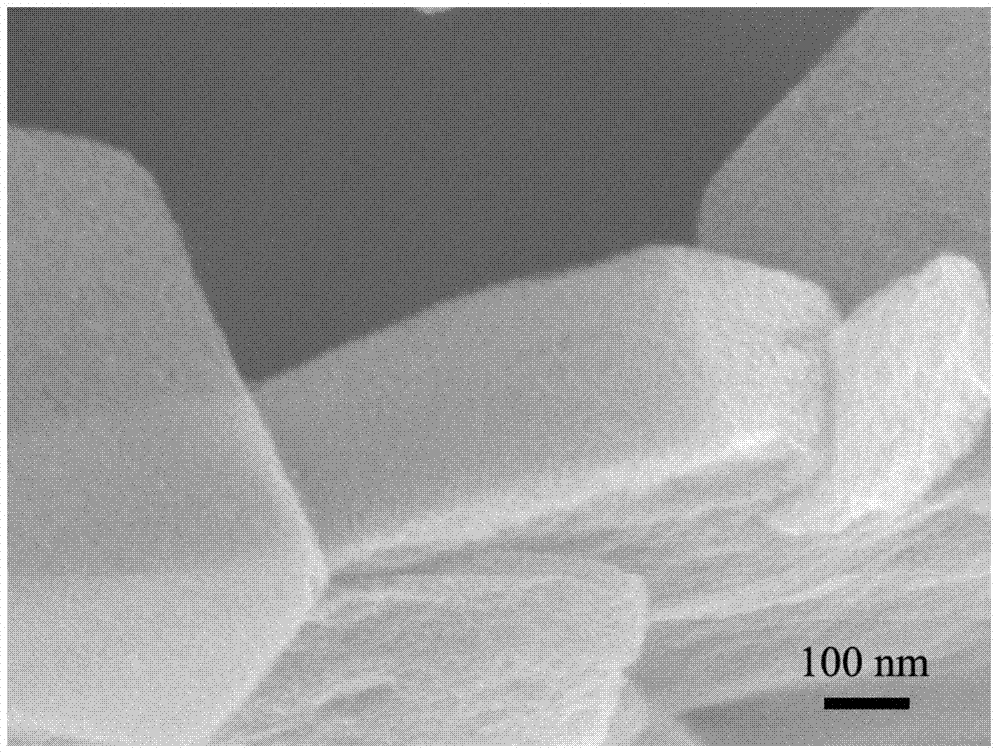

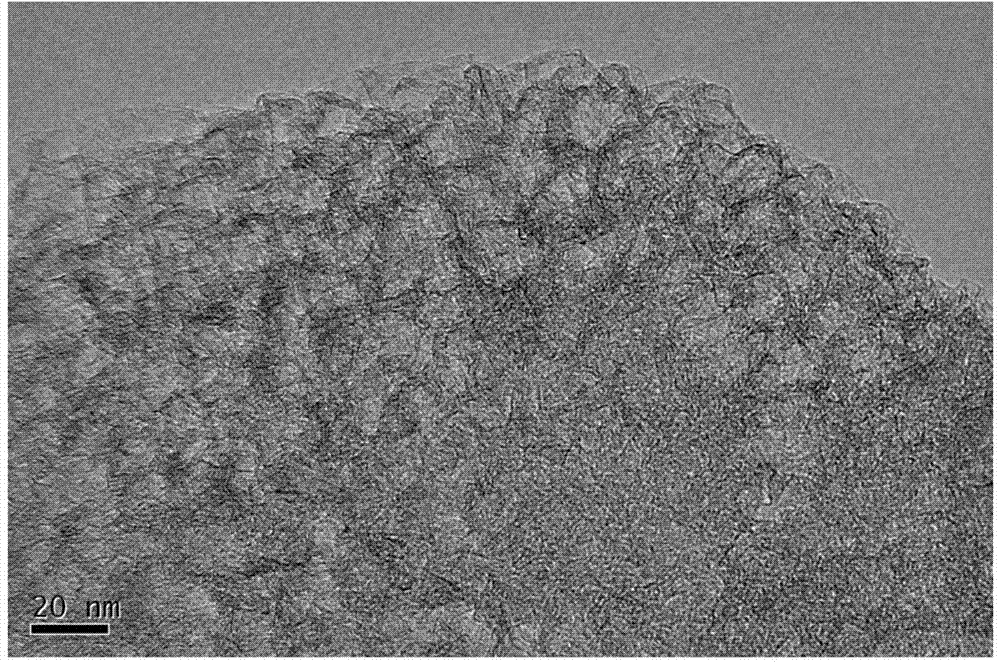

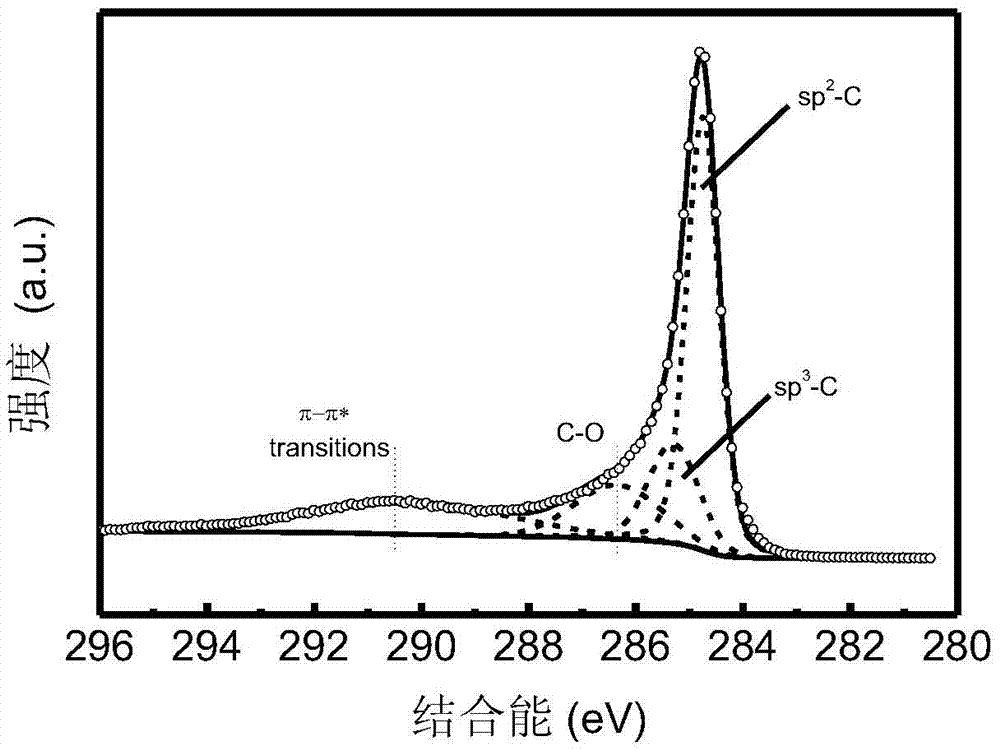

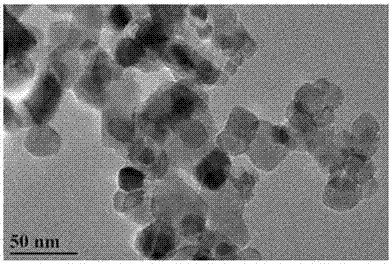

Mesoporous graphene foam as well as preparation method thereof

ActiveCN103482611AStable structureLarge specific surface areaGrapheneNanotechnologyDraw ratioElectric properties

The invention belongs to the technical fields of a novel material as well as preparation, and particularly relates to mesoporous graphene foam as well as a preparation method thereof. The invention realizes hydrothermal preparation of a magnesium oxide texture structure and preparation of the mesoporous graphene foam by using textured magnesium oxide as a template. The mesoporous graphene foam material has abundant mesoporous structures and excellent electric property and can be used as an electrode material of batteries and supercapacitors, so that the energy density and the power density of the batteries or the supercapacitors are expectedly improved to a great extent. The cycling stability of the mesoporous graphene foam material is increased, and the mesoporous graphene foam material combined with materials with high draw ratio or the mesoporous graphene foam material can soften energy storage apparatuses. The advantages have important meaning for realization of commercialization of a new generation of energy storage apparatuses for electromobiles and development of smaller, lighter and flexible portable mobile power supplies. The business prospect is wide. Meanwhile, preparation processes of the high temperature hydrothermal method and a fluidized bed can realize engineering enlargement, so that the method is expected to be industrialized.

Owner:TSINGHUA UNIV

Production technique for chicken powder with great freshness flavor

ActiveCN103689522AIncrease umamiImprove sensory qualityFood ingredientsFood preparationMonosodium glutamateAdditive ingredient

The invention discloses a production technique for chicken powder with a great freshness flavor, and belongs to the technical field of processing food seasoning. The chicken powder comprises the following materials according to mass: 30kg of fresh chicken skeletons, 30kg of fresh chicken, 7kg of maltodextrin, 2.5kg of disodium nucleotide, 0.1kg of sodium citrate, 7kg of trehalose, 10kg of edible salt, 10kg of monosodium glutamate, 2kg of lentinula edodes, 1kg of radix puerariae, and 0.4kg of pepper; the production technique comprises the steps: pretreating active ingredients, and carrying out high-temperature high-pressure sealed cooking, fine treatment, enzymolysis for flavor, mixing, spray drying, filling and capping. According to the production technique, the processes are simple, the energy consumption can be reduced, the loss of flavor components can be effectively reduced and sufficient release of flavor substances is promoted, the chicken powder is rich in chicken flavor, harmonious in saline taste, delicate flavor and perfume, luminous in color, good in rehydration property, smooth in mouthfeeling, free from sand grains, and milkily white in soup feeling.

Owner:GUANGDONG JIALONG FOOD

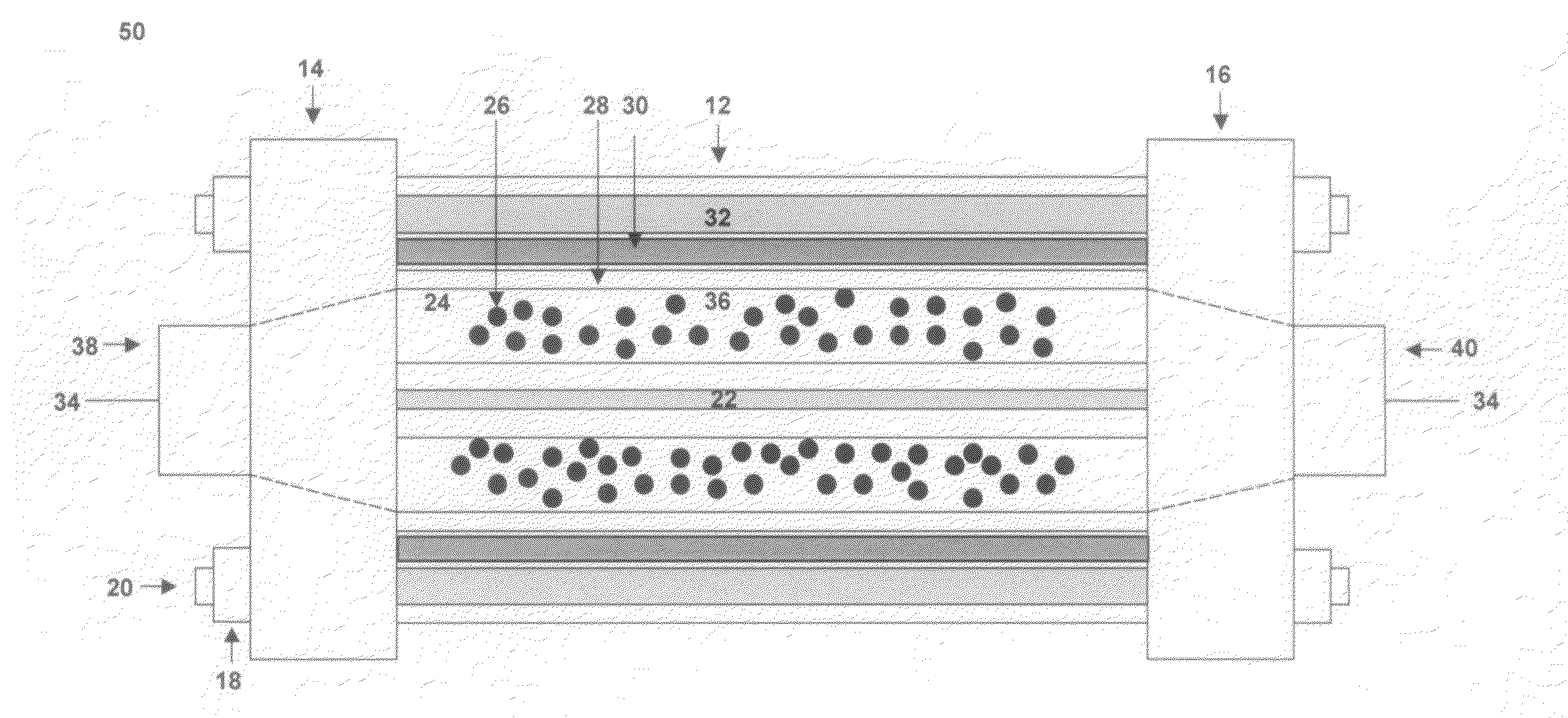

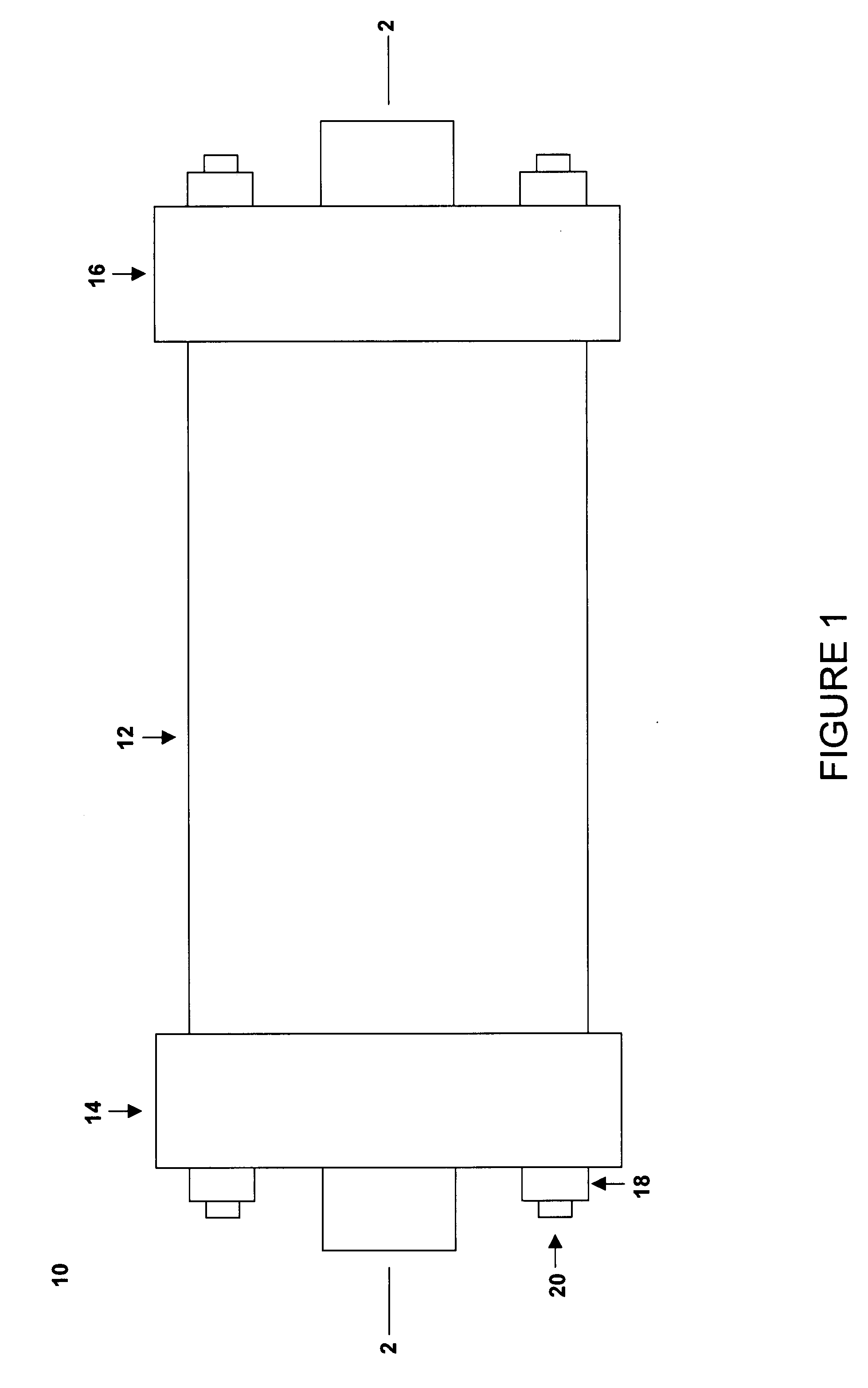

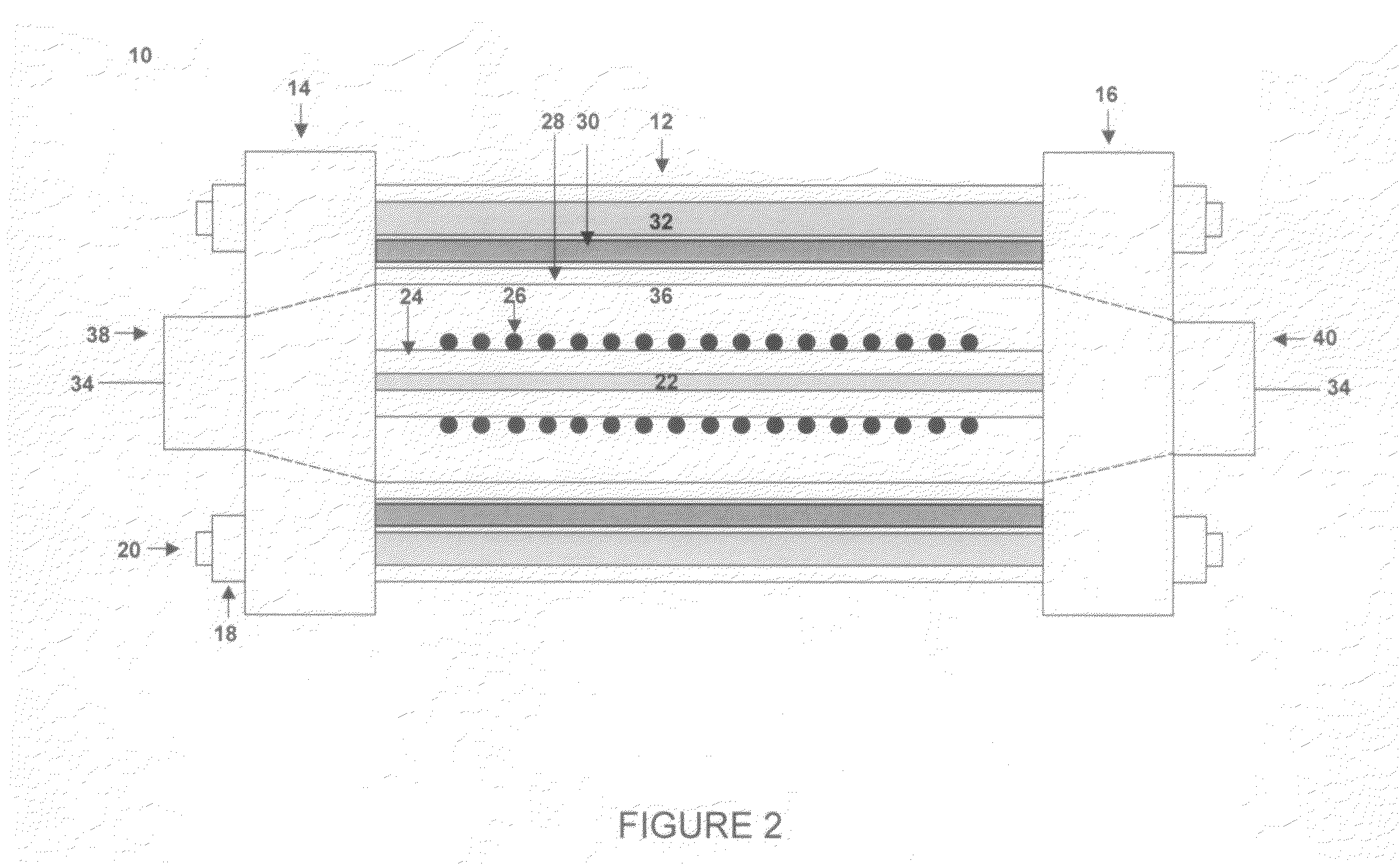

Carbonaceous solid fuel gasifier utilizing dielectric barrier non-thermal plasma

InactiveUS20080314734A1Reduce operating conditionsReduce activation energy barrierGaseous fuelsGasification processes detailsElectric power systemPlasma generator

A system for producing a fuel gas from a carbon-containing material is provided that includes a non-thermal plasma generator, an electric power source, a process stream inlet, and a product stream outlet. The non-thermal plasma generator includes a high voltage electrode separated from a grounded electrode by a modification passage. Moreover, a dielectric layer exists between the high voltage electrode and the grounded electrode. The electric power source is energizable to create non-thermal electrical microdischarges within the modification passage. As the process gas flows through the system, the carbon-containing material is converted to fuel gas.

