Patents

Literature

30results about How to "Increase active sites" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

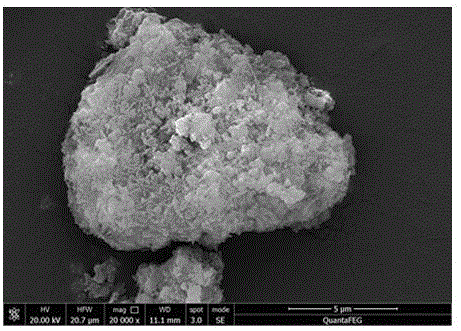

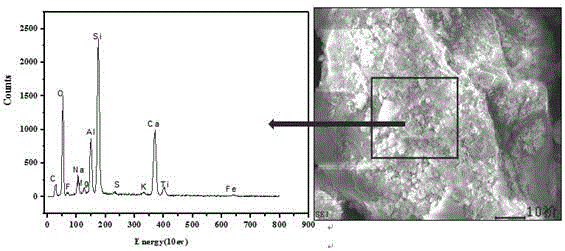

Preparation method of heavy metal ion remover

The invention provides a preparation method of a heavy metal ion remover. Discarded hardened cement concrete is used as a raw material. The preparation method comprises the steps: primary crushing andpresintering; smashing and separation; ball milling and activation; and powder separation. Heavy metal ions in wastewater containing copper, zinc, chromium, nickel and the like can be effectively removed, and an implementation process of a technical method has the advantages that the speed for removing the heavy metal ions is high, the reaction time is short, the removal effect is stable, and themethod can be operated at room temperature. The technical application of a building waste, namely hardened cement stone in discarded concrete, is widened to the field of heavy metal sewage treatment,no problem of limit mixing amount exists, the recycling efficiency of the discarded cement stone is increased, and the economic additional value of the discarded cement stone is increased.

Owner:YANGTZE NORMAL UNIVERSITY

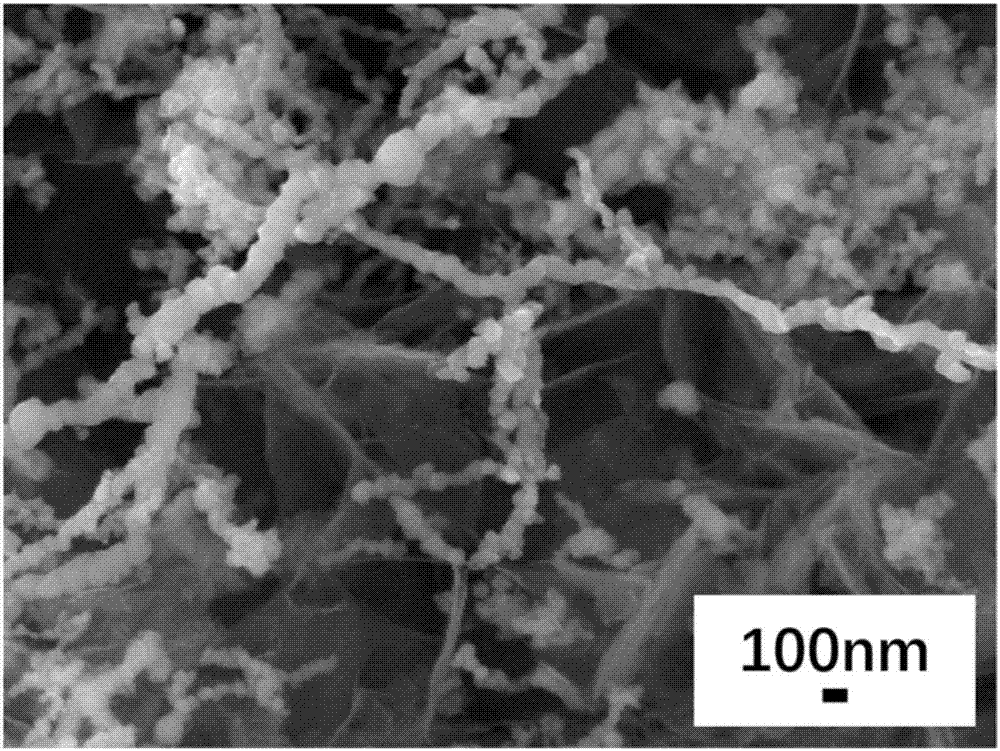

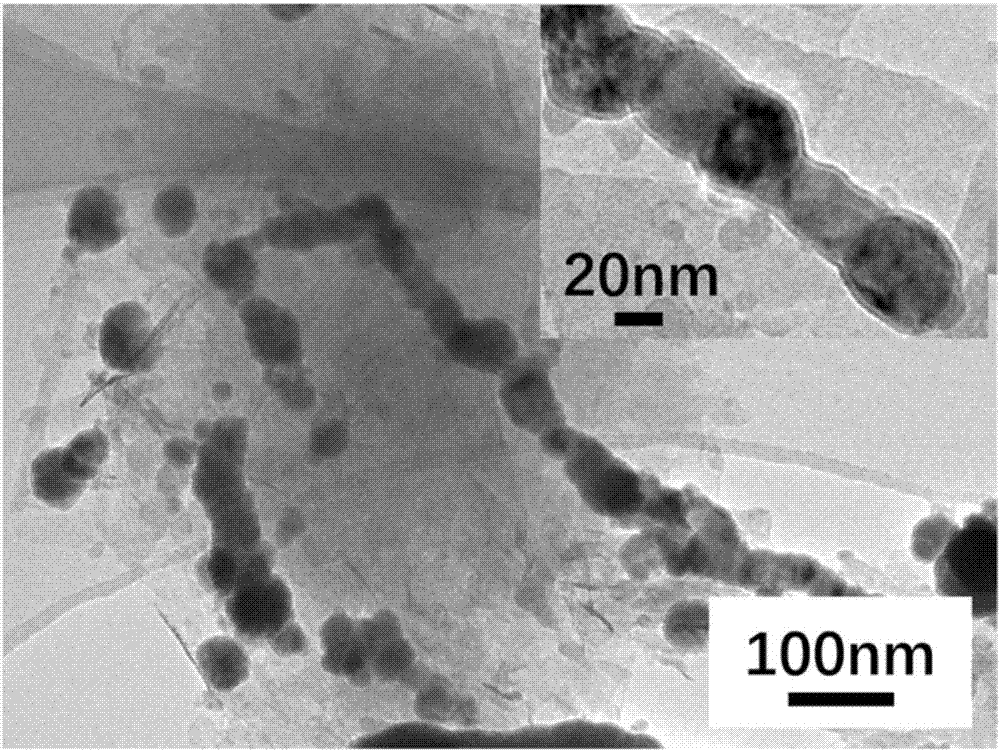

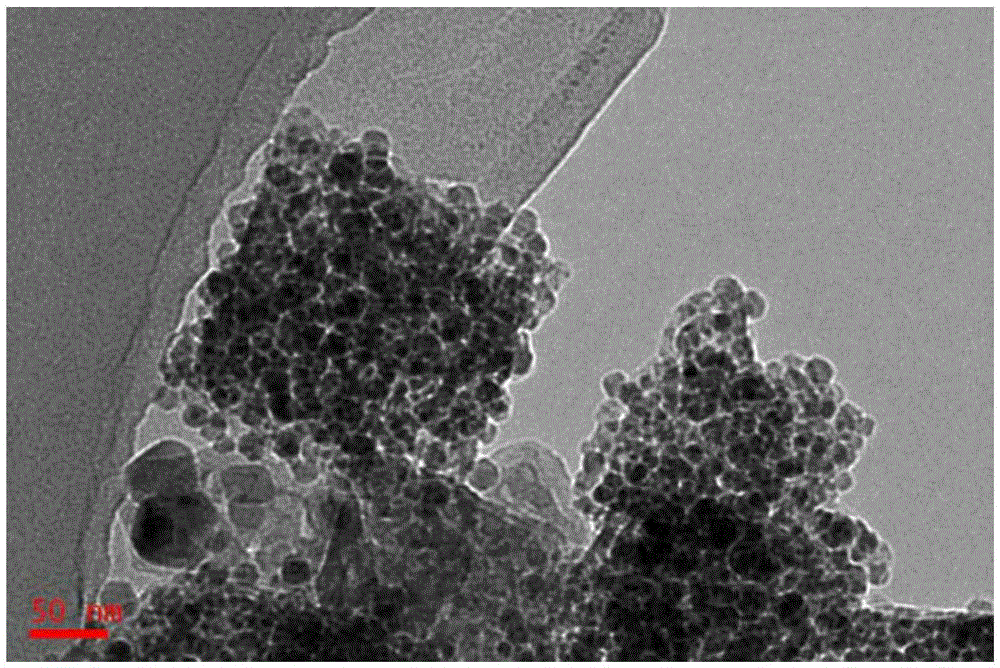

Preparation method of activated-carbon multi-point-location supported nano zero-valent iron composite material

InactiveCN107456967AIncrease active sitesIncrease loadMetal/metal-oxides/metal-hydroxide catalystsActivated carbonNitrogen gas

The invention provides a method for preparing a composite material of activated carbon loaded with nanometer zero-valent iron, comprising the following steps: Step 1: adding microcrystalline cellulose solution and citric acid to the activated carbon, and hydrothermally reacting to prepare modified activated carbon; Step 2 : Polyethylene glycol is dissolved in ultrapure water to prepare a dispersant solution; Step 3: FeSO4·7H2O is dissolved in the dispersant solution, stirred magnetically under nitrogen protection, and slowly dripped into NaBH4 solution to obtain Activated carbon multi-site loaded nano zero-valent iron composite material. The invention prepares multi-point activated carbon, increases the active sites of activated carbon to a large extent, and effectively improves the loading capacity of nano-zero-valent iron; uses polyethylene glycol solution as a dispersant, so that nano-zero-valent iron particles are evenly loaded on the activated carbon , good dispersion, and improve the catalytic degradation ability of the composite material to pollutants; polyethylene glycol is non-toxic and has good stability, and the residual components will not cause secondary pollution during the repair process.

Owner:BEIJING UNIV OF CHEM TECH

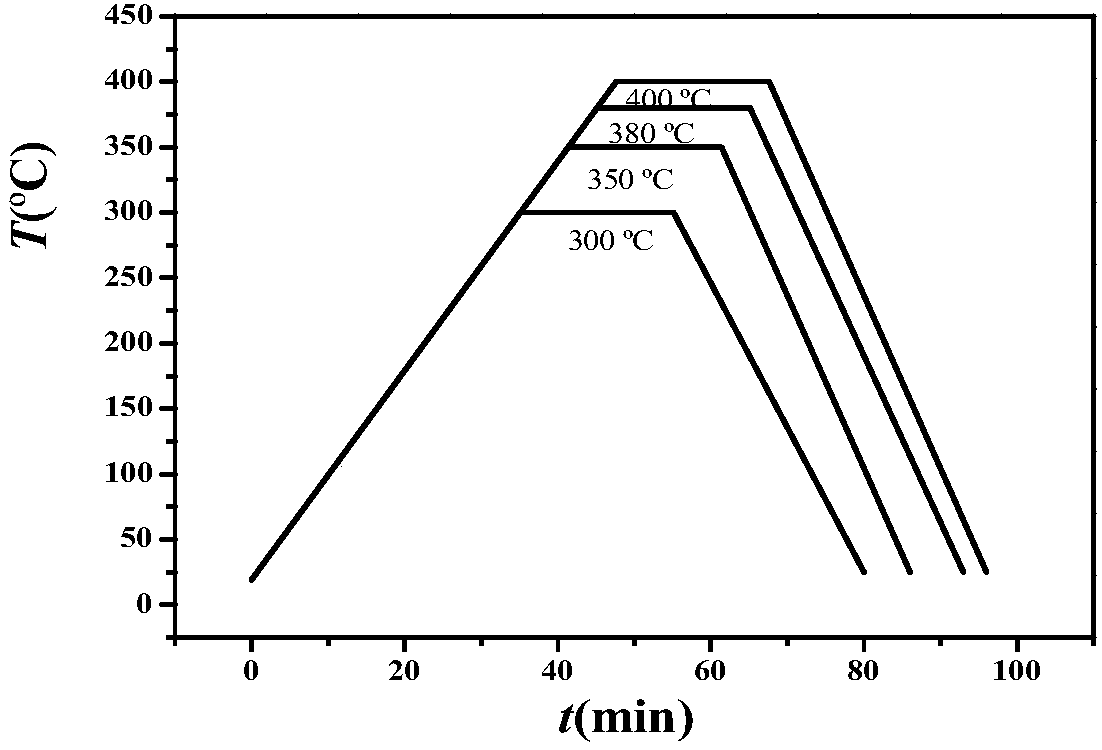

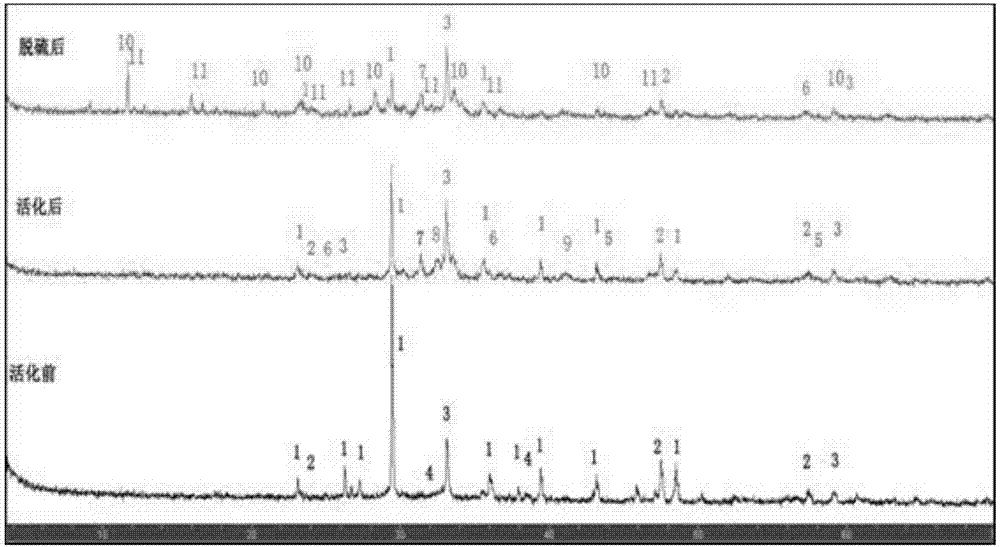

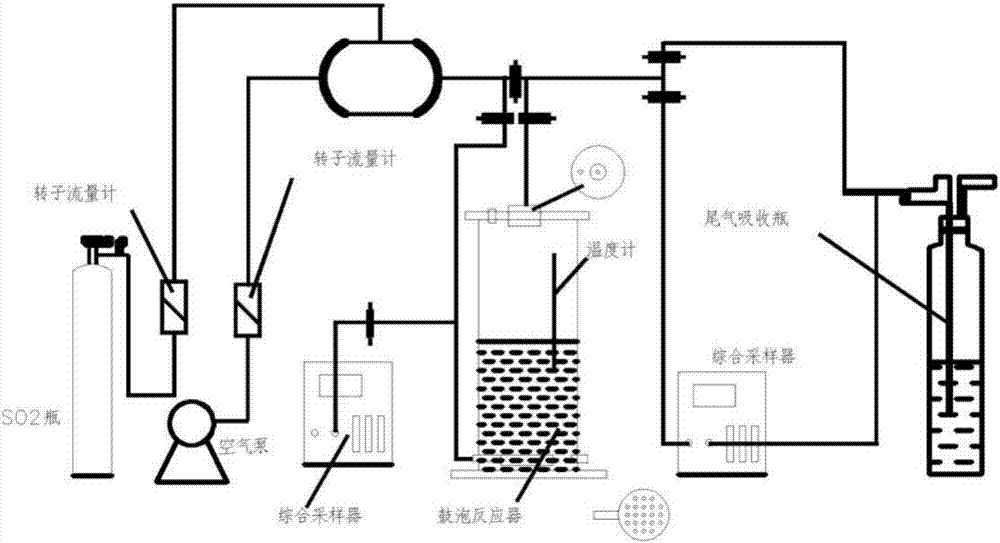

Method for preparing desulfurizing agent by carrying out thermal activation on red mud and active carbon

