Copper catalyst for preparation of acetone from isopropanol through gas phase photocatalytic oxidation and reaction process

A gas-phase photocatalytic isopropanol and copper catalyst technology, applied in the direction of physical/chemical process catalysts, carbon-based compound preparation, organic compound preparation, etc., can solve problems such as poor repeatability, equipment damage, and high temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the examples, and the present invention includes but not limited to the following examples.

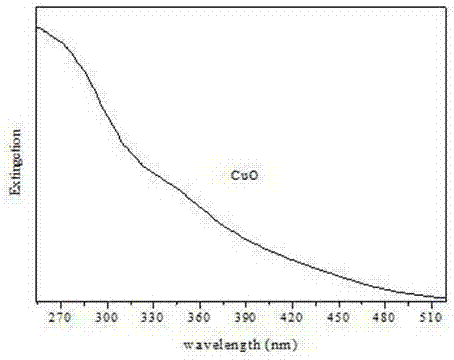

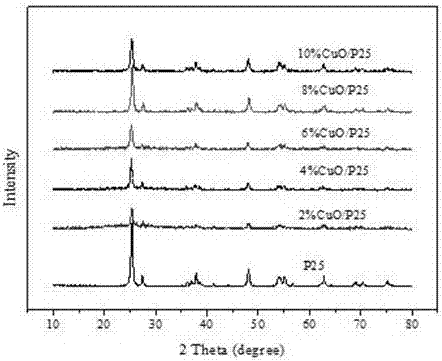

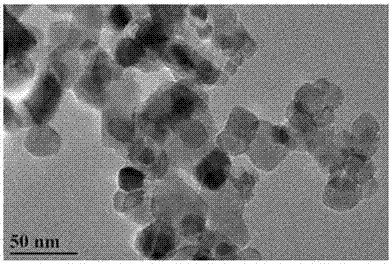

[0030] Measure 10mL0.01mol / LCu(NO 3 ) 2 Put the aqueous solution in a 500ml round bottom flask; weigh 0.4g of P25 titanium dioxide powder and ultrasonically disperse it in 5ml of distilled water, then add it to the above solution and stir; weigh 0.0038g of NaBH 4 , dissolve it in 5ml of distilled water and quickly add it to the suspension of titanium dioxide and copper nitrate; continue to stir for 24 hours, centrifuge, wash, and vacuum dry at 50°C for 6 hours to obtain 2% Cu / TiO 2 composite photocatalyst. In a similar way, change the amount of P25 to prepare Cu / TiO with different molar ratios (4%, 6%, 8%, 10%) 2 Composite catalyst.

[0031] The 2%Cu / TiO prepared by the above method 2 The composite catalyst is sprayed on the glass substrate, and the glass substrate coated with the catalyst is placed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com