Owner:RGT UNIV OF CALIFORNIA

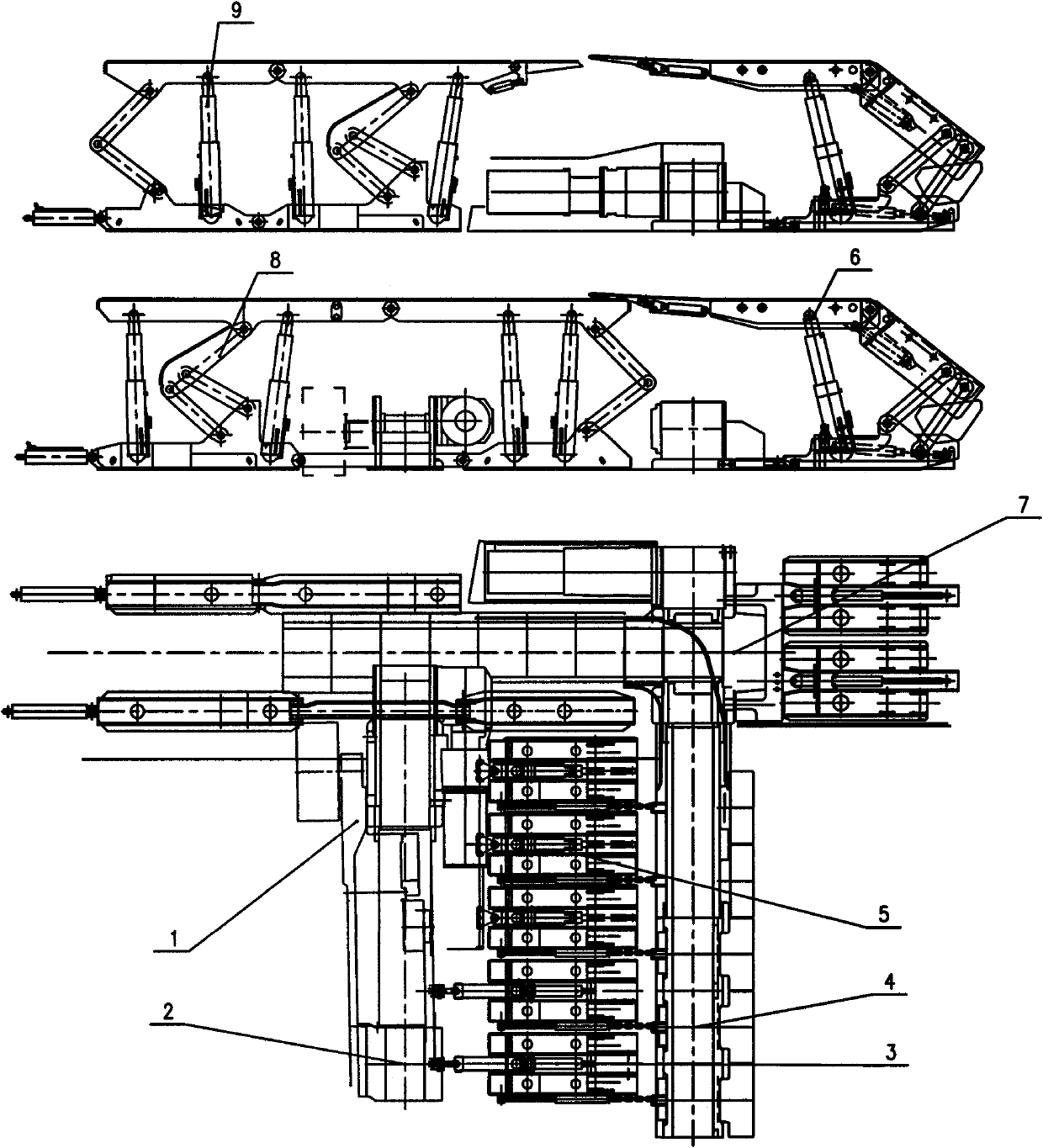

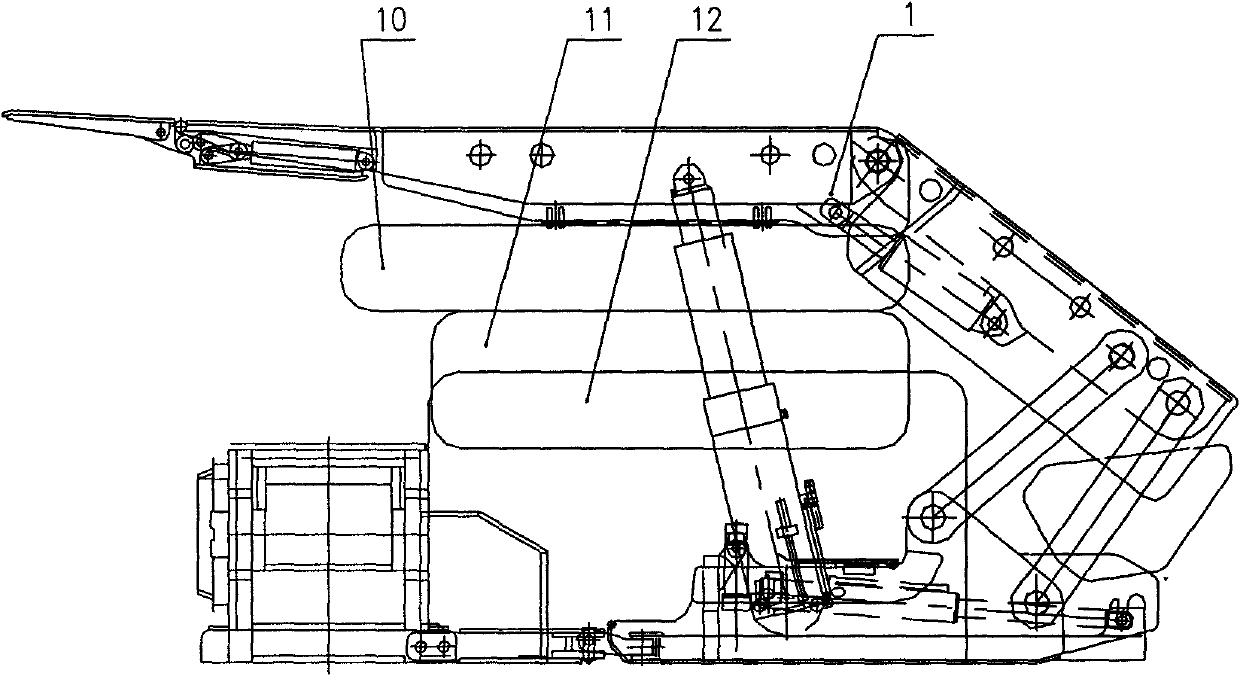

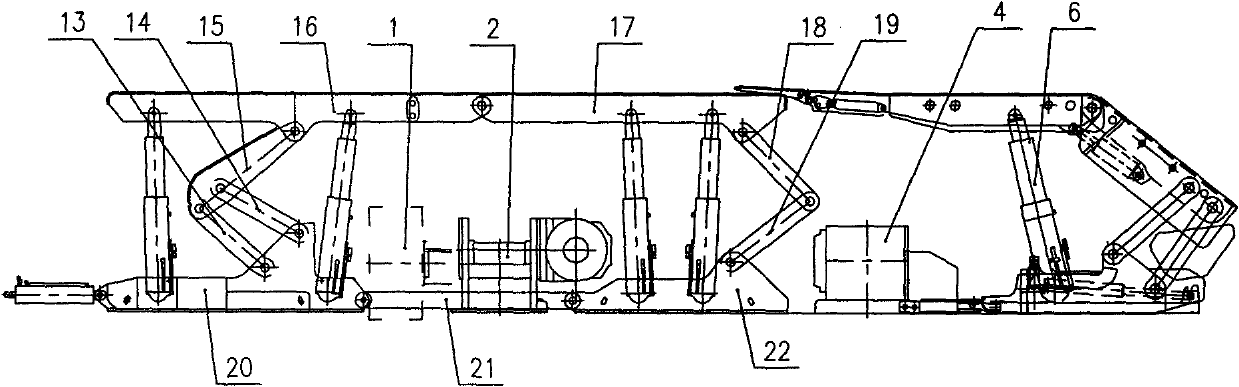

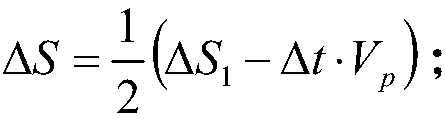

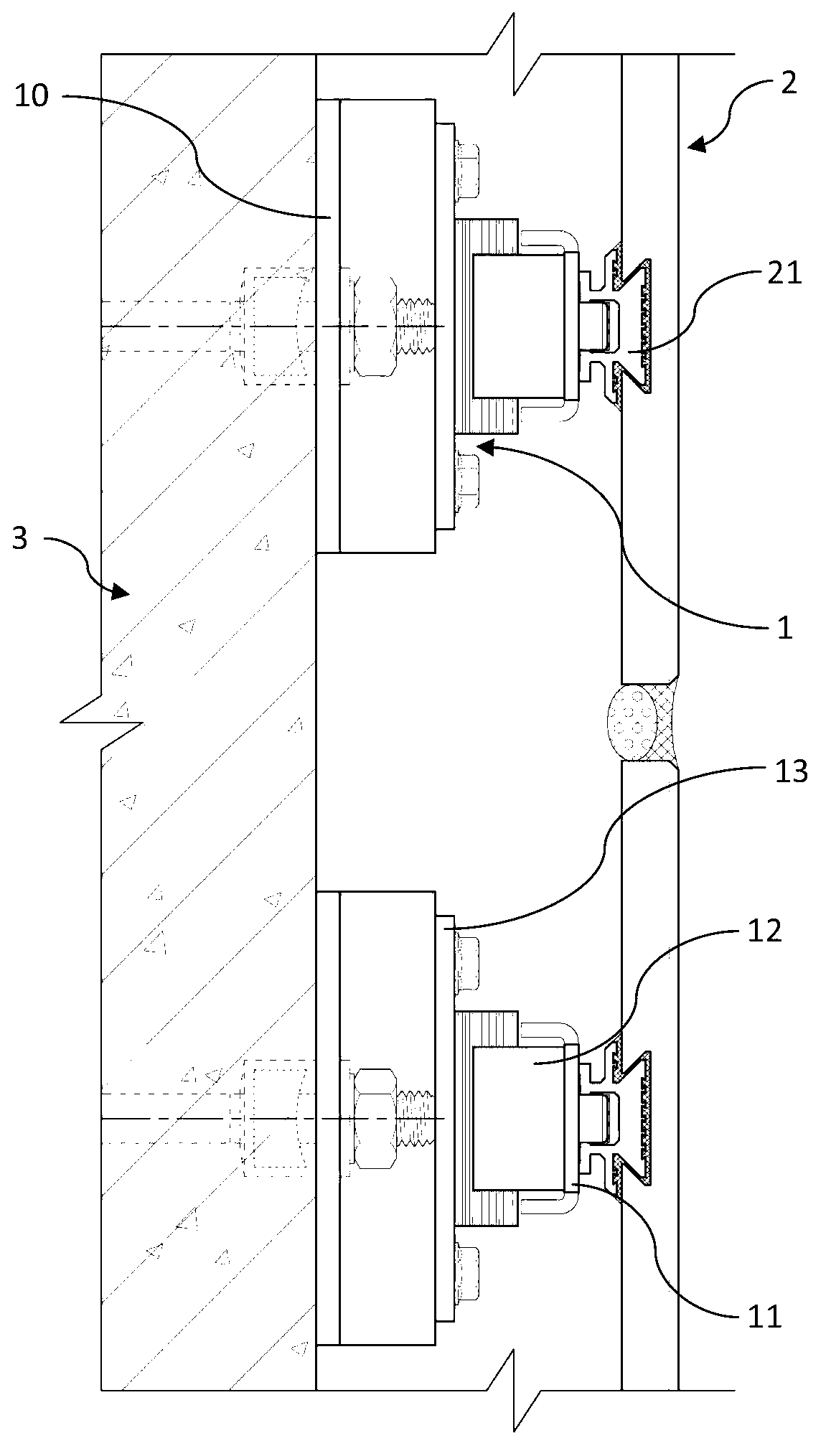

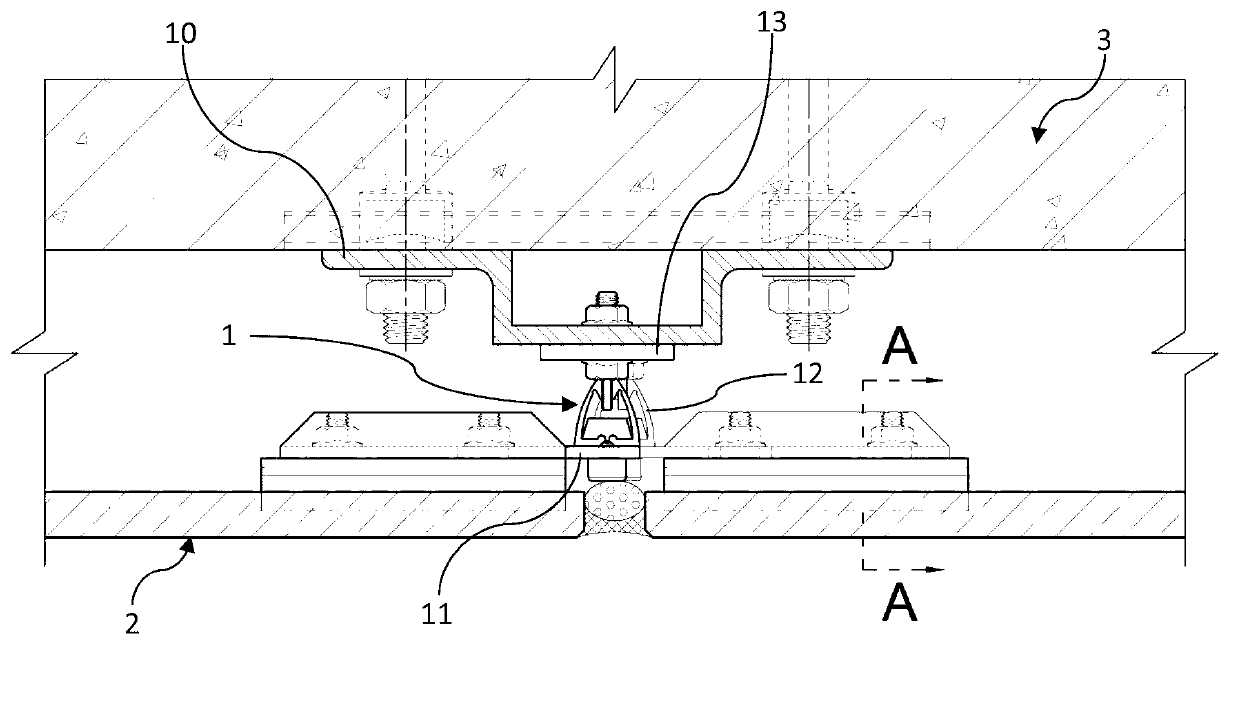

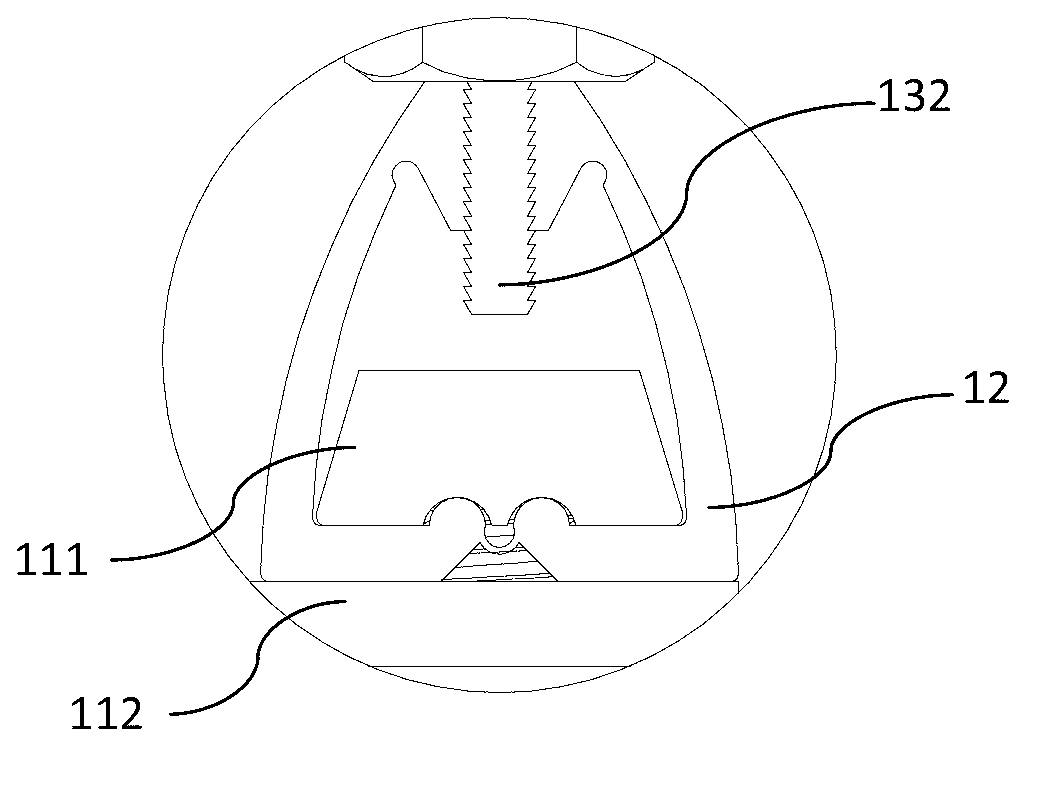

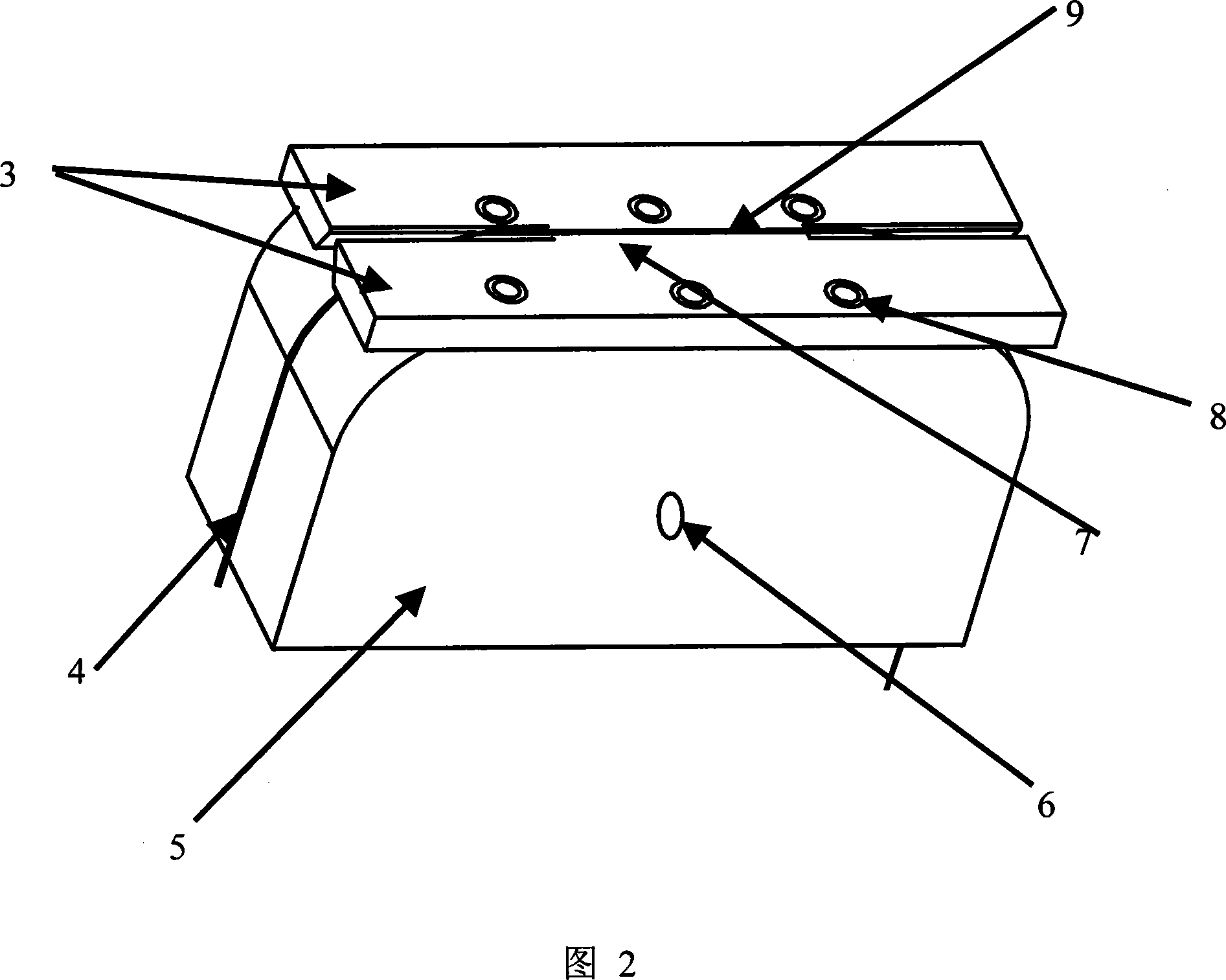

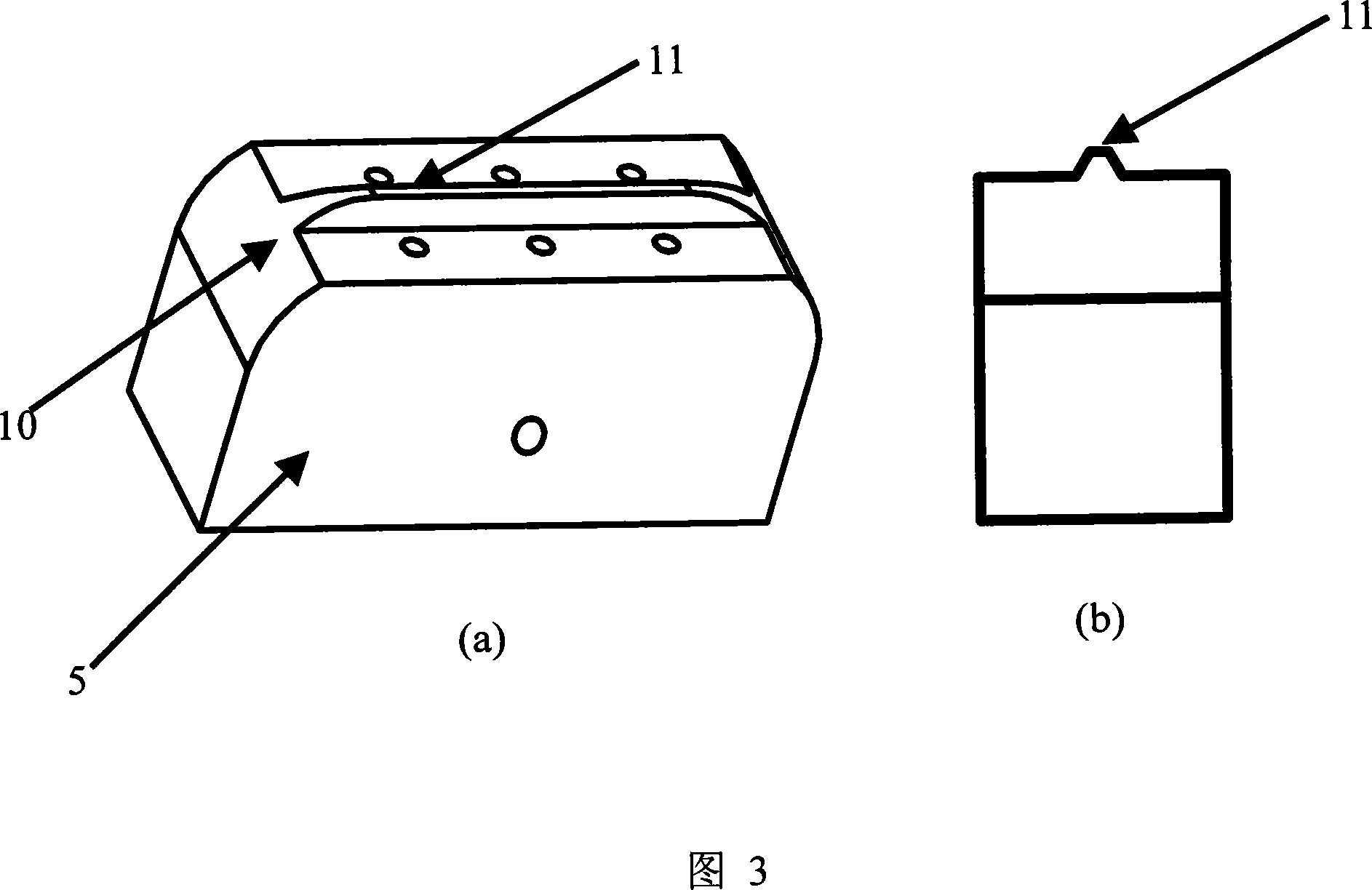

Cross side dumping arrangement coordinated mode of rear conveyer of fully mechanized working face and support structure

ActiveCN102383794ALower unloading heightHigh recovery rateSlitting machinesMine roof supportsMechanical engineeringCoal

The invention discloses a new cross side dumping coordinated technology and a new supporting technology for an end region of a fully mechanized working face. The head of a rear conveyer is changed to a cross side dumping arrangement mode, and a motor of the rear conveyer is arranged in a smooth trough, so that the rear space of a transition support is not occupied any more, the center distance between the heads and the tails of the front and rear conveyers is consistent with the center distance of the middle sections, meanwhile, the unloading height of the conveyers is reduced, and the coal caving effect of the heads and the tails and the recovery rate of coal resources are further improved; and because the transition bracket is in the same structural form as a middle bracket, the category of hydraulic brackets of the working face can be reduced, and effective coal caving of the transition section of the top coal caving working face can be realized. A tunnel tail bracket is arranged at the rear part of a transferring machine, so that protection of the rear part of the transferring machine and smooth push of the transferring machine are realized; meanwhile, side guard plates which can be hinged are arranged on the lateral surfaces of the transferring machine, so that the rear gangue is prevented from falling into the tunnel tail bracket; end brackets are arranged at two sides of the transferring machine and have asymmetrical structures, a top beam has a step-type top beam structure, and the end brackets are matched with the tunnel tail bracket of the rear part, so that the stability of a top plate in the cross side dumping coordinated end region of the fully mechanized working face is maintained, and safe and efficiency recovery of the fully mechanized working face is realized.

