Method for synchronously and efficiently removing hexavalent chromium and trichloroethylene combined pollution

A technology of trichloroethylene and compound pollution, applied in chemical instruments and methods, water pollutants, water/sewage treatment, etc., can solve the problem of inability to achieve simultaneous removal of hexavalent chromium-trichloroethylene compound pollution, and achieve abundant reserves. , Improve dissolution and corrosion ability, increase the effect of exposed area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

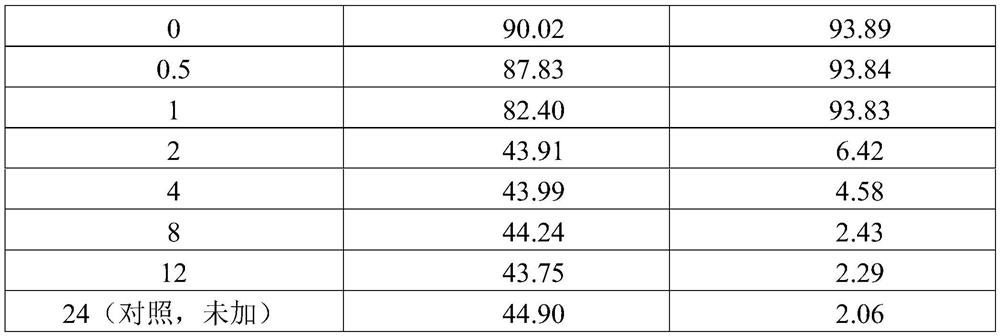

Examples

Embodiment 1

[0019] This example provides a method for separately removing hexavalent chromium, separately removing trichlorethylene, and simultaneously removing hexavalent chromium and trichlorethylene combined pollution by the attapulgite-nano zero-valent iron composite material-sodium persulfate system, and comparing the methods s efficiency.

[0020] A separate removal of hexavalent chromium system

[0021] Step 1, add 20mL of water containing 30mg / L hexavalent chromium and 8mg of attapulgite-nanometer zero-valent iron material in a borosilicate glass bottle lined with a 22mL silica gel pad with a screw cap, and the pH is 3.5;

[0022] Step 2, after sealing, place the borosilicate glass bottle in a thermostatic oscillator, set the rotation speed at 150 rpm, the temperature at 25° C., and the reaction time for 24 hours.

[0023] B. Trichlorethylene removal system alone

[0024] Step 1, weighing 8 mg of the attapulgite-nano zero-valent iron composite material and placing it in a 22 mL ...

Embodiment 2

[0037] This example provides a method for synchronous removal of hexavalent chromium and trichlorethylene by the attapulgite-nano zero-valent iron composite material-sodium persulfate system, and compares the removal of hexavalent chromium and trichlorethylene with different concentrations of sodium persulfate. Impact.

[0038] Step 1, weighing 8 mg attapulgite-nano zero-valent iron composite material, and placing it in a 22 mL borosilicate crimp glass bottle lined with a silica gel pad;

[0039] Step 2, add 20mL of water containing 30mg / L hexavalent chromium with a pH value of 3.5 into the above-mentioned 22mL borosilicate crimp glass bottle;

[0040] Step 3, synchronously add different volumes (0, 10, 20, 40, 80 μL) of 1 mol / L sodium persulfate solution and 100 μL of 4000 mg / L trichlorethylene solution to the above mixed solution;

[0041] Step 4: Immediately seal the above-mentioned borosilicate glass bottle, and place it in a constant temperature oscillator with a rotatio...

Embodiment 3

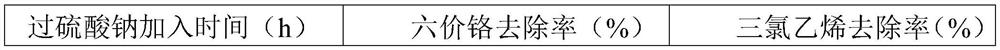

[0047] This embodiment provides a method for synchronously and efficiently removing hexavalent chromium and trichlorethylene composite pollution by the attapulgite-nano zero-valent iron composite material-sodium persulfate system, and compares the effect of different sodium persulfate injection times (0-12h) on the hexavalent chromium and trichlorethylene. Chromium and trichlorethylene removal effects.

[0048] Step 1, weigh 8 mg of attapulgite-nano zero-valent iron composite material, and place them in 22 mL borosilicate crimp glass bottles lined with silica gel pads;

[0049] Step 2, add 20 mL of an aqueous solution containing 30 mg / L hexavalent chromium to the above-mentioned borosilicate crimp glass bottle, the pH is 3.5;

[0050] Step 3: Add 100 μL of 4000 mg / L trichlorethylene solution to the above mixture using a micro-glass sampling needle; then seal and place in a constant temperature oscillator with a rotation speed of 150 rpm and a temperature of 25 °C;

[0051] St...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com