Rubber composition and preparation method thereof

A rubber composition and rubber technology, applied in the field of tire manufacturing, can solve the problems of easy thermal aging, lack of processability, reduction and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] The raw materials of the rubber composition modified by the jelly energy modifier are as follows in Table 1:

[0067] Example 1 (kg) SBR1739 96.25 3,6-bis(2-pyridyl)-1,2,4,5-tetrazine 0.7 N234 20

[0068] The preparation method of above-mentioned rubber composition is:

[0069] SBR1739, 3,6-bis(2-pyridyl)-1,2,4,5-tetrazine and carbon black were heat treated at 150°C for 120s to obtain a modified rubber composition.

Embodiment 2

[0071] Rubber composition raw material is as follows table 2:

[0072] Comparative example 2 (kg) Example 2 (kg) BR9000 20 20 natural rubber 10 10 SBR1739 96.25 The modified rubber composition obtained in embodiment 1 116.95 N234 70 50 6PPD 2 2 Microcrystalline Wax 1.5 1.5 stearic acid 1 1 Zinc oxide 2.5 2.5 CBS 1.5 1.5 sulfur 1.5 1.5

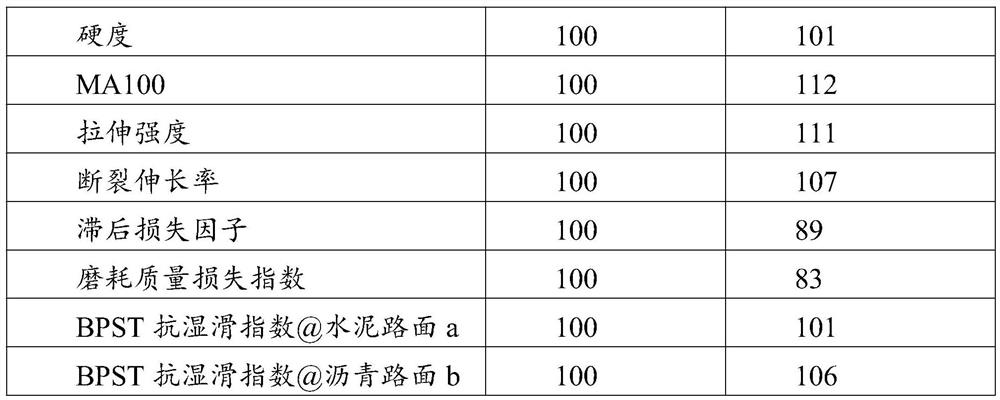

[0073] For the rubber composition modified by adding a multifunctional modifier in Example 2, but not adding a multifunctional modifier in Comparative Example 2; the performance test results for Embodiment 2 and Comparative Example 2 are as follows 3:

[0074] Table 3: Comparison of the performance results of Example 2 and Comparative Example 2

[0075]

[0076]

[0077] *The test results of the rubber composition are expressed in the form of an index,

[0078] The calculation formula is: test item=(Comparative Example 1-1)×100.

[0079] a,...

Embodiment 3

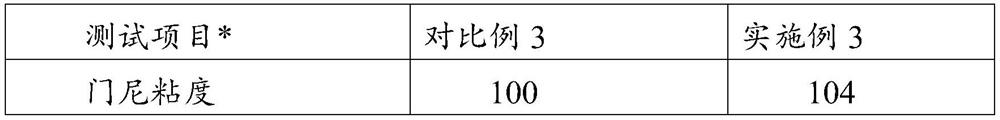

[0088] Rubber composition raw material is as follows table 4:

[0089] Comparative example 3 (kg) Example 3 (kg) SBR1739 96.25 96.25 BR9000 20 20 natural rubber 10 10 3,6-bis(2-pyridyl)-1,2,4,5-tetrazine 0.5 N234 50 50 HD165MP 20 20 Si69 1.6 1.6 6PPD 2 2 Microcrystalline Wax 1.5 1.5 stearic acid 1 1 Zinc oxide 2.5 2.5 CBS 1.5 1.5 sulfur 1.5 1.5

[0090] The preparation method of above-mentioned rubber composition:

[0091] (1) Take each raw material according to the above-mentioned rubber composition;

[0092] (2) Mixing SBR1739, BR9000, natural rubber and multifunctional modifier for 100s to obtain a mixed material;

[0093] (3) The rest of the raw materials were added to the mixed material, kneaded, and vulcanized at 130° C. to obtain a rubber composition.

[0094] For the application method of the multifunctional modifier in Example 3, it is directly added when the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com