Sewage treatment system

A sewage treatment system and secondary treatment technology, applied in the direction of biological water/sewage treatment, water/sludge/sewage treatment, sustainable biological treatment, etc., can solve the problems of large proportion of final treatment volume and large cost burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to solve the above-mentioned problems, the present invention is constituted as follows.

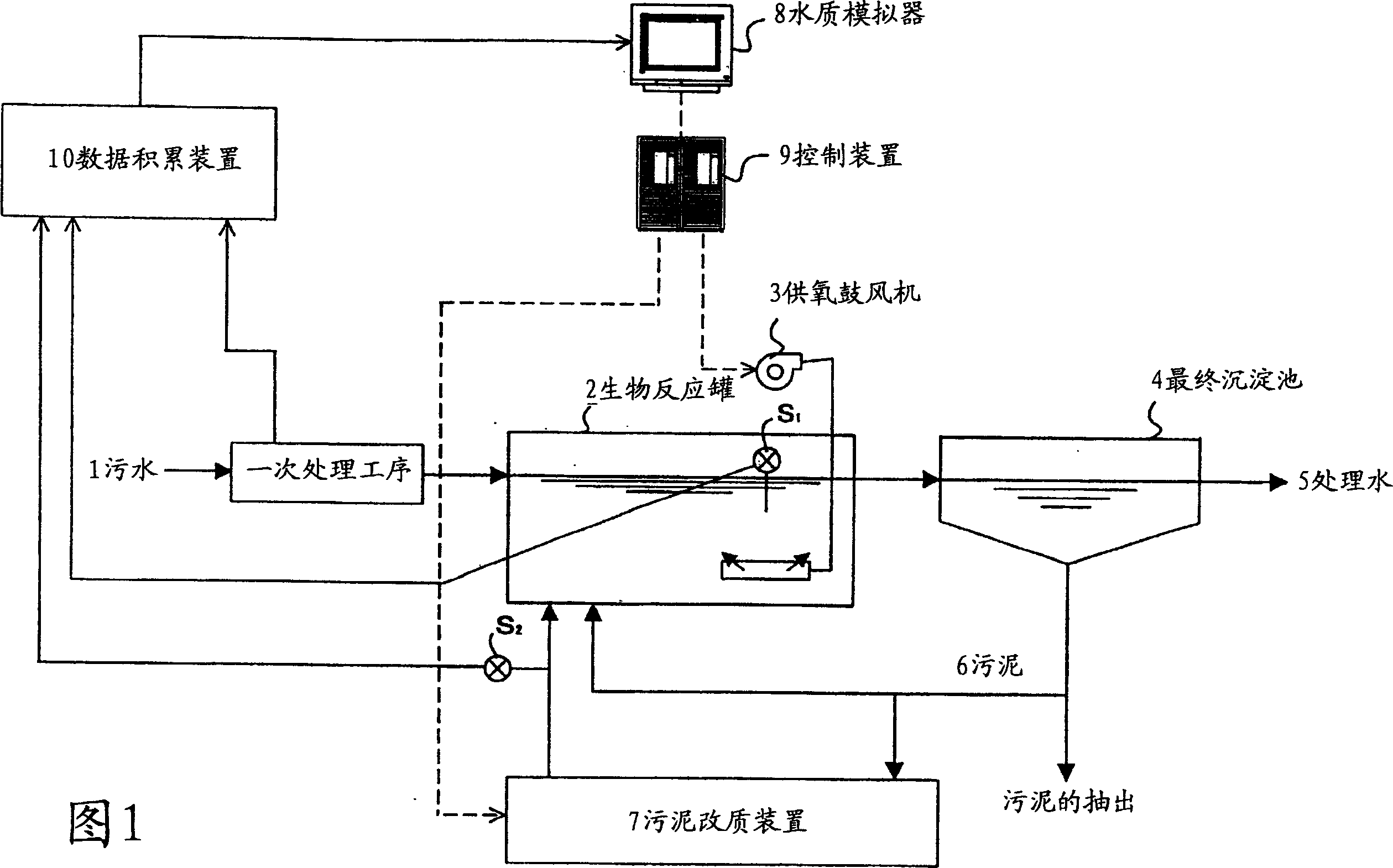

