Nanoparticle-compounded ZIF-8 negative electrode material of high specific capacity bismuth as well as preparation method and application of nanoparticle-compounded ZIF-8 negative electrode material

A ZIF-8, high specific capacity technology, applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., to achieve the effect of mild conditions, high yield and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] (1) 3mmol zinc nitrate hexahydrate (Zn(NO 3 ) 2 ·6H 2 (2) and 6mmol 2-methylimidazole (MeIm) are added respectively in 40mL absolute methanol, ultrasonic 30min, until both solutions become uniform and clear;

[0050] (2) Zinc nitrate hexahydrate (Zn(NO) in step (1) 3 ) 2 ·6H 2 O) solution is poured in 2-methylimidazole (MeIm) solution, under 600rpm continuous mechanical stirring 30min, appears white turbidity to solution;

[0051] (3) Transfer the mixed solution in step (2) to a 100mL polytetrafluoroethylene autoclave, let it stand at 100°C for 12h, centrifuge to remove the supernatant and wash the lower precipitate with anhydrous methanol 3 times, then washed 3 times with ultrapure water and dried at 80°C for 18 hours to obtain a white ZIF-8 precursor;

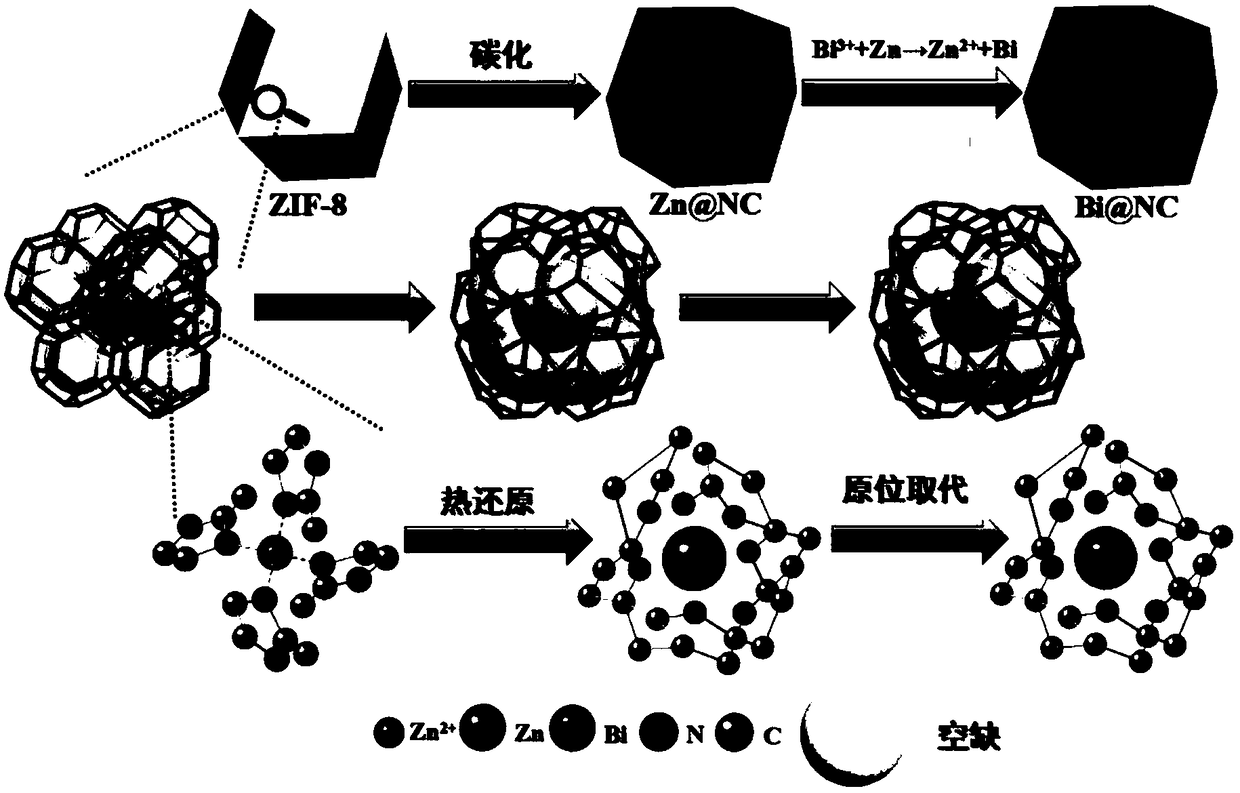

[0052] (4) Put the dried white ZIF-8 precursor in step (3) into a corundum ark, and carbonize at 600°C for 2 hours in a nitrogen protective atmosphere to obtain a black Zn@NC intermediate product;

[0053] (5) A...

Embodiment 2

[0061] (1) 1mmol zinc nitrate hexahydrate (Zn(NO 3 ) 2 ·6H 2 (2) and 2mmol 2-methylimidazole (MeIm) are added respectively in 40mL absolute methanol, ultrasonic 30min, until both solutions become uniform and clear;

[0062] (2) Zinc nitrate hexahydrate (Zn(NO) in step (1) 3 ) 2 ·6H 2 O) solution is poured in 2-methylimidazole (MeIm) solution, under 400rpm continuous mechanical stirring 20min, appears white turbidity to solution;

[0063] (3) Transfer the mixed solution in step (2) to a 100mL polytetrafluoroethylene autoclave, let it stand at 110°C for 16h, centrifuge, remove the supernatant and wash the lower layer with anhydrous methanol Wash 3 times, then wash 3 times with ultrapure water, and then dry at 70°C for 20 hours to obtain the white ZIF-8 precursor;

[0064] (4) Put the dried white ZIF-8 precursor in step (3) into a corundum ark, and carbonize it at 500°C for 4 hours in a nitrogen protective atmosphere to obtain a black Zn@NC intermediate product;

[0065] (...

Embodiment 3

[0068] (1) 2mmol zinc nitrate hexahydrate (Zn(NO 3 ) 2 ·6H 2 (2) and 4mmol 2-methylimidazole (MeIm) are added respectively in 40mL of absolute methanol, ultrasonic 30min, until both solutions become uniform and clear;

[0069] (2) Zinc nitrate hexahydrate (Zn(NO) in step (1) 3 ) 2 ·6H 2 O) solution is poured in 2-methylimidazole (MeIm) solution, under 500rpm continuous mechanical stirring 10min, appears white turbidity to solution;

[0070] (3) Transfer the mixed solution in step (2) to a 100mL polytetrafluoroethylene autoclave, let it stand at 120°C for 18h, centrifuge, remove the supernatant, and use anhydrous methanol to precipitate the lower layer first. Washing 3 times, then washing 3 times with ultrapure water, and then drying at 60°C for 24h to obtain a white ZIF-8 precursor;

[0071] (4) Put the dried white ZIF-8 precursor in step (5) into a corundum ark, and carbonize it at 700°C for 2 hours in a nitrogen protective atmosphere to obtain a black Zn@NC intermediat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com