Lithium ion battery silicon oxide composite negative electrode material and preparation method thereof

A lithium-ion battery and silicon oxide technology, applied in battery electrodes, circuits, electrical components, etc., to achieve the effect of cheap raw materials, simple production process, and improved electrochemical cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

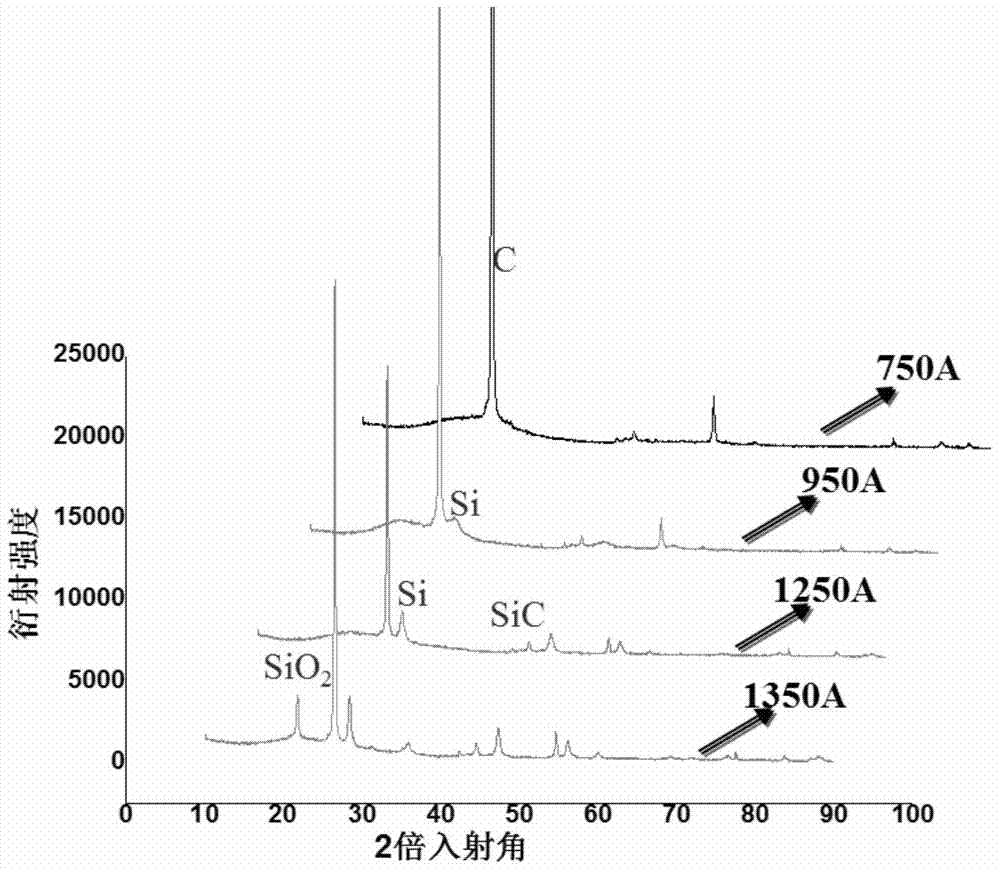

[0032] Weigh 13.2g of SiO (350 mesh), 3.6g of glucose and 10.62g of AGP-8, according to the principle of ball mill material ratio, the ratio of material ratio is greater than 2:1, under the condition of planetary ball mill, 950 rpm , ball milled for 4 hours to obtain a mixed precursor.

[0033] Put the above-mentioned mixed precursor into a ceramic crucible, put the covered ceramic crucible into a high-temperature tube furnace; evacuate and pass argon; keep warm at 750° C. for 2 hours to obtain a composite negative electrode material.

[0034] The above composite negative electrode material was mechanically ground and sieved through a 325-mesh steel sieve to obtain a powdered silicon oxide composite negative electrode material 750A with a D50 particle size of 5.7 μm.

[0035] Take the above synthetic material with a mass ratio of 70wt% as the active material, 15wt% of Super P as the conductive agent, 15wt% of PVDF (polyvinylidene fluoride) (PVDF is a prepared 0.6wt% PVDF / NMP s...

Embodiment 2

[0037] Weigh 13.2g of SiO (350 mesh), 3.6g of glucose and 10.62g of AGP-8, according to the principle of ball mill material ratio, the ratio of material ratio is greater than 2:1, under the condition of planetary ball mill, 950 rpm , ball milled for 4 hours to obtain a mixed precursor.

[0038] The above mixed precursor was put into a ceramic crucible, and the covered ceramic crucible was put into a high-temperature tube furnace; vacuumed and argon flowed; kept at 950° C. for 2 hours to obtain a composite negative electrode material.

[0039] The above composite negative electrode material was mechanically ground and sieved through a 325-mesh steel sieve to obtain a powdered silicon oxide composite negative electrode material 950A with a D50 particle size of 5.7 μm.

Embodiment 3

[0041] Weigh 13.2g of SiO (350 mesh), 3.6g of glucose and 10.62g of AGP-8, according to the principle of ball mill material ratio, the ratio of material ratio is greater than 2:1, under the condition of planetary ball mill, 950 rpm , ball milled for 4 hours to obtain a mixed precursor.

[0042] The above mixed precursor was put into a ceramic crucible, and the covered ceramic crucible was put into a high-temperature tube furnace; vacuumed and argon flowed; kept at 1250° C. for 2 hours to obtain a composite negative electrode material.

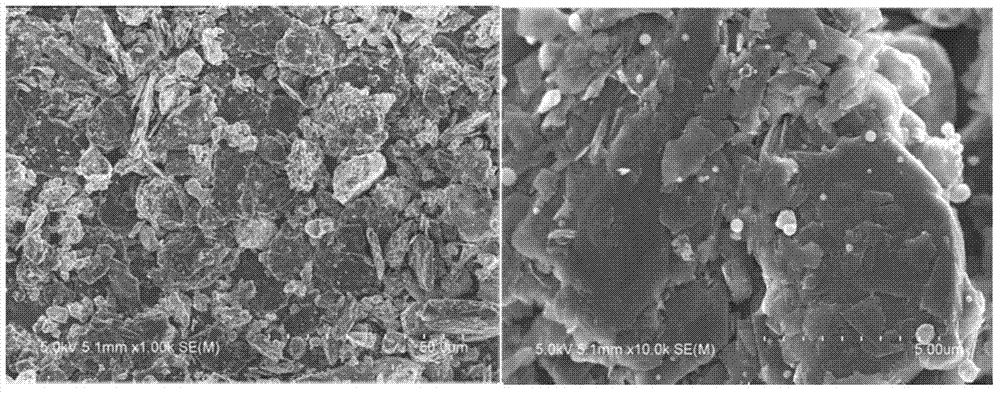

[0043] The above composite negative electrode material was mechanically ground and sieved through a 325-mesh steel sieve to obtain a powdered silicon oxide composite negative electrode material 1250A with a D50 particle size of 5.7 μm. figure 1 The SEM of the composite material shows that the particle size of the material obtained by high temperature reaction is relatively uniform, and a small amount of silicon particles are distributed on the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com