Owner:TIANDI SCI & TECH CO LTD +1

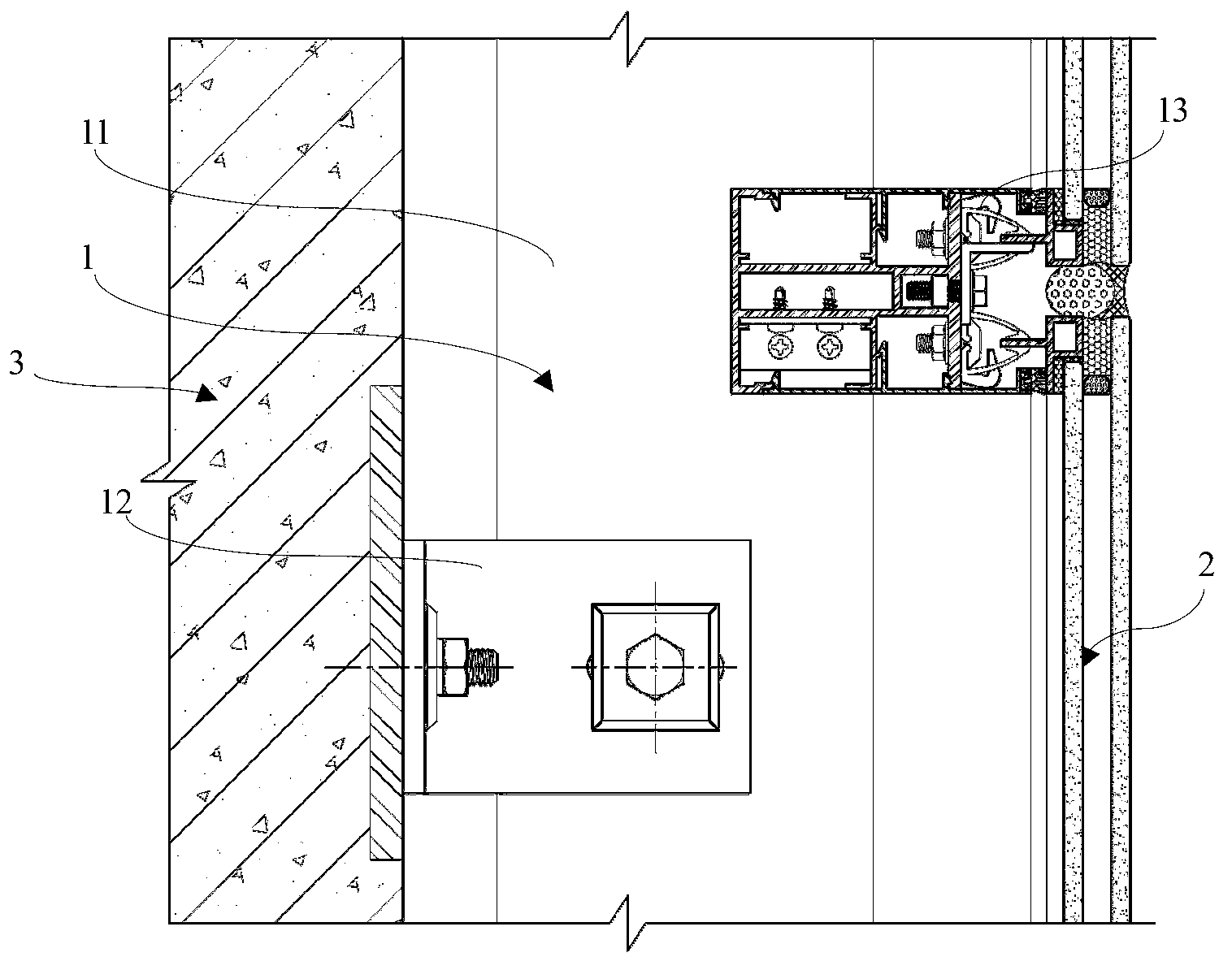

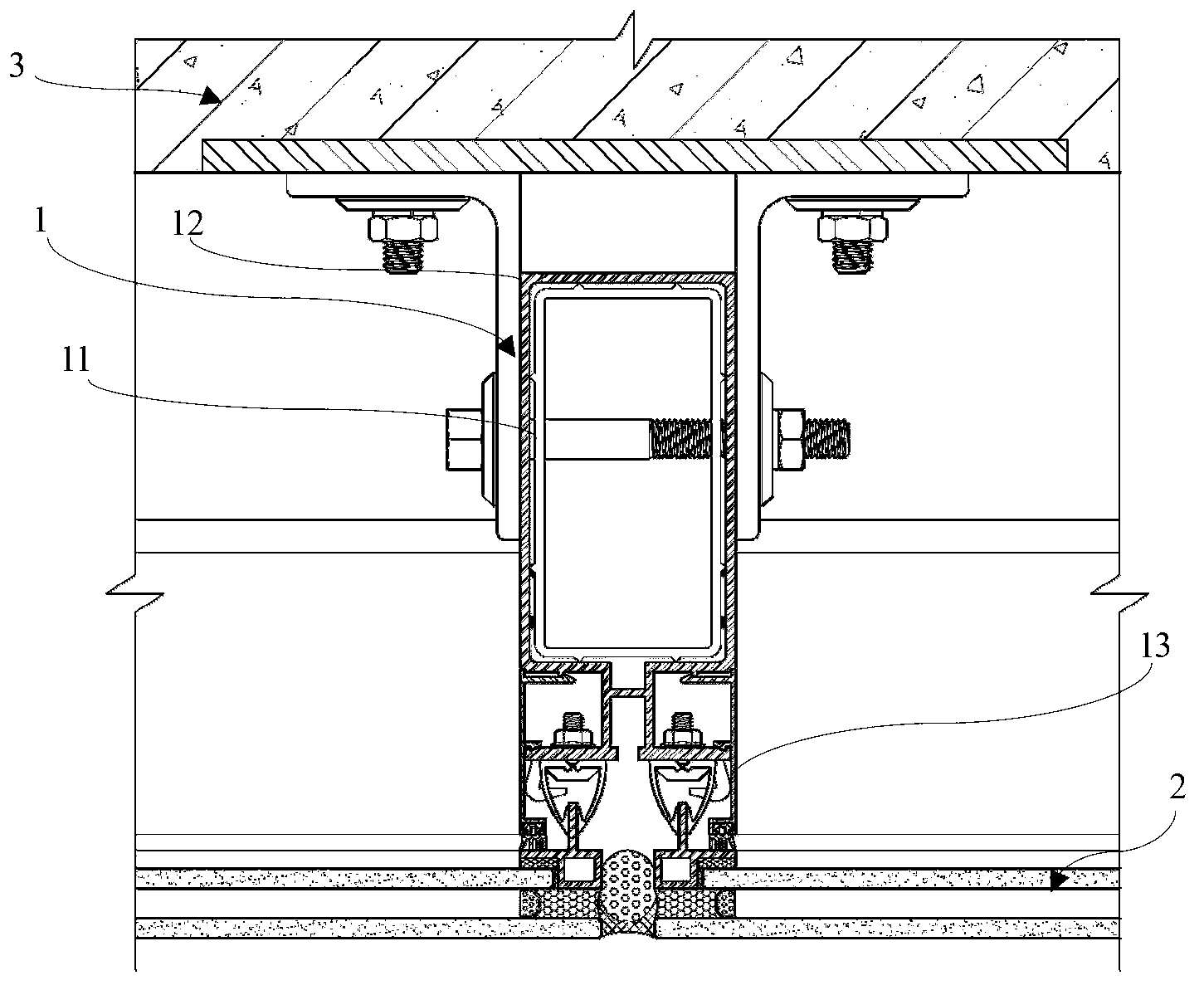

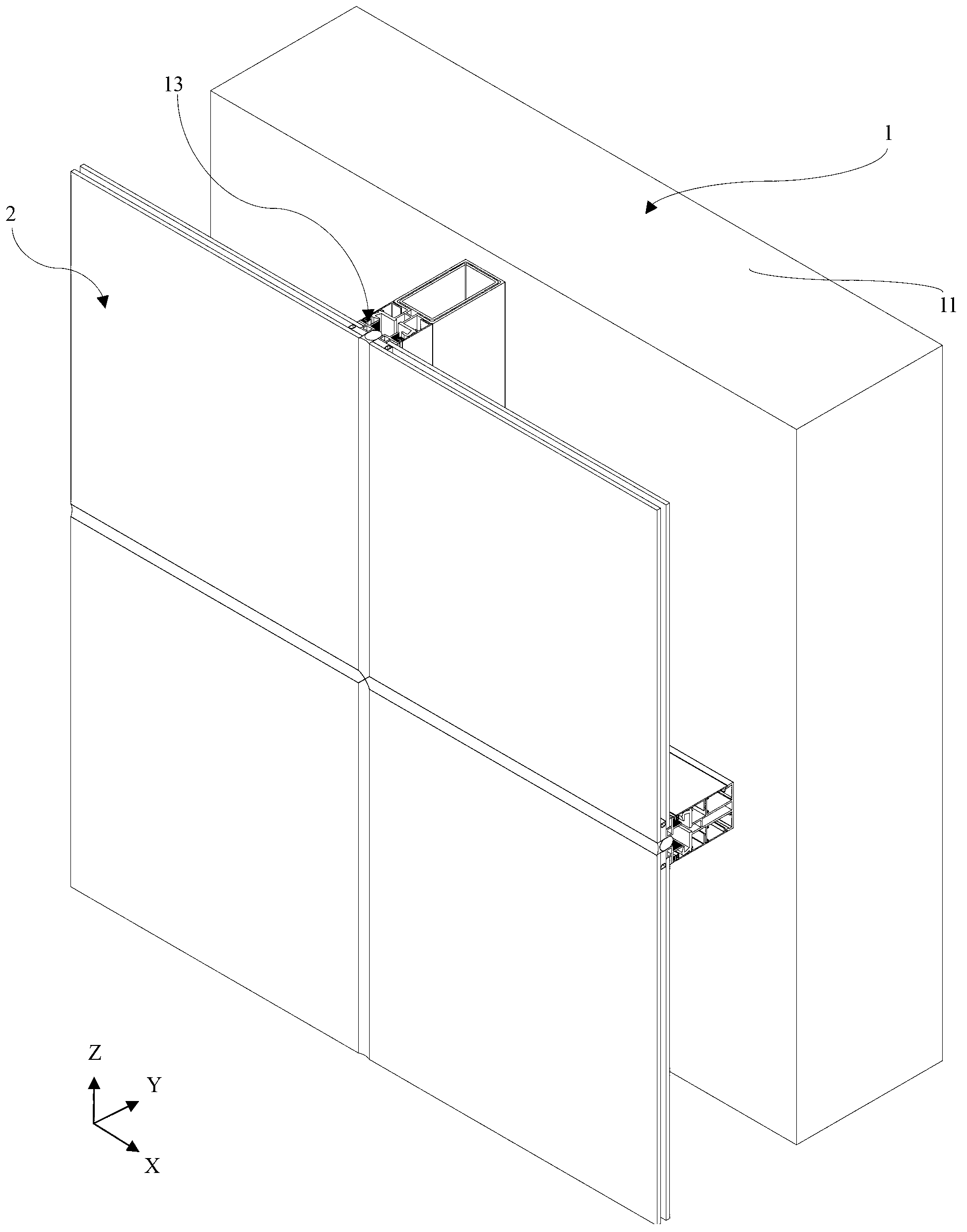

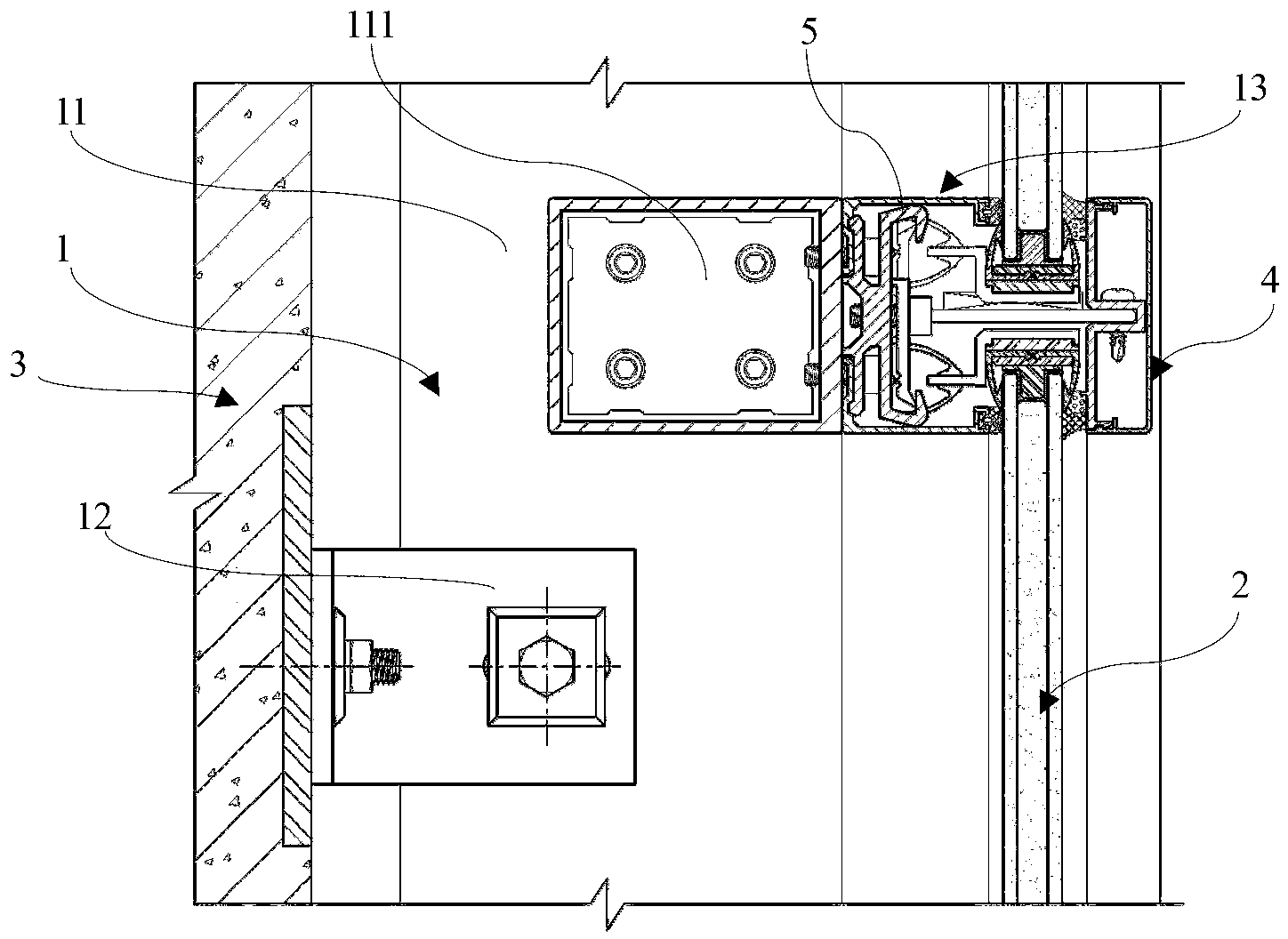

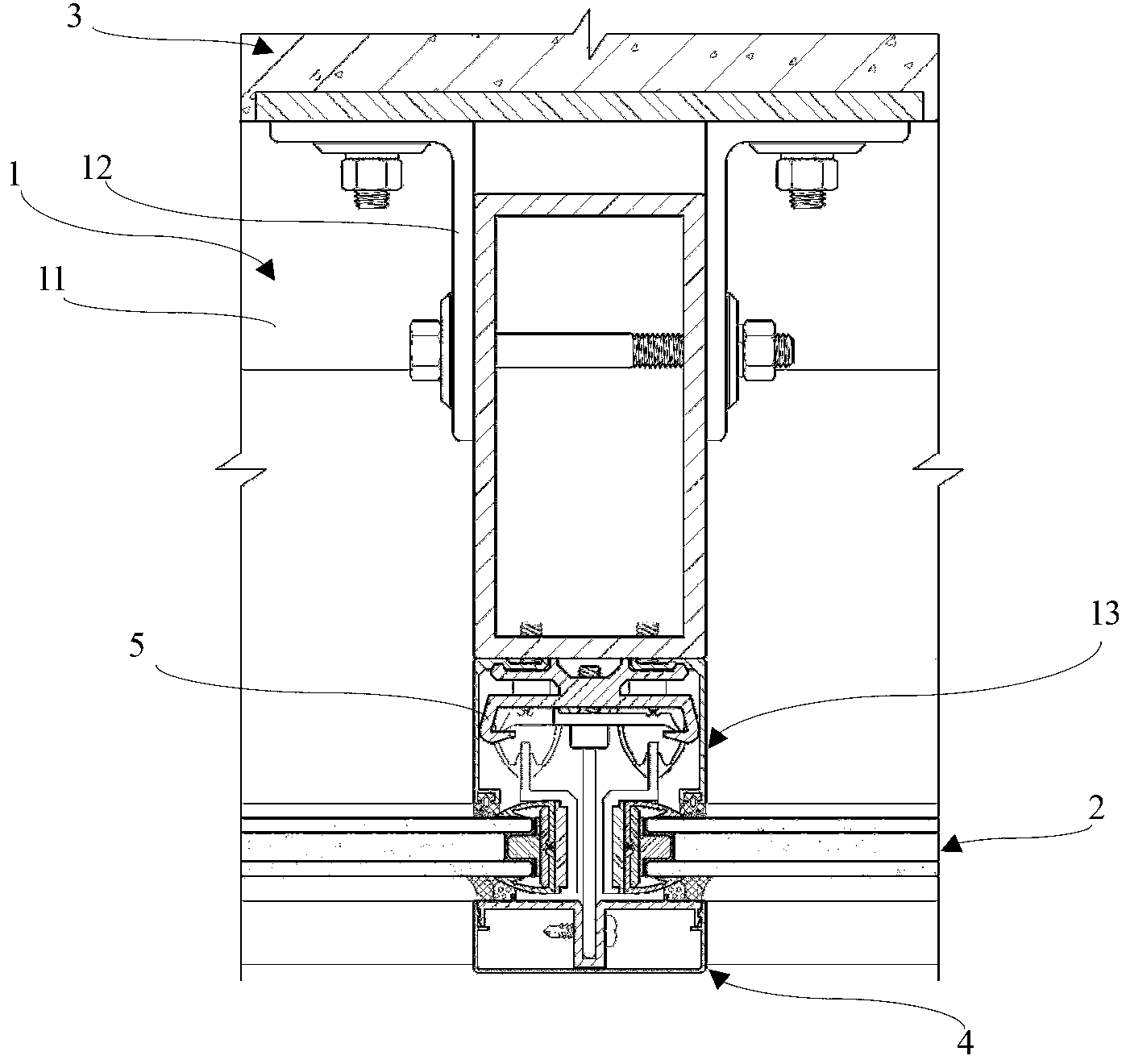

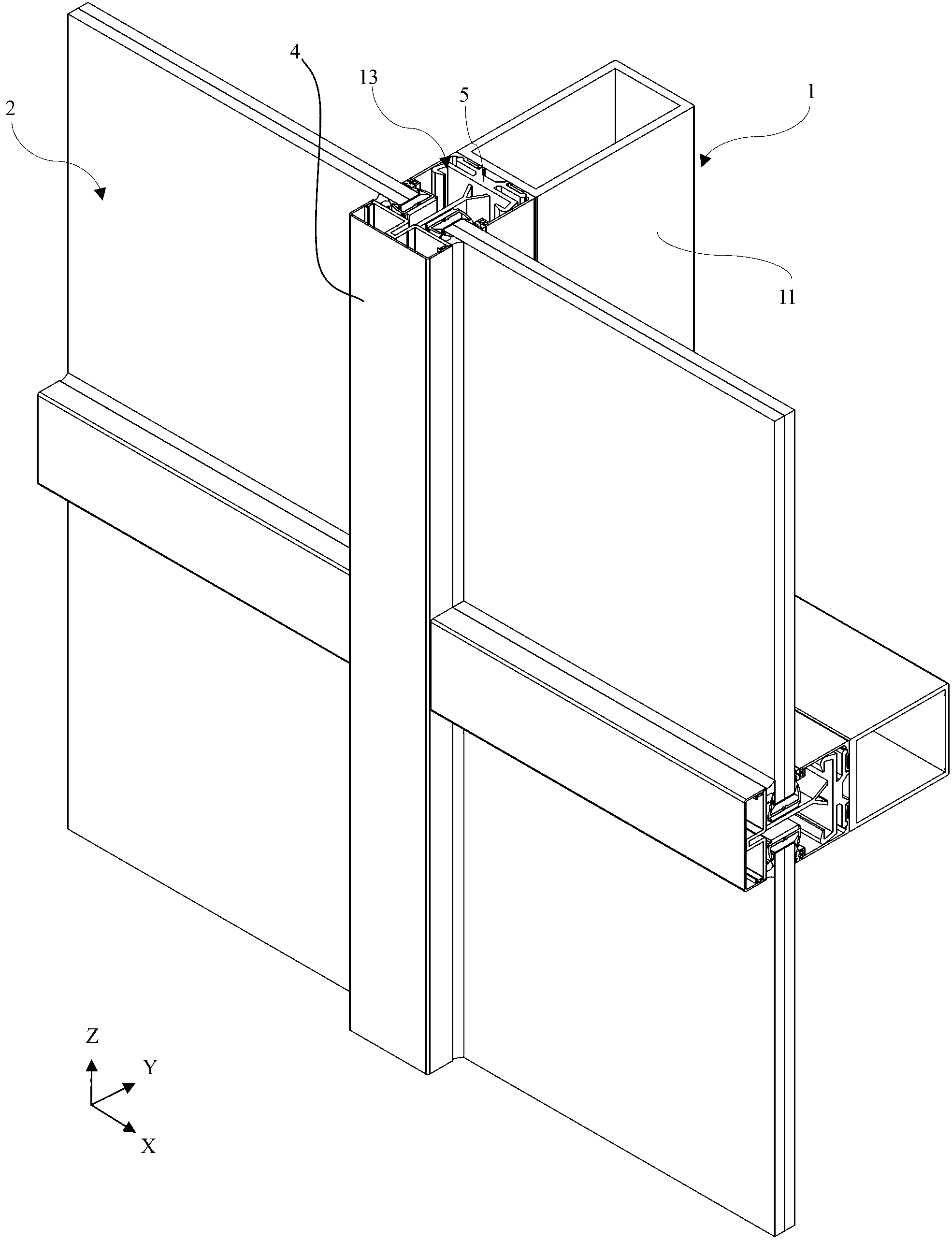

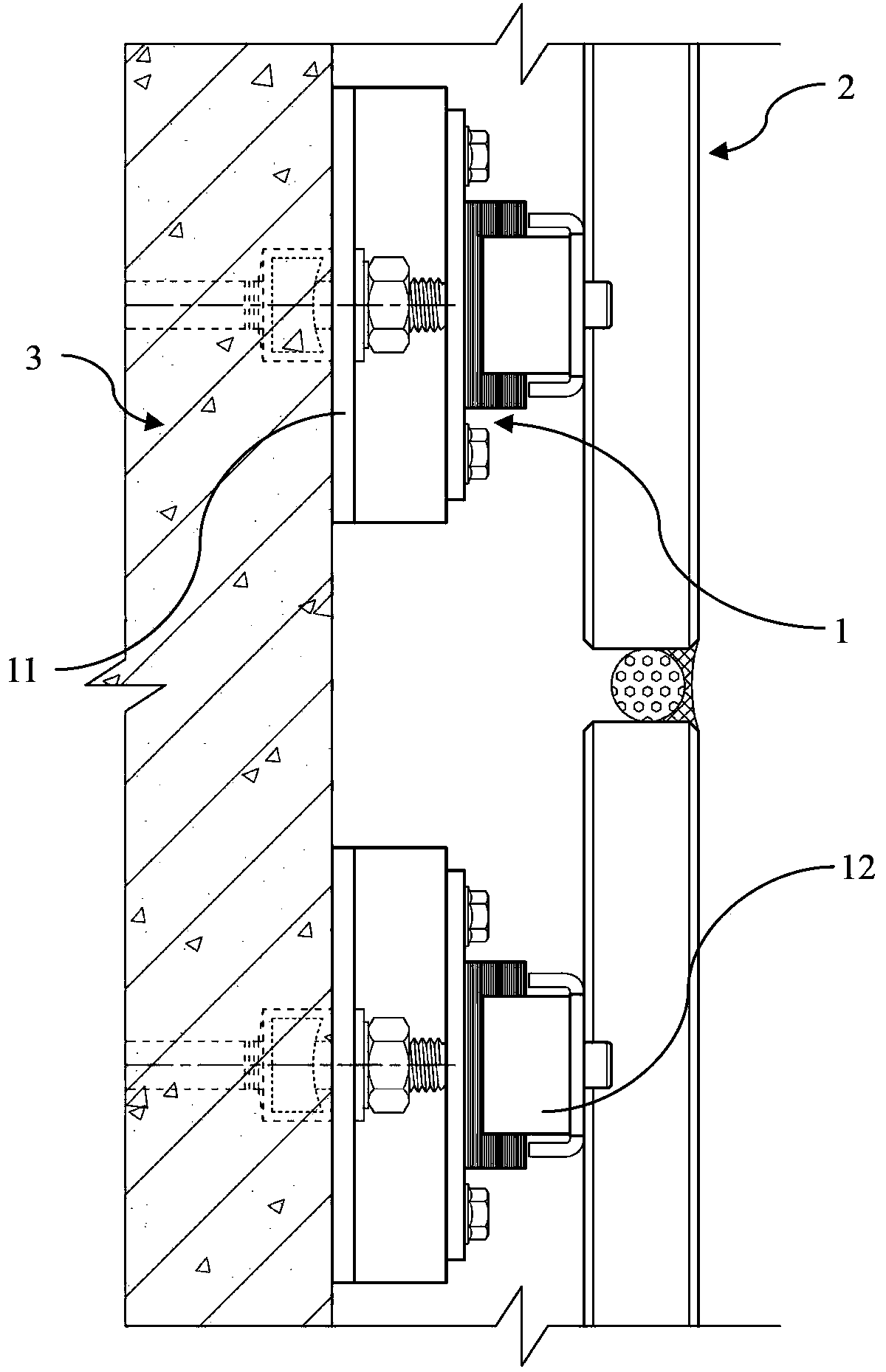

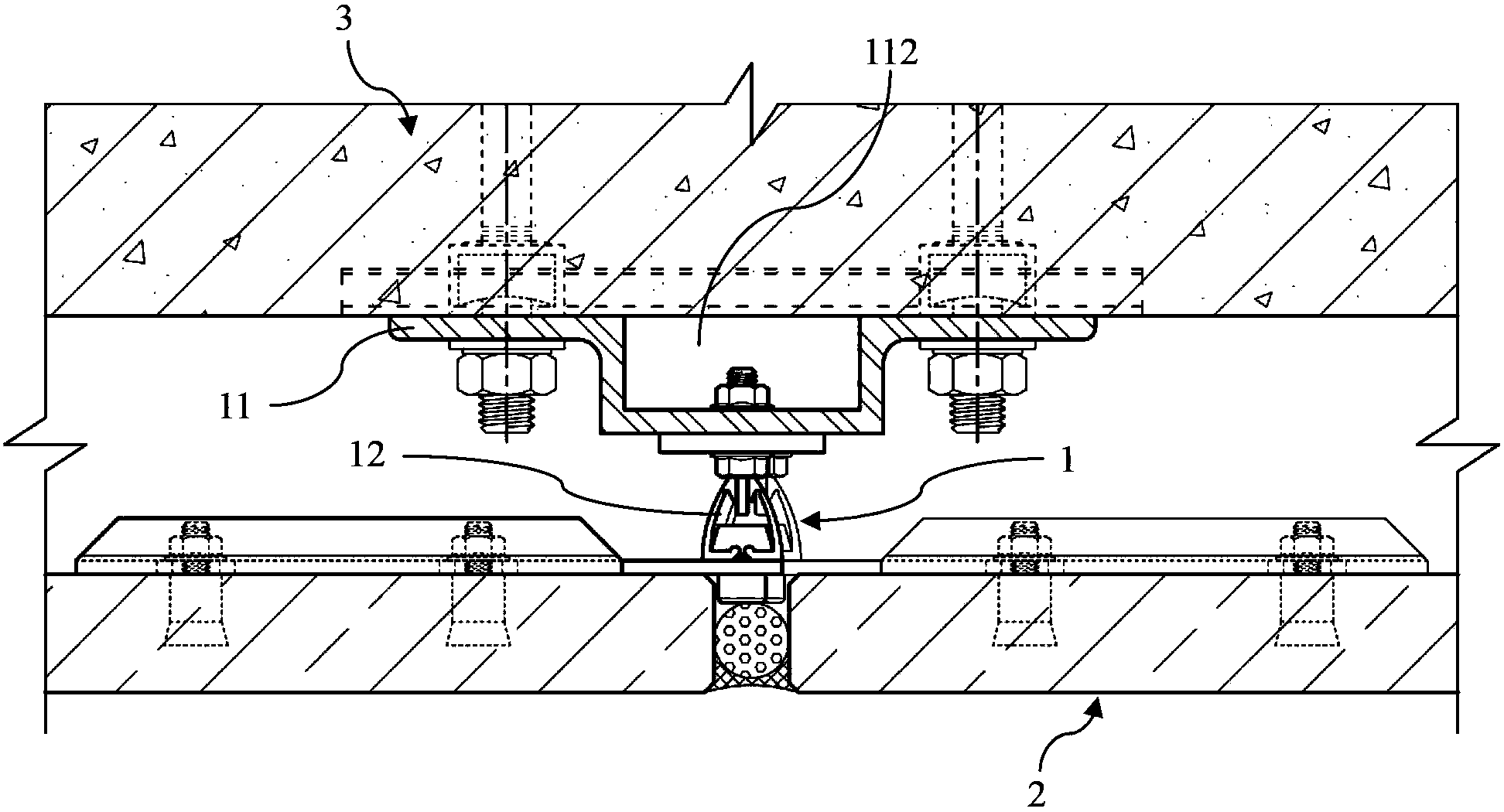

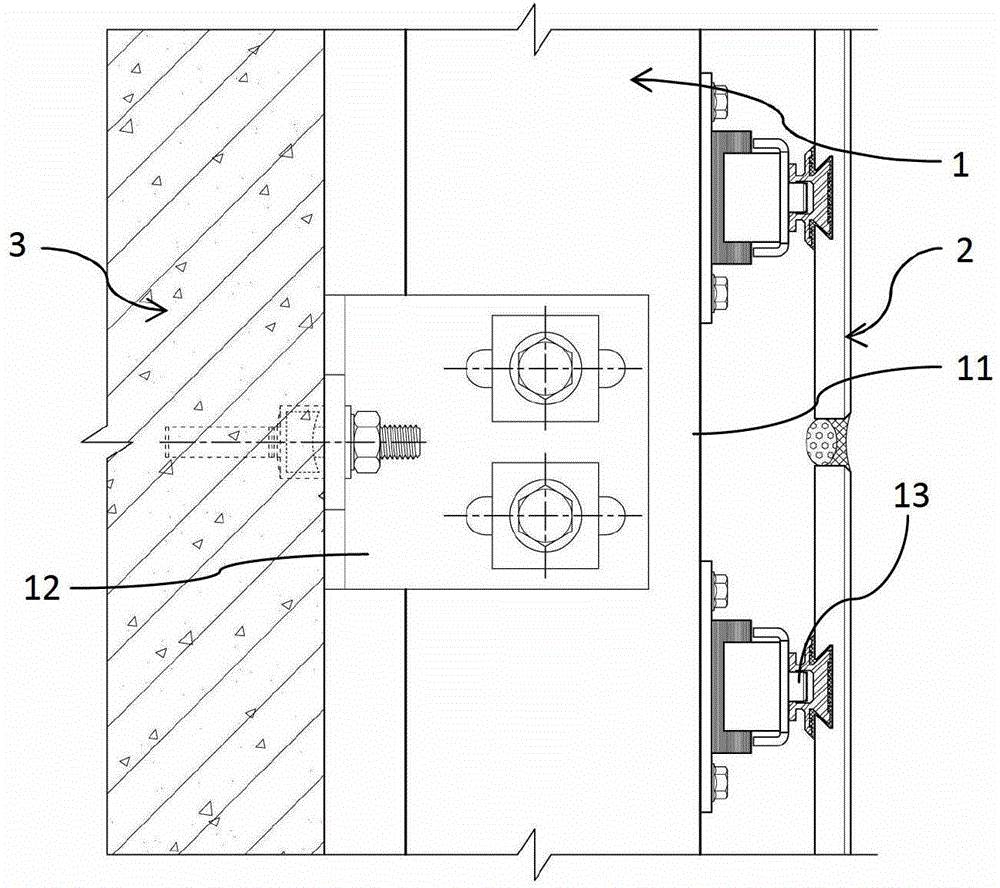

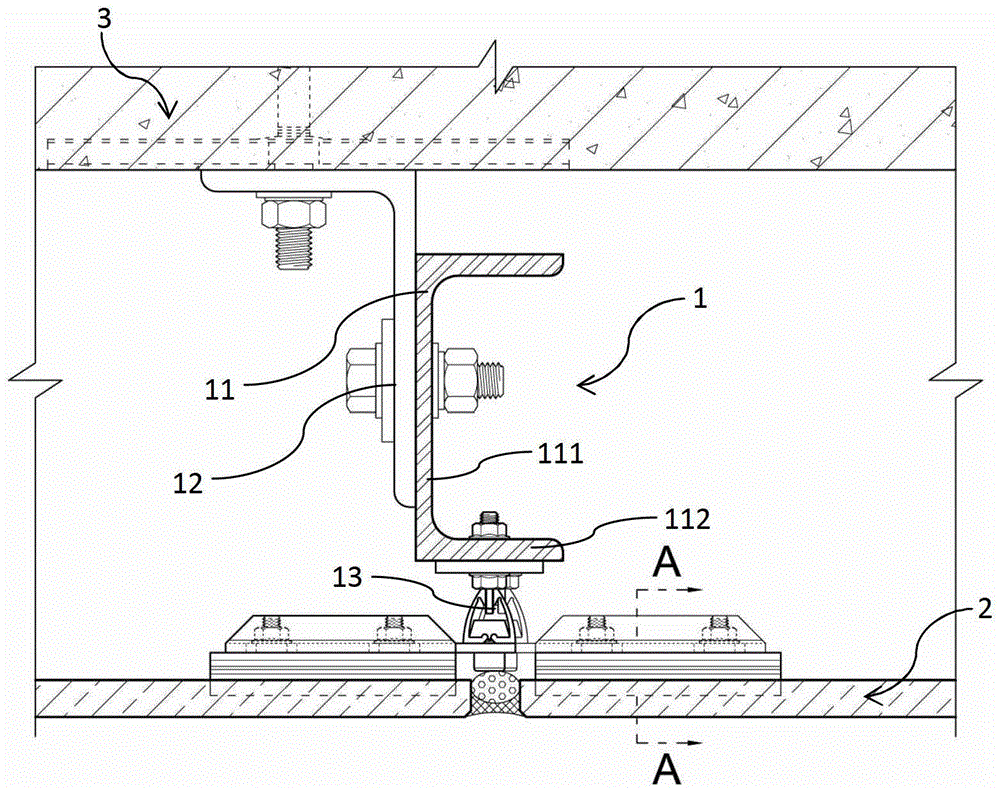

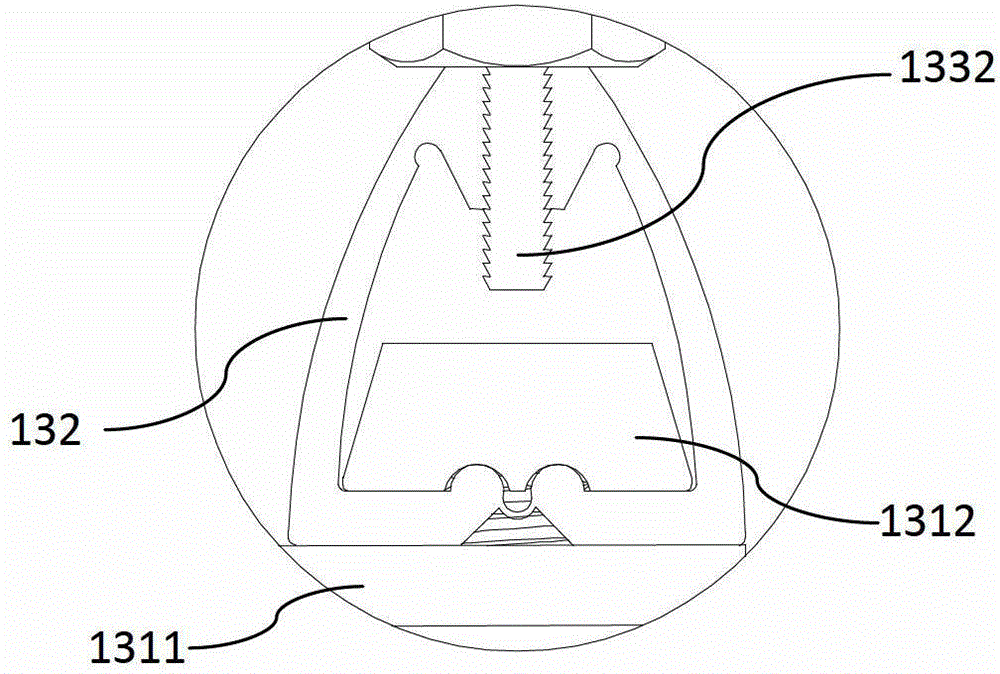

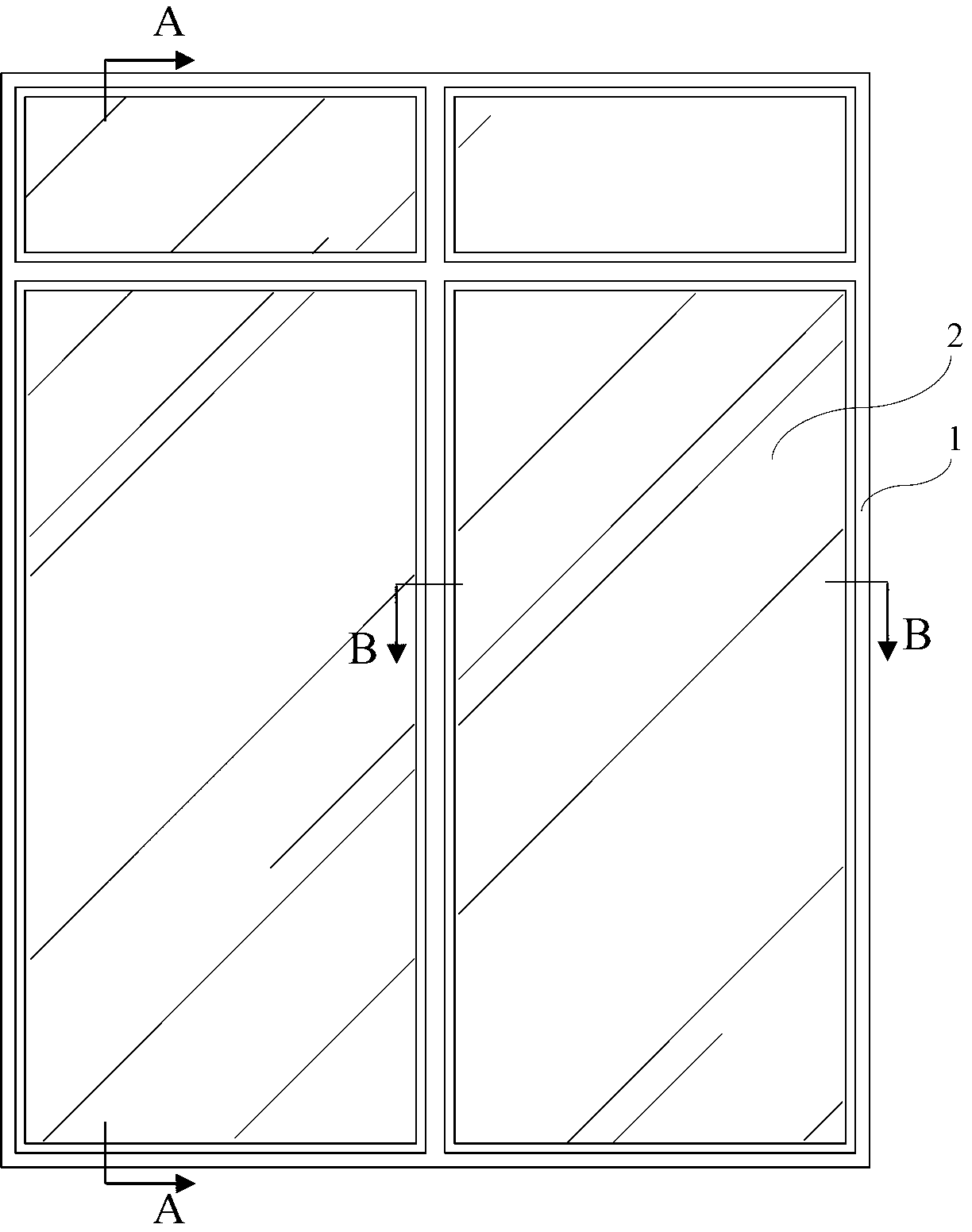

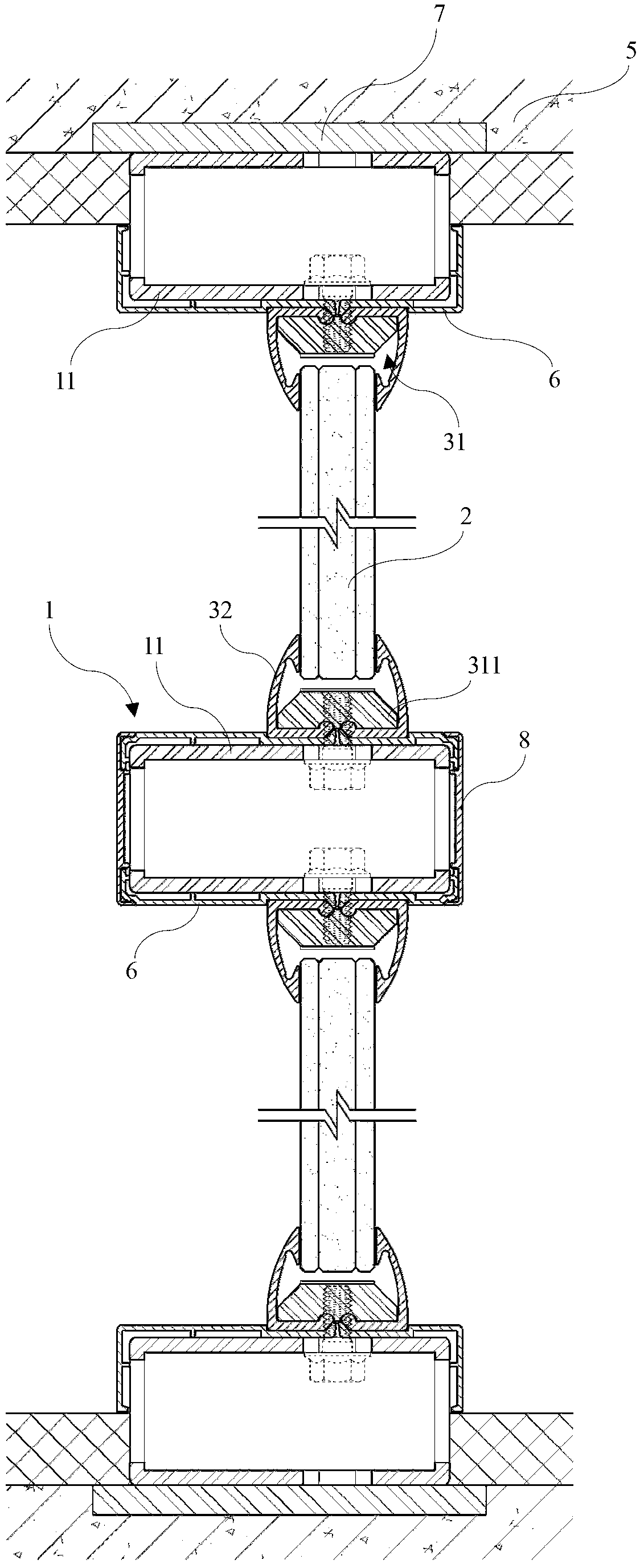

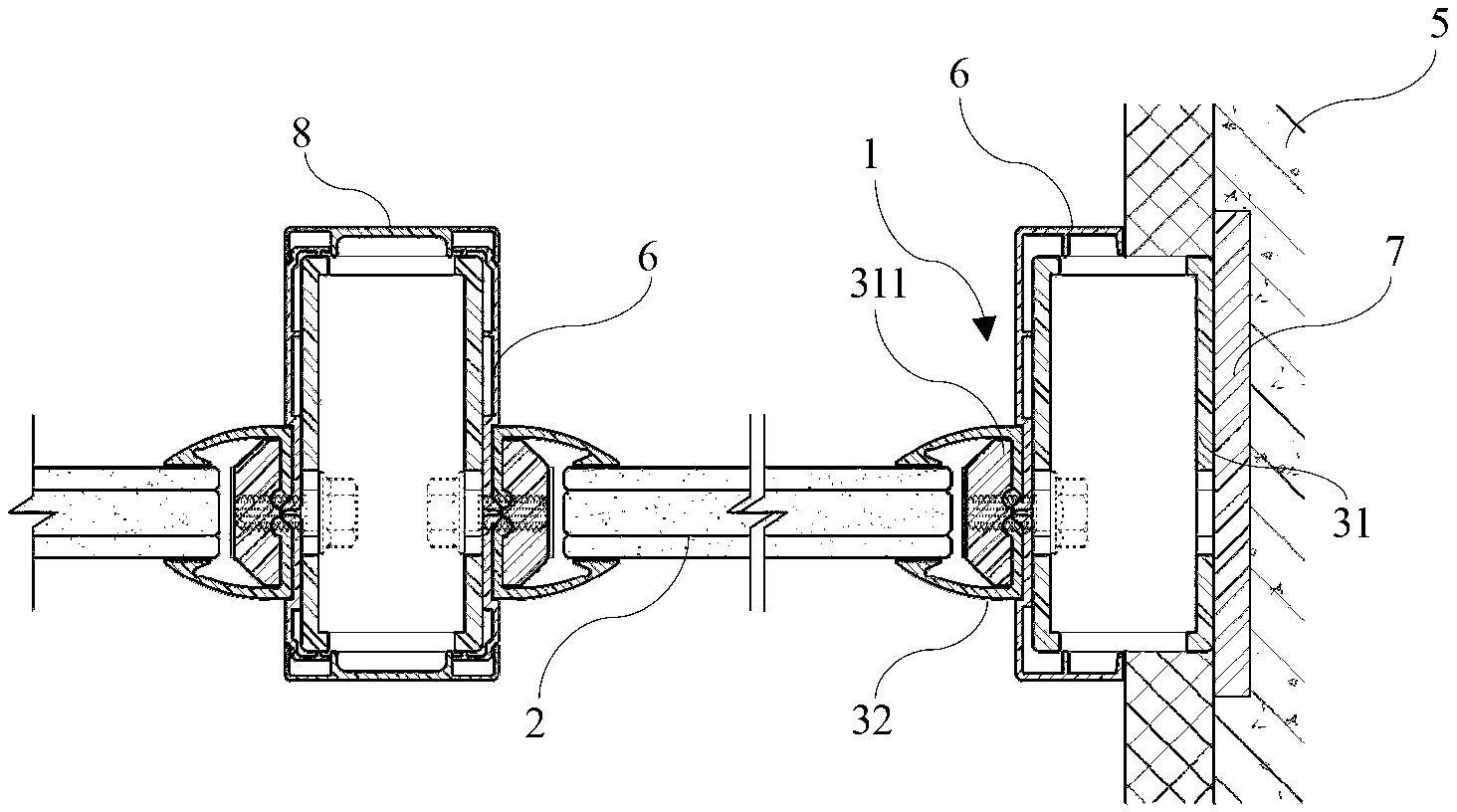

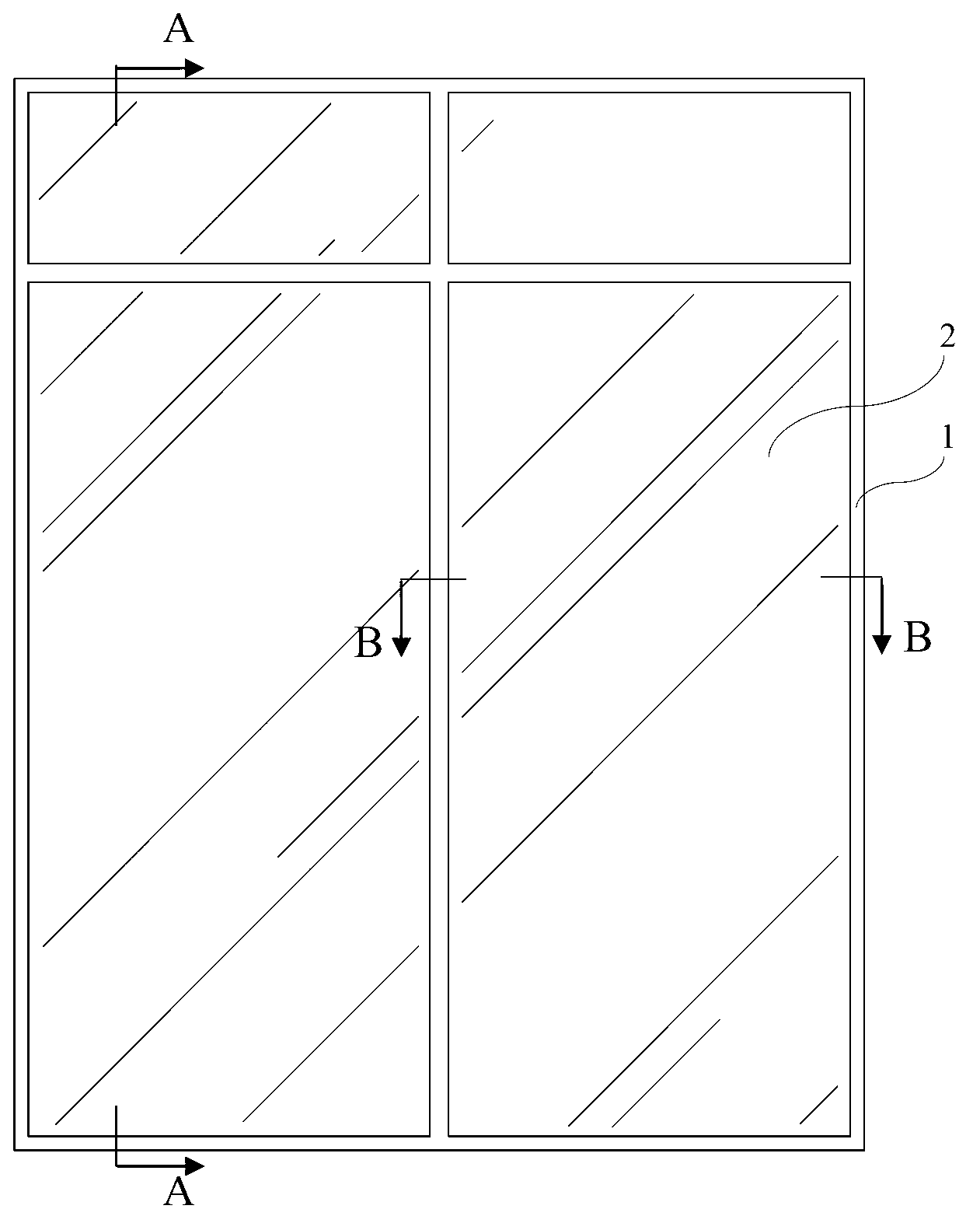

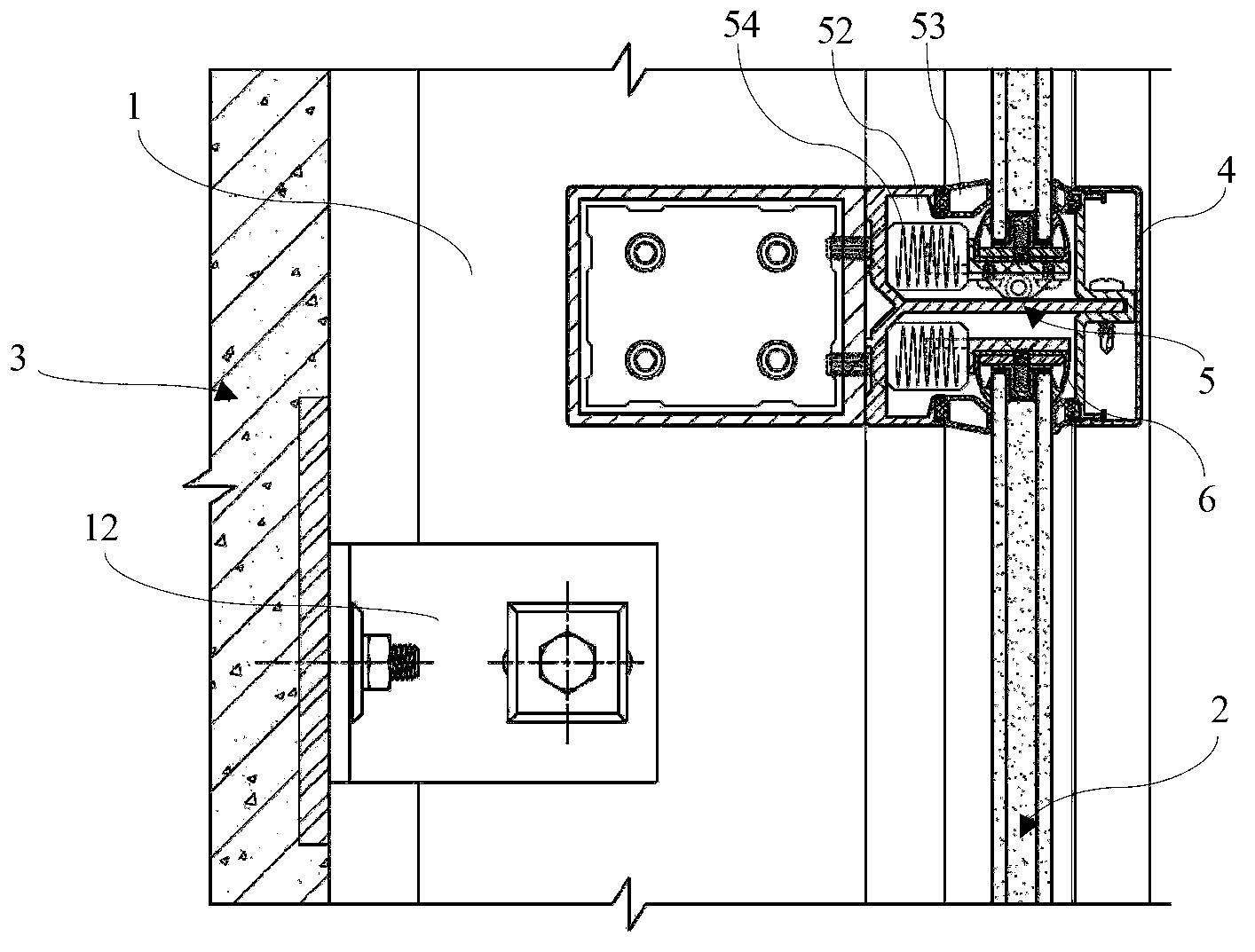

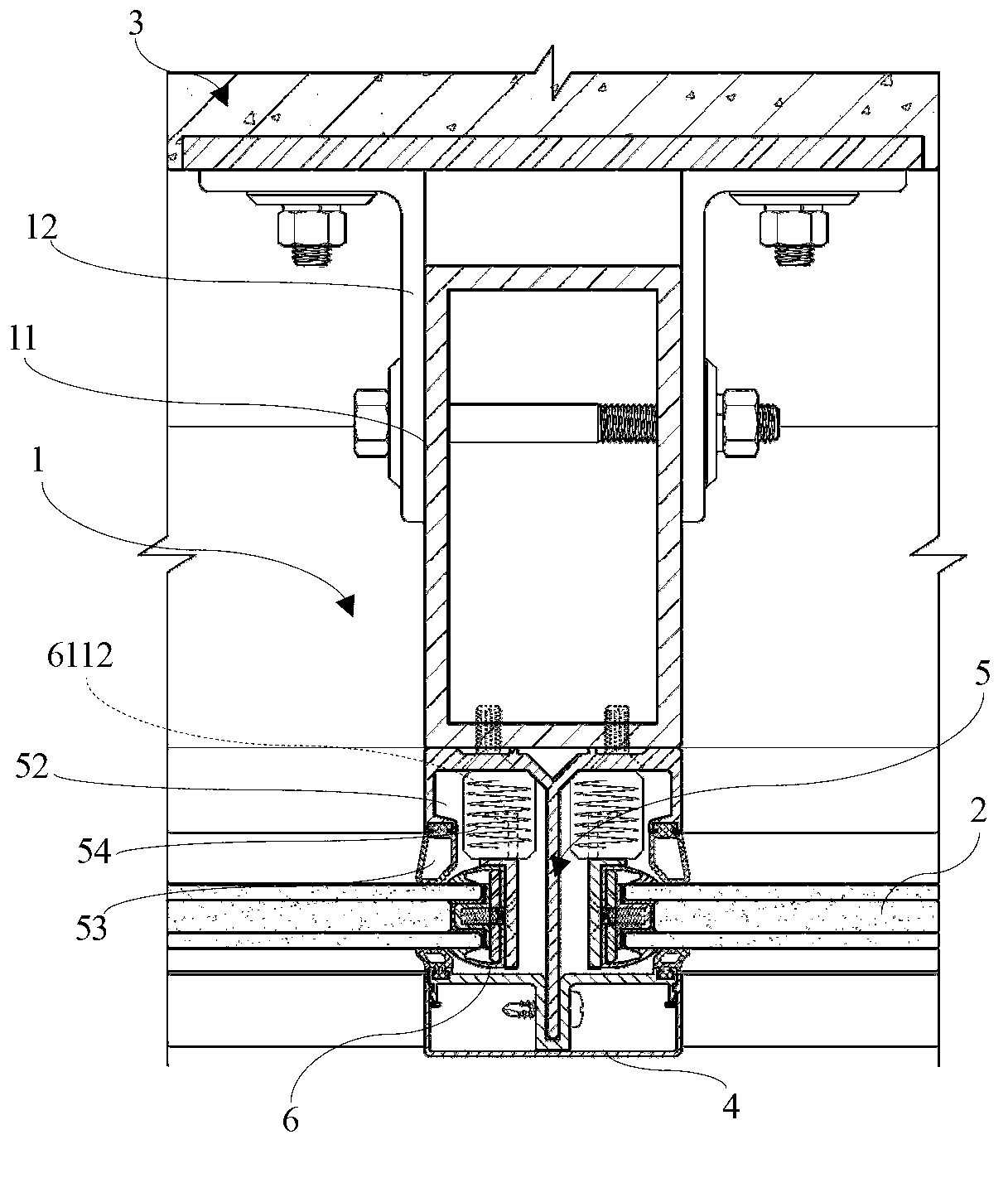

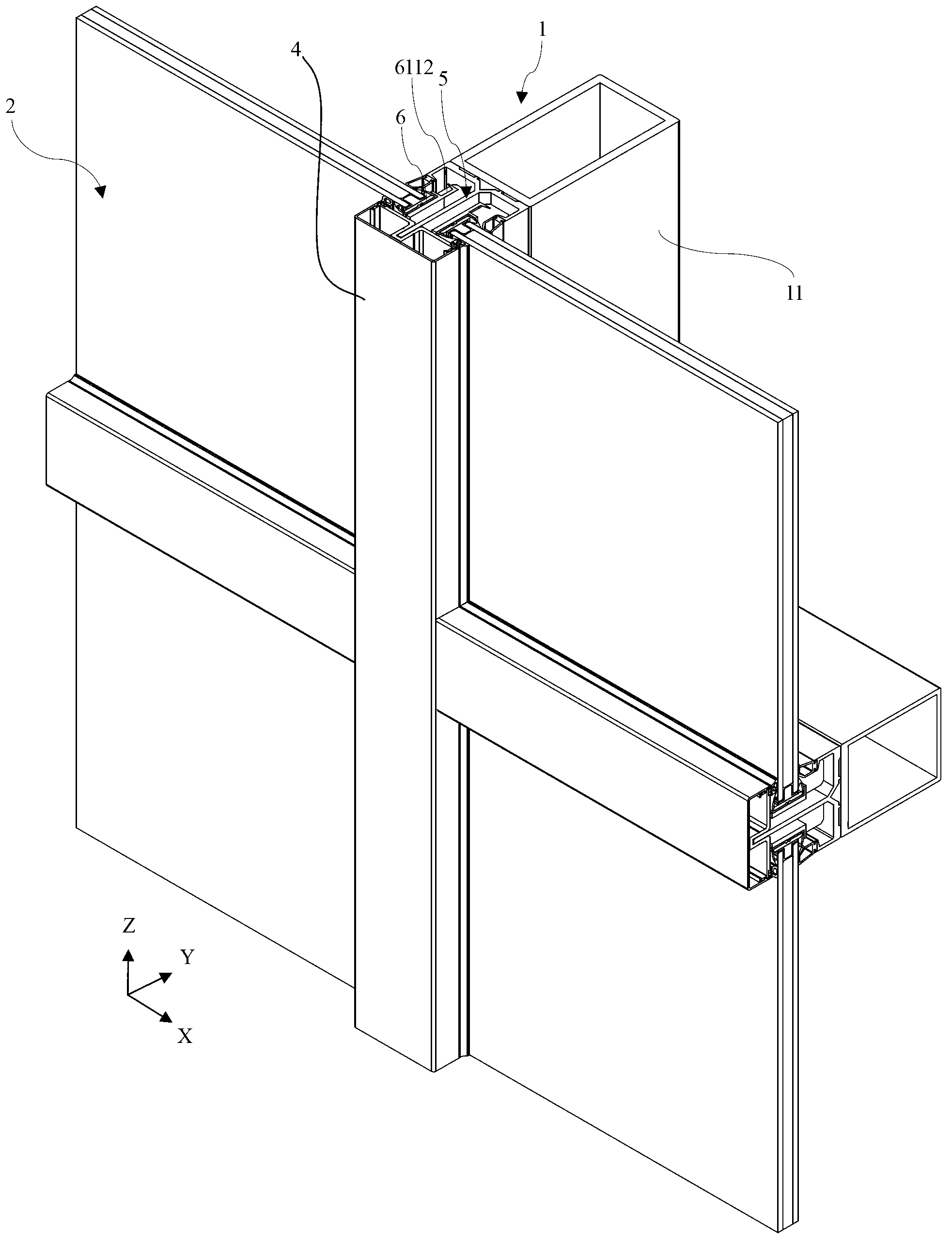

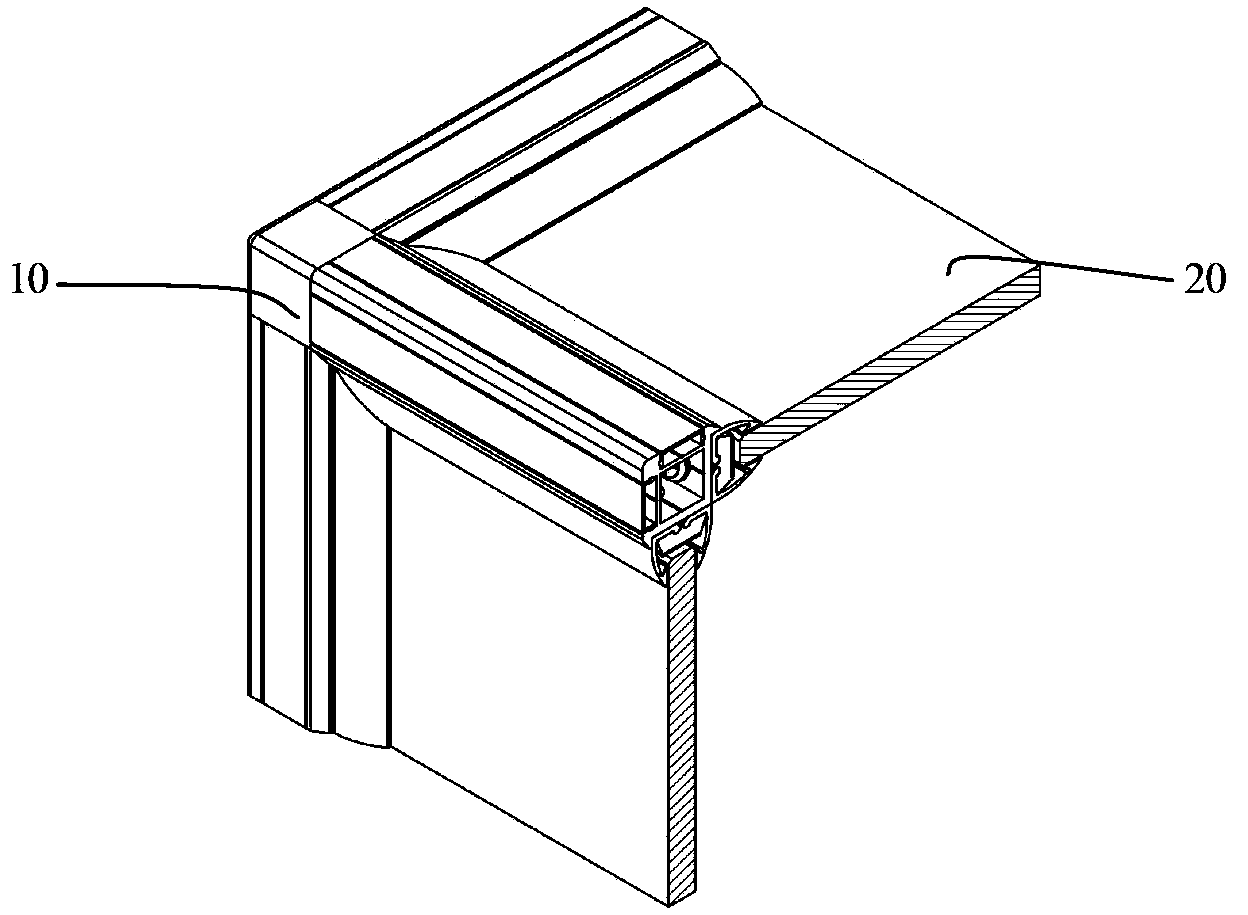

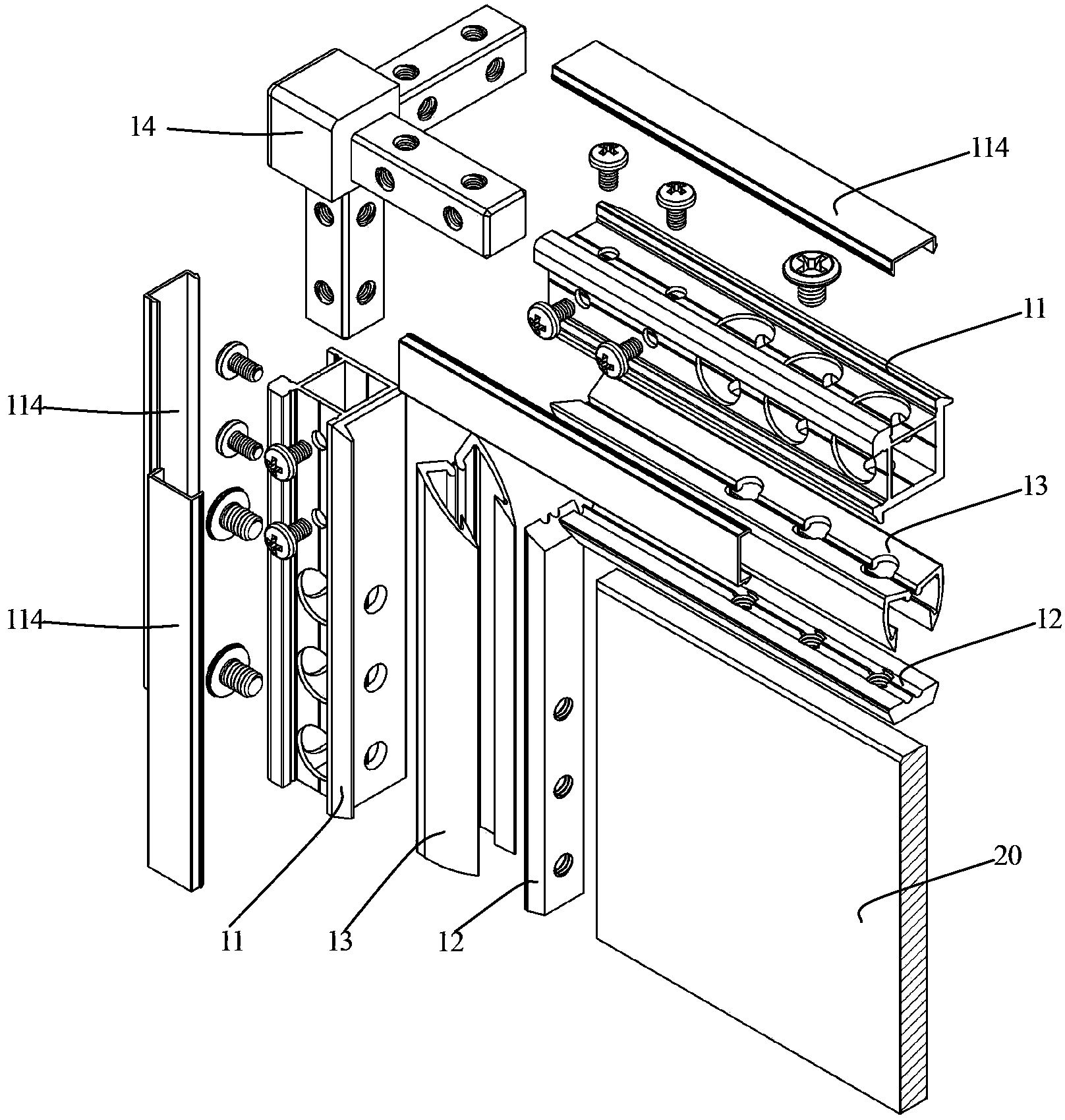

Hidden frame glass curtain wall installation structure and hidden frame glass curtain wall installation method

ActiveCN103306409AEffective prestressed fasteningMeet the requirements of installation accuracyCovering/liningsWallsChassisPrestressed structure

The invention discloses a hidden frame glass curtain wall installation structure which comprises a building main body and a glass curtain wall installed on the building main body, wherein the installation structure further comprises an installation chassis, the glass curtain wall is regulated through the installation chassis to a set position and is fastened, and the position of the glass curtain wall is unchanged in the fastening process. Due to the adoption of the hidden frame glass curtain wall installation structure, the hidden frame glass curtain wall installation structure exciting and controlling the dynamic production process of prestress of an elastic material to form a stable prestress structure