InactiveCN106881019AEasy to get from a wide range of sourcesThe source is easy to getGas treatmentDispersed particle separationMass ratioRed mud

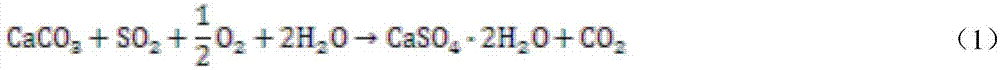

The invention discloses a method for preparing a desulfurizing agent by carrying out thermal activation on red mud and active carbon and belongs to the field of coal desulfurization. The method comprises the specific steps: step a: sieving the red mud and the active carbon with a 300-mesh sieve respectively; drying at 105 DEG C until the weight is constant; step b: mixing the red mud and the active carbon according to the mass ratio ranging from (1 to 10) to (1 to 30); step c: activating a mixture in the step b in a muffle furnace at 700 DEG C to 1100 DEG C for 10min to 30min; after finishing the thermal activation, naturally cooling to room temperature under a sealed condition. The method disclosed by the invention has the advantages that the waste dreg red mud produced in a production process of aluminum oxide is prepared into the desulfurizing agent; a preparation process is simple and the activation time is short; the wet-method desulfurizing efficiency can reach 90 percent; the desulfurizing rate can be maintained to be 87 percent when the desulfurizing agent is continuously used under a low pH (Potential of Hydrogen) condition; the dosage of the desulfurizing agent is reduced so that the desulfurizing agent is economical and feasible.

