Fermentation lactic acid bacteria light bread and making method thereof

A production method and technology of lactic acid bacteria, applied in the direction of dough preparation, dough processing, pre-baked dough processing, etc., can solve problems such as insufficient fermentation of lactic acid bacteria, and achieve the effect of extending shelf life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

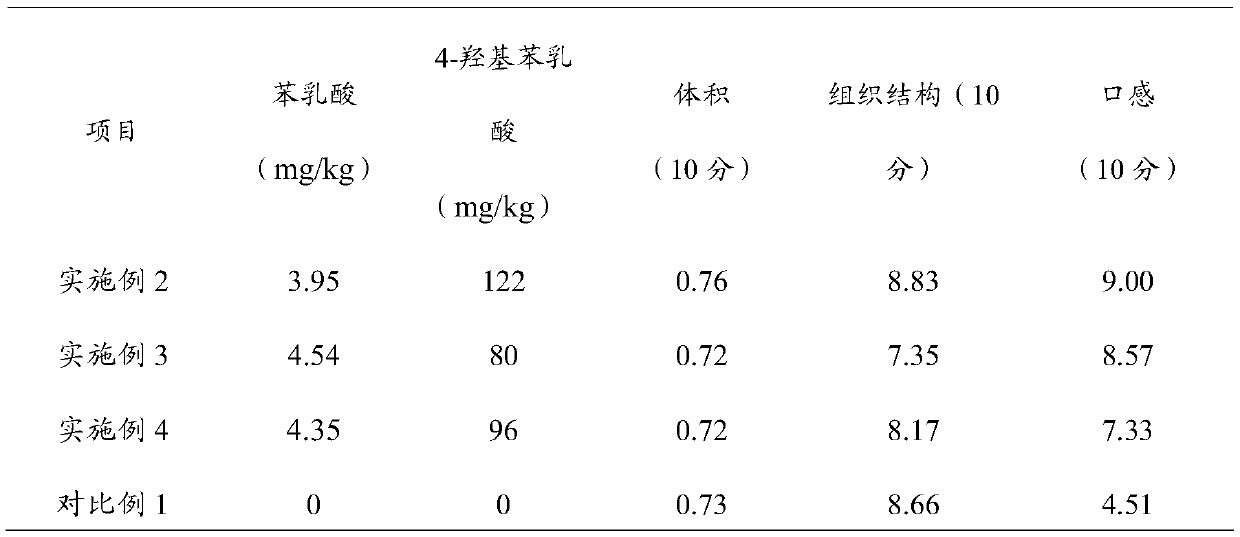

Examples

Embodiment 1

[0034] 1. A fermented lactic acid bacteria white bread, characterized in that: its bread base comprises the following components: by weight, characteristic lactic acid bacteria fermentation liquid, 98-102 parts of flour, 1.5-2.0 parts of dry yeast, 10-10 parts of whole egg liquid 12 parts, 0.5-0.6 parts of bread improver, 0.2-0.5 parts of bread emulsifier, 1-1.2 parts of table salt, 2-3 parts of fructose syrup, 10-12 parts of reduced starch syrup, 14-16 parts of shortening and 38 parts of water -42 copies;

[0035] The characteristic lactic acid bacteria fermentation broth is mixed with 0.01-0.02 parts of compound lactic acid bacteria strains, 2-4 parts of milk powder, 1-1.2 parts of glucose and 14-16 parts of other water at 37 ° C. Obtained after fermenting for 1 hour;

[0036] The compound lactic acid bacteria strain is a compound lactic acid bacteria strain powder mainly containing Lactobacillus bulgaricus, Streptococcus thermophilus, and screened high-yield phenyllactic a...

Embodiment 2

[0038] A method for making fermented lactic acid bacteria white bread, comprising the steps of:

[0039] (1) Culture of fermented liquid of characteristic lactic acid bacteria

[0040] Add 0.1 g of compound lactic acid bacteria strains to milk prepared by mixing and dissolving 20 g of milk powder, 10 g of glucose, and 140 g of water. After mixing evenly, ferment at 37° C. for 1 hour to obtain a characteristic lactic acid bacteria fermentation liquid; wherein, the compound Lactic acid bacteria strains are compound lactic acid bacteria strain powder mainly containing Lactobacillus bulgaricus, Streptococcus thermophilus, and screened high-yield phenyllactic acid and 4-hydroxyphenyllactic acid Lactobacillus plantarum;

[0041] (2) Preparation of seed noodles

[0042] Mix 500g of flour with 3g of dry yeast, the special lactic acid bacteria fermentation broth prepared in advance, and 140g of water, stir to form a dough, and proof at 24°C for 3.5 hours;

[0043] (3) Preparation of ...

Embodiment 3

[0055] A method for making fermented lactic acid bacteria white bread, comprising the steps of:

[0056] (1) Culture of fermented liquid of characteristic lactic acid bacteria

[0057] Add 0.2g of compound lactic acid bacteria strains to the milk prepared by mixing and dissolving 40g of milk powder, 12g of glucose and 160g of water. After mixing evenly, ferment at 37°C for 1 hour to obtain a characteristic lactic acid bacteria fermentation liquid;

[0058] (2) Preparation of seed noodles

[0059] Mix 500g of flour with 3g of dry yeast, the special lactic acid bacteria fermentation broth prepared in advance, and 160g of water, stir to form a dough, and proof at 24°C for 3.5 hours.

[0060] (3) Preparation of main dough

[0061] Mix 120g of whole egg liquid, 5g of bread emulsifier, 12g of salt, 30g of fructose syrup, 120g of reduced starch syrup, 260g of water and the seed dough and stir slowly for 2 minutes, then add 510g of flour, 17g of dry yeast, and 6g of bread improver ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com