and conducting three-dimensional regulation in the installation process to substantially improve the installation accuracy is provided, and the hidden frame glass curtain wall installation structure has the characteristics of excellent firmness, accuracy, safety, convenience and replacement.

Owner:明威科技集团股份有限公司

Fluid catalytic cracking catalyst having desulfurizing functions, process for production of the same, and process for production of low-sulfur catalytically cracked gasoline with the catalyst

InactiveUS20090230023A1Efficient productionMaximum functionCatalytic crackingMolecular sieve catalystsClay mineralsReverse osmosis

The present invention 1, 2 or 3 provides a desulfurization function-added FCC catalyst which can efficiently reduce the sulfur content of FCC gasoline while maintaining the yield of FCC gasoline in a process of producing FCC gasoline by cracking of heavy oil. The catalyst has vanadium supported on a carrier comprising (a) an alumina-coated zeolite and (b) a porous inorganic oxide except zeolite and / or a clay mineral, wherein the supported vanadium amount is from 500 to 20000 ppm by mass in terms of vanadium metal and the acid amount is from 20 to 450 μmol / g and the macropore surface area is from 30 to 150 m2 / g; or the catalyst has vanadium supported on a carrier containing from 5 to 40% by mass of (a) an alumina-coated zeolite and from 30 to 70% by mass of (b) an alumina, wherein the vanadium concentration ratio before and after grinding the catalyst is at least 2; or the catalyst has at least vanadium and manganese and / or phosphorus supported on a porous inorganic oxide-containing carrier, wherein the supported vanadium amount is from 500 to 20000 ppm by mass in terms of vanadium metal, vanadium and manganese and / or phosphorus form a complex ion in the supporting solution for use in supporting vanadium and manganese and / or phosphorus, and the permeability of the complex ion through a reverse osmosis membrane is at most 25% relative to the permeability of vanadium through the reverse osmosis membrane.