Owner:CHINA UNIV OF MINING & TECH

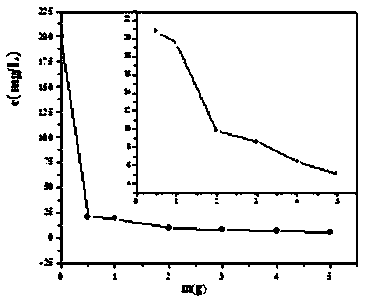

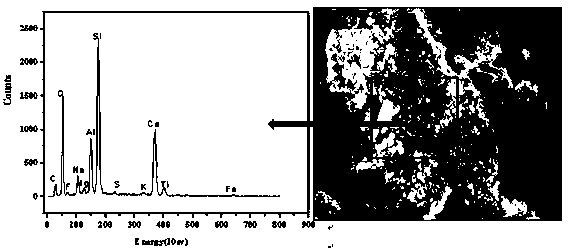

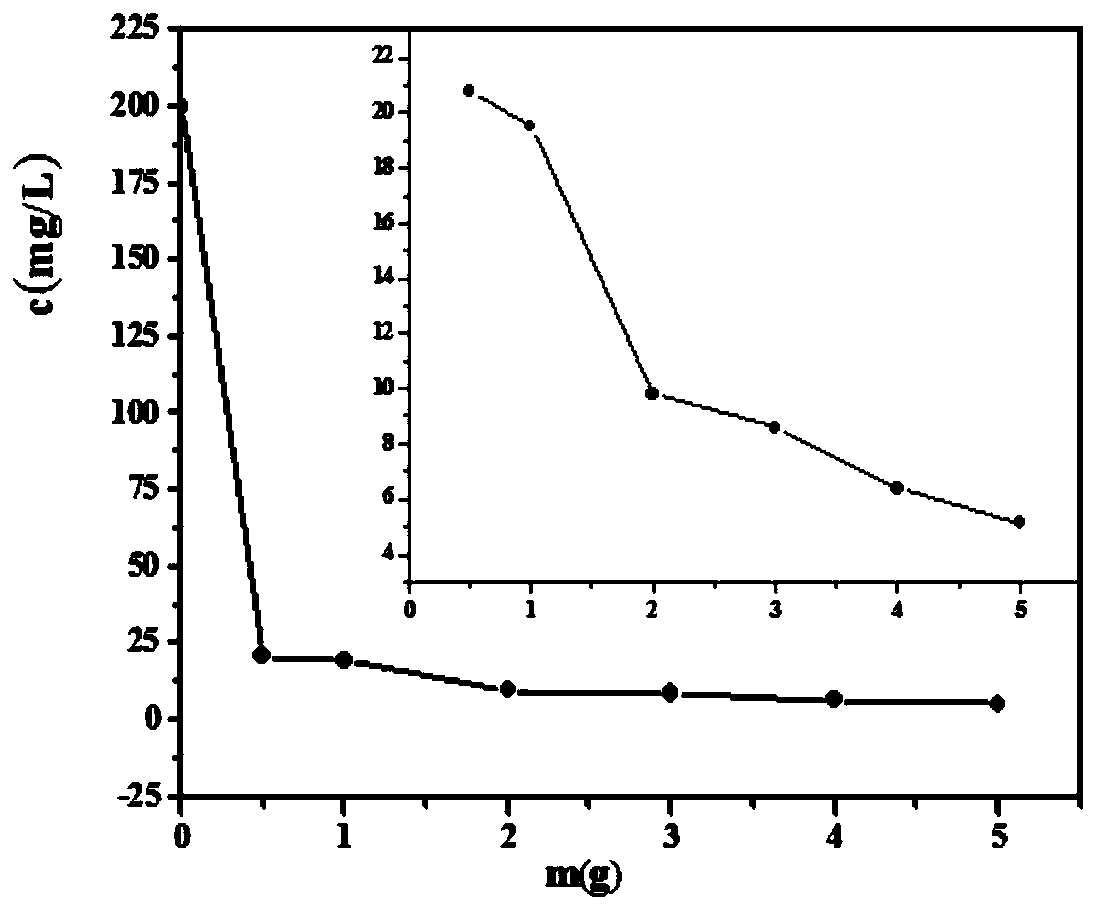

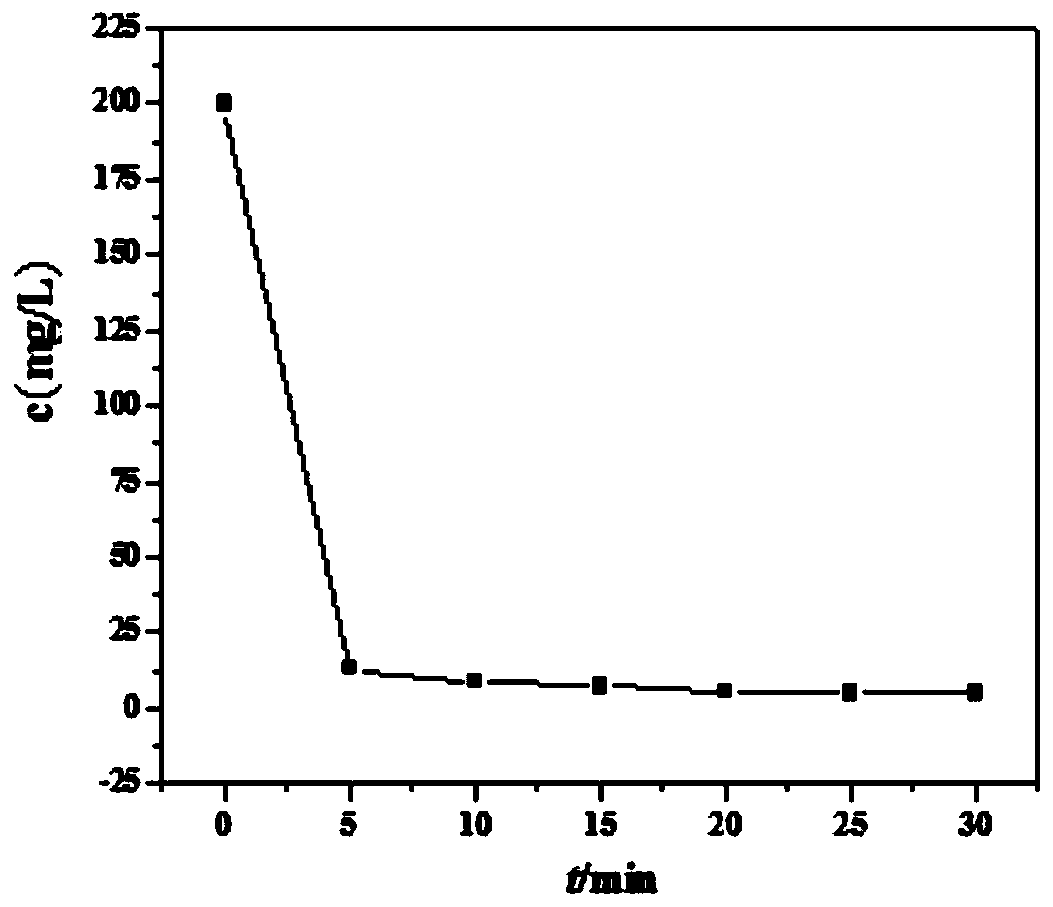

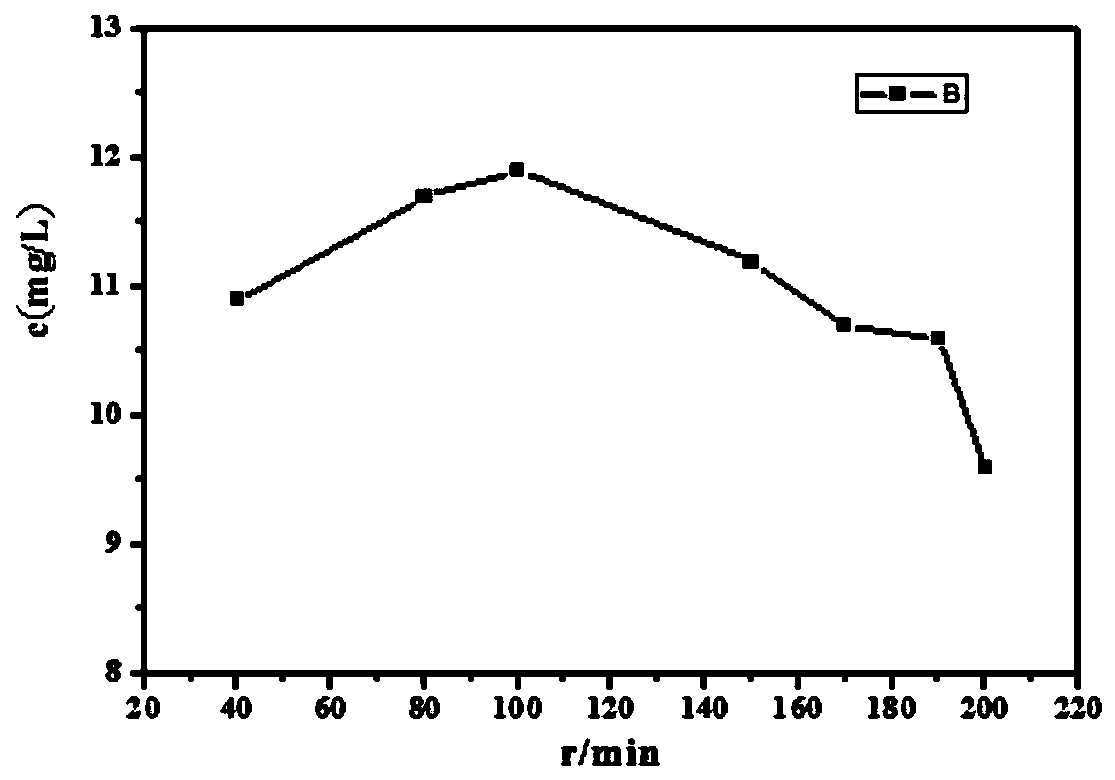

Application of waste concrete to fluorine removal in water

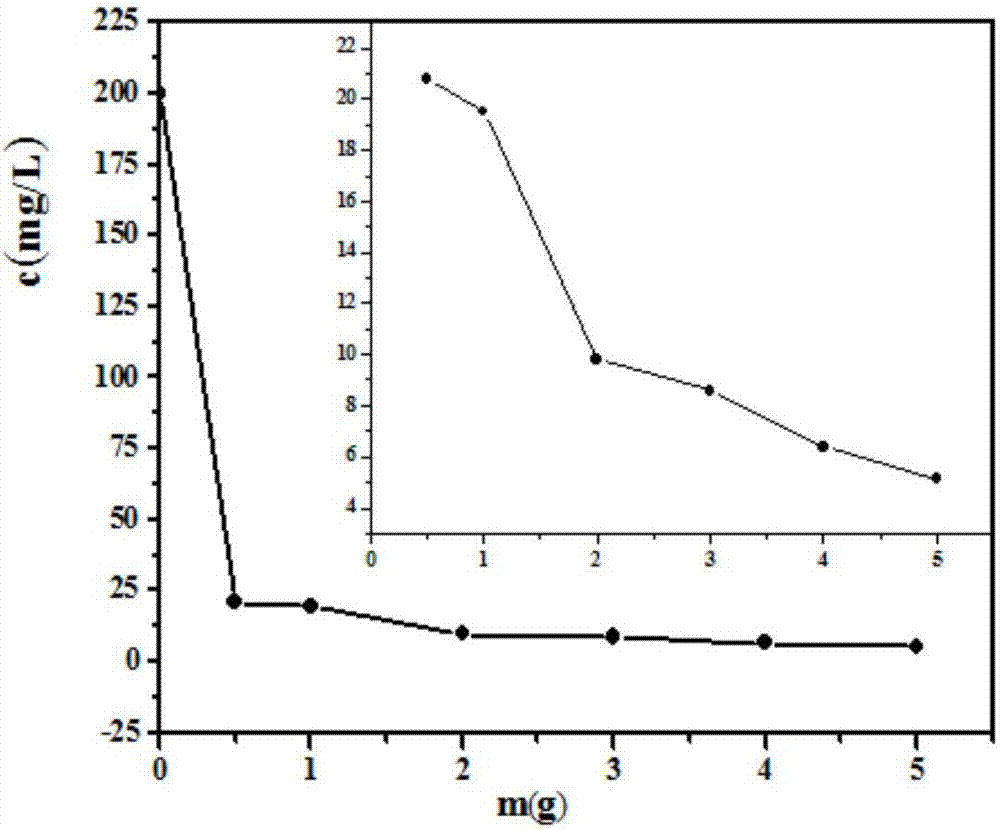

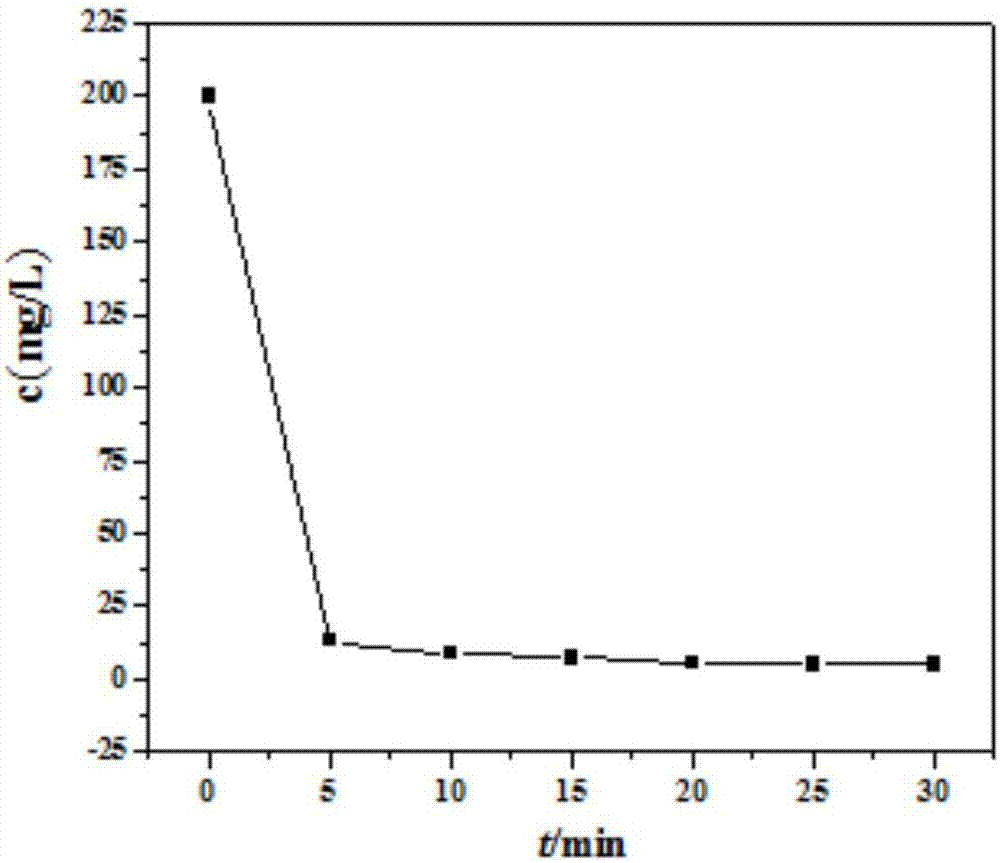

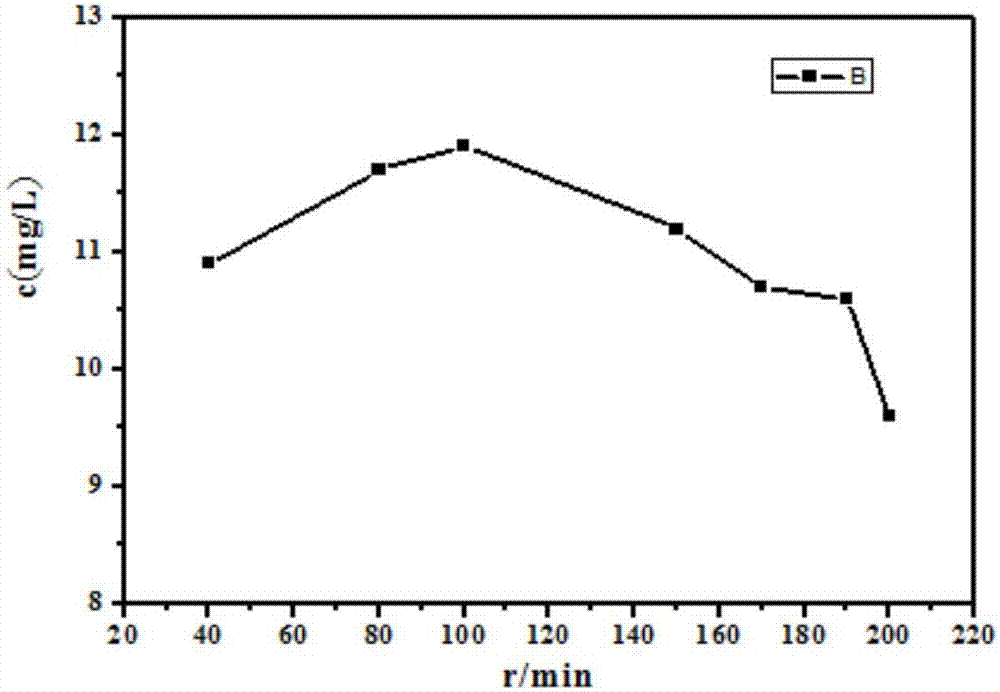

ActiveCN107540041AAvoid high porosityPrevent water absorptionWater contaminantsWater/sewage treatment by flocculation/precipitationResource utilizationRoom temperature

The invention discloses application of waste concrete to fluorine removal in water. During application, the method comprises the following steps: (1) primarily crushing and calcining the waste concrete serving as a raw material, screening out cement stone, ball-milling the cement stone, performing powder selecting separation and collecting particles with the particle size being below 80 [mu]m to obtain a water fluorine removing agent; and (2) throwing the water fluorine removing agent obtained in the step (1) into fluorine-containing wastewater to remove the fluorine from the wastewater. Application of the building waste, namely waste concrete, is enlarged to the field of treatment of the fluorine-containing wastewater, the water fluorine-removing material is prepared, the reaction speed is high in the water fluorine removing process, limit doped amount does not exist, the utilization efficiency is high, the fluorine-removing effect is stable, operation can be conducted at room temperature, the resource utilization efficiency of the waste cement stone is improved, and a technological route is provided for high-additional-value utilization of hardened cement stone in the waste concrete.

