Preparation method of lithium ion battery anode material using biomass as carbon source and with C@Co3O4 core-shell structure

A lithium-ion battery, core-shell structure technology, applied in battery electrodes, secondary batteries, structural parts, etc., can solve the problems of large volume effect, poor conductivity, etc., to improve lithium storage capacity, improve conductivity, increase The effect of conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

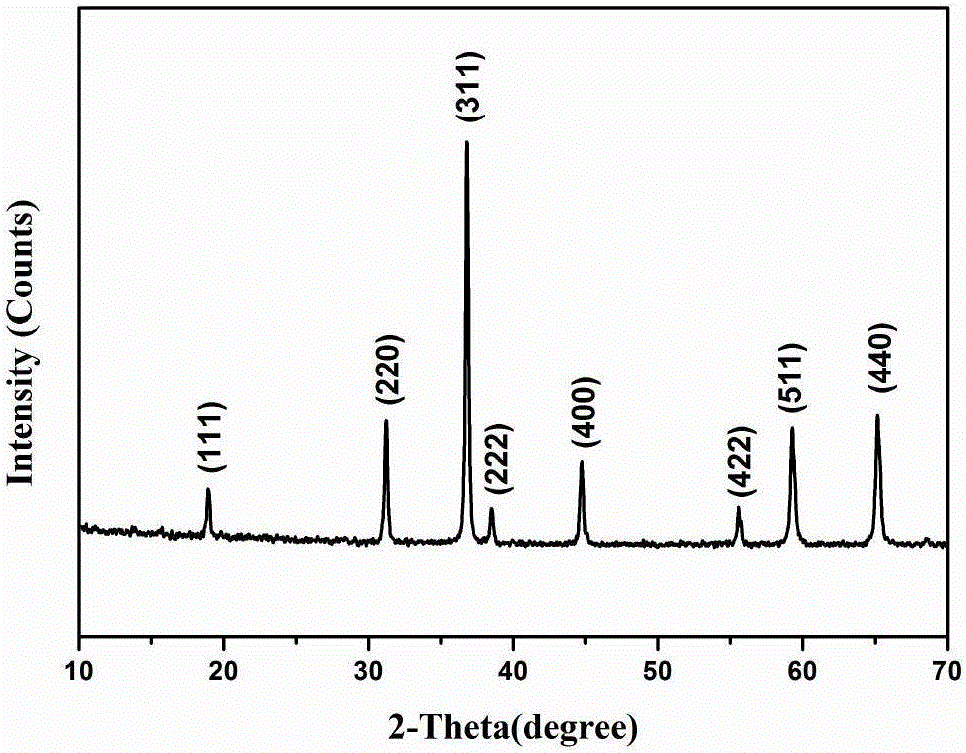

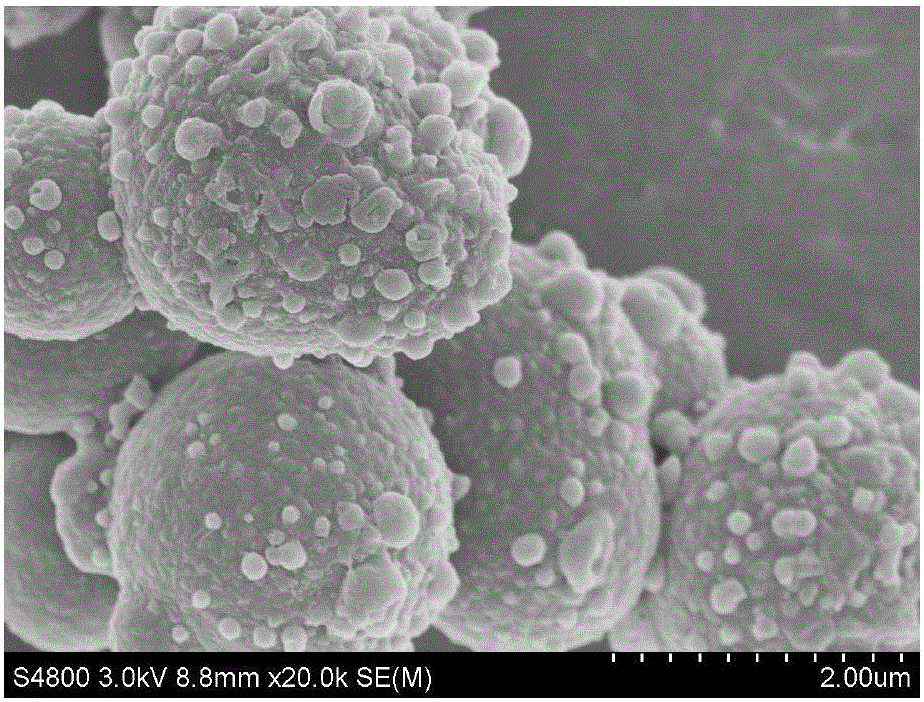

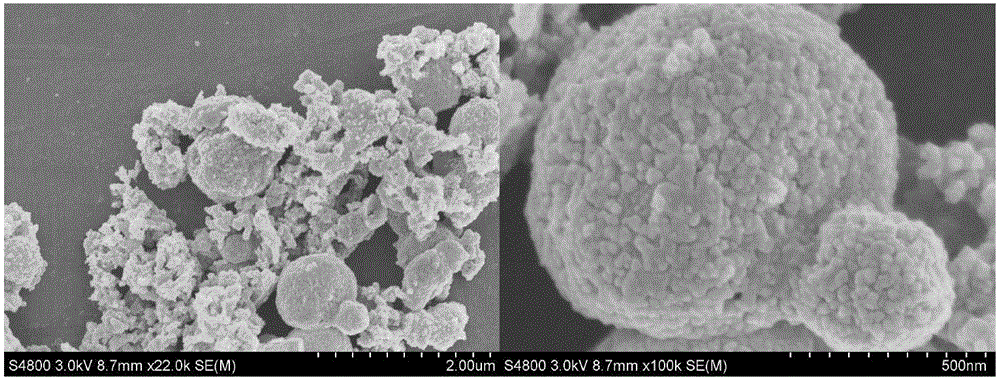

[0016] Embodiment 1: A kind of CCo with biomass as carbon source 3 o 4 The preparation method of core-shell structure lithium ion battery negative electrode material,

[0017] 1) Wash the dried fungus and put it into an oven to dry, grind and pass through a 50-mesh nylon sieve to obtain the fungus particles and dry them for later use;

[0018] 2) Prepare 60ml of sulfuric acid solution with a concentration of 5mol / L, put 3g of fungus particles into the sulfuric acid solution and transfer it to a hydrothermal kettle, set the hydrothermal temperature to 120°C, keep it warm for 24h, suction filter and freeze-dry for 12h to obtain the precursor A;

[0019] 3) Get 0.02mol of analytically pure cobalt acetate tetrahydrate (Co(CH 3 COO) 2 4H 2 O) and 0.06mol of urea (CO(NH 2 ) 2 ) were added to 100ml of deionized water in turn, stirred until the solution was clear and transparent, then 3g of precursor A was put into the solution, magnetically stirred for 12 hours, then suction f...

Embodiment 2

[0025] Embodiment 2: A kind of CCo with biomass as carbon source 3 o 4 The preparation method of core-shell structure lithium ion battery negative electrode material,

