Method and device for extracting asphalt from oil sand through solvent extraction

A solvent and oil sand technology, applied in the field of petroleum extraction and smelting, can solve the problems of large water content changes in raw materials, high fine powder content, and large dust, and achieve low equipment investment costs, low solvent loss, and less investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

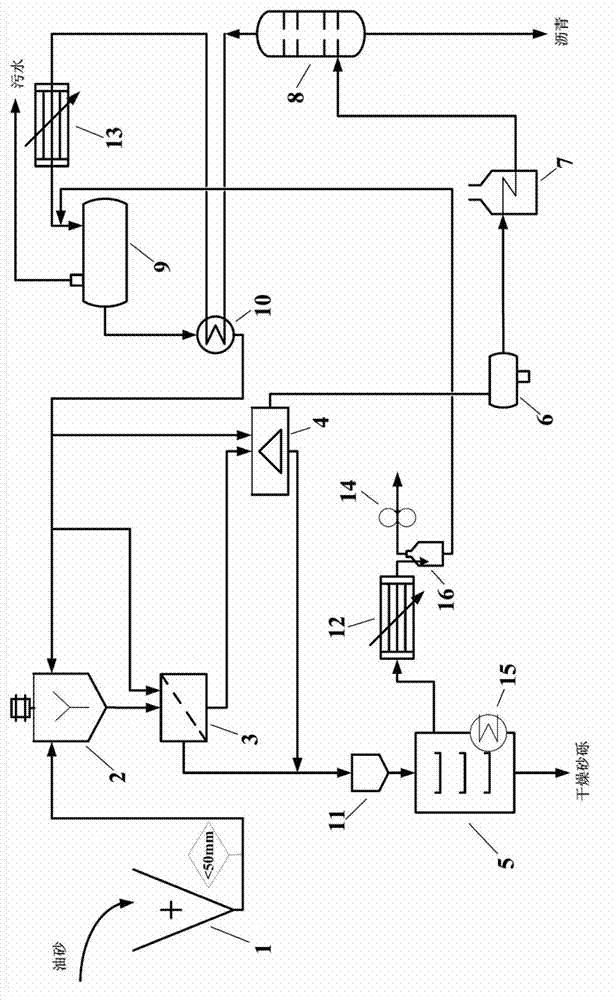

[0056] This embodiment provides a device for extracting asphalt from oil sands through solvent extraction, its structure is as follows figure 1 shown.

[0057] The device includes a crushing and screening machine 1, a stirring tank 2, a secondary screening machine 3, a centrifugal filter 4, a dryer 5, an asphalt solution tank 6, a heating furnace 7, a distillation tower 8, a solvent tank 9, a heat exchanger 10, an intermediate Tank 11, first water condenser 12, second water condenser 13, vacuum pump 14, wherein,

[0058] The crushing and screening machine 1 communicates with the entrance of the stirring tank 2, and a lifting hopper is arranged between the two;

[0059] The outlet of the stirred tank 2 is communicated with the inlet of the secondary screening machine 3;

[0060] The secondary screening machine 3 communicates with the entrance of the intermediate tank 11 and the entrance of the centrifugal filter 4 respectively;

[0061] The outlet of intermediate tank 11 com...

Embodiment 2

[0071] This embodiment provides a method for extracting bitumen from oil sands, which is carried out using the extraction device provided in Example 1, and includes the following specific steps:

[0072] 1. Take 100.5 kg of bitumen-containing oil sand (oil content 25%, water content 1.2%, gravel particle size 2-3000 μm, mainly CaCO 3 and SiO 2 ) is transported to the crushing and screening machine 1 for crushing the raw ore of oil sand asphalt, and crushed into particles with a diameter below 50 mm, and the particles larger than 50 mm are returned to the crushing and screening machine 1 for crushing again;

[0073] Then the granular oil sand with diameter D3 Dichlorohydrocarbons: C 8 Aromatic hydrocarbons volume ratio=2:1, distillation range range: 60-140 ℃) carry out mixing and stirring, stirring speed is 180 rpm, and stirring time is 15 minutes, obtains mixed slurry; The recovery solvent at the top is exchanged in the heat exchanger 10 to increase the temperature to 60° C....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com