Owner:YANGTZE NORMAL UNIVERSITY

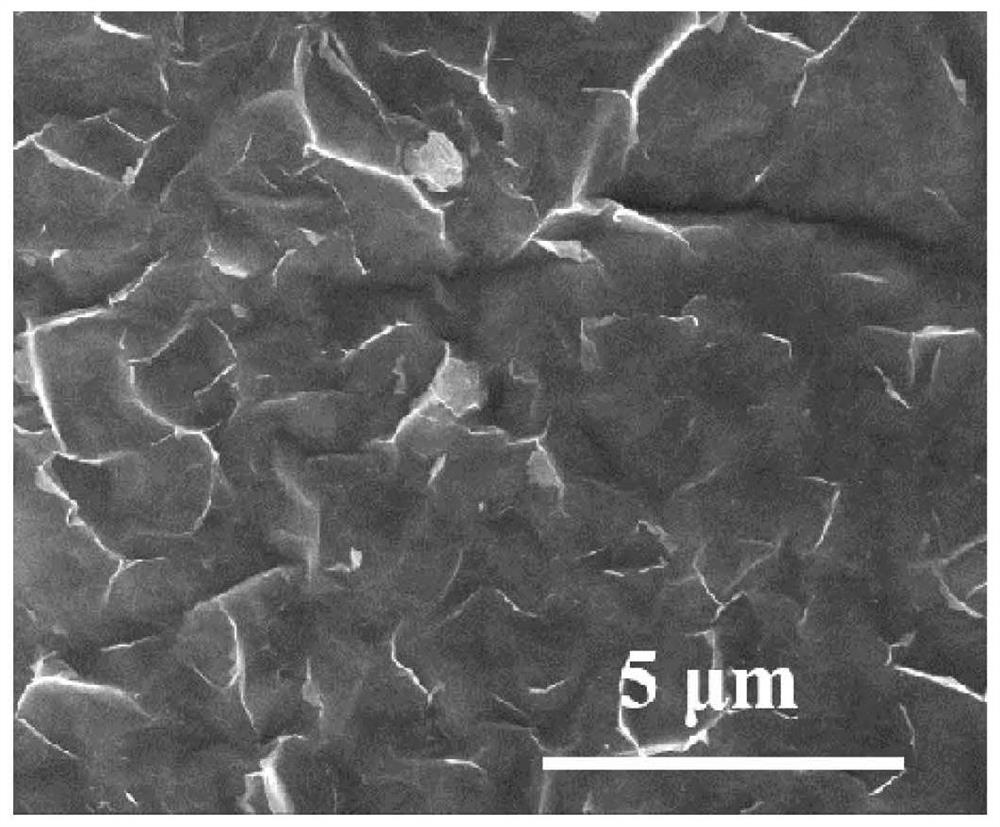

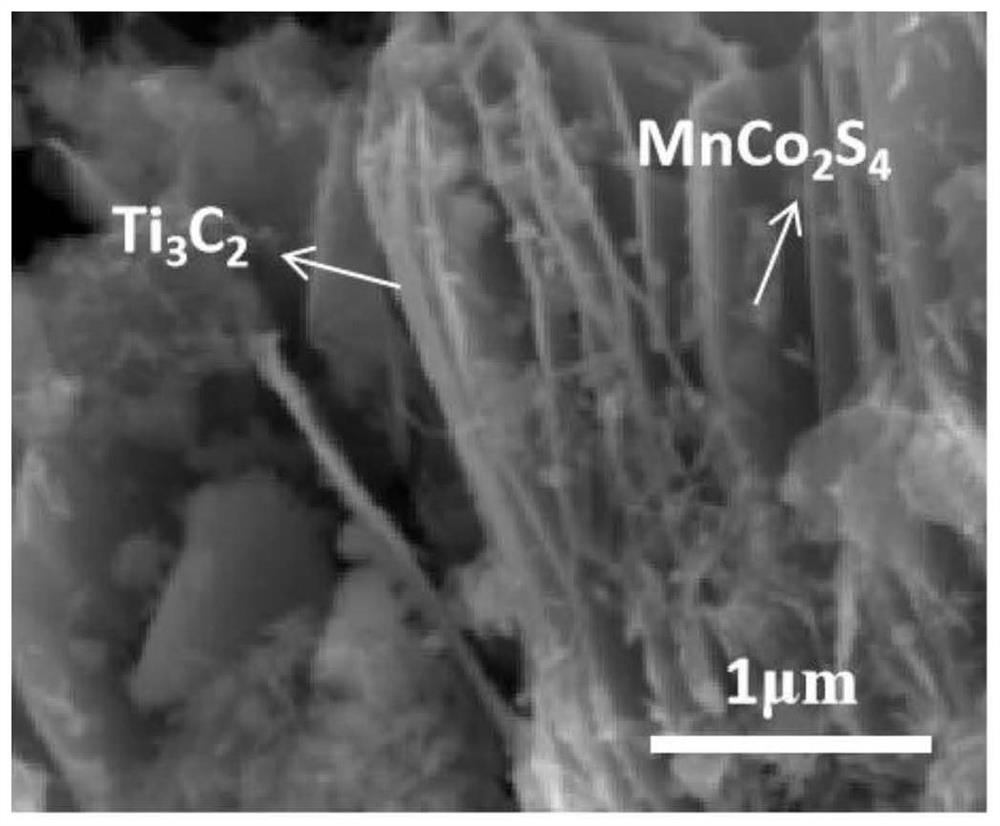

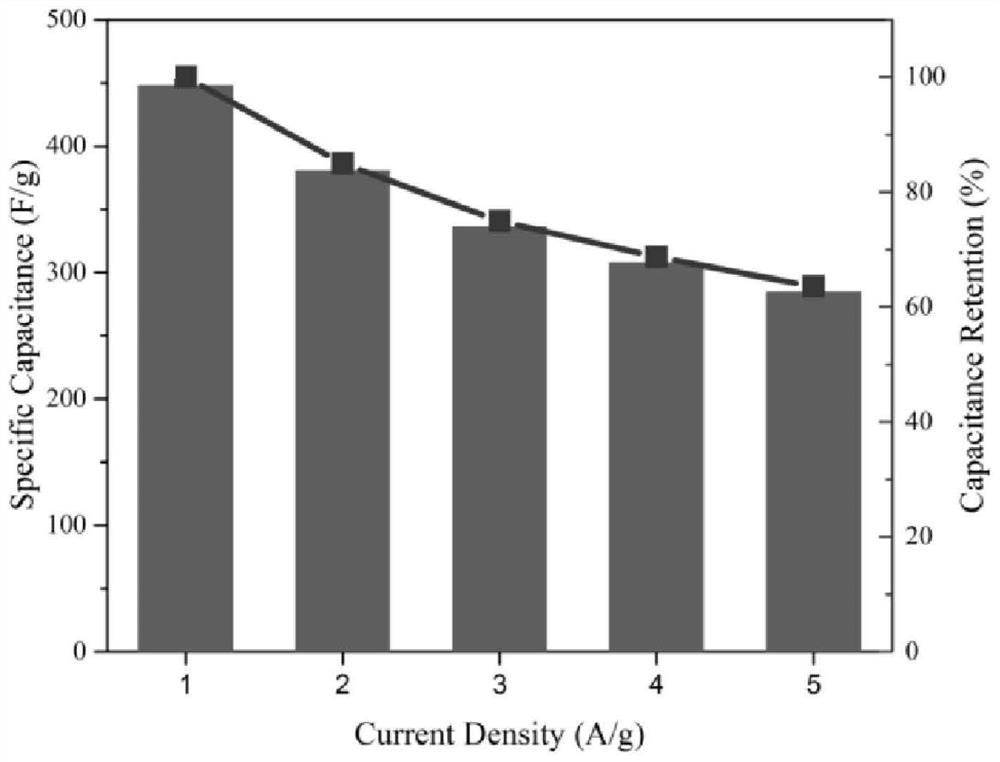

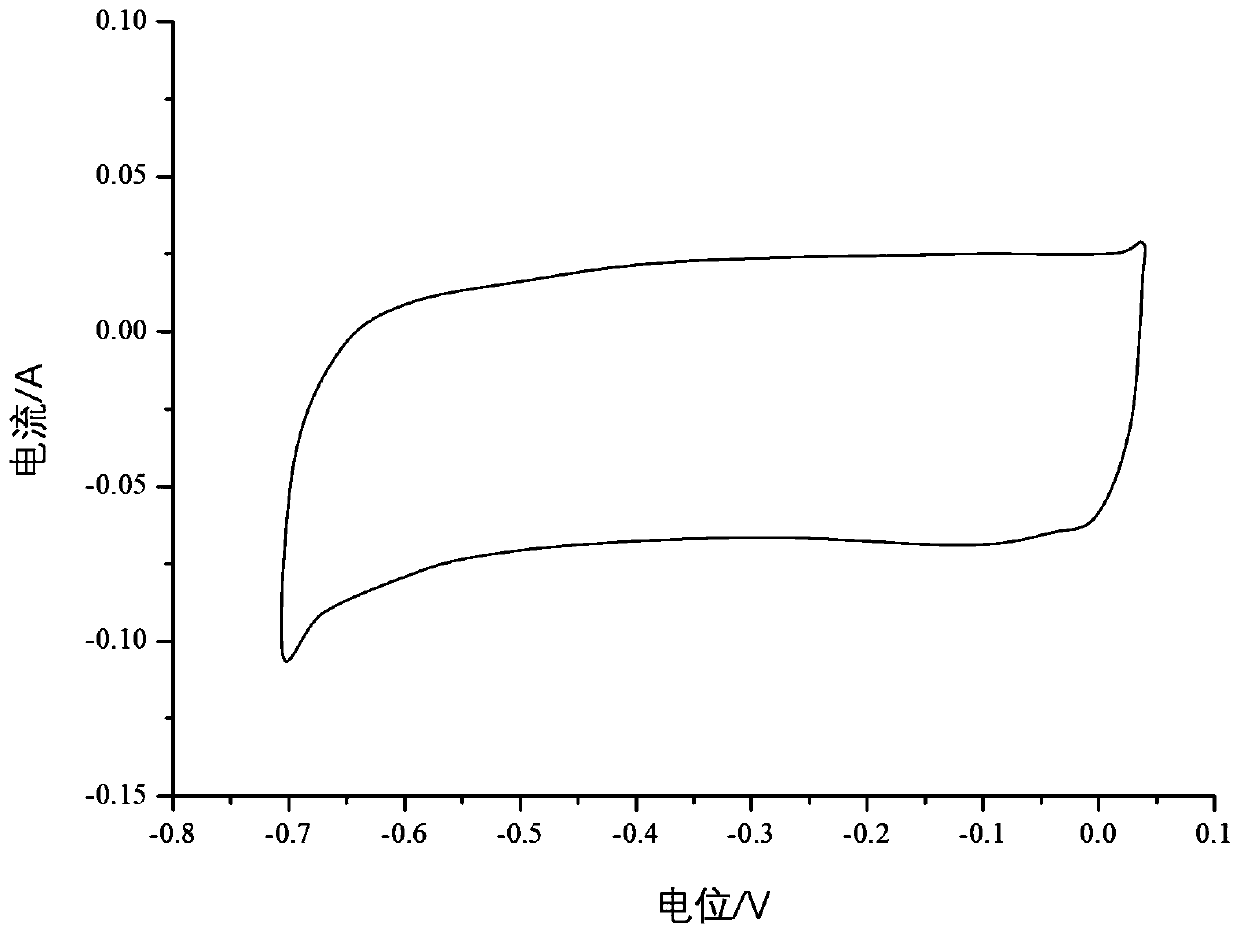

Ti3C2/MnCo2S4 composite hybrid electrode material and preparation method thereof

InactiveCN111816457AIncrease energy densityImprove stabilityHybrid capacitor electrodesTitanium carbideCapacitanceHigh energy

The invention relates to a Ti3C2 / MnCo2S4 composite hybrid electrode material and a preparation method thereof. The preparation method comprises the steps of: acquiring a large number of single-layer or few-layer two-dimensional Ti3C2 by adopting in-situ corrosion, high-power ultrasonic assistance, centrifugal screening and other methods; preparing a MnCo2S4 nano material by taking manganese nitrate tetrahydrate, cobalt nitrate hexahydrate and urea as raw materials; and then uniformly mixing single-layer or few-layer two-dimensional Ti3C2, urea and a MnCo2S4 solution, and preparing the Ti3C2 / MnCo2S4 composite hybrid electrode material by adopting a hydrothermal method. The preparation method is low in equipment requirement, controllable in operation process and simple in process; and the prepared supercapacitor electrode material has the advantages of environmental friendliness, good charge-discharge cycling stability and rate capability, high specific capacitance, high energy density and the like, and has good application potential in the fields of energy storage and the like.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Eco-friendly modified-rice-straw soil modifier

InactiveCN105948967AIncrease disorderImprove adsorption capacitySuperphosphatesExcrement fertilisersSodium BentonitePotassium

The invention discloses an eco-friendly modified-rice-straw soil modifier. The soil modifier is made from the following raw materials, by weight part, 6-7 of sodium alginate, 3-4 of calcium lignosulphonate, 1-2 of zinc lignosulphonate, 36-39 of fresh chicken manure, 5-6 of cocoa powder, 5-6 of calcium dihydrogen phosphate, 4-5 of potassium humate, 44-46 of rice straw, 1.7-1.8 of monochloro acetic acid, 13-14 of kaolin, 3-5 of calcium-based bentonite and a proper amount of water. Natural raw materials are adopted in the soil modifier and can be totally absorbed by soil during soil modification, and the problem of non-decomposable residues resulting from adoption of chemical organic materials in a conventional soil modifier is overcome. The soil modifier also has the functions of growth promotion, stress resistance and soil activation. Through the soil modifier, consumption of a fertilizer during a planting process in modified soil is reduced, and comprehensive development of recycling economy is achieved.

Owner:JIXI YUANDAO AGRI IND TECH

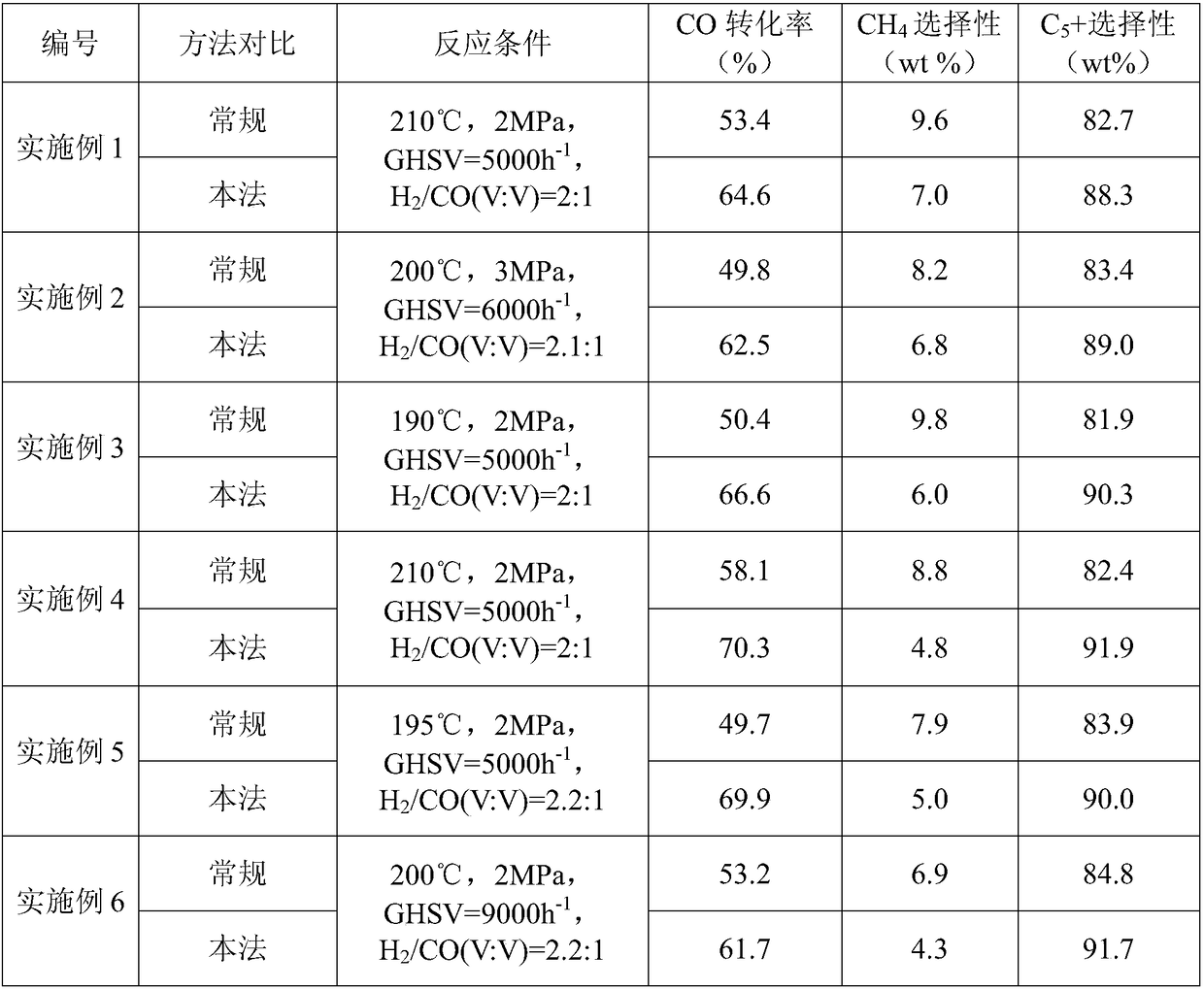

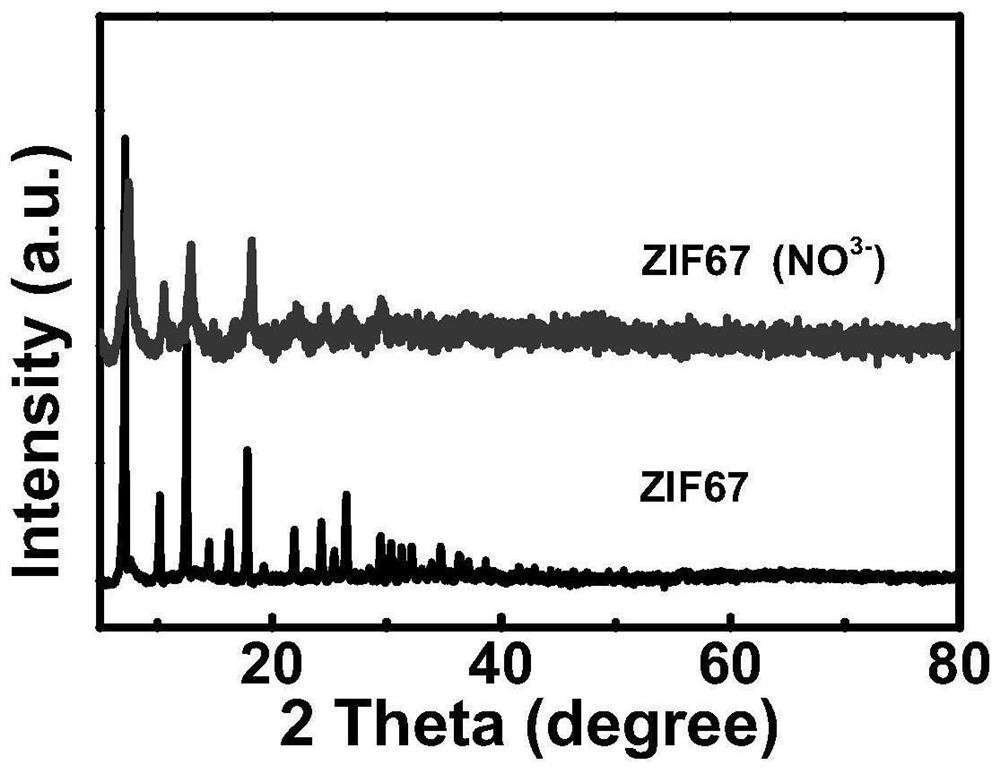

High-dispersion heavy-hydrocarbon Fischer-Tropsch synthetic catalyst based on carbonization processing method and preparation method thereof

ActiveCN108246313AHigh activityHigh selectivityCatalyst activation/preparationLiquid hydrocarbon mixture productionSyngasCobalt salt

The invention discloses a high-dispersion heavy-hydrocarbon Fischer-Tropsch synthetic catalyst based on a carbonization processing method and a preparation method thereof. The preparation method of the high-dispersion heavy-hydrocarbon Fischer-Tropsch synthetic catalyst comprises the following steps: loading a soluble salt of a metal additive on a formed carrier by using an impregnation method, drying and roasting to obtain a pre-processed carrier; loading a soluble cobalt salt and an organic matter on the pre-processed carrier by using the impregnation method, and drying to obtain the catalyst. According to the preparation method, a process of carbonization processing is introduced into a conventional evaluation step of reduction-Fischer-Tropsch synthesis of the catalyst, and the evaluation step is optimized as a step of reduction - synthesis gas processing - carbonization - H2 reprocessing, so the Co average grain size of the catalyst through the above actions is reduced. The secondary reduction is performed on the carbonized catalyst, the excess carbon deposition is eliminated, and thereby the Fischer-Tropsch reactivity of the catalyst is improved. Through the secondary reduction, the grain size is reduced, the activity point location is increased, and the reduction degree of the catalyst is further improved, so the performance of the catalyst is improved.

Owner:SYNFUELS CHINA INNER MONGOLIA CO LTD

Preparation method of fluorine removal agent for water

ActiveCN107522276ALarge specific surface areaWide range of raw materialsWater contaminantsWater/sewage treatmentEnvironmental resistanceMicrometer

The invention disclose a preparation method of a fluorine removal agent for water. The method includes: waste concrete is used as the raw material and subjected to primary crushing and calcining to screen out set cement, and the set cement is subjected to ball milling and powder selection and separation to collect particles with the particle size being below 80 micrometers so as to obtain the fluorine removal agent for water. The preparation method has the advantages that the waste concrete is used to prepare the fluorine removal agent, and the method is wide in raw material source and low in cost and provides a new approach for the recycling of the waste concrete; the method which is simple to operate, widely applicable, low in cost, environmentally friendly and capable of using waste materials to treat pollution is provided for the treatment of fluorine-containing wastewater of rivers and lakes of China, industrial and domestic fluorine-containing wastewater of China, and the like; the recycling efficiency of waste set cement is increased, and a technical path is provided for the high-additional-value utilization of the hardened cement paste in the waste concrete.

