Preparation method of high-content trehalose

A trehalose, high-content technology, applied in the preparation of sugar derivatives, biochemical equipment and methods, chemical instruments and methods, etc., can solve the problems of inability to completely remove, limit the scope of application of trehalose, and improve the degree of water locking and moisturizing. , the effect of reducing Maillard reaction and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] A method for preparing high-content trehalose, which specifically includes: (1) preparation of starch milk, (2) liquefaction, (3) double enzymatic hydrolysis, (4) filtering to remove protein, (5) decolorization, (6) desalination, (7) Purification, (8) concentration and crystallization, (9) separation and drying; wherein:

[0021] (1) Preparation of starch milk: Soak corn in water, the ratio of corn to water is 5:2, the temperature of soaking water is 40°C, and soak until the seed coat of corn can be peeled off to obtain soaked corn; filter out the water and dry the soaked corn Crushing is carried out to separate the seed coat until the whole grain amount is 8 grains / 100g to obtain broken corn; the broken corn is ground to remove the germ in the corn until the number of corn germ in the grinding liquid is 3 pieces / 100ml to obtain the grinding liquid ; Separating the discs from the grinding liquid until the protein content in the grinding liquid is 10%, to obtain starch m...

Embodiment 2

[0032] A method for preparing high-content trehalose, which specifically includes: (1) preparation of starch milk, (2) liquefaction, (3) double enzymatic hydrolysis, (4) filtering to remove protein, (5) decolorization, (6) desalination, (7) Purification, (8) concentration and crystallization, (9) separation and drying; wherein:

[0033](1) Preparation of starch milk: Soak corn in water, the ratio of corn to water is 6.6:4.5, the temperature of soaking water is 50°C, and soak until the seed coat of corn can be peeled off to obtain soaked corn; Crushing is carried out to separate the seed coat until the whole grain amount is 5 grains / 100g to obtain broken corn; the broken corn is ground to remove the germ in the corn until the number of corn germ in the grinding liquid is 2 / 100ml to obtain the ground liquid; the grinding liquid is subjected to disc separation until the protein content in the grinding liquid is 6%, and starch milk is obtained;

[0034] (2) Liquefaction: (1) Afte...

Embodiment 3

[0044] A method for preparing high-content trehalose, which specifically includes: (1) preparation of starch milk, (2) liquefaction, (3) double enzymatic hydrolysis, (4) filtering to remove protein, (5) decolorization, (6) desalination, (7) Purification, (8) concentration and crystallization, (9) separation and drying; wherein:

[0045] (1) Preparation of starch milk: Soak corn in water, the ratio of corn to water is 8:5, the soaking water temperature is 60°C, and soak until the seed coat of corn can be peeled off to obtain soaked corn; filter out the water and dry the soaked corn Carry out crushing until the whole grain amount is 2 grains / 100g to obtain broken corn; grind the broken corn (remove the germ in the corn), until the number of corn germs in the grinding liquid is 1 piece / 100ml, obtain the grinding liquid; grinding liquid Carry out disk separation until the protein content in the grinding liquid is 3%, to obtain starch milk;

[0046] (2) Liquefaction: (1) After the...

PUM

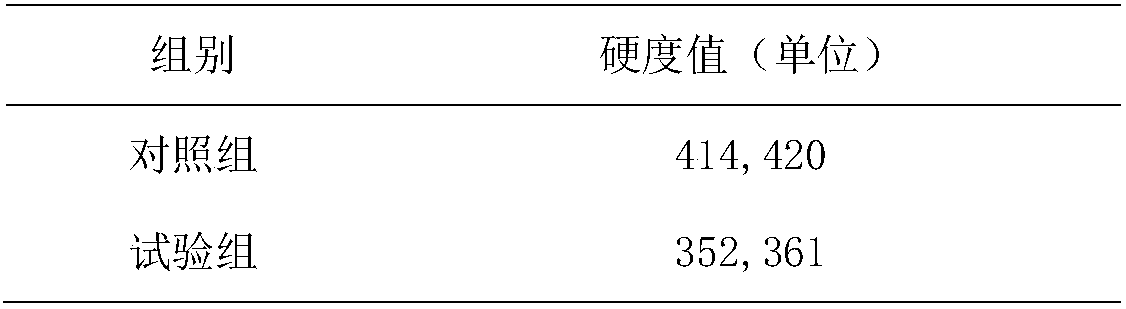

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com