[0026] 1) Wash the dried fungus and put it into an oven to dry, grind and pass through a 50-mesh nylon sieve to obtain the fungus particles and dry them for later use;

[0027] 2) Configure 60ml of sulfuric acid solution with a concentration of 8mol / L, put 5g of fungus particles into the sulfuric acid solution and transfer it to a hydrothermal kettle, set the hydrothermal temperature to 140°C, keep it warm for 26h, suction filter and freeze-dry for 14h to obtain the precursor A;

[0028] 3) Get 0.03mol of analytically pure cobalt acetate tetrahydrate (Co(CH 3 COO) 2 4H 2 O) and 0.06mol of urea (CO(NH 2 ) 2 ) were added to 100ml of deionized water in turn, stirred until the solution was clear and transparent, then 4g of precursor A was put into the solution, magnetically stirred for 16 hours, then suction...

Embodiment 3

[0031] Embodiment 3: A kind of CCo with biomass as carbon source 3 o 4 The preparation method of core-shell structure lithium ion battery negative electrode material,

[0032] 1) Wash the dried fungus and put it into an oven to dry, grind and pass through a 50-mesh nylon sieve to obtain the fungus particles and dry them for later use;

[0033] 2) Prepare 60ml of sulfuric acid solution with a concentration of 10mol / L, put 8g of fungus particles into the sulfuric acid solution and transfer it to a hydrothermal kettle, set the hydrothermal temperature to 160°C, keep it warm for 28h, suction filter and freeze-dry for 18h to obtain the precursor A;

[0034] 3) Get 0.04mol of analytically pure cobalt acetate tetrahydrate (Co(CH 3 COO) 2 4H 2 O) and 0.06mol of urea (CO(NH 2 ) 2 ) were added to 100ml of deionized water in turn, stirred until the solution was clear and transparent, then 5g of precursor A was put into the solution, magnetically stirred for 18h, then suction filte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com