Owner:YANGTZE NORMAL UNIVERSITY

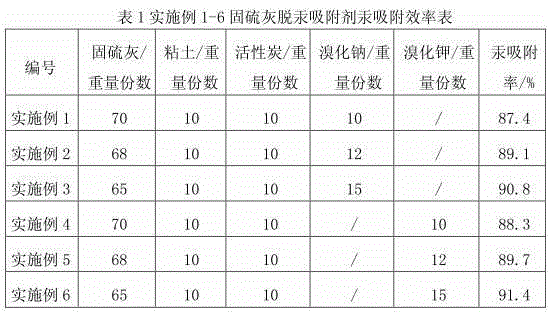

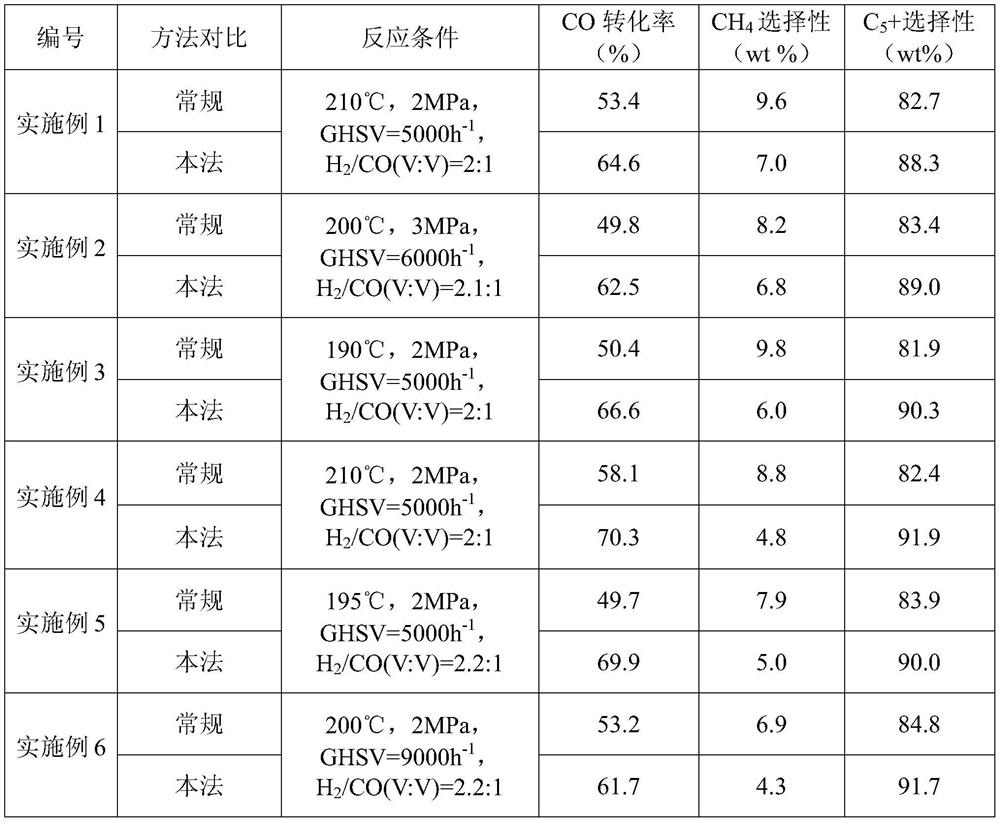

Method for preparing circulating fluidized bed boiler ash based flue gas mercury removal adsorbent for coal-fired power plant

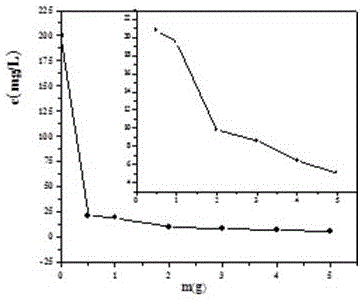

ActiveCN103599748ALow costImprove mercury adsorptionOther chemical processesDispersed particle separationSorbentNatural state

The invention relates to a method for preparing a circulating fluidized bed boiler ash based flue gas mercury removal adsorbent for a coal-fired power plant. The method is used for solving the problem that energy-saving, environment-friendly and simply-operated methods for preparing the circulating fluidized bed boiler ash based flue gas mercury removal adsorbent for the coal-fired power plant do not exist currently. The method is characterized by comprising the following steps: (1) weighing the raw materials in parts by weight: 60-80 parts of circulating fluidized bed boiler ash, 10-15 parts of clay, 5-10 parts of activated carbon and 5-15 parts of bromide, adding water to mix uniformly, dipping for 4-8 hours, and stirring at a constant speed by using a stirrer during dipping modification; (2) preparing spherical granules from a dipping-modified adsorbent by a granulator by adopting a cold-curing forming process, and naturally drying for 10-14 hours; (3) drying naturally-dried spherical adsorbent granules in a vacuum drying oven for 12-24 hours, then, taking out, putting into a drier and cooling to room temperature, thereby obtaining the circulating fluidized bed boiler ash based flue gas mercury removal adsorbent. The method has the advantages that the cost can be reduced effectively, and the operation is simple.

Owner:HUADIAN ELECTRIC POWER SCI INST CO LTD

Modified-rice-straw soil modifier for desertificated soil

InactiveCN105950161AImprove adsorption performanceIncreased soil aggregatesOther chemical processesOrganic fertilisersRice strawChemistry

The invention discloses a modified-rice-straw soil modifier for desertificated soil. The soil modifier is made from the following raw materials, by weight part, 24-25 of konjac flour, 5-7 of guar gum powder, 28-30 of diatomite, 3-4 of carboxymethyl cellulose, 2-3 of ferric citrate, 2.0-2.4 of silicon sulfate, 6-7 of potassium dihydrogen phosphate, 45-47 of rice straw, 1.6-1.8 of monochloro acetic acid, 15-16 of kaolin, 6-7 of calcium-based bentonite and a proper amount of water. The soil modifier aims at a desertificated soil structure. Through addition of guar gum powder and cured diatomite, adhesion power among desertificated soil particles is improved, and through the addition of water-retention materials, the water retention ability of desertificated soil is improved, thereby improving and solidifying the quality and structure of desertificated soil. The soil modifier is simple to apply and is suitable for large-scale popularization for improvement of desertificated soil.

Owner:JIXI YUANDAO AGRI IND TECH

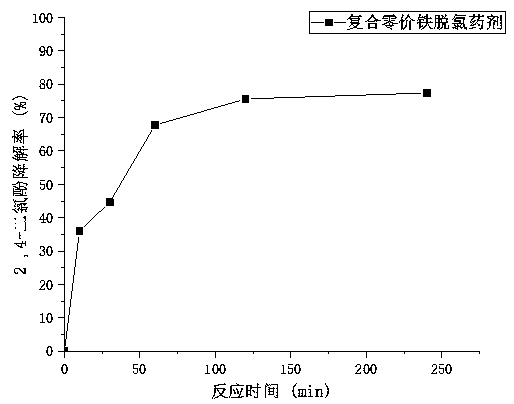

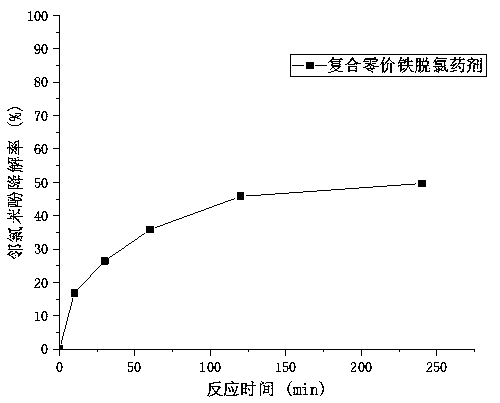

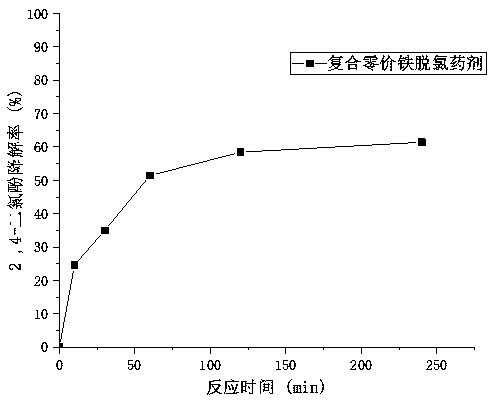

Preparation method for composite zero-valent iron dechlorination agent from flos sophorae and application of composite zero-valent iron dechlorination agent

InactiveCN110550720AIncrease the load pointIncrease loadWater contaminantsContaminated soil reclamationPollutantEnvironmental restoration

The invention relates to the field of environmental restoration, and in particular, relates to a preparation method for a composite zero-valent iron dechlorination agent from flos sophorae and an application of the composite zero-valent iron dechlorination agent, wherein the composite zero-valent iron dechlorination agent can degrade chlorine-containing organic matters. The preparation method comprises the steps of pretreatment of biochar, preparation of a flos sophorae dissolution liquid, preparation and loading of zero-valent iron and the like. The composite zero-valent iron dechlorination agent has the advantages of large loading capacity, good dispersity, uniform loading, large specific surface area and the like, has excellent reaction activity in reduction and dechlorination of chlorine-containing organic pollutants, has good degradation effect, and cannot cause secondary pollution to the environment in the repair process.

Owner:BEIJING UNIV OF CHEM TECH

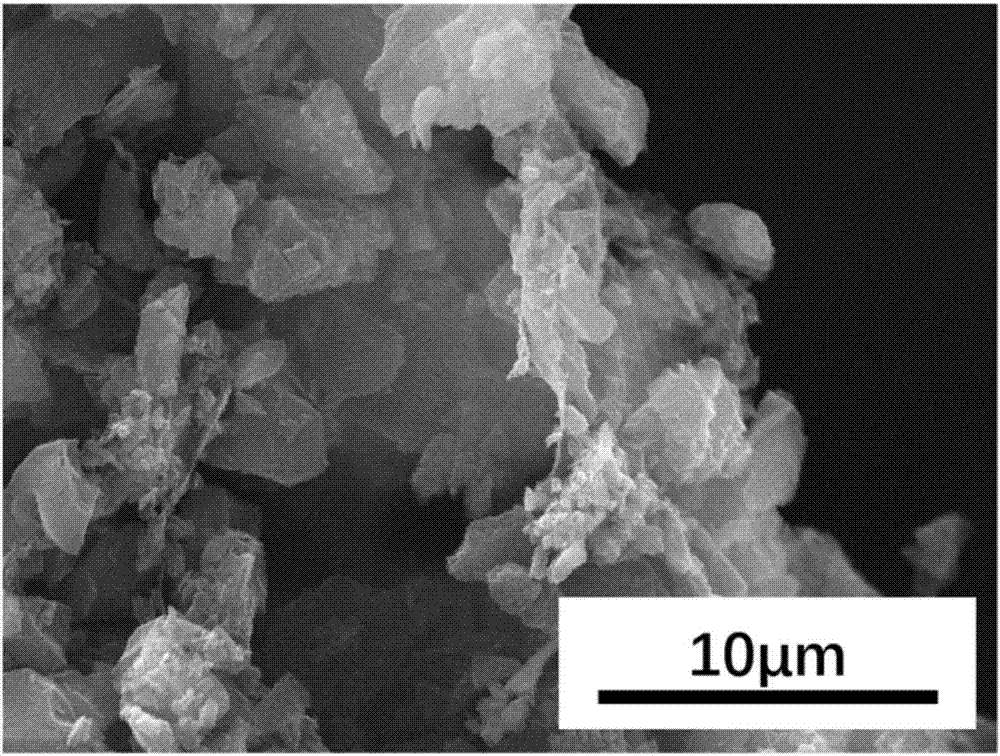

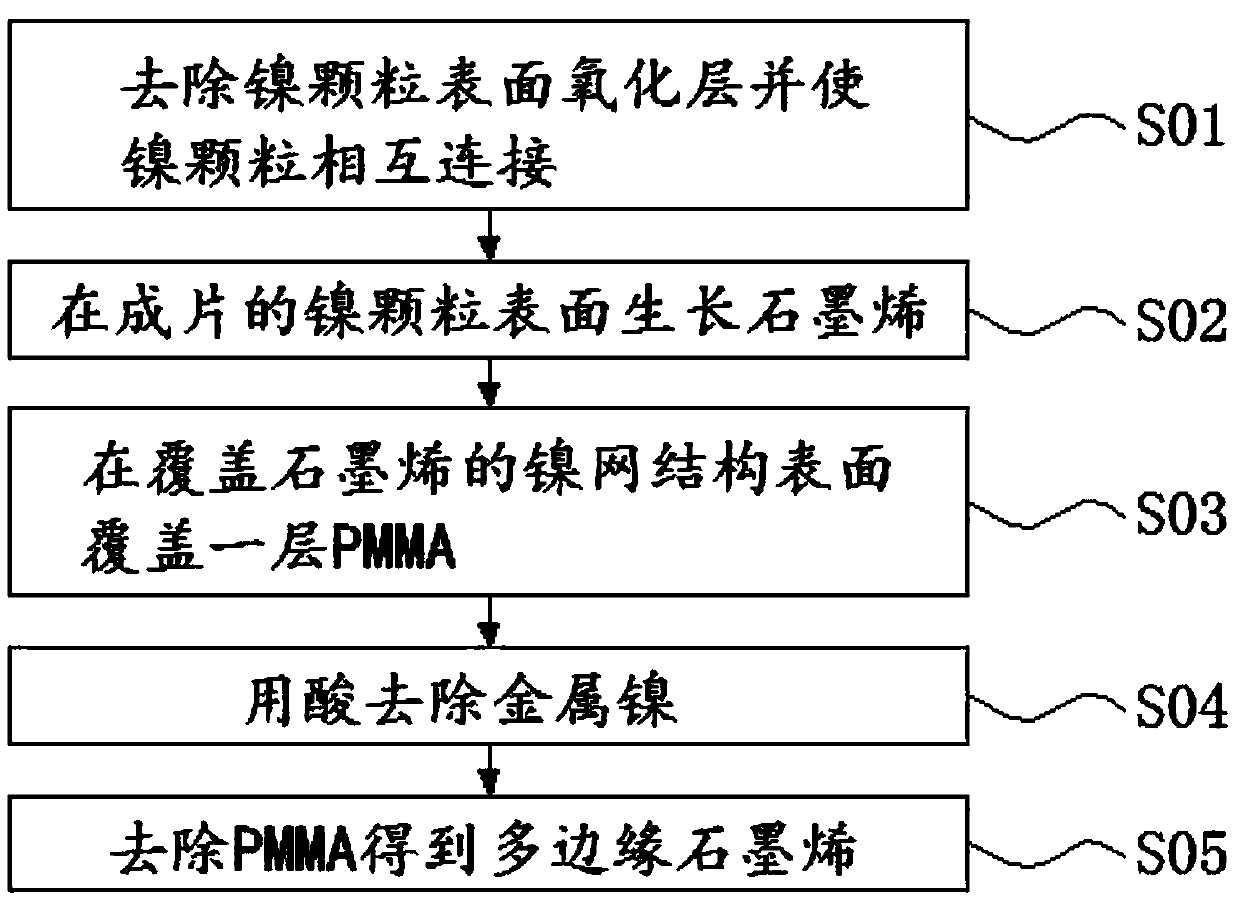

Preparation method of multi-edge graphene and prepared aluminum ion battery

InactiveCN110817851AFreestanding is goodGood flexibilityGrapheneSecondary cellsAluminum IonAluminium-ion battery

The invention discloses a preparation method of multi-edge graphene and an aluminum ion battery prepared by the method. The preparation method comprises the following steps of removing an oxide layeron surfaces of the nickel particles and connecting the nickel particles with each other; then growing graphene on the surfaces of the flaky nickel particles to form a nickel net structure covered withthe graphene; covering a layer of PMMA (polymethyl methacrylate) on the surface of the nickel net structure covered with the graphene to obtain a PMMA / graphene / nickel net structure; removing the metal nickel by using acid to obtain a PMMA / graphene structure sample; and finally, removing PMMA to obtain the multi-edge graphene. According to the preparation method disclosed by the invention, the nickel particles are used as the template and the catalyst to prepare the independent multi-edge graphene with improved energy density, excellent mechanical strength and excellent conductivity at low temperature through a chemical vapor deposition process, the multi-edge graphene is an excellent positive electrode material of the rechargeable aluminum ion battery; and the method realizes low energy consumption and low cost, large-scale mass production is facilitated, and the aluminum ion battery based on the multi-edge graphene has a wide working temperature range and high coulombic efficiency.