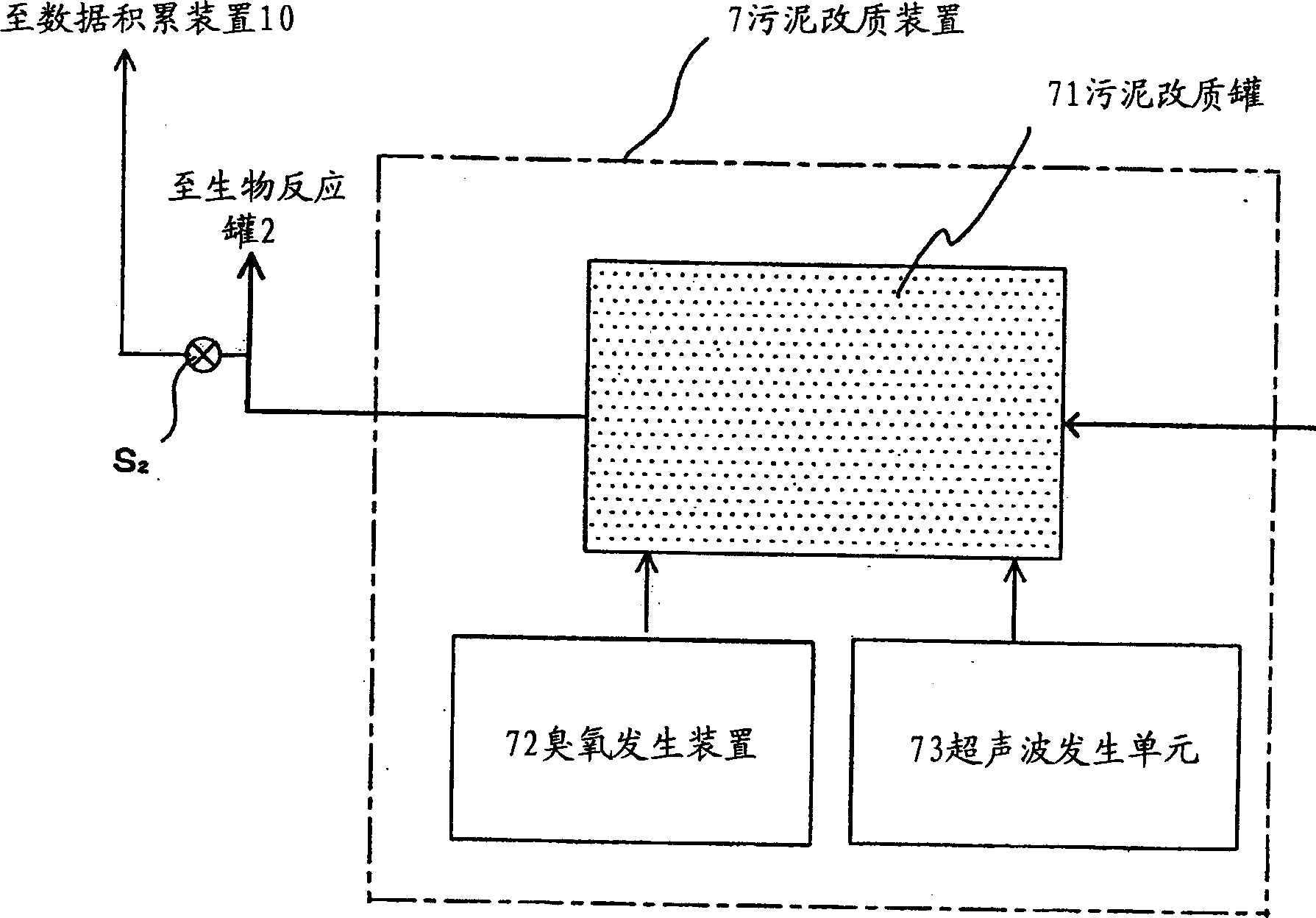

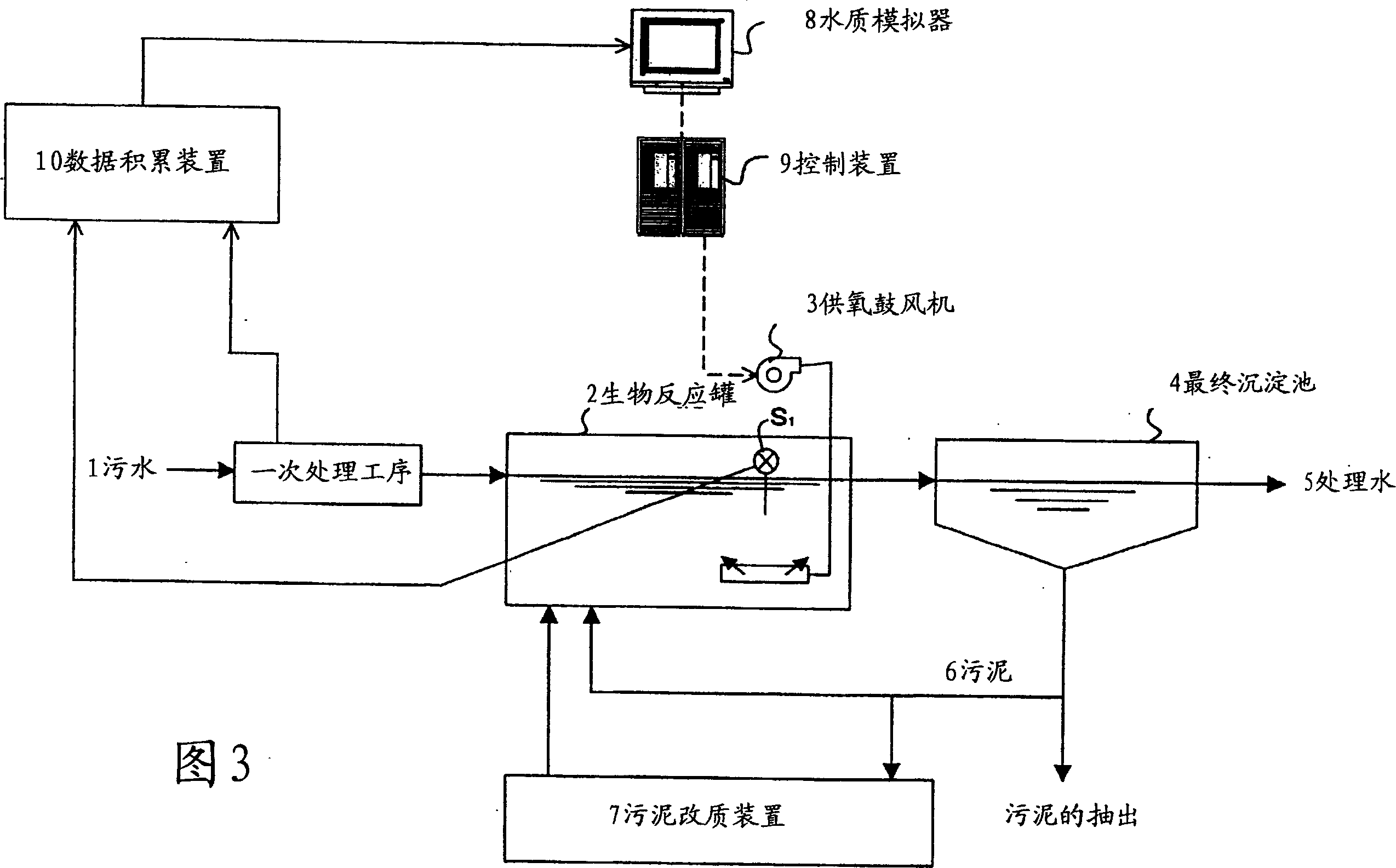

[0040] The invention described in Scheme 1 is the following sewage treatment system, which includes a primary treatment process, a secondary treatment process, an oxygen supply blower, a sludge reforming device, a control device, a water quality simulator, and a data accumulation device; The process consists of an initial sedimentation tank that separates solids by simple physical operations such as sedimentation; the secondary treatment process consists of a biological reaction tank that uses microorganisms to adsorb and separate soluble dirty substances, and a final sedimentation tank that settles and separates activated sludge 1. A part of the sludge after sedimentation and separation is sent back to the sludge return line of the secondary biological reaction tank; the oxygen supply blower is used to supply oxygen to the biological reaction tank; the sludge reforming dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com