Preparation method of activated-carbon multi-point-location supported nano zero-valent iron composite material

A technology of nano-zero-valent iron and composite materials, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of low loading capacity, limited adsorption capacity, activated carbon Poor adsorption selectivity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

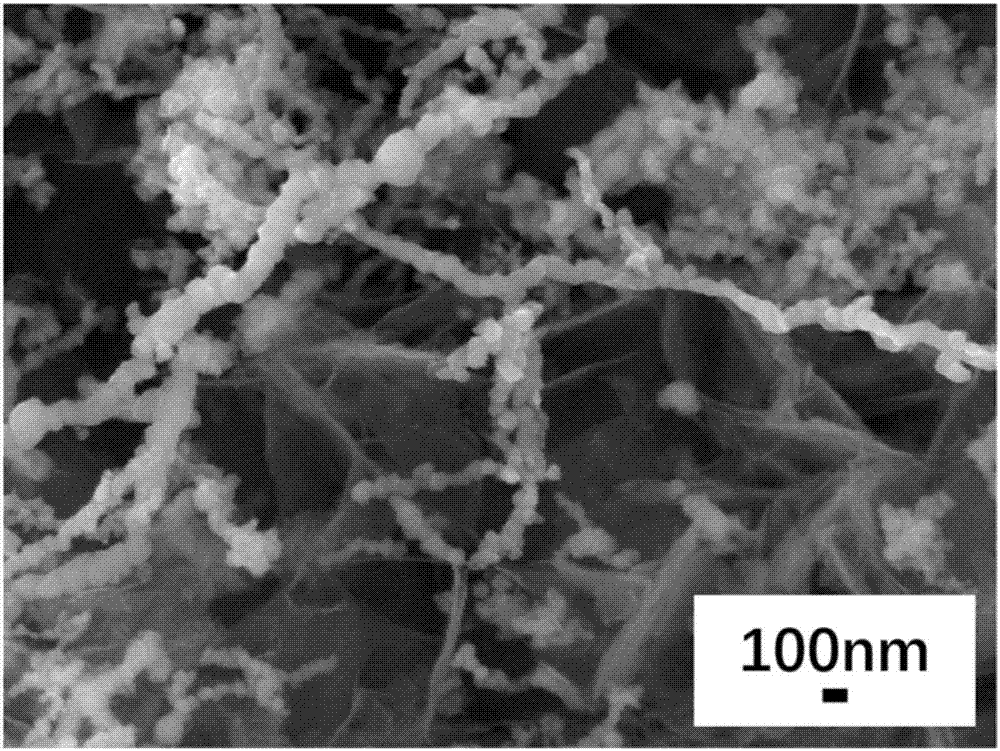

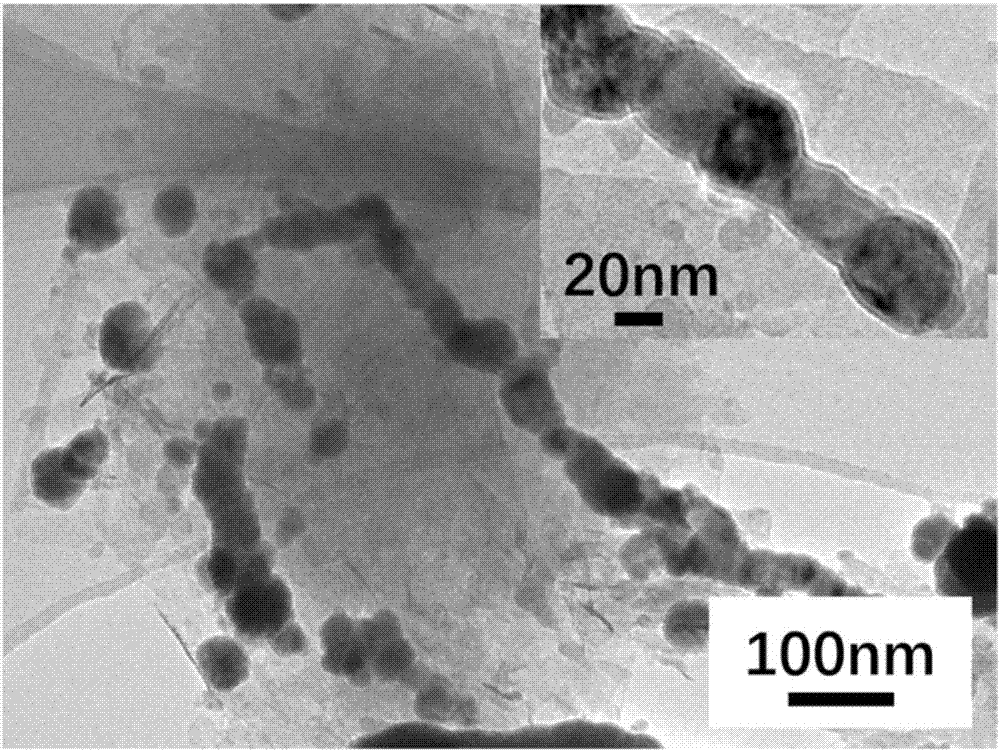

[0017] The preparation method of a multi-site activated carbon-loaded nano zero-valent iron composite material provided by the present invention will be described in detail below in conjunction with the accompanying drawings.

[0018] The method for the composite material of activated carbon multi-point loaded nanometer zero-valent iron, the specific steps are:

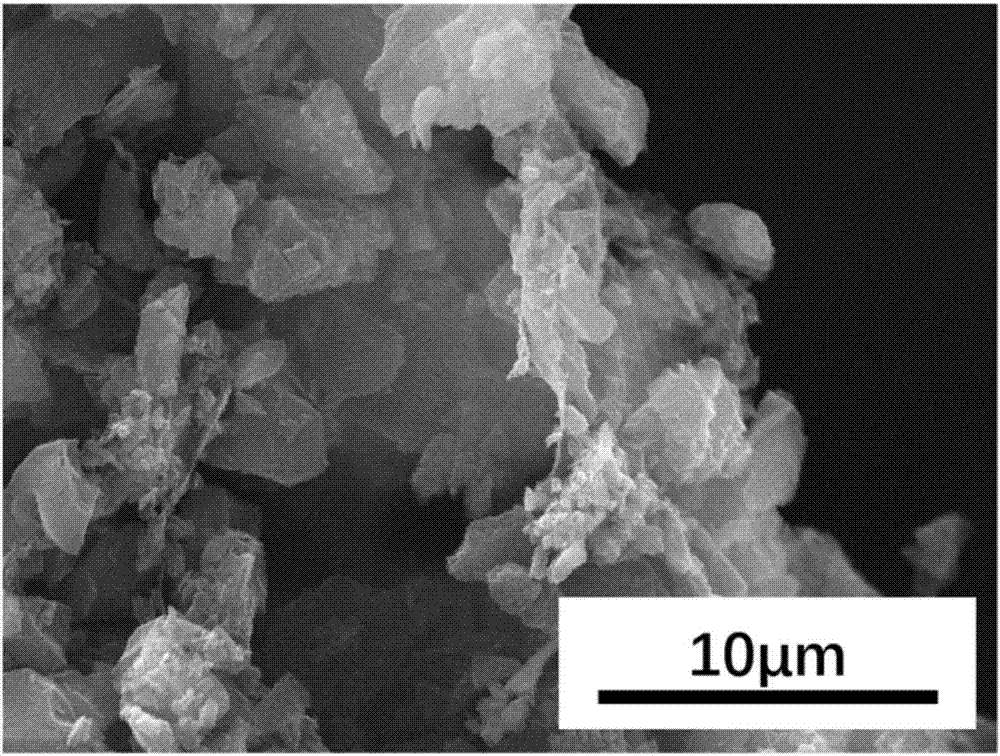

[0019] Step 1: Weigh 0.5g of dry activated carbon (100 mesh) and add it to 30mL of 12g / L microcrystalline cellulose solution, then add 0.22g of citric acid, ultrasonically disperse in an ultrasonic cleaner for 30min, and then place it at a constant temperature of 25°C Shake at constant temperature for 4 hours in a shaking incubator. After the shaking is completed, place it in a 50mL high-pressure sealed reaction kettle, react at a constant temperature at 220°C for 12h, cool naturally to room temperature, wash with absolute ethanol three times and centrifuge, and dry at a constant temperature in an oven at 75°C for 12h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com