Owner:福建海峡石墨烯产业技术研究院有限公司

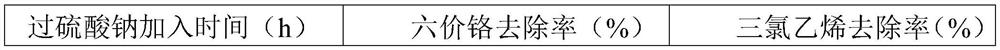

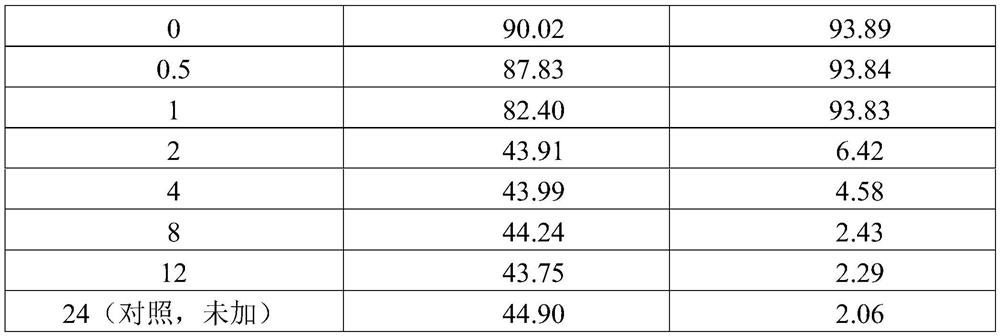

Method for synchronously and efficiently removing hexavalent chromium and trichloroethylene combined pollution

InactiveCN113979527ARich reservesWide variety of sourcesWater treatment parameter controlWater treatment compoundsEnvironmental engineeringZerovalent iron

The invention discloses a method for synchronously and efficiently removing hexavalent chromium and trichloroethylene combined pollution, which is characterized by comprising the following steps of: adding an attapulgite-nano zero-valent iron composite material into polluted water containing hexavalent chromium and trichloroethylene, adding sodium persulfate, oscillating at the constant temperature of 25 DEG C for 24 hours, and synchronously removing hexavalent chromium and trichloroethylene. The method is simple, convenient and rapid, and the pollutant removal condition can be accurately judged. According to the method, agglomeration of the zero-valent iron is reduced, the activity and the utilization rate of the attapulgite-nano zero-valent iron are remarkably improved, and the method has the advantages of high synchronous removal efficiency of hexavalent chromium and trichloroethylene, low cost and the like, and has a very good application prospect in heavy metal-chlorinated hydrocarbon combined pollution remediation.

Owner:INST OF SOIL SCI CHINESE ACAD OF SCI

A kind of preparation method of water body defluoridation agent

ActiveCN107522276BEnhanced interactionLarge specific surface areaWater contaminantsWater/sewage treatmentWastewaterCement paste

The invention disclose a preparation method of a fluorine removal agent for water. The method includes: waste concrete is used as the raw material and subjected to primary crushing and calcining to screen out set cement, and the set cement is subjected to ball milling and powder selection and separation to collect particles with the particle size being below 80 micrometers so as to obtain the fluorine removal agent for water. The preparation method has the advantages that the waste concrete is used to prepare the fluorine removal agent, and the method is wide in raw material source and low in cost and provides a new approach for the recycling of the waste concrete; the method which is simple to operate, widely applicable, low in cost, environmentally friendly and capable of using waste materials to treat pollution is provided for the treatment of fluorine-containing wastewater of rivers and lakes of China, industrial and domestic fluorine-containing wastewater of China, and the like; the recycling efficiency of waste set cement is increased, and a technical path is provided for the high-additional-value utilization of the hardened cement paste in the waste concrete.

Owner:YANGTZE NORMAL UNIVERSITY

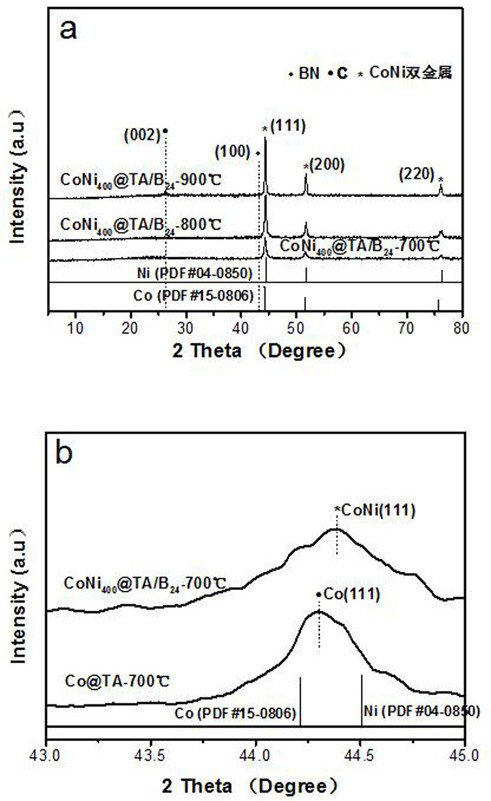

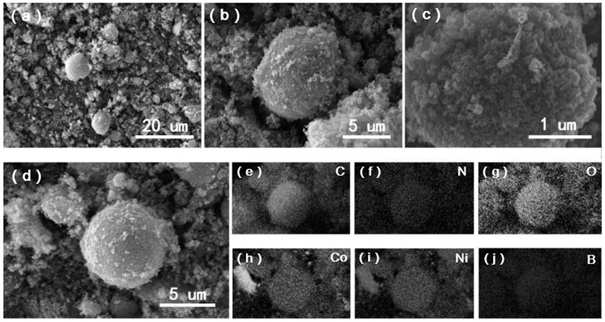

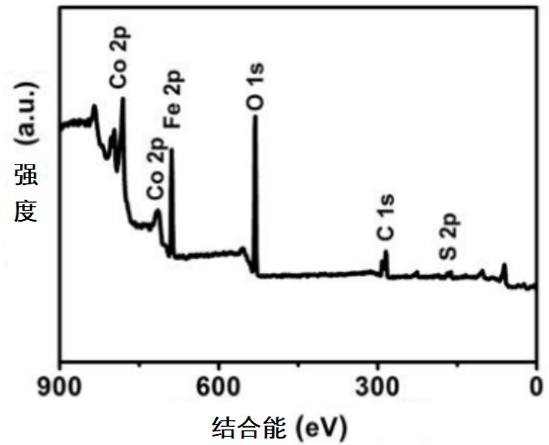

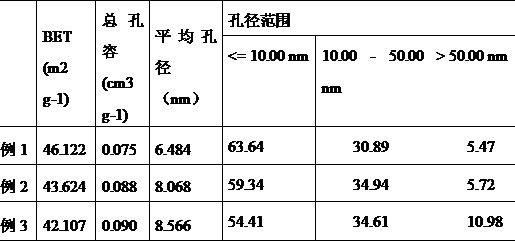

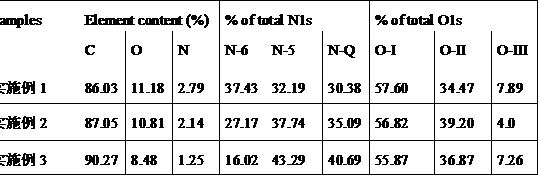

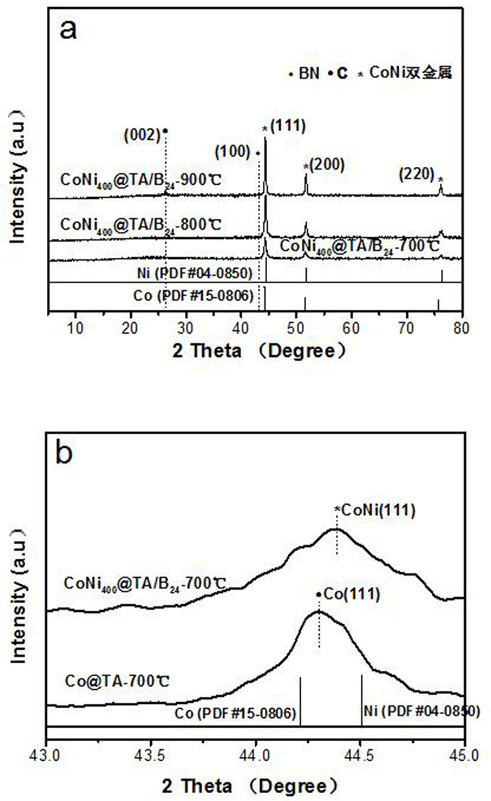

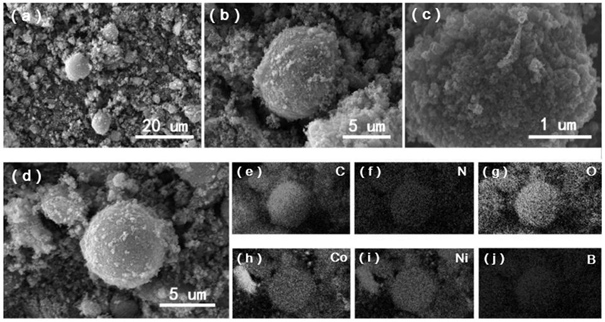

Preparation method of bayberry-shaped cobalt-nickel-boron composite carbon material proton membrane fuel cell catalyst

ActiveCN112886024BEasy to operateReaction conditions are easy to controlMaterial nanotechnologyCell electrodesPtru catalystFuel cells

The invention relates to a method for preparing a bayberry-shaped cobalt-nickel-boron composite carbon material proton membrane fuel cell catalyst. The nanomaterial active substance is a bayberry-shaped cobalt-nickel-boron composite carbon material, referred to as CoNi@TA / B. Solve the existing problems of existing fuel cell catalysts and overcome the defects of the prior art. At present, fuel cell catalysts generally face the problems of single precursor and synthesis cost, as well as defects such as high cost and toxicity of Pt-based catalytic materials; based on CoNi MOF With a unique structure, a metal-organic framework nanocomposite material for proton membrane fuel cells has been developed, which has high onset potential, half-slope potential, excellent limiting current, excellent stability and good methanol tolerance, It has the advantages of strong resistance to methanol poisoning.

Owner:FUZHOU UNIV

Preparation method of porous carbon-nitrogen material loaded nano bimetallic catalyst and use method of catalyst in benzoic acid hydrogenation reaction

ActiveCN112473719AGood dispersionHigh yieldMaterial nanotechnologyCatalyst activation/preparationBenzoic acidPtru catalyst

The invention is applicable to the technical field of catalysts, and provides a preparation method of a porous carbon-nitrogen material loaded nano bimetallic catalyst. The preparation method comprises the following steps: 1, preparing a biomass-based porous carbon-nitrogen carrier material, and carrying out pretreatment, high-temperature pyrolysis, cleaning, drying and grinding; 2, preparing a porous carbon-nitrogen loaded Fe / CoS2 / HCCS nano bimetallic catalyst; The invention relates to a method for using a porous carbon-nitrogen material loaded nano bimetallic catalyst in benzoic acid hydrogenation reaction. The method comprises the following steps: sealing a mixture of benzoic acid, a solvent and the porous carbon-nitrogen material loaded nano bimetallic catalyst in a reaction kettle forreaction. Therefore, the dispersity of the catalyst in the reaction solvent can be enhanced, the active sites of the carbon material are increased, the activity of the catalyst is enhanced through the cooperation of double metals, and the product yield is increased.

