Decolorizing method for Huping jujube polysaccharide solution

A jujube polysaccharide and jujube jujube technology, which is applied in the field of decolorization of jujube polysaccharide solution in pots and bottles, can solve the problems of high equipment requirements, difficult separation of activated carbon, high loss of polysaccharides, etc., to achieve improved purity, high decolorization rate, high retention rate of polysaccharides, and low cost and low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

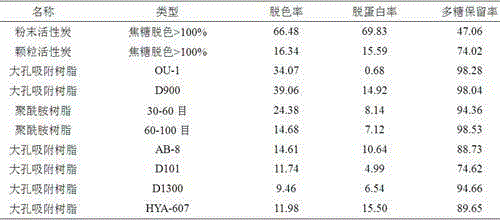

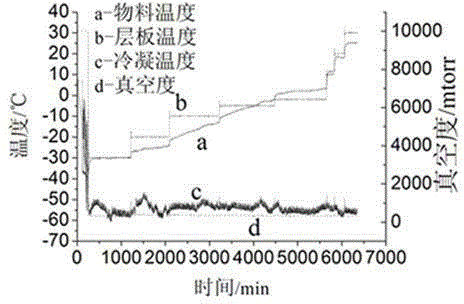

[0026] A certain amount of jujube jujube is peeled, pitted and sliced with a stainless steel knife, 1000g of jujube meat is taken, and 5000ml of distilled water is added to make a pulp with a colloid mill, and it is dried and powdered by vacuum freeze-drying technology. After freezing for 4 hours, dry for 100 hours at a vacuum degree of 320mtorr and a condensation temperature of -55°C. The drying curve is shown in the appendix figure 2 , The measured powder moisture content is 6.87%. Jujube jujube polysaccharides were extracted by decompression and internal boiling method. The process parameters were as follows: internal temperature of the system was 50°C, ratio of liquid to solid was 50:1 (ml:g), time was 30 minutes, vacuum degree was 87kPa, and external temperature was 60°C. The extract was suction-filtered twice continuously, concentrated under reduced pressure at 50°C to a certain volume, and precipitated with 4 times the volume of 95% ethanol, and the precipitate was w...

Embodiment 2

[0028] Use a stainless steel knife to peel, pit, and slice a certain amount of jujube jujube in a pot, take 800g of jujube meat, add 4000ml of distilled water and use a colloid mill to make a pulp, and use vacuum freeze-drying technology to dry it to make powder. After freezing for 4 hours, dry for 100 hours at a vacuum degree of 320mtorr and a condensation temperature of -55°C. The drying curve is shown in the appendix figure 2 , The measured powder moisture content is 6.87%. Jujube jujube polysaccharides were extracted by decompression and internal boiling method. The process parameters were as follows: internal temperature of the system was 60°C, ratio of liquid to solid was 50:1 (ml:g), time was 45min, vacuum degree was 80kPa, and external temperature was 71°C. The extract was suction-filtered twice continuously, concentrated under reduced pressure at 55°C to a certain volume, and precipitated with 4 times the volume of 95% ethanol, and the precipitate was washed with a c...

Embodiment 3

[0030] A certain amount of jujube jujube is peeled, pitted and sliced with a stainless steel knife, 500g of jujube meat is taken, and 2500ml of distilled water is added to make a pulp with a colloid mill, and it is dried and powdered by vacuum freeze-drying technology. After freezing for 4 hours, dry for 100 hours at a vacuum degree of 320mtorr and a condensation temperature of -55°C. The drying curve is shown in the appendix figure 2 , The measured powder moisture content is 6.87%. Jujube jujube polysaccharide was extracted by decompression and internal boiling method. The process parameters were as follows: temperature inside the system was 70°C, ratio of liquid to material was 60:1 (ml:g), time was 30 minutes, vacuum degree was 74kPa, and external temperature was 82°C. Suction-filter the extract twice consecutively, concentrate under reduced pressure at 60°C to a certain volume, precipitate with 3 times the volume of 95% ethanol, and wash the precipitate with a certain a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com