Owner:IDEMITSU KOSAN CO LTD +1

Mounting structure of anti-explosion glass curtain wall and curtain wall glass mounting method

ActiveCN103290960AReduce technical difficultyReduce operation links and contentWallsWar-like protectionPrestressed structureUltimate tensile strength

The invention discloses a mounting structure of an anti-explosion glass curtain wall. The mounting structure comprises a building body, curtain wall glass mounted on the building body and a mounting base plate, a decorating frame is covered on the outer wall surface of the curtain wall glass, the curtain wall glass is adjusted to a preset position via the mounting base plate and then fastened, the position of the curtain wall glass is not changed during fastening, and the decorating frame is fixed on the mounting base plate via a mounting piece. The curtain wall glass with edges covered by a prestressed structure is firmly fastened via a stand column and crossbeam frame, and in case of glass crushing or deformation caused by impact, and the glass cannot be integrally separated from the stand column and crossbeam frame, so that anti-explosion and separation functions are effectively realized, and indoor persons are protected to the greatest extend; since profile steel serving as the stand column and crossbeam frame is adopted to replace an existing aluminum profile frame, strength and rigidity of a whole curtain wall bearing system are greatly enhanced, and the anti-explosion glass curtain wall structure is stronger in capability for bearing impact loads from explosion and the like and good in safety performance.