Owner:WEIFANG UNIV OF SCI & TECH

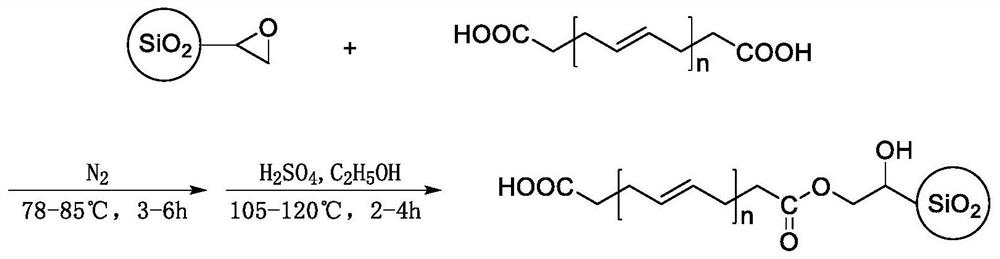

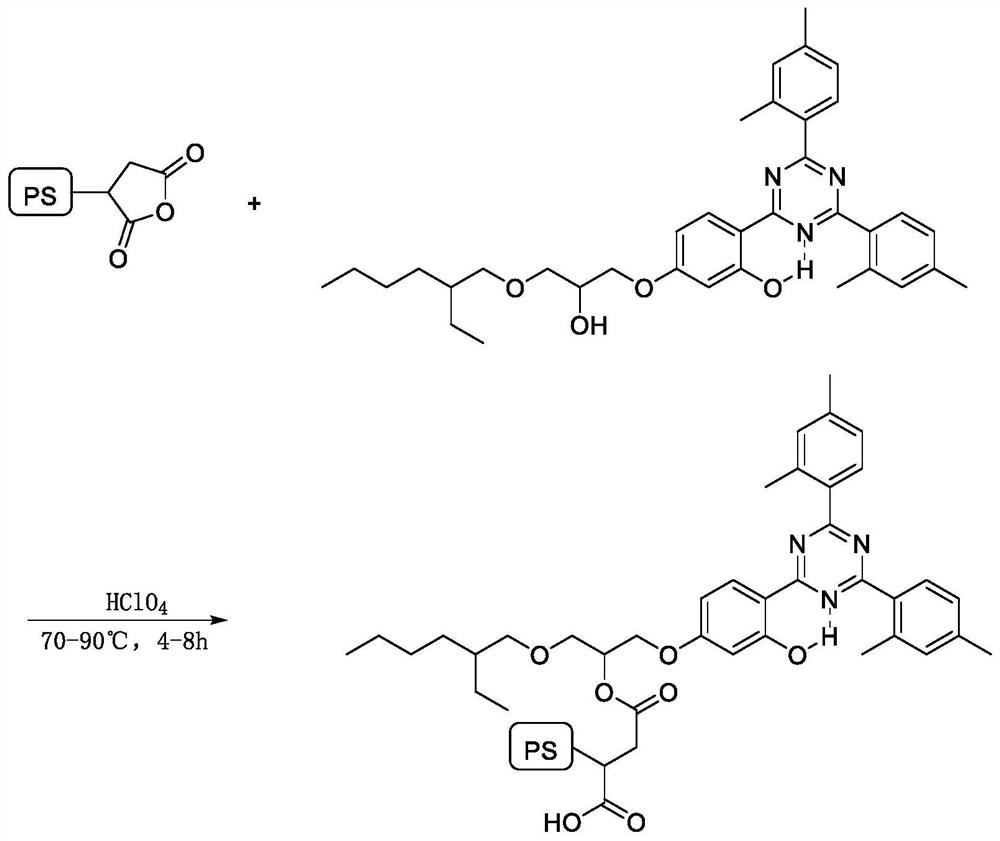

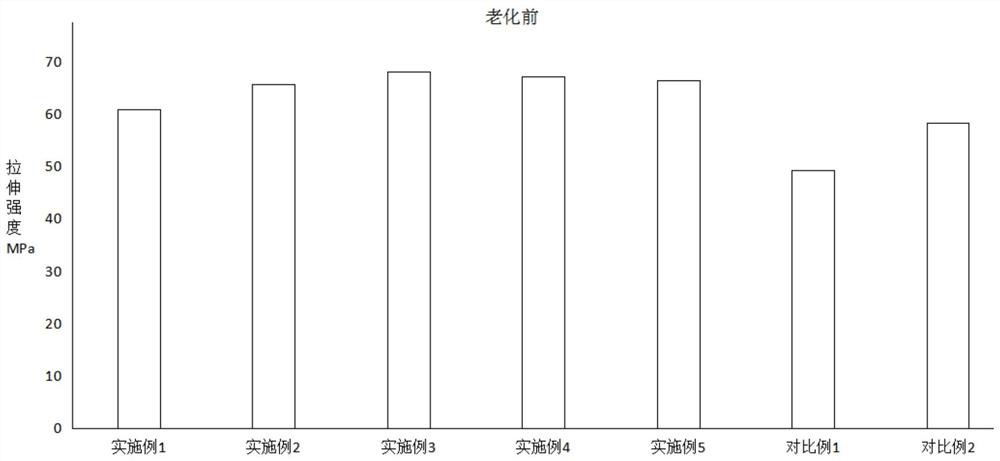

Modified high-impact-resistance polystyrene and preparation method thereof

The invention relates to the technical field of high-impact-resistance polystyrene, and discloses modified high-impact-resistance polystyrene which is prepared from modified polystyrene, modified polybutadiene rubber, a defoaming agent and an antioxidant through melt blending. According to the present invention, the polystyrene has the high reflectivity on the ultraviolet ray with the wavelength of less than 490 nm, the polybutadiene rubber can improve the impact strength of the polystyrene, and the 2-[2-hydroxy-4-[3-(2-ethylhexyloxy)-2-hydroxypropoxy] phenyl]-4, 6-bis (2, 4-dimethylphenyl)-1, 3, 5-triazine can improve the anti-ultraviolet ability of the polystyrene matrix so as to improve the anti-ultraviolet ability of the polystyrene matrix; the flexible long chain can improve the impact resistance of polystyrene, and hydroxyl groups contained in the modified polybutadiene rubber and carboxyl groups on a modified polystyrene matrix form hydrogen bonds, so that the compatibility between the polybutadiene rubber and the polystyrene matrix is improved, and an effective network structure is formed; the obtained polystyrene has excellent impact resistance and aging resistance.

Owner:汕头市华麟塑化有限公司

Modified-rice-straw soil modifier for red soil

InactiveCN105948968AImprove adsorption performanceIncreased soil aggregatesCalcareous fertilisersExcrement fertilisersRice strawChemistry

The invention discloses a modified-rice-straw soil modifier for red soil. The soil modifier is made from the following raw materials, by weight part, 23-25 of cassava residue, 27-28 of bird droppings, 4-5 of quick lime, 3-4 of chitosan oligosaccharide, 2.8-3.2 of sodium ferric ethylene diamine tetraacetic acid, 2-3 of sodium pyrophosphate, 7-8 of calcium ammonium nitrate, 52-55 rice straw, 2.2-2.4 of monochloro acetic acid, 13-14 of kaolin, 5-6 of calcium-based bentonite and a proper amount of water. The soil modifier aims to solve problems of hardening and acidification of red soil. Through addition of alkaline raw materials and organic raw materials, the unit weight of the red soil is effective reduced, the content of water stable aggregate and organic matters in the red soil are added, and the red soil is loosened. The physical biological indices of the red soil are overall improved, thereby achieving the purpose of high yield of plant growing in the red soil.

Owner:JIXI YUANDAO AGRI IND TECH

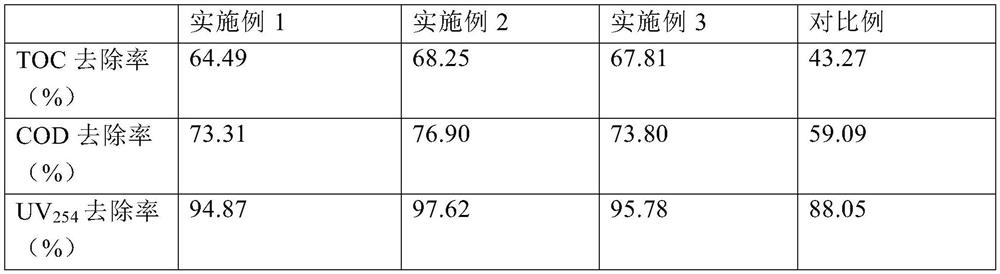

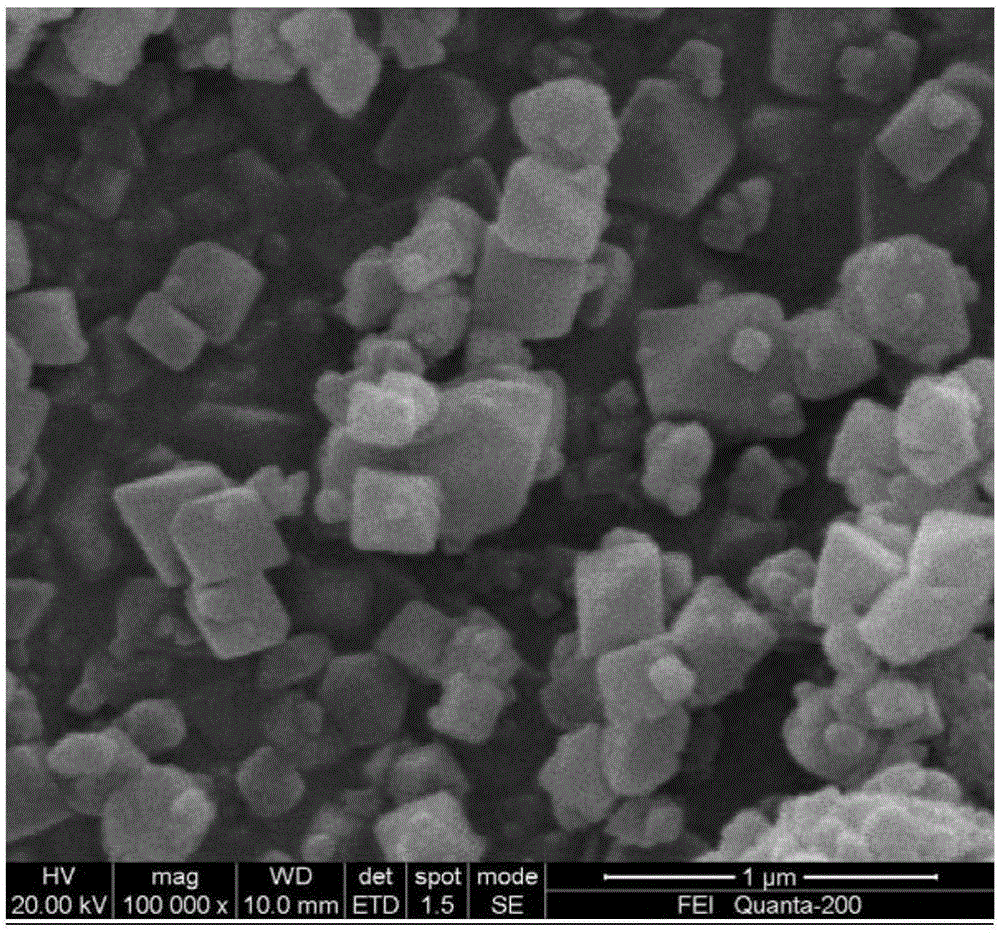

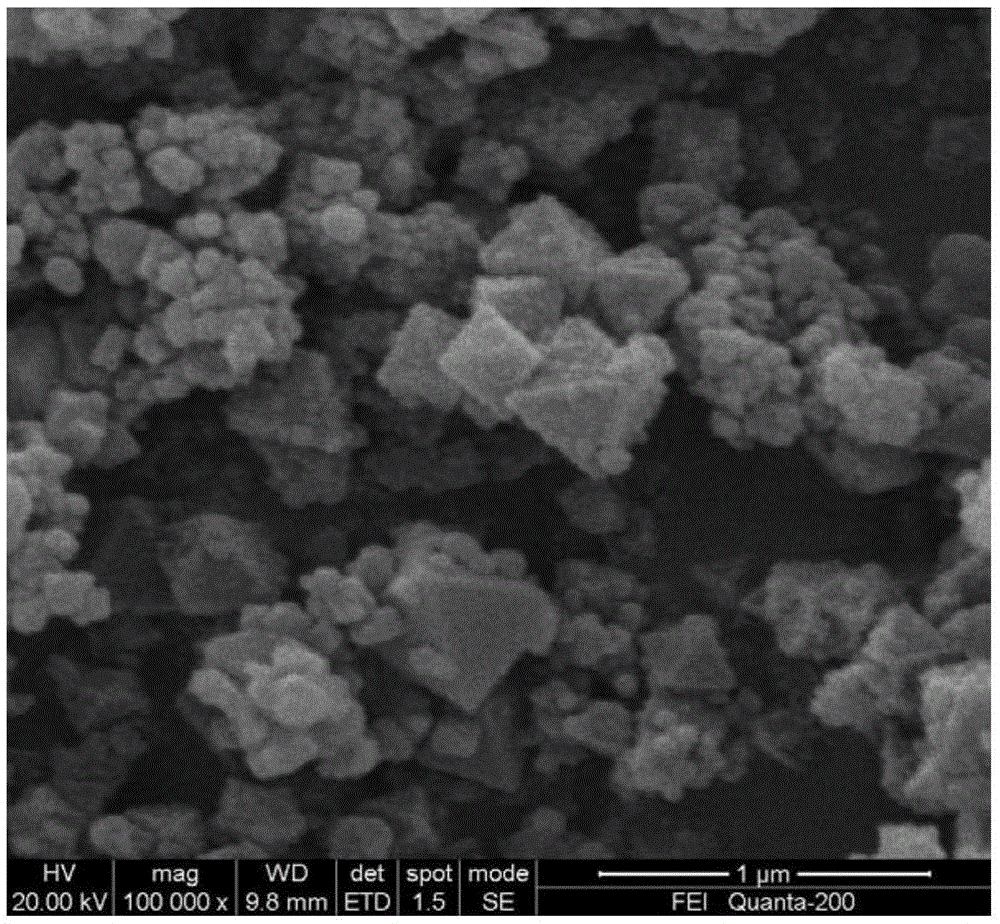

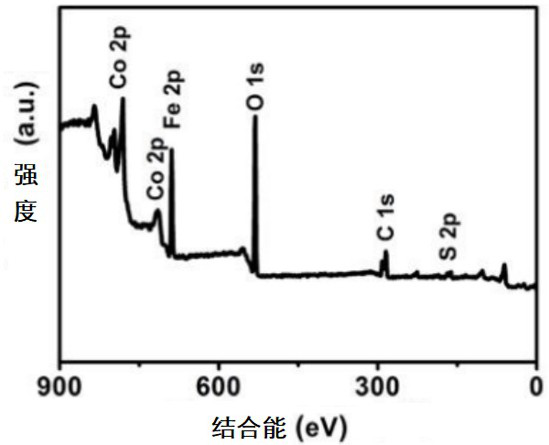

A kind of surface-modified reactive electrochemical membrane and preparation method thereof

ActiveCN108187507BIncrease load capacityAchieve compositeSemi-permeable membranesMembranesIridiumElectrochemistry

The invention discloses a surface-modified reactive electrochemical membrane and a preparation method thereof. The reactive electrochemical membrane is a ring-shaped Ti 4 o 7 The ceramic membrane is loaded with one or several metal elements such as cobalt, tin, antimony, ruthenium, iridium, titanium, tantalum, etc. on the inner surface. The obtained reactive electrochemical oxidation active membrane has high chlorine analysis activity and high OH excitation activity, and can constitute an electrochemical active membrane reactor, which can combine electrochemical oxidation process and membrane separation process to effectively remove difficult degrade organic matter.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

A kind of nano-iron nitride-carbon composite catalyst for positive electrode of lithium-air battery and preparation method thereof

ActiveCN103794806BLarge specific surface areaHigh porosityMaterial nanotechnologyFuel and secondary cellsPorosityCarbon composites

The invention relates to a nano iron nitride-carbon composite catalyst for a lithium-air battery and a preparation method of the composite catalyst. The method comprises the steps of feeding iron salt, organic ligand and a surface active agent into a solvent, and carrying out heating reflux; mixing the obtained nano-sized mesoporous metal organic framework complex and a nitrogenous organic compound, and carrying out heat treatment on the mixture in the presence of ammonia gas to realize carbonization and nitridation by one step. The catalyst is formed by compounding nanoscale primary iron nitride particles and carbon material; carbon covers and partly covers the surfaces of the nanoscale primary iron nitride particles; rich mesoporous gaps exist among the stacked nanoscale primary iron nitride particles. The rich mesoporous structure of a precursor is maintained by the catalyst, the catalyst has large specific surface area and high porosity, and is beneficial to diffusing oxygen molecules into the catalyst material particles, so that the contact between oxygen and the catalyst is promoted, and the utilization rate of the catalyst is increased; the electrical conductivity is effectively improved by the carbon material on the surfaces of the particles; the nano iron nitride-carbon composite catalyst is good in stability, so that the catalytic performance is well exerted. The charge and discharge polarization of the lithium-air battery is effectively reduced; furthermore, the method is simple and convenient, the operation is easy, the cost is low, and large-scale production can be easily implemented.

