Transparent cabinet and assembly method thereof

A technology of transparent and transparent parts, which is applied in the direction of cabinets, kitchen cabinets, display cabinets, etc., can solve the problems of transparent cabinet deformation, safety hazards, loss of function, etc., to achieve enhanced safety and convenience, enhance overall strength, physical The effect of performance enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0067] The present invention will be further described below in conjunction with specific examples.

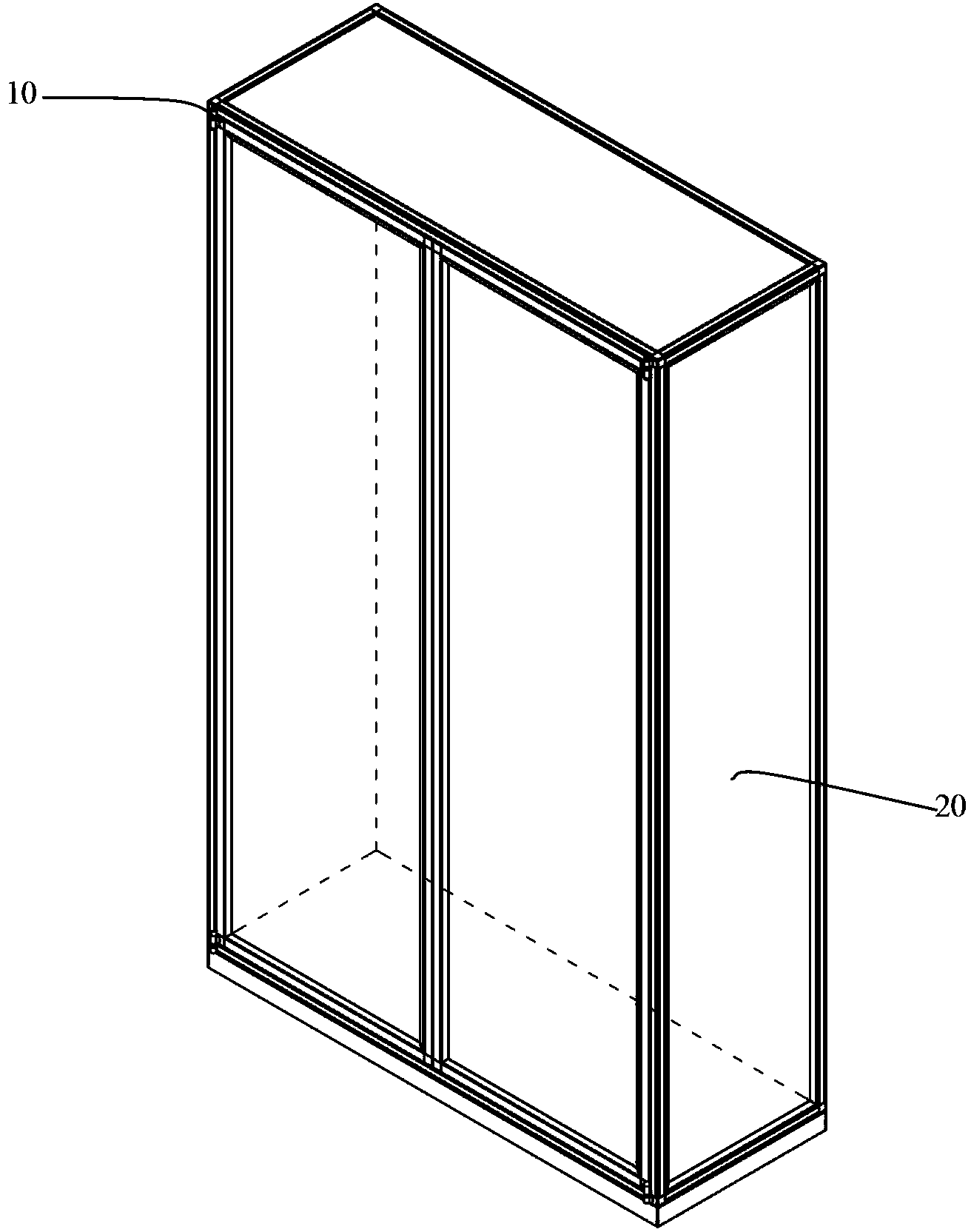

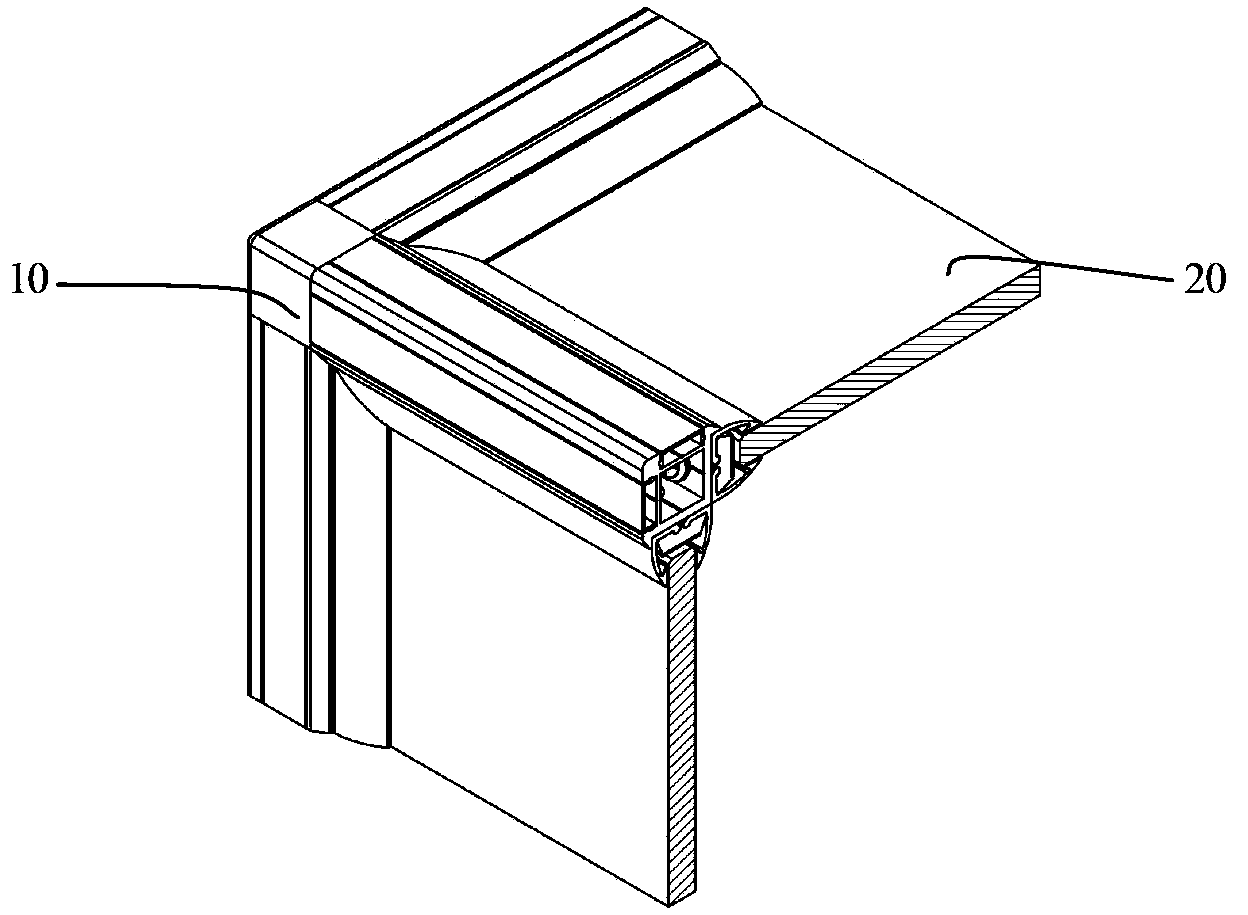

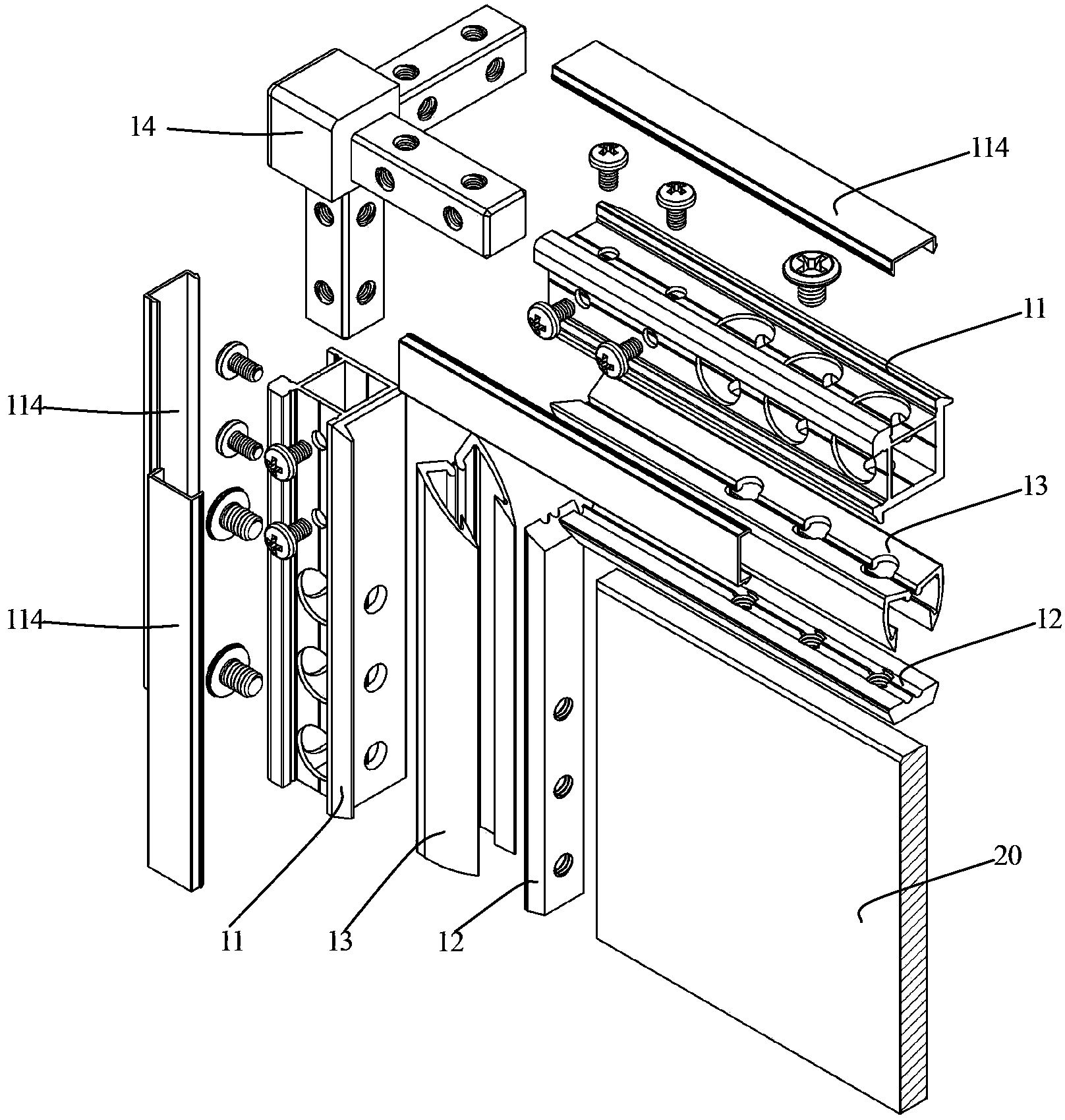

[0068] see Figure 1-4 , a transparent cabinet of the present invention includes a frame body 10 and a transparent member 20 combined on the frame body 10. The frame body 10 is mainly composed of a connecting box body 11, a pressure strip 12 and a fastening assembly 13. In the present invention, the transparent member 20 can choose toughened glass, laminated glass, anti-riot glass or plexiglass, etc., of which:

[0069] Cooperate Figure 8 , 9 As shown, the fastening component 13 includes two bow-shaped arms 131 symmetrically clamped on both sides of the transparent member 20, and its material should be selected from a material with considerable strength and a certain degree of elasticity and toughness, such as metal, engineering plastics, polymers, etc. Materials, etc.; an enclosed space 132 is formed between the two arched arms 131. The arched arms 131 include a first mom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com