Owner:珠海博曼建筑科技有限公司

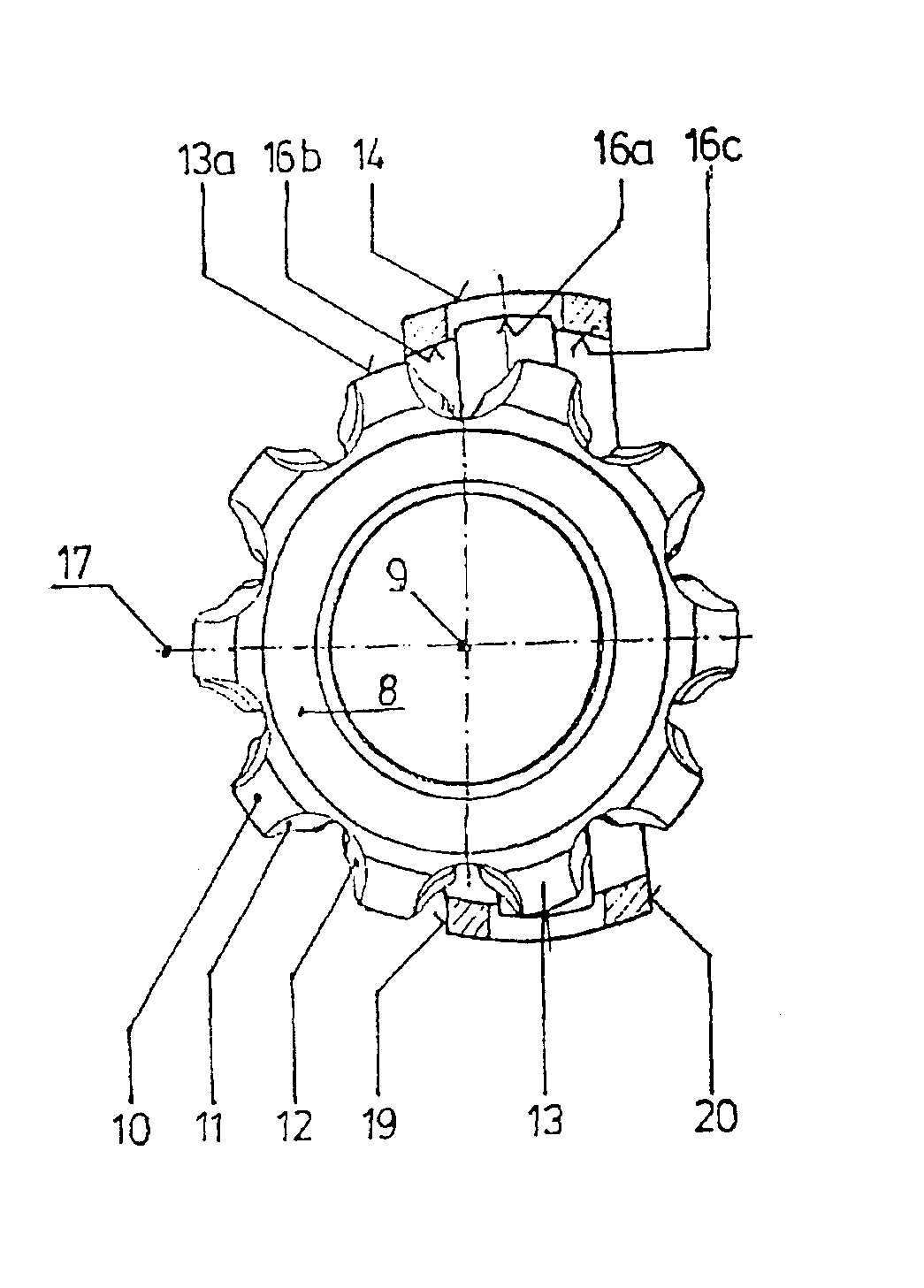

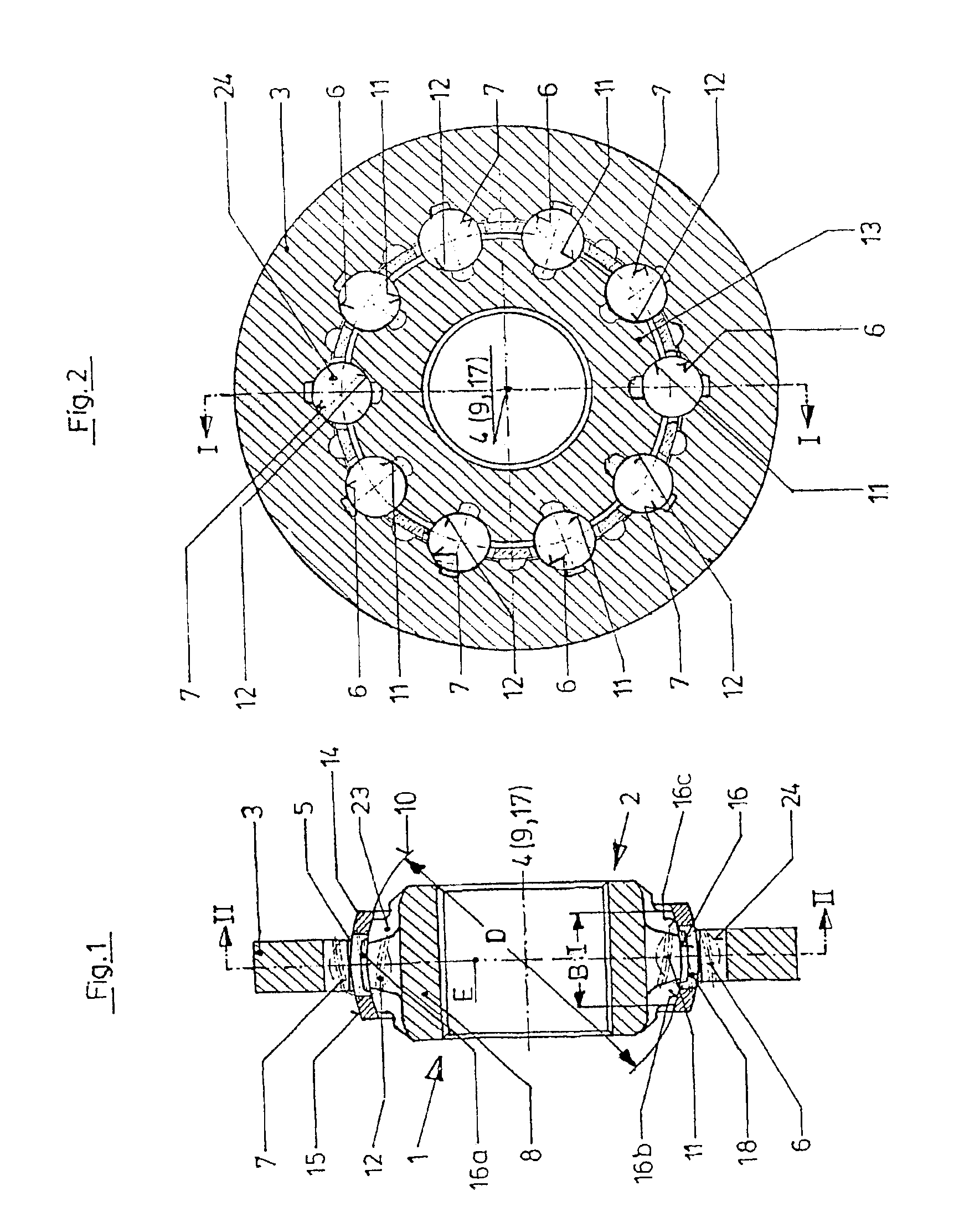

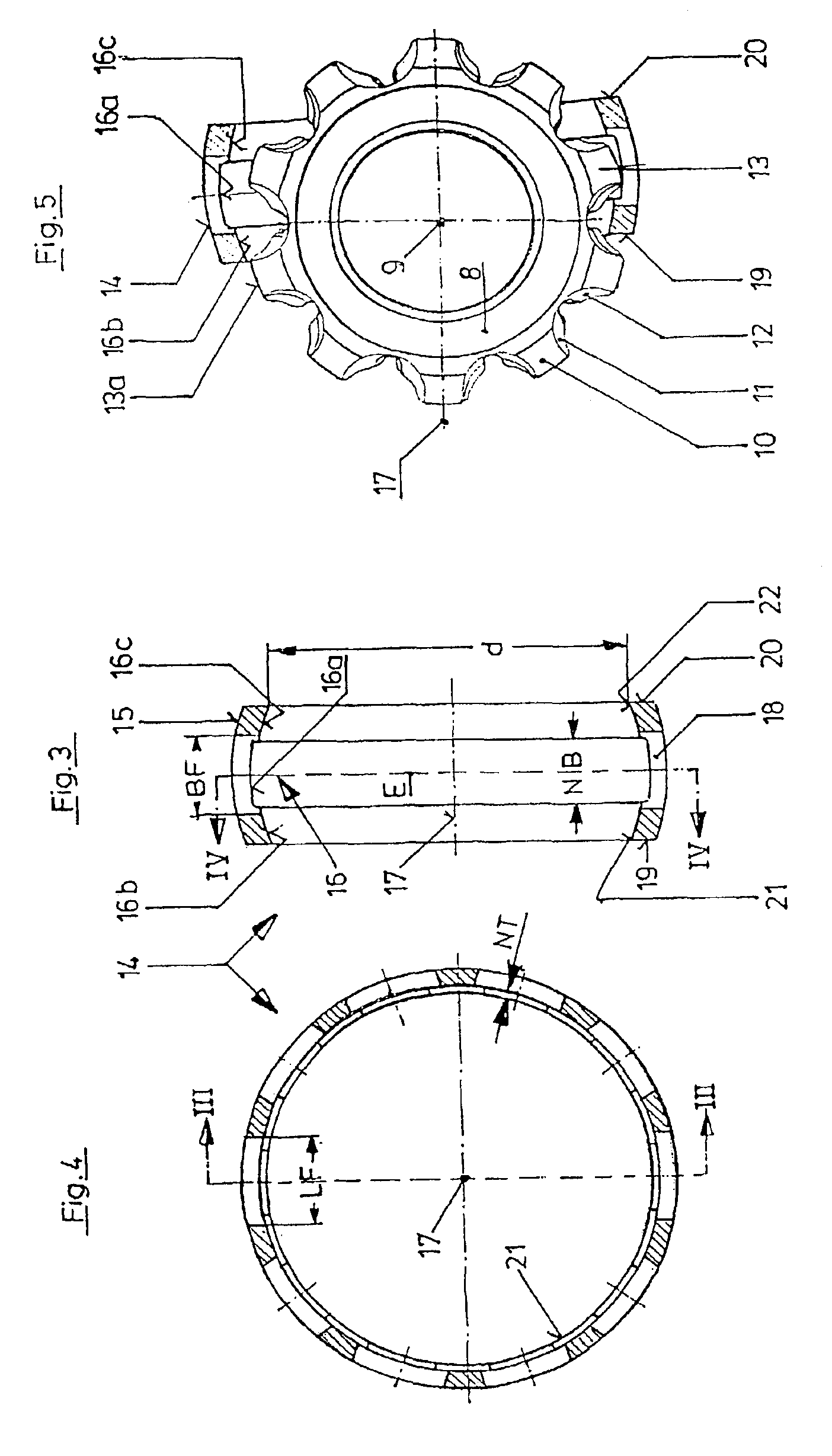

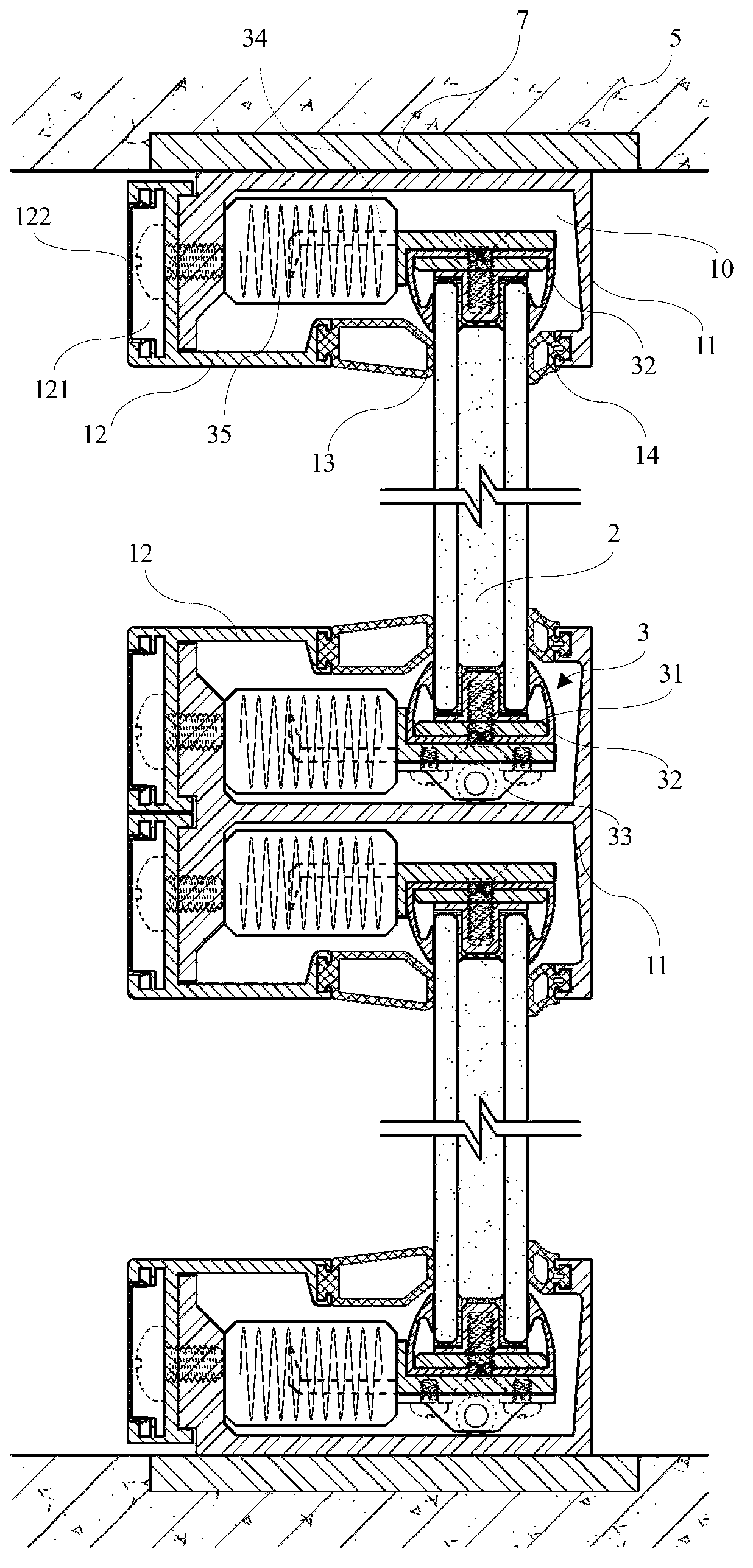

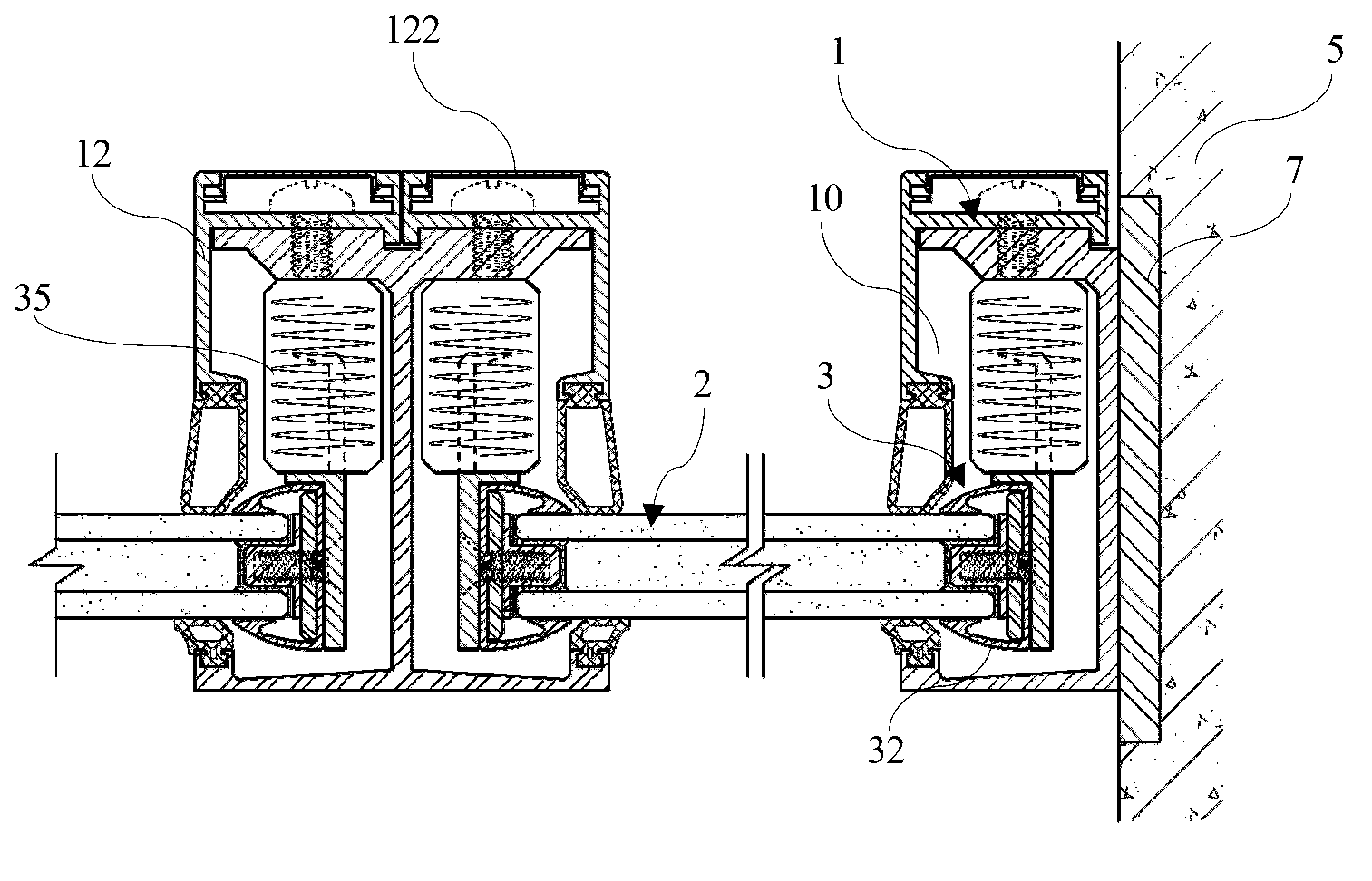

Homocinetic joint

InactiveUS6893352B2Avoid attenuationReduce operating conditionsClutchesYielding couplingEngineeringSacroiliac joint

The invention relates to a constant velocity joint having an outer part (3), an inner part (8), a cage (14) and balls (24). For the purpose of fitting the inner part (8) in the cage (14), there is provided a groove (16a) which can be entered by the inner part (8) by means of the web (13), so that the inner part (8) can be introduced into the cage (14), although the outer diameter of the inner part (8) is greater than that of the end aperture of the cage (14).

Owner:GKN LOBRO

Catalytic agent for synthesizing succinic acid through maleic acid hydrogenation and preparation method thereof

InactiveCN102430404AImprove stabilityHigh activityCarboxylic preparation by ozone oxidationMetal/metal-oxides/metal-hydroxide catalystsActive componentDistilled water

The invention relates to a catalytic agent for synthesizing succinic acid through maleic acid hydrogenation; the catalytic agent comprises the following components in percent by weight: 0.1-10% of active component ruthenium and 80-99.9% of acid resistance carrier. A preparation method of the catalytic agent comprises the following steps of: uniformly mixing a ruthenium chloride solution with the concentration of 0.1-50.0mg / ml and the carrier, adding an alkaline solution into mixed liquor under stirring at the temperature of 15-95 DEG C, adjusting pH value to be 6-14, and then maintaining for 0.5-24h; filtering the mixed liquor, washing solid precipitates by using distilled water till Cl <-> does not exist, drying naturally, and then feeding reducing gas at the temperature of 150-450 DEG C and reducing for 1-24h, wherein space velocity of the reducing gas is 200-100h<-1>, and obtaining the ruthenium catalytic agent. The catalytic agent has the advantages of good stability, low cost, high activity and high selectivity.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

A kind of conductive silicone rubber adhesive formed at room temperature and its application method

InactiveCN102277128AImprove conductivityReduce operating conditionsNon-macromolecular adhesive additivesElectrically-conducting adhesivesSilicone resinChemistry

The invention provides a conductive silicone rubber adhesive formed at room temperature on site. The adhesive includes component A and component B. The component A includes: 400-1000 parts by weight of metal-based conductive filler, 20-80 parts by weight of vinyl-terminated polysiloxane, 20-80 parts by weight of ethylene base silicone resin, 0.01~1 weight part of Karstedt catalyst; the component B includes: 400~1000 parts by weight of metal-based conductive filler, 20~80 parts by weight of vinyl-terminated polysiloxane, 20~80 parts by weight of vinyl silicon Resin, 10-35 parts by weight of hydrogen-containing silicone oil, and 0.01-1 part by weight of inhibitor. The invention has the characteristics of high conductivity and low operating conditions, and the formed conductive layer has reliable bonding, long service life, good sealing performance, vibration resistance, and high and low temperature impact resistance. The present invention also provides a method for using the above-mentioned room temperature in-situ forming conductive silicone rubber adhesive. The adhesive includes component A and component B. The ratio is thoroughly mixed. Easy to use, can be molded on site, cured at room temperature, not affected by the thickness of the adhesive layer.

Owner:JIANGSU NANOWELL ADVANCED MATERIALS SCI&TECH

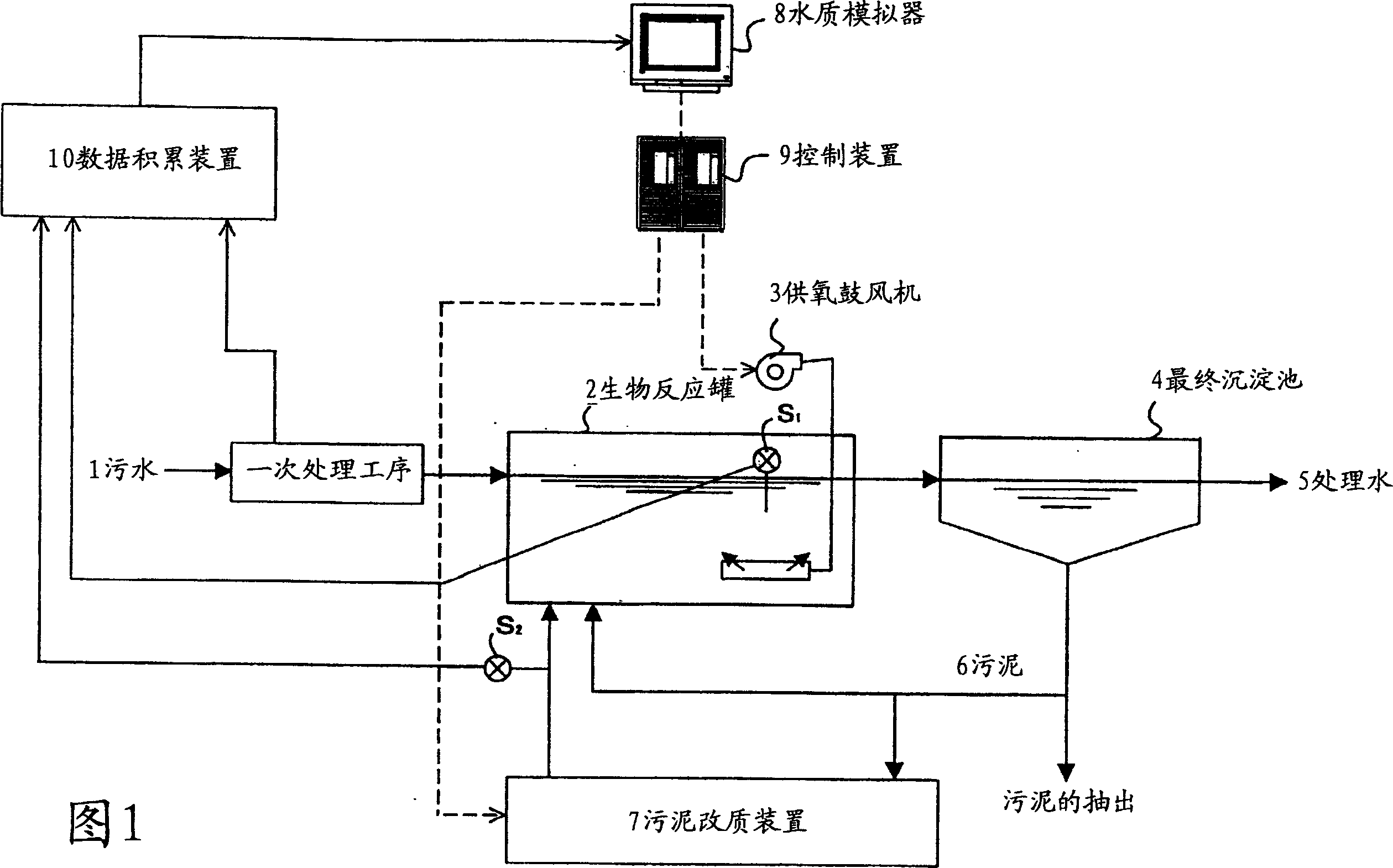

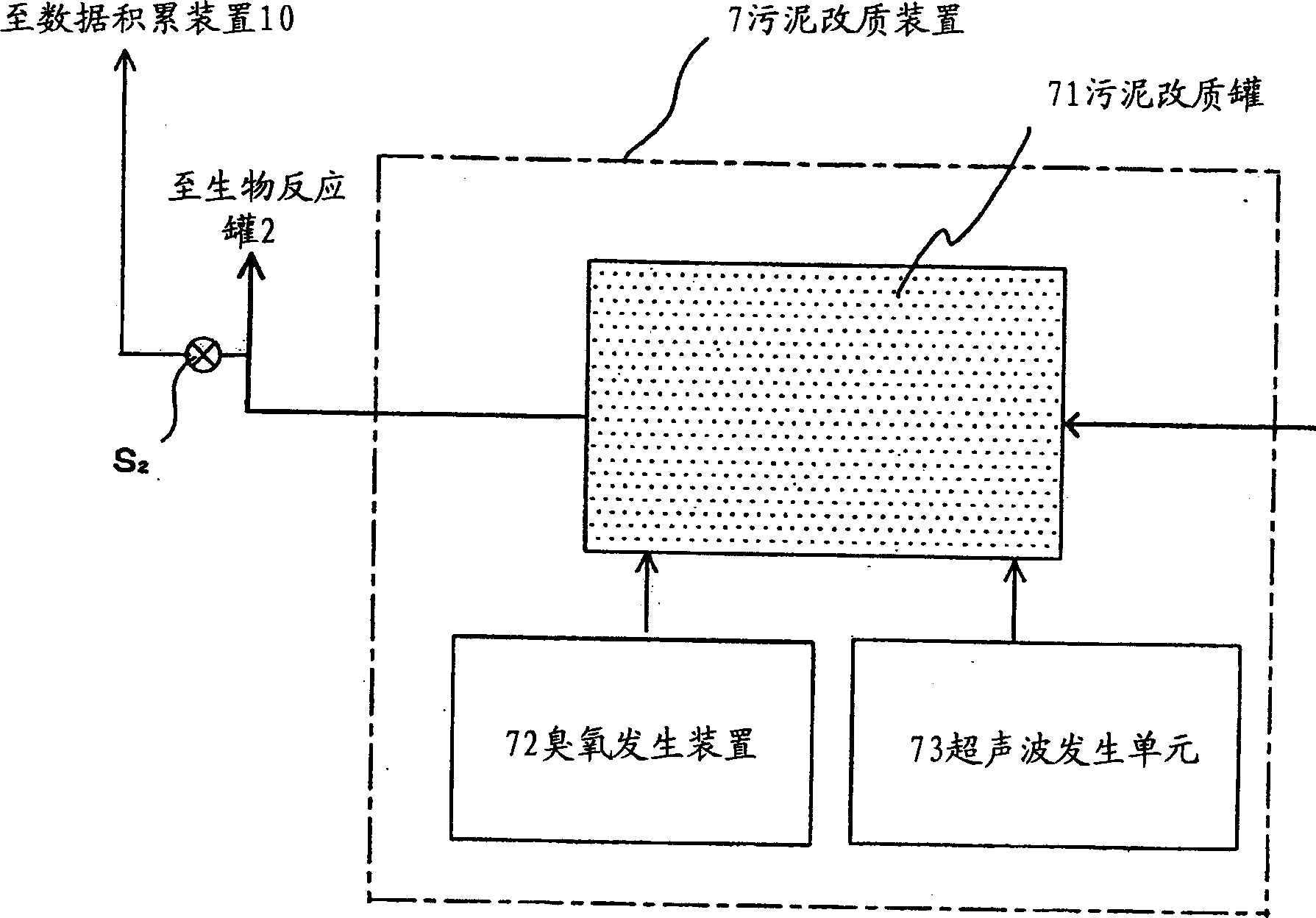

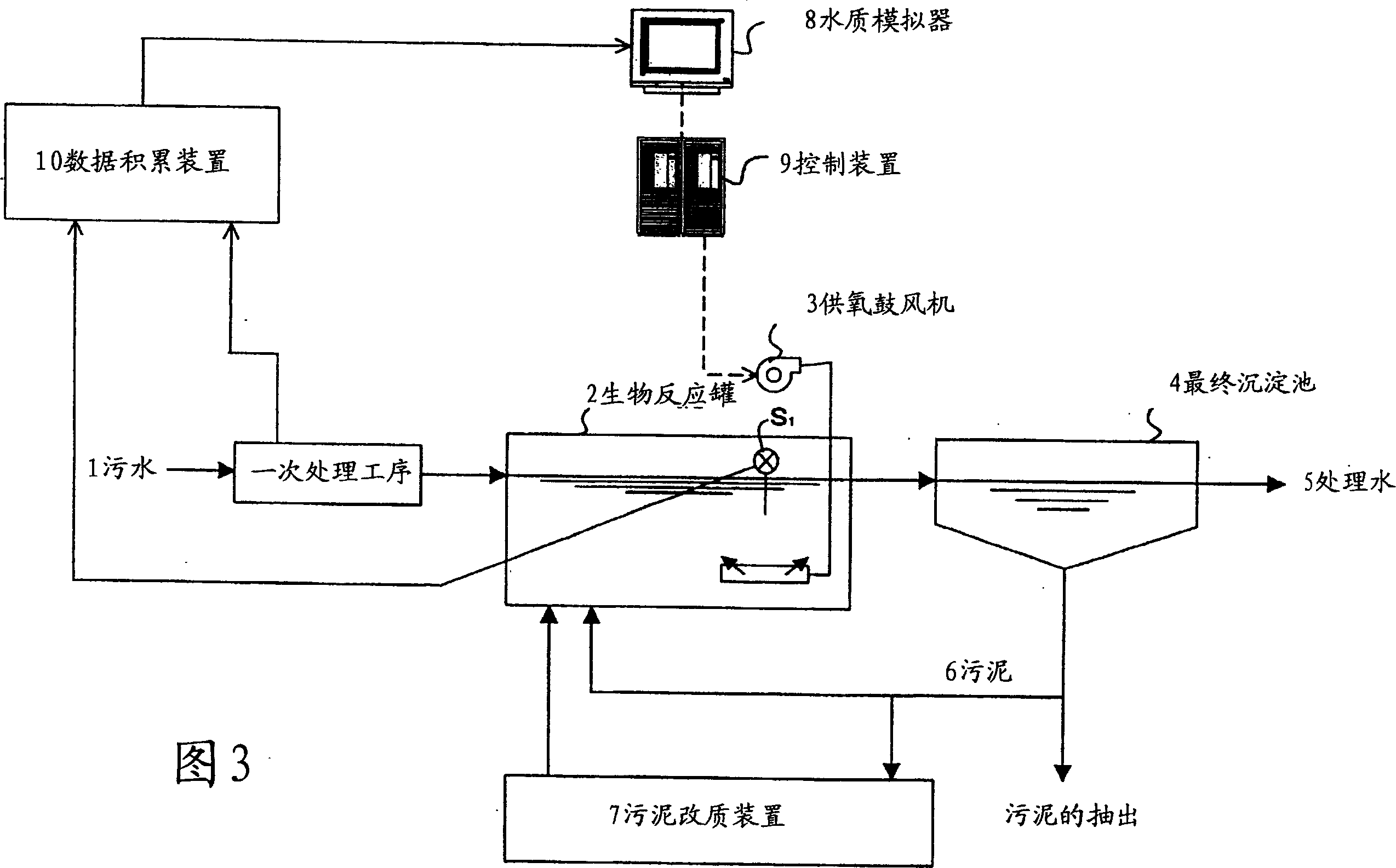

Sewage treatment system

InactiveCN1746117AImprove water qualityGood operating capacitySustainable biological treatmentBiological water/sewage treatmentEngineeringEnvironmental engineering

The invention obtains a sewage treatment system which can be automatically operated while properly setting the operation condition of reducing surplus sludge according to the condition change of water quality, water quantity, water temperature, and the like with improving water quality of treated water or without deteriorating the water quality, and optimizing the driving operation amount of an oxygen supply blower. The sewage treatment system comprises a water quality simulator 8 that calculates water quality by using an activated sludge model representing microorganism reactions in a biological reaction tank 2, a control device 9, and a data storage device 10. Easily biodegradable organic matter data of a sludge improvement device 7 are fetched into the water quality simulator 8, and the driving operation amount of the sludge improvement device 7 and the driving operation amount of the oxygen supply blower 3 for the biological reaction tank 2 are controlled from the results of water quality calculation by the water quality simulator 8.

Owner:YASKAWA DENKI KK

Stone installation structure and method for installing stone

InactiveCN103362283AEnhanced security and convenienceStrong prestressCovering/liningsPrestressed structureGeneration process

The invention discloses a stone installation structure, which comprises a building main body and stone installed on the building main body. The stone installation structure is characterized in that the installation structure also comprises a plurality of installation units mutually independent; the stone is adjusted to a setting position by the installation units and is fastened, and moreover, the position of the stone is not changed during a fastening process. As the stone installation structure disclosed by the invention is adopted, stimulation and control are provided for the dynamic generation process of the prestress of an elastic material to form a stable prestressed structure, and three-dimensional adjustment can be performed during an installation process, and therefore, the installation accuracy of the stone is greatly improved. The stone installation structure has the characteristics that the firmness, the accuracy and the safety degree are high and the convenience and the changeability are good.

Owner:YIHE TECH DEV SHANGHAI

Pen system with internal pressure tilt rotation

ActiveUS10296108B2Function increaseReduce operating conditionsInput/output processes for data processingInternal pressureEngineering

A pen apparatus with a pressure sensitive tip mechanism that internally generates pressure, tilt, and / or barrel rotation through the use of a multi-axis measurement scheme with simultaneous transmit, receive, and sensing driver capability operable in conjunction with a receiving system or in a relative stand-alone manner. Signaling schemes are provided for operating the pen apparatus to achieve improved function. Systems and methods are provided for operating a pen, and for operating a pen with a touch sensor system. Drive / receive circuitry and methods of driving and receiving sensor electrode signals are provided that allow digital I / O pins to be used to interface with touch sensor electrodes. This circuitry may be operated in modes to sense various combinations of signals coupled within a pen, or from outside of a pen.

