Lithium ion battery negative electrode active material, preparation method thereof, negative electrode and lithium ion battery comprising negative electrode

A negative electrode active material and lithium-ion battery technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of poor battery cycle performance, unsuitable for practical use, and increased expansion of pole pieces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

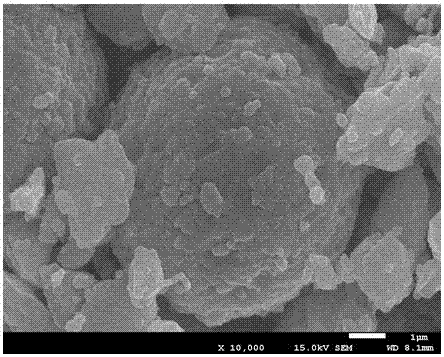

Image

Examples

preparation example Construction

[0022] The present invention also proposes a preparation method of the negative electrode active material of lithium ion battery, comprising:

[0023] (1) Mix and disperse the carbon source precursor, lithium-silicon alloy particle powder and organic solvent to obtain a slurry;

[0024] (2) Drying the slurry in step (1) to remove the organic solvent to obtain a precursor of carbon source precursor coated lithium-silicon alloy particles.

[0025] (3) Sintering the precursor in step (2) under an inert atmosphere to obtain a lithium-ion battery negative electrode active material whose core is lithium-silicon alloy particles and whose shell is a carbon layer.

[0026] Preferably, in the step (1), the mass ratio of the carbon source precursor to the lithium-silicon alloy particle powder is 5:1-20:1. By controlling the mass ratio of the carbon source precursor to the lithium-silicon alloy particles, the thickness of the carbon shell coated on the surface of the lithium-silicon allo...

Embodiment 1

[0048] (1) Get 10g polyacrylonitrile and dissolve in the dimethylformamide of 100ml, form the solution of 100g / L, get the lithium-silicon alloy particle powder (in the lithium-silicon alloy particle powder, the weight of lithium in the lithium-silicon alloy particle powder of 1000nm) of 2g mean particle size ratio of 44%), under electromagnetic stirring, the lithium-silicon alloy particles were dropped into the above solution, stirred evenly and ultrasonically dispersed to obtain a slurry;

[0049] (2) placing the slurry in step (1) under an argon protective atmosphere and spray-drying at 80° C. to obtain a carbon source precursor-coated lithium-silicon alloy particle precursor;

[0050] (3) Place the precursor in step (2) in a graphite dry crucible, keep it warm at 800°C for 6 hours under an argon protective atmosphere, and obtain a lithium-ion battery negative electrode with lithium-silicon alloy particles as the core and carbon layer as the shell after cooling Active materi...

Embodiment 2

[0053] The same method as in Example 1 was used to prepare the lithium-ion battery negative active material nuclear battery, except that in step (1) 10 g of polyvinyl alcohol was added instead of polyacrylonitrile to prepare negative active material A2 and battery S2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com