D type optical fiber clamp

An optical fiber and grinding technology, which is applied in the direction of grinding/polishing equipment, grinding machines, manufacturing tools, etc., can solve the problem of D-shaped optical fiber being fragile, and achieve the effects of low cost, reduced operation requirements, and reduced cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

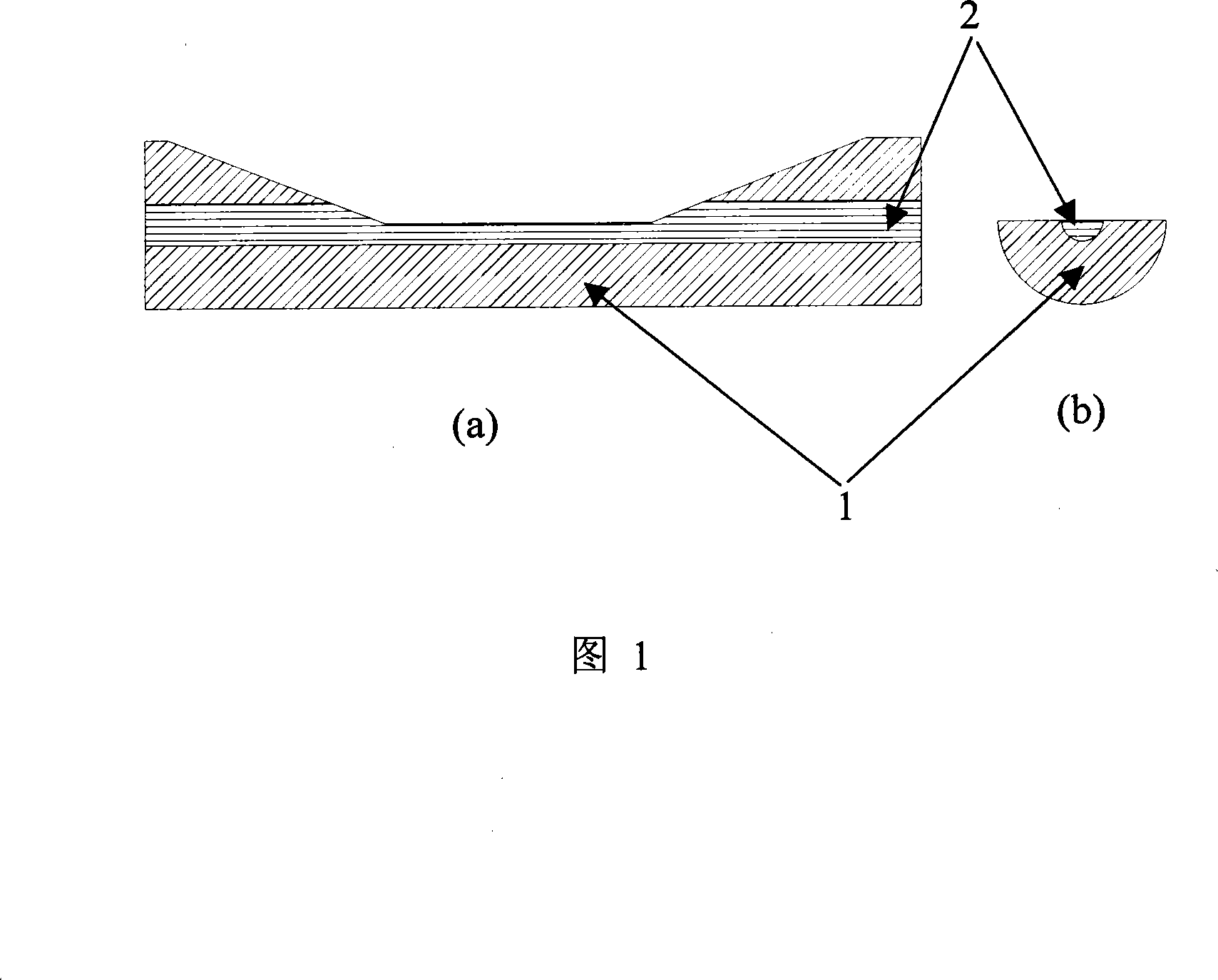

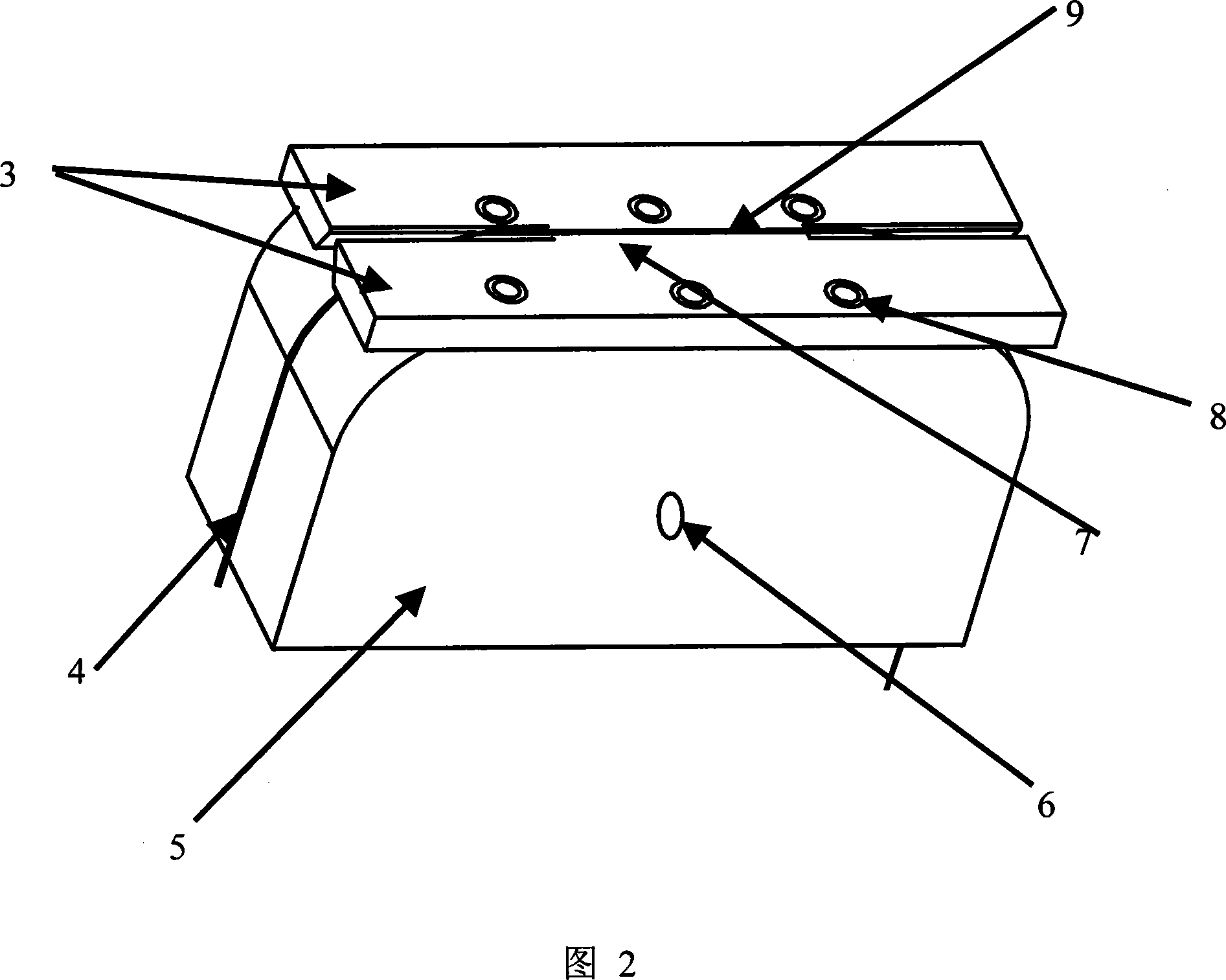

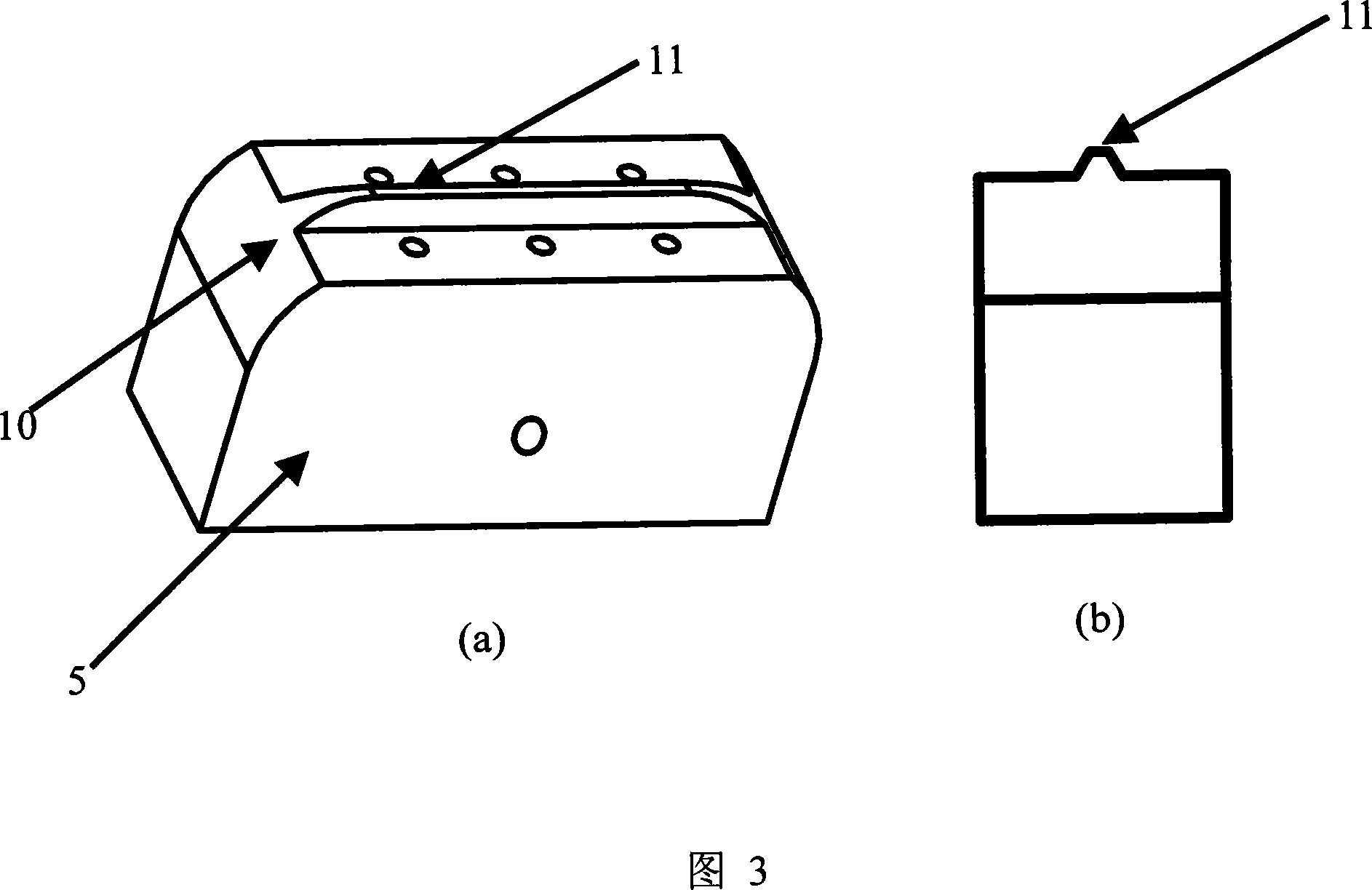

[0023] Concrete implementation steps of the present invention are as follows:

[0024] 1. Adopt 00Cr12 stainless steel plate, process the base 5 of the fixture according to Figure 2, the base length is 60 mm, the height is 30 mm, and the width is 20 mm. 1.5 millimeters at the bottom of trapezoidal table top 11, trapezoidal base angle 60 degrees, high 2.6 millimeters. The screw holes 6 on both sides of the base are M6-7H type, the depth of tapping is 5 mm, and the depth of the hole is 6 mm. The distance between any one of them and the base bottom surface is 7 mm, and the other is 18 mm. The specification of the screw hole for fixing the pressure plate is M2-7H type, the tapping depth is 5mm, and the hole depth is 6mm.

[0025] 2. Use 00Cr12 stainless steel plate to process the front and rear pressure plates 3 of the fixture. The length of the pressure plate is 54 mm, the height is 3 mm, and the width is 10 mm. Three holes with a diameter of 2.6 mm are drilled on each pressure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com