Owner:SIGMASENSE LLC

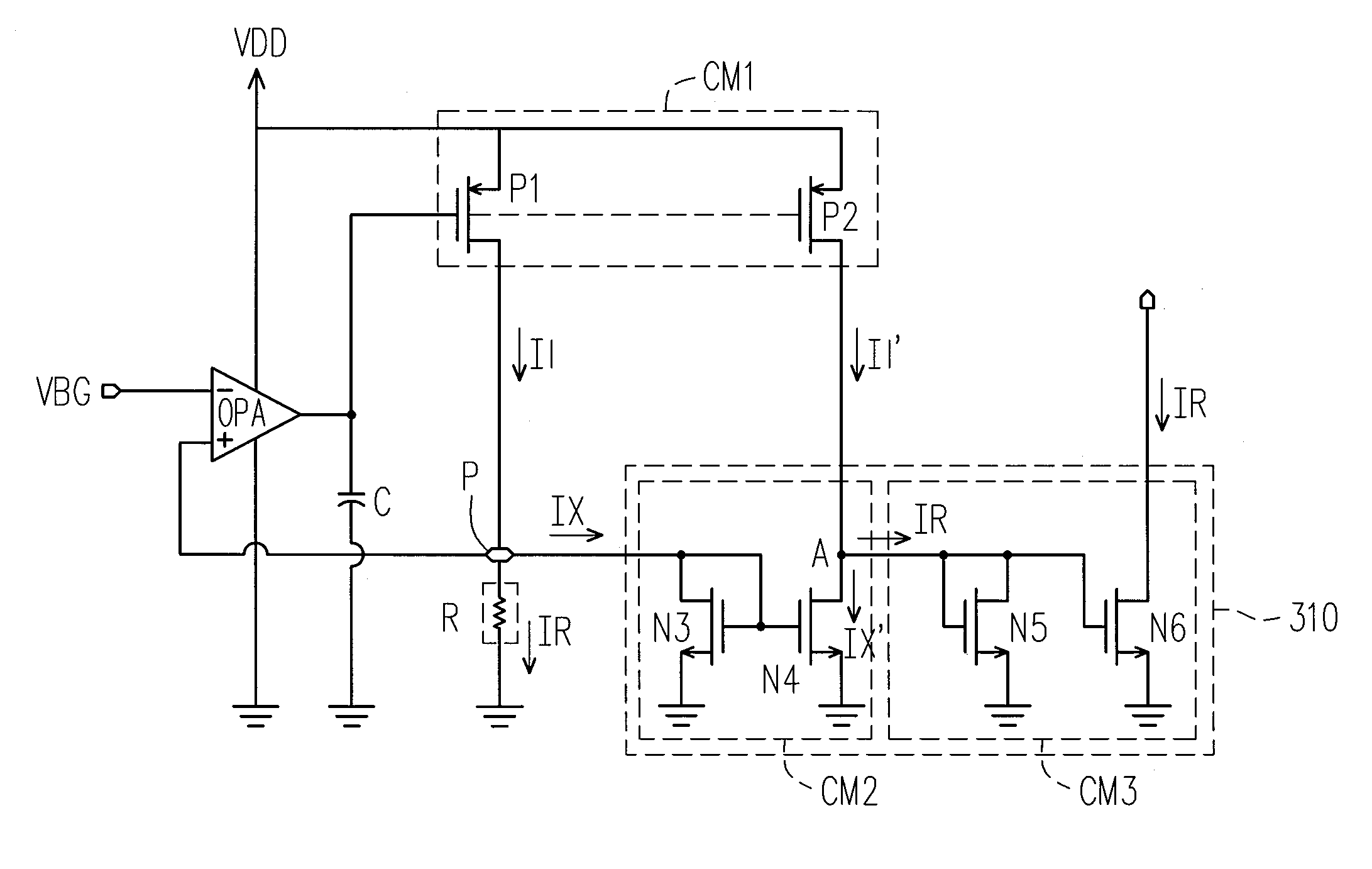

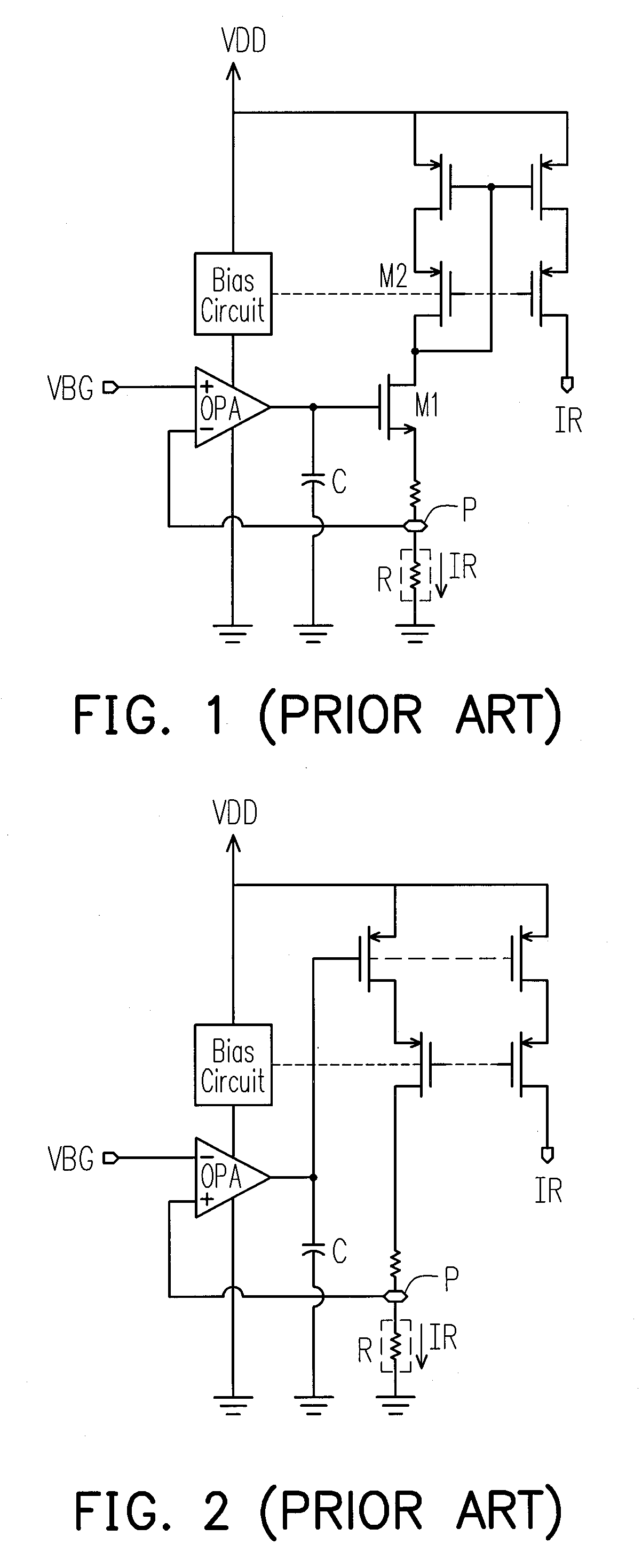

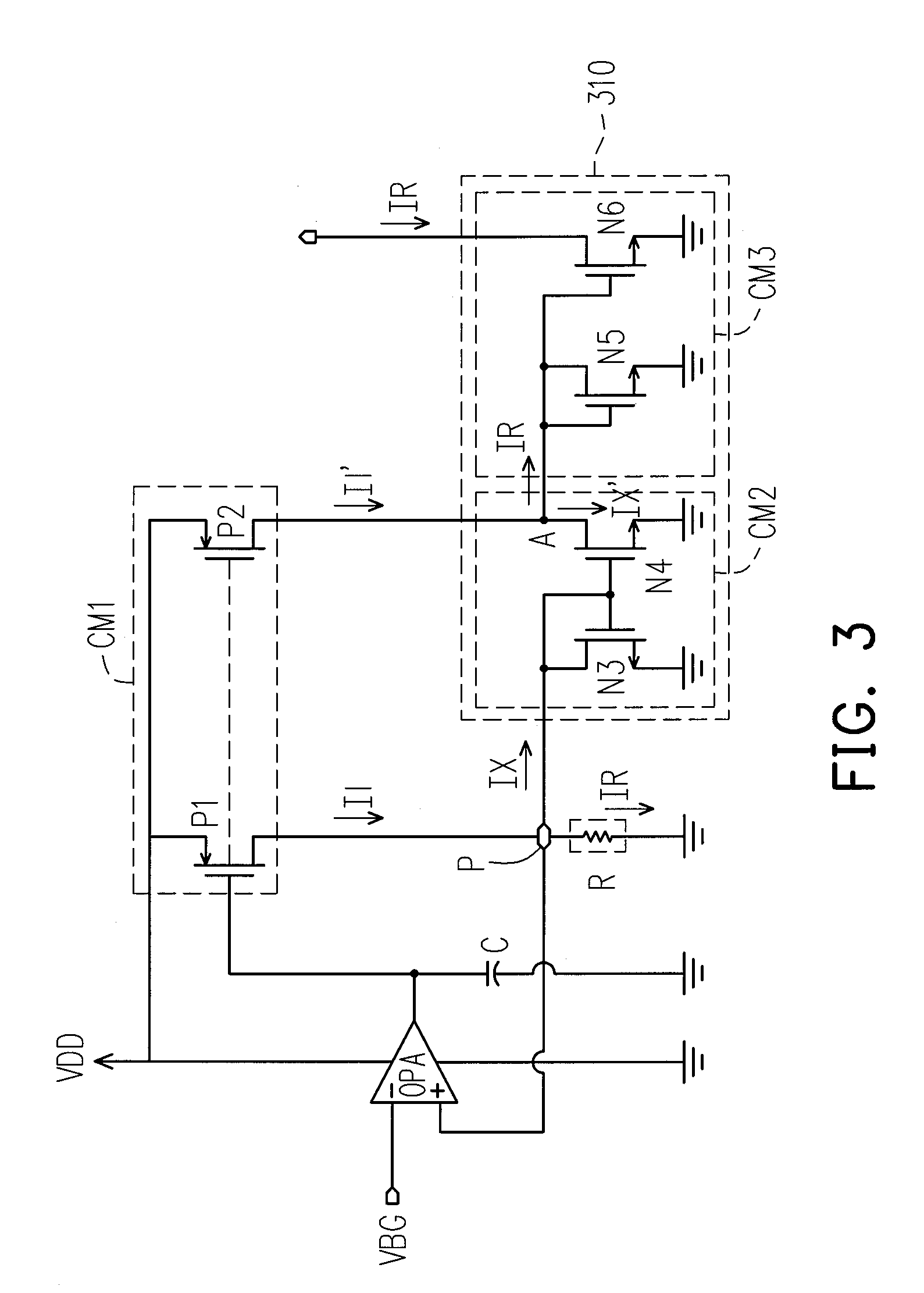

Reference current generator circuit for low-voltage applications

ActiveUS7944194B2Reduce operating conditionsImprove phase marginElectric variable regulationCapacitanceElectrical resistance and conductance

A reference current generator circuit suitable for low-voltage applications is provided. The generator circuit is fabricated in a chip for generating a precise reference current based on a precise reference voltage and a precise external resistor. The generator circuit provides an equivalent resistance coupled in parallel with the external resistor to provide resistance compensation and reduce the impedance of seeing into the chip from a chip pad. In addition to the resistance compensation, only moderate capacitance compensation is required to enhance the phase margin of the generator circuit, so as to achieve a stable loop. Therefore, chip area and cost can be reduced in low-voltage applications. In addition, the generator circuit reproduces the reference current generated by the external resistor by utilizing current mirrors, so as to eliminate the effect on currents caused by parallel coupling of the equivalent resistance and the external resistor.

Owner:FARADAY TECH CORP

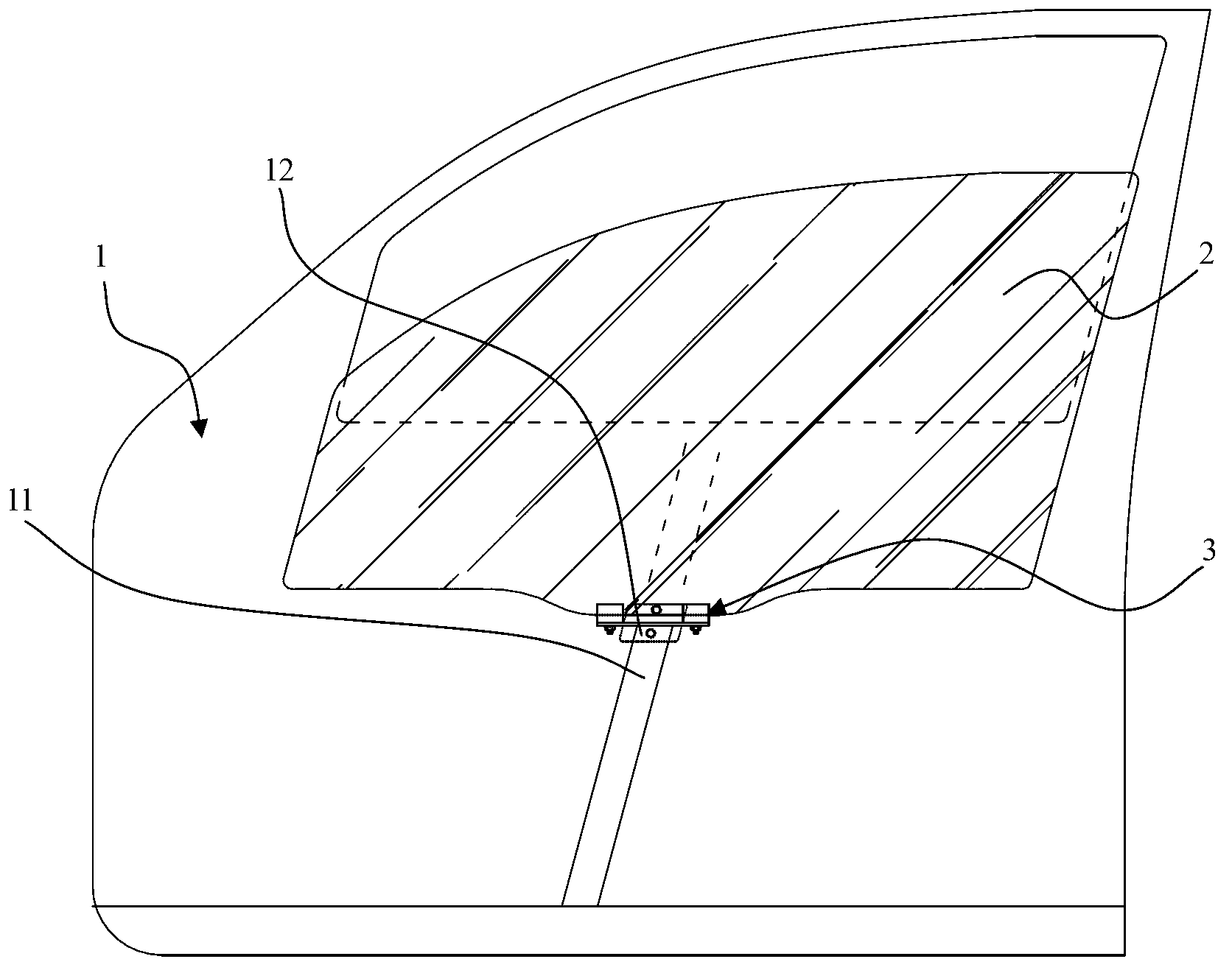

Mounting structure for car door glass tightening and method for mounting car door glass

ActiveCN103303105ATo achieve fastening effectImprove smoothnessWindowsWindscreensPre stressPre stressing

The invention discloses a mounting structure for car door glass tightening, which comprises a car door glass body, wherein the car door glass is movably arranged on a car door through a moving device on a car window track; the car door glass body is fixed on the moving device through a tightening system; the tightening system comprises an oppressing component and a plurality of tightening components; and the tightening components are oppressed through the match of the oppressing component with the car door glass body to generate a pre-stressing force to tighten the car door glass body. In the mounting structure for the car door glass tightening provided by the invention, the tightening components are oppressed through the match of the oppressing component with the car door glass body together to generate the pre-stressing force; the car door glass body becomes a main control element to generate the pre-stressing force; the tightening components are made of elastic materials; and under the action of external forces, a stable pre-stressing force is formed at the inner part of the materials and stored to form a stable pre-stressing force system with the car door glass body and the oppressing component together.

Owner:WM MOTOR TECH GRP CO LTD

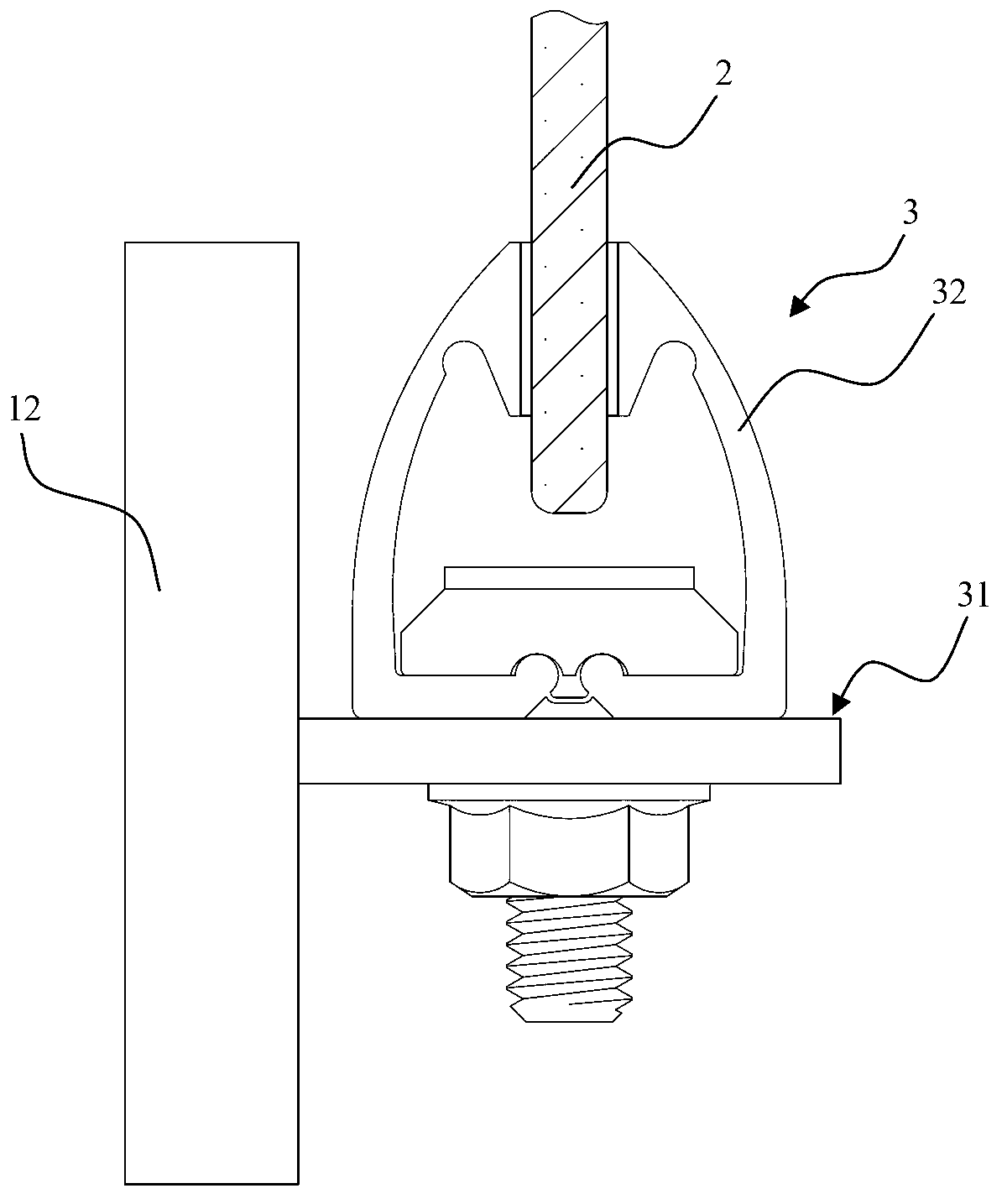

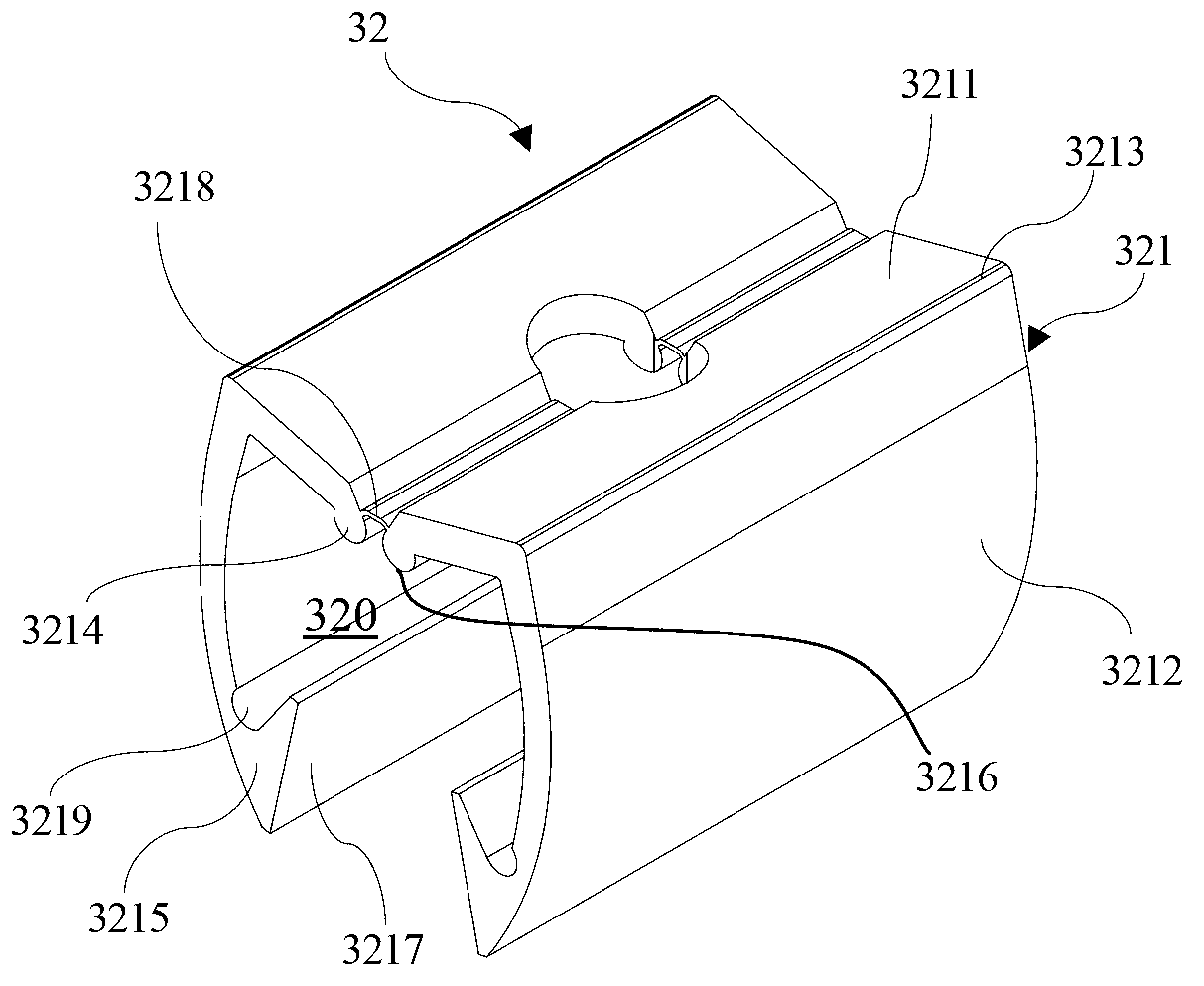

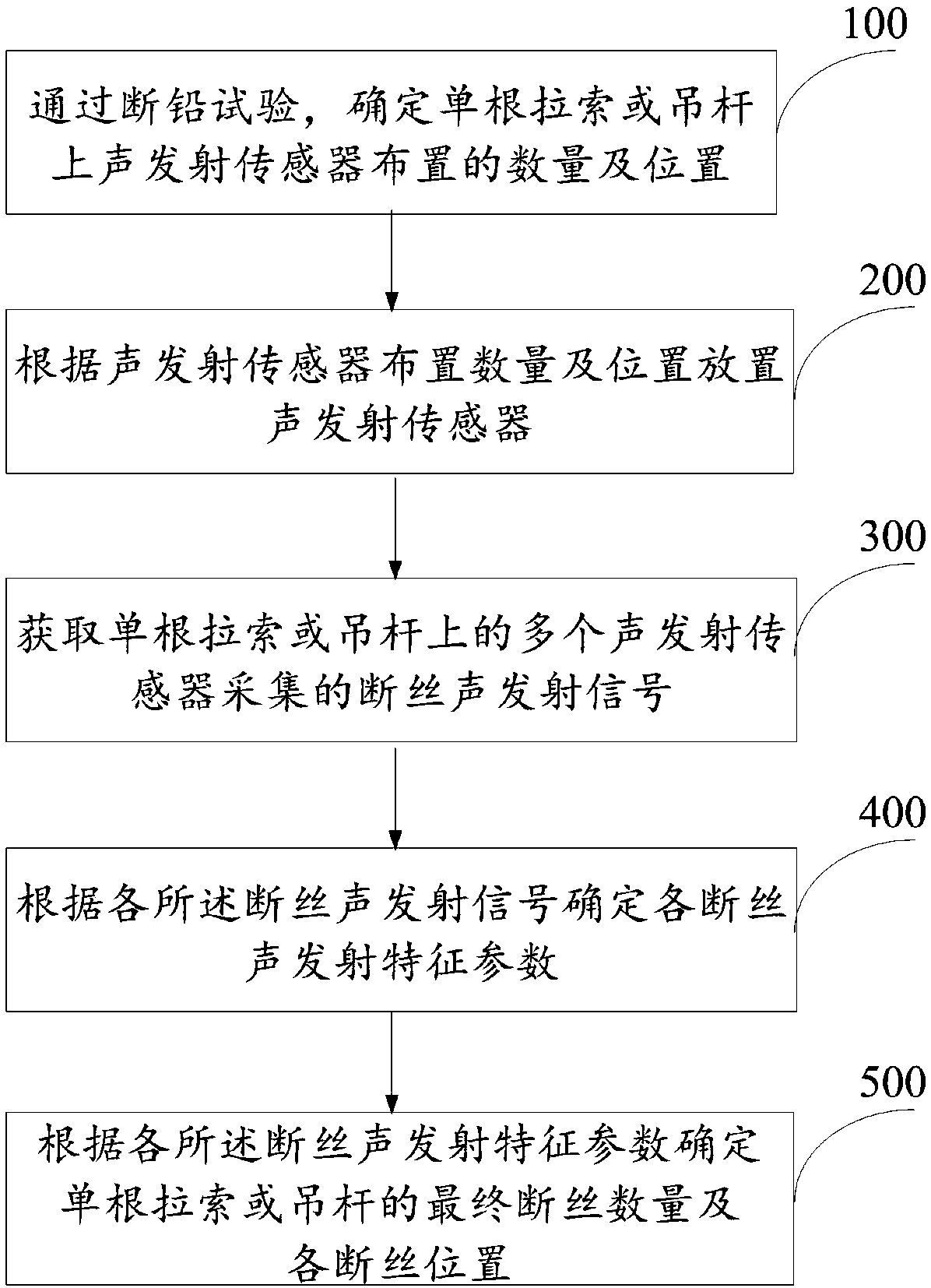

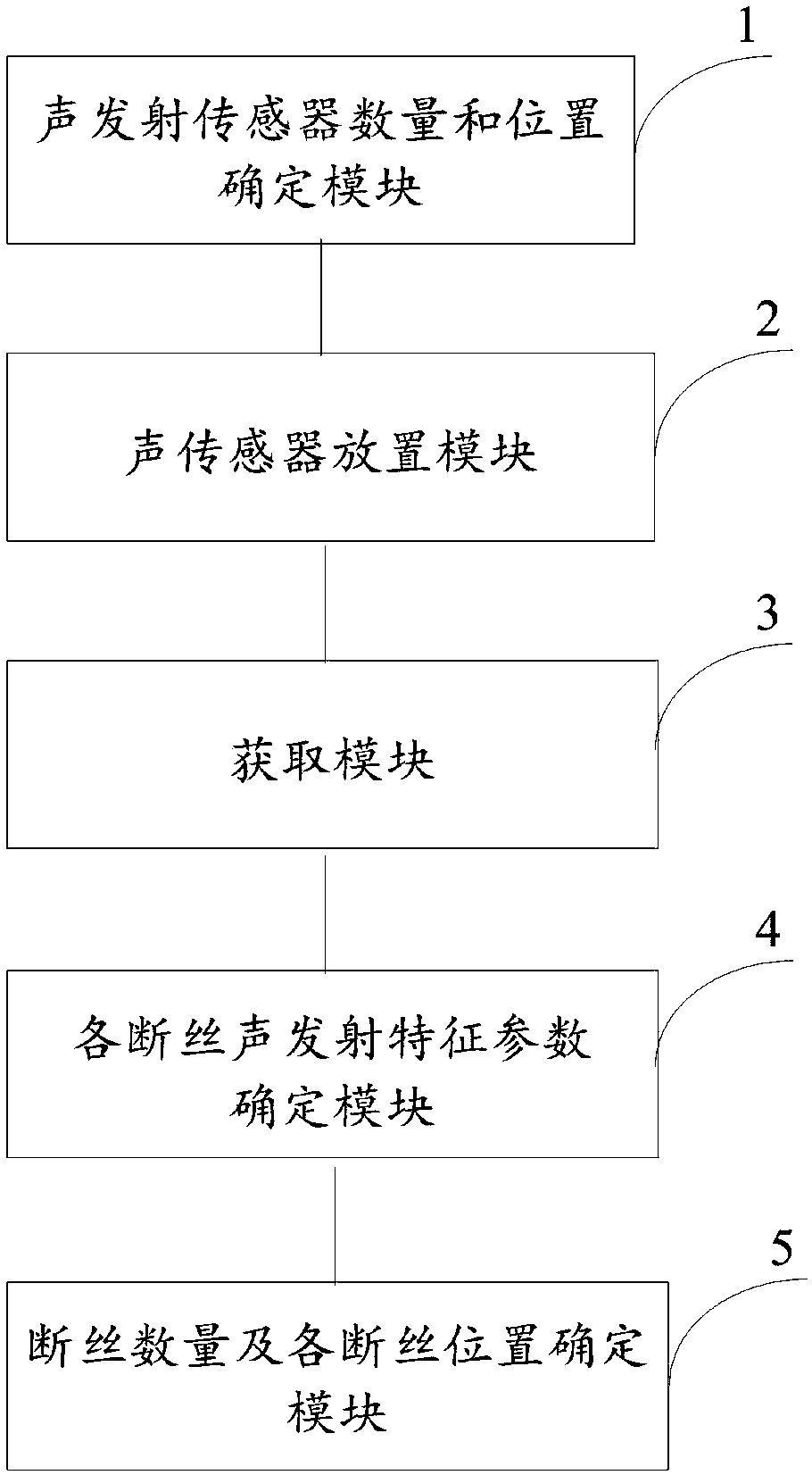

Broken wire monitoring method and system based on digging lines or suspension rods

ActiveCN108445084AMonitoring broken wiresReduce operating conditionsMaterial analysis using acoustic emission techniquesAcoustic emissionEngineering

The invention discloses a broken wire monitoring method and system based on a digging line or a suspension rod; according to the method, broken wire acoustic emission signals collected by a pluralityof acoustic emission sensors on a single digging line or suspension rod can be firstly obtained; broken wire acoustic emission characteristic parameters can be determined according to the broken wireacoustic emission signals; and the number of final broken wires and the position of each broken wire of the single digging line or suspension rod can be determined according to the broken wire acoustic emission characteristic parameters; the broken wires of the digging line or suspension rod can be monitored in a whole day, and the method not only reduces the operating conditions and the danger ofworking at heights, but also improves the monitoring effect.