Owner:CENT SOUTH UNIV

Application of Waste Concrete in Defluoridation of Water Body

ActiveCN107540041BQuick responseImprove resource utilization efficiencyWater contaminantsWater/sewage treatment by flocculation/precipitationWastewaterFluorine containing

The invention discloses application of waste concrete to fluorine removal in water. During application, the method comprises the following steps: (1) primarily crushing and calcining the waste concrete serving as a raw material, screening out cement stone, ball-milling the cement stone, performing powder selecting separation and collecting particles with the particle size being below 80 [mu]m to obtain a water fluorine removing agent; and (2) throwing the water fluorine removing agent obtained in the step (1) into fluorine-containing wastewater to remove the fluorine from the wastewater. Application of the building waste, namely waste concrete, is enlarged to the field of treatment of the fluorine-containing wastewater, the water fluorine-removing material is prepared, the reaction speed is high in the water fluorine removing process, limit doped amount does not exist, the utilization efficiency is high, the fluorine-removing effect is stable, operation can be conducted at room temperature, the resource utilization efficiency of the waste cement stone is improved, and a technological route is provided for high-additional-value utilization of hardened cement stone in the waste concrete.

Owner:YANGTZE NORMAL UNIVERSITY

A high-dispersion low-mercury catalyst for acetylene hydrochlorination and its preparation method

ActiveCN107442175BGood dispersionImprove effective utilizationPreparation by halogen halide additionOrganic-compounds/hydrides/coordination-complexes catalystsCatalytic transformationPtru catalyst

The invention discloses a high-dispersion and low-solid mercury catalyst for acetylene hydrochlorination and a preparation method thereof. The catalyst uses coconut shell, melamine and pyrrole formaldehyde as raw materials to prepare a high-area nitrogen-doped carrier, and uses mercury chloride as the main catalyst. Chemically active components, indium chloride as a synergistic catalytic promoter, potassium chloride as a mercury-fixing agent, and nanometer cerium dioxide as an anti-carbon deposition agent, were used to prepare the catalyst in a step-by-step ultrasonic impregnation-infrared drying method under vacuum conditions. The catalyst has the characteristics of large specific surface area, high dispersion of active components, high utilization rate of mercury chloride, high catalytic conversion rate, good anti-coking effect and long service life.

Owner:贵州重力科技环保股份有限公司

A kind of preparation method of carbon negative electrode plate

ActiveCN108962622BImprove wettabilityLarge specific surface areaMaterial nanotechnologyLead-acid accumulatorsCapacitanceCarbon composites

Owner:晋江瑞碧科技有限公司 +1

Preparation method of waxberry-shaped cobalt-nickel-boron composite carbon material proton membrane fuel cell catalyst

ActiveCN112886024AEasy to operateReaction conditions are easy to controlMaterial nanotechnologyCell electrodesPtru catalystFuel cells

The invention relates to a preparation method of a waxberry-shaped cobalt-nickel-boron composite carbon material proton membrane fuel cell catalyst. A nanomaterial active substance is a waxberry-shaped cobalt-nickel-boron composite carbon material called CoNi@TA / B for short. The problems of the existing fuel cell catalyst are solved, the defects of the prior art are overcome, the problems of single precursor obstacle and low synthesis cost of the existing fuel cell catalyst are generally faced, and the defects of high cost, toxicity and the like of a Pt-based catalytic material are overcome. On the basis of the unique structure of CoNi MOF, the metal organic framework nanocomposite material for the proton membrane fuel cell is developed, and the metal organic framework nanocomposite material has the advantages of being high in initial potential and half-slope potential, excellent in limiting current, excellent in stability, good in methanol tolerance, high in methanol poisoning resistance and the like.

Owner:FUZHOU UNIV

A preparation method of porous carbon-nitrogen material-supported nano-bimetallic catalyst and its application method in benzoic acid hydrogenation reaction

ActiveCN112473719BGood dispersionHigh yieldMaterial nanotechnologyCatalyst activation/preparationBenzoic acidPtru catalyst

The present invention is applicable to the technical field of catalysts, and provides a method for preparing a porous carbon-nitrogen material-supported nano-bimetallic catalyst, including step 1, preparation of a biomass-based porous carbon-nitrogen carrier material; pretreatment, high-temperature pyrolysis, cleaning and drying, Grinding; Step 2, preparation of porous carbon-nitrogen loaded Fe / CoS2 / HCCS nano-bimetallic catalyst; a method for using porous carbon-nitrogen material-loaded nano-bimetallic catalyst in benzoic acid hydrogenation reaction, benzoic acid, solvent and porous The mixture of carbon-nitrogen material-loaded nanometer bimetallic catalysts is sealed in a reaction kettle for reaction. Thereby, the invention can enhance the dispersibility of the catalyst in the reaction solvent, increase the active sites of the carbon material, enhance the activity of the catalyst synergistically with the double metal, and increase the product yield.

Owner:WEIFANG UNIV OF SCI & TECH

Treatment and application method of nut waste

PendingCN113117677AGreen useImprove qualityCatalyst activation/preparationLiquid carbonaceous fuelsCatalytic pyrolysisPtru catalyst

The invention belongs to the technical field of agriculture and forestry waste biomass energy, and particularly relates to a treatment and application method of nut waste. According to the invention, a biochar catalyst is prepared by collecting biochar which is one of the products obtained by pyrolysis of nut waste, and then a modified biochar catalyst is prepared by loading cheap transition metal onto the biochar by utilizing a precipitation method. Then the modified biochar catalyst is returned to be applied to the catalytic pyrolysis reaction of the nut waste, high-quality bio-oil and charcoal are generated through the reaction, and the charcoal is modified to serve as a catalyst for the catalytic pyrolysis reaction of the nut waste, so that a circulating closed loop is formed. The mode of recycling the catalyst preparation material and the conversion product reflects the high-value full-quality utilization of the nut waste.

Owner:JIANGSU UNIV

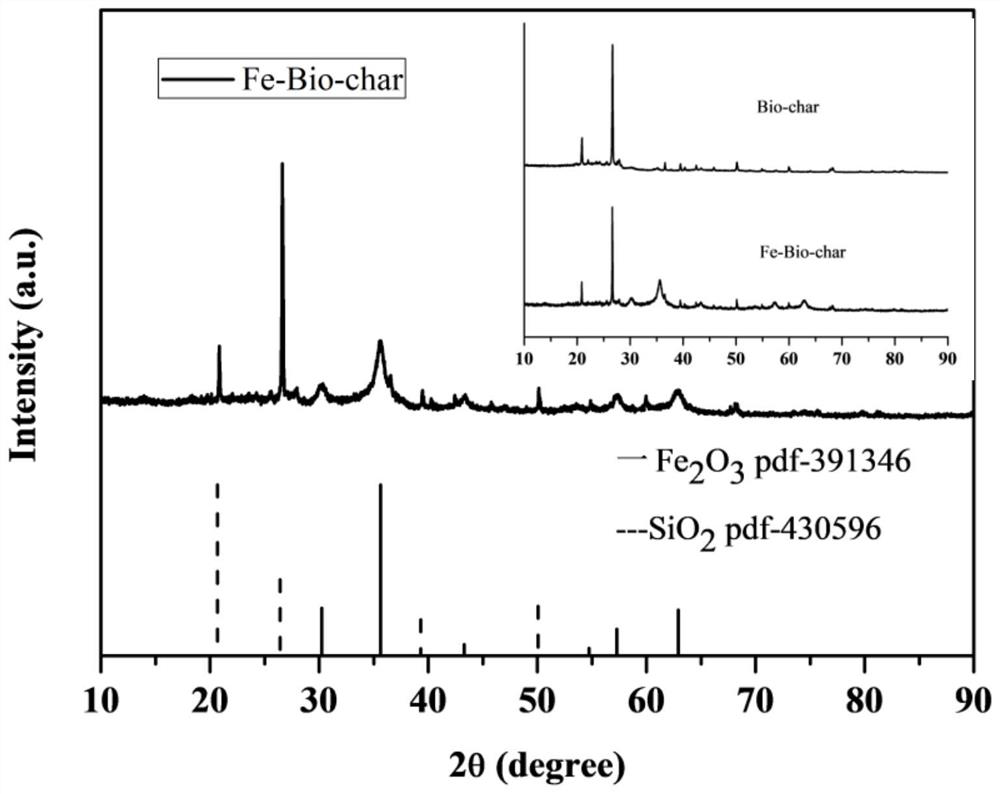

A kind of preparation method of heavy metal ion remover

ActiveCN107694512BIncreased structural defectsGood removal effectWater contaminantsSilicon compoundsBiological activationMaterials science

Owner:YANGTZE NORMAL UNIVERSITY

A highly dispersed heavy hydrocarbon Fischer-Tropsch synthesis catalyst based on a carbonization treatment method and its preparation method

ActiveCN108246313BHigh activityHigh selectivityCatalyst activation/preparationLiquid hydrocarbon mixture productionPtru catalystCobalt salt

Owner:SYNFUELS CHINA INNER MONGOLIA CO LTD

Preparation method of sulfur-fixed ash based coal-fired power plant flue gas mercury removal adsorbent

ActiveCN103599748BLow costImprove mercury adsorptionOther chemical processesDispersed particle separationSorbentNatural state

The invention relates to a preparation method of a sulfur-fixing ash-based coal-fired power plant flue gas mercury removal adsorbent. At present, there is no energy-saving, environmentally friendly, and simple-to-operate preparation method for the sulfur-fixing ash-based coal-fired power plant flue gas mercury removal adsorbent. The present invention is characterized in that it comprises the following steps: (1) taking by weight 60-80 parts of sulfur-fixing ash, 10-15 parts of clay, 5-10 parts of activated carbon and 5-15 parts of bromide, And add water to mix evenly, impregnate for 4-8h, use a mixer to stir at a constant speed during the impregnation modification; (2) adopt the cold-setting molding process, use the granulator to make the impregnated and modified adsorbent into spherical particles, and place it in a natural state (3) Place the naturally dried spherical adsorbent particles in a vacuum drying oven to dry for 12-24 hours, then take them out and cool them to room temperature in a desiccator to obtain sulfur-fixed ash fume Mercury removal adsorbent. The invention can effectively reduce the cost and is easy to operate.

Owner:HUADIAN ELECTRIC POWER SCI INST CO LTD

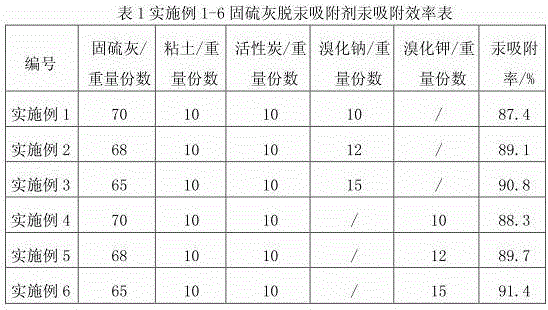

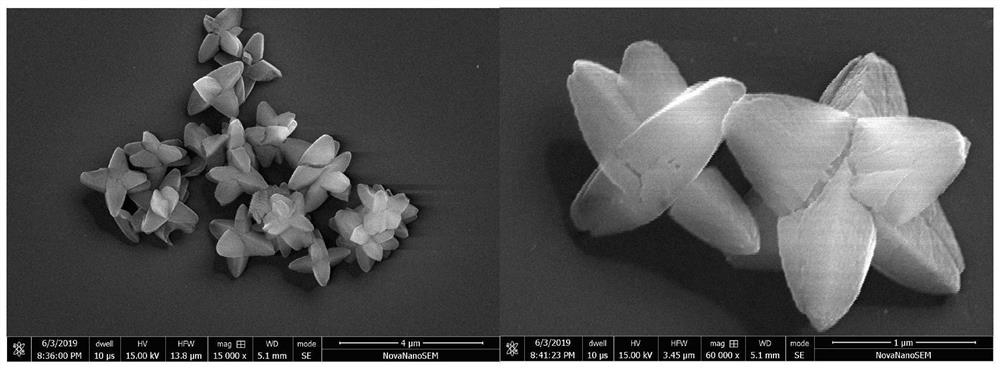

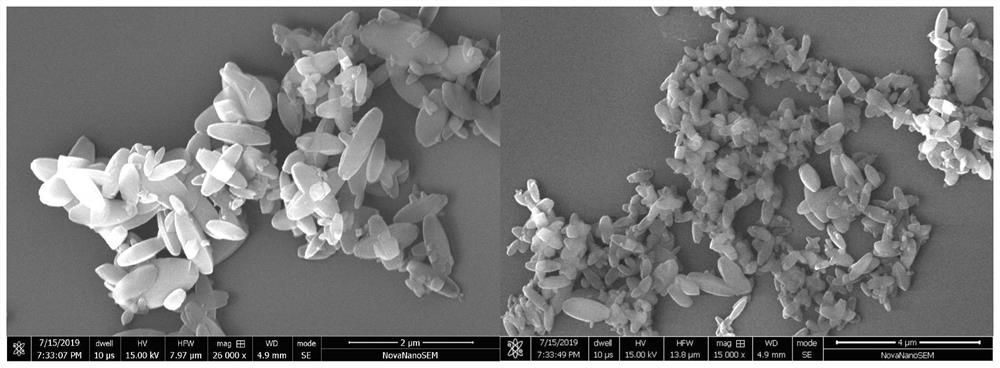

A kind of preparation method of flower cluster-like hierarchical structure ZIF series metal organic framework

The invention relates to the technical field of nanometer materials, in particular to a preparation method of ZIF series metal-organic frameworks with a flower cluster hierarchical structure. It includes: 1) preparation of template solution 2) preparation of precursor solution A containing metal ligands and precursor solution B containing organic ligands; 3) separation of precursors: mixing precursor solution A and precursor solution B and standing still, after standing Centrifuge to obtain the precursor; 4) Product acquisition: Add the precursor to the organic liquid, filter to remove impurities and centrifuge to separate the solid product, and then obtain the ZIF series metal organic framework with a flower cluster hierarchical structure. The preparation method of the present invention is simple and efficient, can realize high-efficiency preparation under low temperature conditions, and has low demand for equipment; the prepared ZIF series metal-organic frameworks with flower cluster-like hierarchical structure have larger specific surface area and higher active sites; overall The preparation is highly controllable, and is suitable for the preparation of various ZIF series metal-organic frameworks.

Owner:ZHEJIANG UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com