Preparation method of sulfur-fixed ash based coal-fired power plant flue gas mercury removal adsorbent

A technology for coal-fired power plants and sulfur ash fixing, which is applied in separation methods, chemical instruments and methods, and other chemical processes, etc., can solve the problems of unsatisfactory adsorption effect, high energy consumption, unfavorable energy conservation and environmental protection, etc., so as to improve the mercury adsorption rate. , the effect of large specific surface area and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

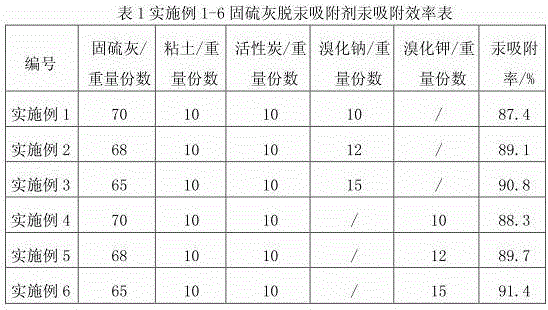

Embodiment 1

[0017] The steps of the preparation method of the sulfur-fixing ash-based coal-fired power plant flue gas mercury removal adsorbent in this embodiment are as follows: the sulfur-fixing ash, clay, activated carbon, and sodium bromide are respectively 70 parts, 10 parts, and 10 parts by weight. Mix evenly with 10 parts, add 28 parts of water and stir, impregnate for 6 hours, and use a mixer to stir at a constant speed during the impregnation modification period. The impregnated and modified adsorbent was made into spherical particles with a diameter of about 10mm by a granulator, and dried naturally for 12 hours. The adsorbent particles after natural drying are dried in a vacuum drying oven for 24 hours, then taken out, placed in a desiccator and cooled to room temperature, and the sulfur-fixed ash and mercury-removing adsorbent is obtained.

Embodiment 2

[0019] The steps of the preparation method of the sulfur-fixing ash-based coal-fired power plant flue gas mercury removal adsorbent in this embodiment are as follows: the sulfur-fixing ash, clay, activated carbon, and sodium bromide are respectively 68 parts, 10 parts, and 10 parts by weight. , 12 parts, mix evenly, add 27 parts of water and stir, impregnate for 6 hours, and use a mixer to stir at a constant speed during the impregnation modification period. The impregnated and modified adsorbent was made into spherical particles with a diameter of about 10mm by a granulator, and dried naturally for 12 hours. The adsorbent particles after natural drying are dried in a vacuum drying oven for 24 hours, then taken out, placed in a desiccator and cooled to room temperature, and the sulfur-fixed ash and mercury-removing adsorbent is obtained.

Embodiment 3

[0021] The steps of the preparation method of the sulfur-fixing ash-based coal-fired power plant flue gas mercury removal adsorbent in this embodiment are as follows: the sulfur-fixing ash, clay, activated carbon, and sodium bromide are respectively 65 parts, 10 parts, and 10 parts by weight. , 15 parts, mix evenly, add 26 parts of water and stir, impregnate for 8 hours, and use a mixer to stir at a constant speed during the impregnation modification period. The impregnated and modified adsorbent was made into spherical particles with a diameter of about 10mm by a granulator, and dried naturally for 12 hours. The adsorbent particles after natural drying are dried in a vacuum drying oven for 24 hours, then taken out, placed in a desiccator and cooled to room temperature, and the sulfur-fixed ash and mercury-removing adsorbent is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com