Owner:SHENZHEN MUNICIPAL DESIGN & RES INST

Wall brick installation structure and wall brick installation method

ActiveCN103343604AStrong prestressStable characteristicsCovering/liningsPrestressed structureInternal stress

The invention discloses a wall brick installation structure which comprises a building body and wall bricks installed on the building body. The wall brick installation structure is characterized by further comprising multiple installation units which are independent from one another. The wall bricks are adjusted to be at set positions and fastened through the installation units, and the positions of the wall bricks do not change in the fastening process. By means of the wall brick installation structure, stimulation and control of the dynamic generation process of the prestress of elastic materials are provided, a stable prestress structure is formed, and three-dimensional adjustment can be conducted in the installation process so that the installation accuracy of the wall bricks is improved substantially. The wall brick installation structure has the advantages of good firmness, safety, convenience and easy replacement. In the fastening process, the wall brick installation structure cannot cause irregular compression on the wall bricks, therefore, damage to existing flatness and self-balanced internal stress of the wall bricks is avoided, wherein the damage is caused by component errors, installation carrier errors, the errors of the wall bricks, workpiece displacement and other factors, and the safety and the capability for resisting external force of a whole wall brick structure are enhanced.

Owner:贵州建工安顺建筑工程有限公司

Wall brick installing structure and method for installing wall bricks

InactiveCN103334564AStrong prestressed fasteningStable prestressed fasteningCovering/liningsBrickStructural engineering

The invention disclose a wall brick installing structure, which comprises a building main body and wall bricks installed on the building main body, and is characterized by further comprising an installing base plate, wherein the installing base plate comprises a framework, a first installing module and a second installing module; the framework comprises a building main body connecting end and a wall brick connecting end; the building main body connecting end is arranged on the building main body through the first installing module; the wall bricks are adjusted to set positions through the second installing module, and are fastened; and in a fastening process, the positions of the wall bricks are not changed. In a process of fastening by using the prestress of the second installing module, the wall bricks are prevented from being pressed and deformed irregularly by fastening, damages to the existing flatness of the wall bricks and inner stress of self-balance caused by the factors of error of each member, error of an installing carrier, errors of the wall bricks, and displacement of workpieces are avoided, and the safety and the capability of the external force resistance of an entire wall brick fastening system are enhanced greatly.

Owner:盖南南

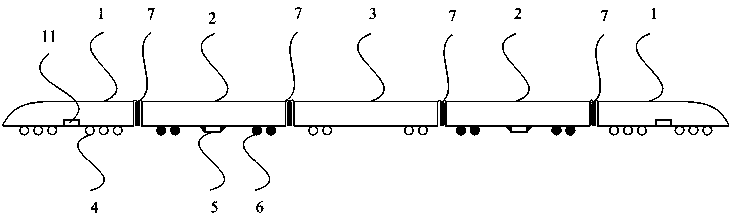

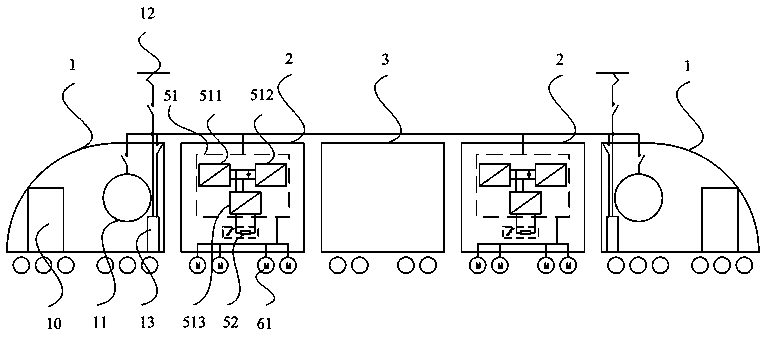

Hybrid power type power distributed motor train unit

ActiveCN104290762AReduce axle weightExtended operating intervalPropulsion using ac induction motorsElectric locomotivesPower steeringTraction system

The invention provides a hybrid power type power distributed motor train unit which comprises at least one power source vehicle, at least one motor car and at least one trailer, wherein a diesel generating set, a pantograph and a transformer are arranged on the power source vehicle; the pantograph is connected with a transformer; the power source vehicle and the trailer are provided with power-free bogies; the motor car is provided with a traction system and a power bogie which are electrically connected together; the power source vehicle, the motor car and the trailer are connected together through a motor train unit; the diesel generating set and the transformer are respectively connected with a motor train unit connector through switches; and the motor train unit connector is electrically connected with the traction system. The diesel generating set is arranged in the power source vehicle, and the traction system is arranged in the motor car, so that the diesel generating set and the traction system are distributed in different vehicles, and the layout that the power sources are centralized and the power is distributed is realized. Therefore, the axle weight of each vehicle is wholly alleviated, and the operating requirement on the high speed railway is met.

Owner:青岛中车四方轨道车辆有限公司

Sodium-rich transition metal oxide composite sodium-supplementing positive electrode active material, positive electrode material, positive electrode, preparation of positive electrode and application of positive electrode in sodium-ion battery

ActiveCN111293290AHigh specific capacityImprove the first Coulombic efficiencyCell electrodesSecondary cellsElectrical batteryOxide composite

The invention belongs to the field of sodium-ion battery materials, and discloses a sodium-rich transition metal oxide composite sodium-supplementing positive electrode active material. The material is characterized by comprising a sodium-ion battery positive electrode active material and a sodium-supplementing additive; the sodium-supplementing additive is a sodium-rich transition metal oxide ofwhich the chemical formula is NaxMOy, wherein M is one or more of Ni, Co, Fe, Mn, Ru, Ir, Sn, Cr, Cu, Nb and Mo, x is 1-6, and y is 1-4; the average valence state of M in the sodium-supplementing additive is not higher than the highest oxidation valence state of M. The specific capacity of the sodium-supplementing additive is far higher than that of a conventional positive electrode active material; sodium ions can be removed before or together with the conventional active material in a charging process, meanwhile, the structure of the sodium-supplementing additive is changed, and sodium vacancies in the transition metal layer of the sodium-supplementing additive are difficult to fill.

Owner:CENT SOUTH UNIV

Anti-explosion transparent partition mounting structure and mounting method thereof

ActiveCN103290954ATo achieve fastening effectImprove smoothnessWallsEngineeringUltimate tensile strength

The invention discloses an anti-explosion transparent partition mounting structure. The anti-explosion transparent partition mounting structure comprises a partition body fixed on a building body, a circle of mounting frame is bonded around the partition body which is fixed on the main building body or an adjacent partition body via the mounting frame, the mounting frame comprises a pressing assembly and a fastening assembly, and the pressing assembly is matched with the fastening assembly to press the same to generate prestressing force so as to fasten the partition body. By the aid of the mounting frame, the partition body cannot be separated after being impacted by explosion and the like, so that anti-explosion and separation functions are effectively realized, and indoor persons are protected to the greatest extent. Since a rigid bearing frame is firmly connected with the main building body structure, strength and rigidity of a whole partition bearing system are greatly improved, and the anti-explosion transparent partition structure is stronger in capability for bearing impact loads from explosion and the like and better in safety performance.

Owner:SHANDONG BAIER BUILDING MATERIAL CO LTD

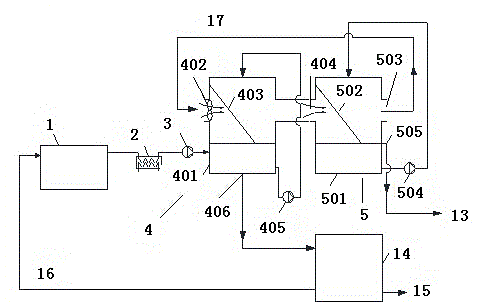

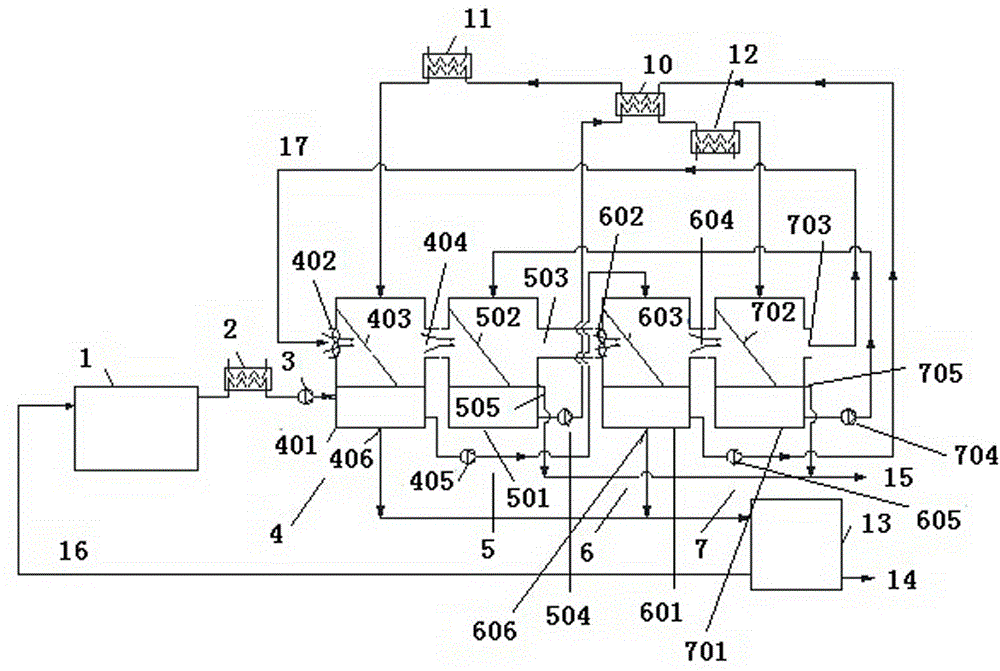

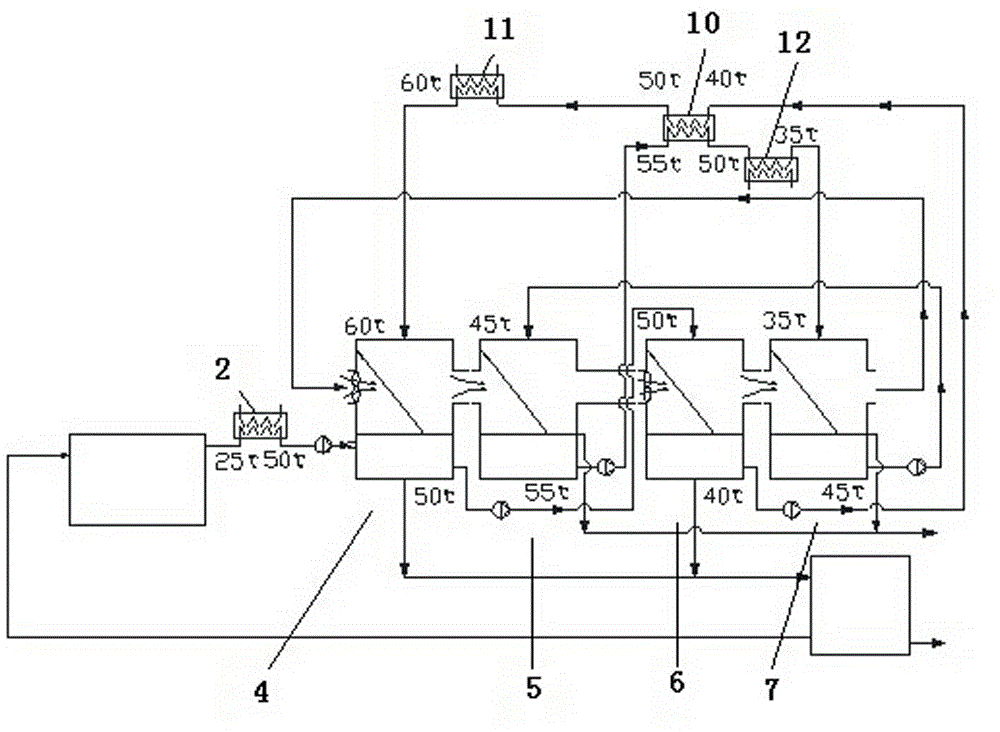

Method and system for treating high-concentration wastewater by virtue of low-temperature evaporative crystallization

InactiveCN104649493AAchieve evaporationAchieve direct crystallizationMultistage water/sewage treatmentWater/sewage treatment by heatingHigh concentrationAfter treatment

The invention provides a method for treating high-concentration wastewater. The method comprises the following steps: preheating raw water in a raw water tank and then feeding the preheated raw water into an evaporation chamber, and feeding the raw material into the top of the evaporation chamber through a circulating pump so that the water flows downwards along the surface of an inclined plate in the evaporation chamber; blowing air at the air inlet to contact the air with the water layer on the surface of the inclined plate to generate saturated wet air, discharging the saturated wet air out of the evaporation chamber via an air outlet to feed into a condensation chamber for cooling in the condensation chamber; lifting the concentrated liquor flowing into the bottom of the evaporation chamber to the top of the evaporation chamber by an evaporation chamber circulating pump for cyclic evaporation; and when the concentrated liquor in the evaporation chamber is saturated and crystalized, discharging the crystals out of the evaporation chamber via a crystal discharge hole to enter into a crystal treatment system, and returning the liquor obtained after treatment back to the raw water tank, and recycling the precipitate. The method and the system for treating the high-concentration wastewater are used for solving the problems of low evaporation efficiency, easy equipment scaling, heavy corrosion and high cost of current high-concentration wastewater treatment.

Owner:北京特里高膜技术有限公司

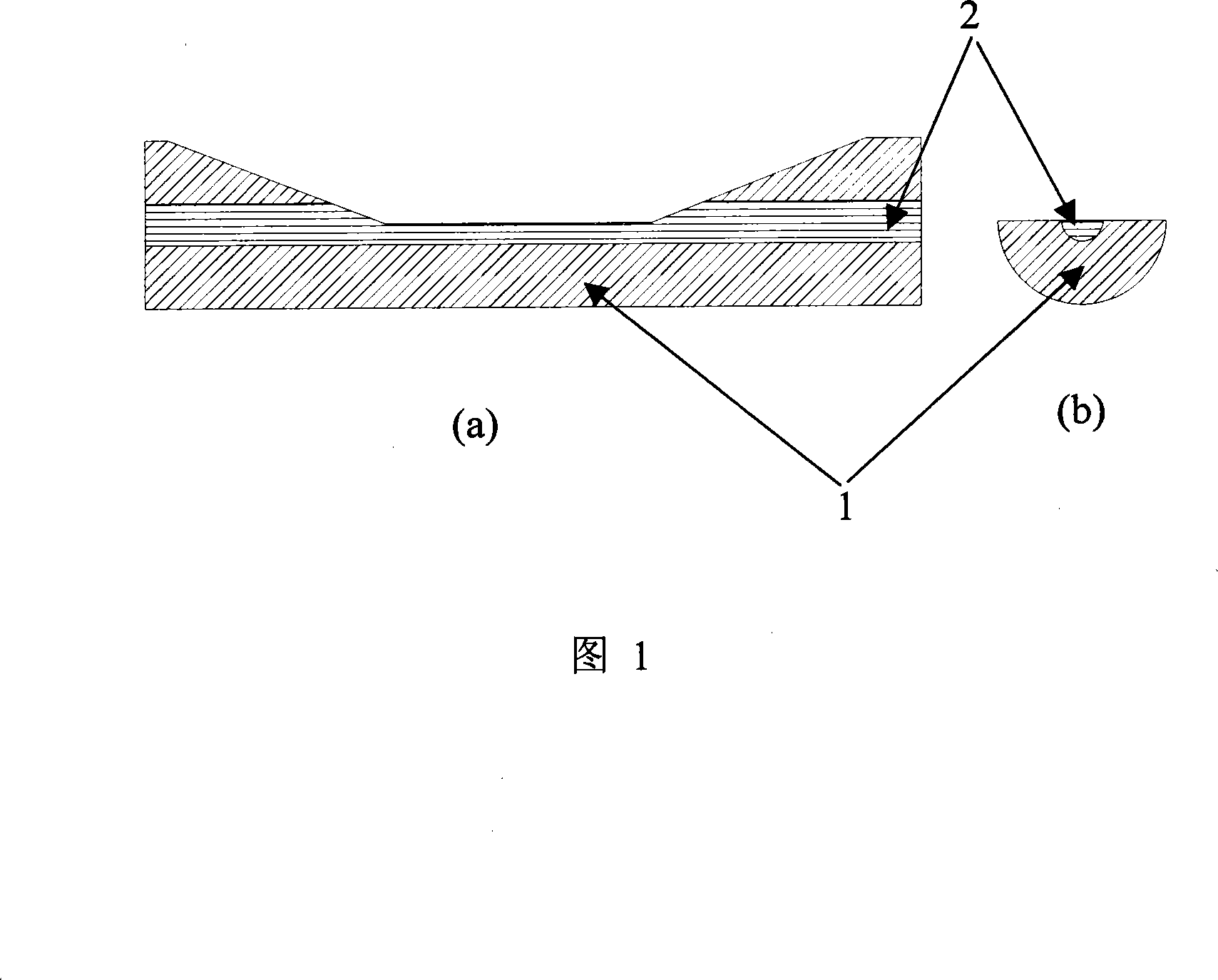

D type optical fiber clamp

InactiveCN101200047AEasy to useReduced operating requirementsGrinding machinesMedial axisBiochemical engineering

The invention belongs to the special optical fiber producing technical field, which is a clamp for grinding a D shaped optical fiber. A base and a front and a back pressure plate of the clamp are produced in mechanical technology and are assembled to form an optical fiber groove for fixing the optical fibers. And then the depth of the optical fiber groove is controlled through the grinding allowance for grinding the front and the back pressure plates being controlled. A screw hole is drilled respectively at the different height on medial axis at the two sides of the base of the clamp; the clamp and a grinder clamp are fixed by a bolt through the hole, so that the clamp has the characteristic of self leveling. The invention uses the microscopic mechanical processing to realize the micron processing technique, the grinding and the packaging of the optical fiber are combined well. The invention has the advantages of reliable operating performance, strong impact resistance ability, easy processing and low cost; after the invention is assembled, the manufacture cost and difficulty are decreased, the flexibility is increased and the maintenance becomes convenient through the processing technique, and the clamp is convenient to be used with the self leveling characteristic.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

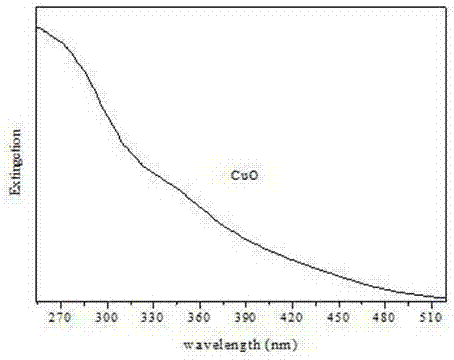

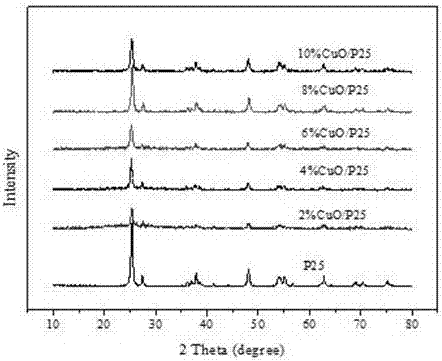

Copper catalyst for preparation of acetone from isopropanol through gas phase photocatalytic oxidation and reaction process

InactiveCN107398275ALow reaction temperatureReduce operating conditionsOrganic compound preparationCarbonyl compound preparationPartial oxidationGas phase

The invention relates to a copper catalyst for preparation of acetone from isopropanol through gas phase photocatalytic oxidation and a reaction process and provides a preparation method of titanium dioxide loaded copper-based compound photocatalyst as well as a process for preparing acetone through photocatalytic oxidation of a part of isopropanol under a gas phase condition. With titanium dioxide as a carrier (containing anatase or a mixed phase of anatase and a little rutile), soluble copper salt as a precursor of copper species (metal copper, copper oxide and cuprous oxide) and sodium borohydride as a reducing agent, the titanium dioxide loaded nanocopper compound catalyst is prepared. The catalyst can oxidize a part of isopropanol in atmosphere containing oxygen for preparation of acetone. The prepared catalyst has the characteristics of good stability, high conversion rate and high principal product selectivity.

Owner:INNER MONGOLIA UNIVERSITY

Explosion-proof and anti-riot transparent partition mounting structure with buffer function and mounting method of mounting structure

Owner:平邑经济开发区投资发展有限公司

Explosion-proof and anti-riot glass curtain wall mounting structure with buffer function and mounting method of mounting structure

ActiveCN103290958ATo achieve fastening effectImprove smoothnessWallsWar-like protectionForce structureGeneration process

The invention discloses an explosion-proof and anti-riot glass curtain wall mounting structure with a buffer function. The explosion-proof and anti-riot glass curtain wall mounting structure comprises a building body, a frame and a glass curtain wall. A decorative frame is fixed on the frame through a mounting component, a first mounting groove is formed in the mounting component, the side of the glass curtain wall is inserted into the first mounting groove, an escape-prevention frame is combined on the side of the glass curtain wall, and elastic buffer parts are mounted between the escape-prevention frame and the mounting component. The stable prestressing force structure is formed by triggering and controlling dynamic prestressing generation process of elastic materials, the elastic buffer parts and a buffer displacement slide device can function in buffering effectively at the first time after the glass curtain wall is impacted by explosion and the like, time and probability of breaking of the glass curtain wall after being impacted can be remarkably alleviated and reduced, and safety protection performance of the integral glass curtain wall is remarkably improved.

Owner:珠海博曼建筑科技有限公司

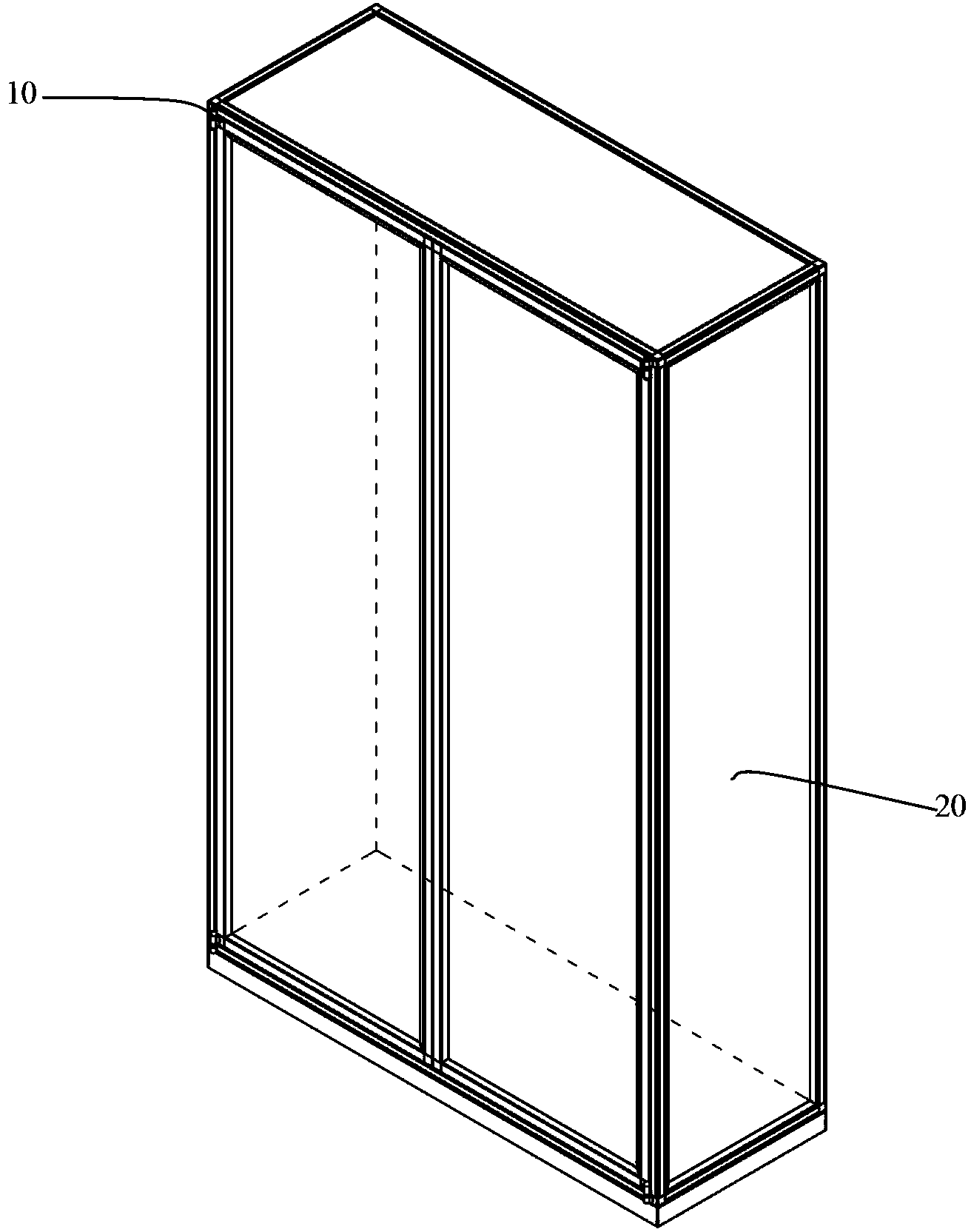

Transparent cabinet and assembly method thereof

ActiveCN103355962AImprove physical performanceEnhanced security and convenienceShow cabinetsFurniture partsPre stressingInternal stress

The invention discloses a transparent cabinet, which comprises a frame body and transparent parts combined onto the frame body. The frame body comprises compression assemblies and fastening assemblies. The fastening assemblies are compressed by matching the compression assemblies with the transparent parts to generate pre-stressing force to further fasten the transparent parts. During a whole implementation process of pre-stressing force fastening, irregular compression and surface deformation caused to the transparent parts due to the fastening cannot be generated, and therefore, the phenomenon that the existing flatness and the balanced internal stress of the transparent parts can be possibly broken due to the errors of all members and errors of the transparent parts is avoided. Meanwhile, the section stress of a single transparent part of an original transparent cabinet is changed into the overall stress of the transparent cabinet, and therefore, the overall strength, the torsion resistance and the external force resistance of the transparent cabinet are greatly enhanced.

Owner:SHANDONG BAIER BUILDING MATERIAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com