Process for treating cyclic cooling water

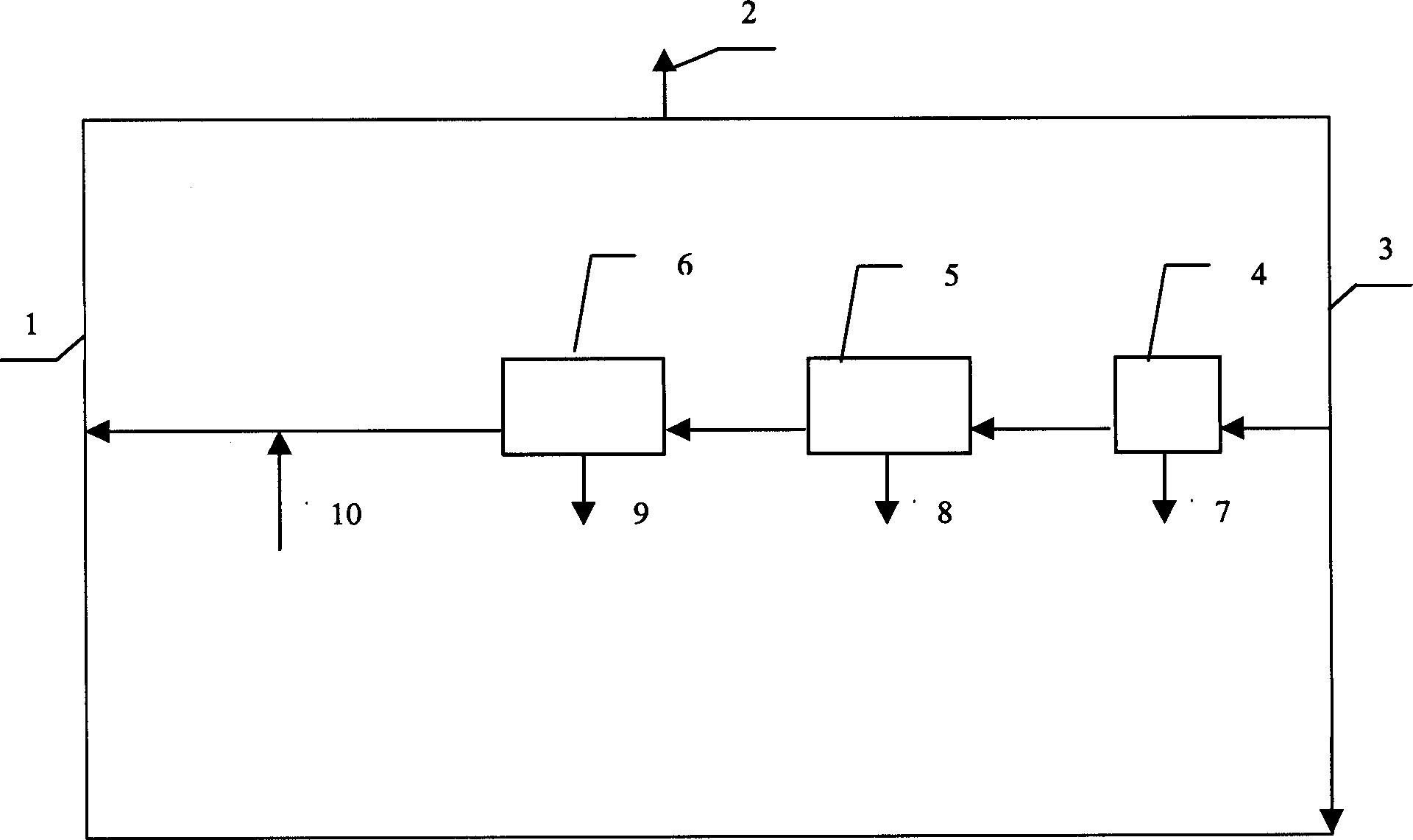

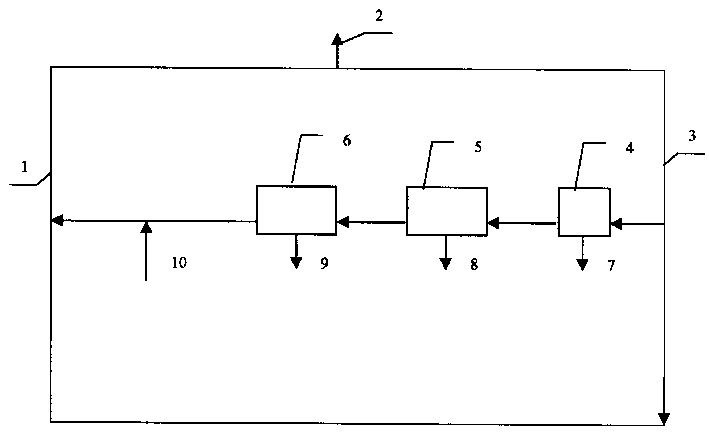

A technology of circulating cooling water and treatment methods, which is applied in the direction of osmosis/dialysis water/sewage treatment, flocculation/sedimentation water/sewage treatment, separation methods, etc., which can solve the problem of not fundamentally increasing the concentration multiple of the circulating cooling system and reducing the cooling cycle The water system supplements water volume, one-time investment and large area, and achieves good environmental and social benefits, ideal economy, and no consumption of chemicals.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] In the circulating cooling water system of a petrochemical refinery in China, the total amount of circulating water is 20858m 3 h -1 , the evaporation loss of the circulation system is 188m 3 h -1 , the wind blowing loss of the air-cooled tower is 22m 3 h -1 , the system discharge volume is 223m 3 h -1, the cycle concentration factor is 1.77, the surface water is used as the supplementary water of the circulating cooling water system, and the supplementary water volume is 433m 3 h -1 . The main water quality of circulating water is: calcium hard 102mgL -1 , Alkalinity 115mgL -1 , Turbidity 15mgL -1 , conductance 1590mgL -1 , Cl-150mgL -1 , pH8.2.

[0016] Adopt the present invention to carry out fiber filtration and low-pressure reverse osmosis treatment to the effluent of the side filter tank of the circulating cooling system, and the treated water volume is 206m 3 h -1 , the fiber filter is filled with fiber bundles, and the filter depth of the control ...

Embodiment 2

[0019] In the circulating cooling water system of a petrochemical refinery in China, the total circulating water is 42800m 3 h -1 , circulation system evaporation loss 652m 3 h -1 , the wind blowing loss of the air cooling tower is 40m 3 h -1 , the system discharge volume is 504m 3 h -1 , control the cycle concentration multiple of 2.2, use surface water as the supplementary water of the circulating cooling water system, and the supplementary water volume is 1196m 3 h -1 , the main water quality of circulating water is: calcium hard 60.3mgL -1 , Alkalinity 58.8mgL -1 , Turbidity 13mgL -1 , conductance 386mgL -1 , Cl-55mgL -1 , pH7.99.

[0020] Adopt the present invention to carry out fiber filtration and low-pressure reverse osmosis treatment to the effluent of the side filter tank of the circulating cooling system, and the treated water volume is 422m 3 h -1 , the fiber filter is filled with fiber bundles, and the filter depth of the control line is 18mh -1 , u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com