High-performance silicon/carbon anode nanocomposite and preparation method thereof

A carbon nanocomposite, negative electrode material technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc. Uniform mixing and other problems, to achieve the effect of low volume expansion effect, conducive to electron transport, and stable electrochemical cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

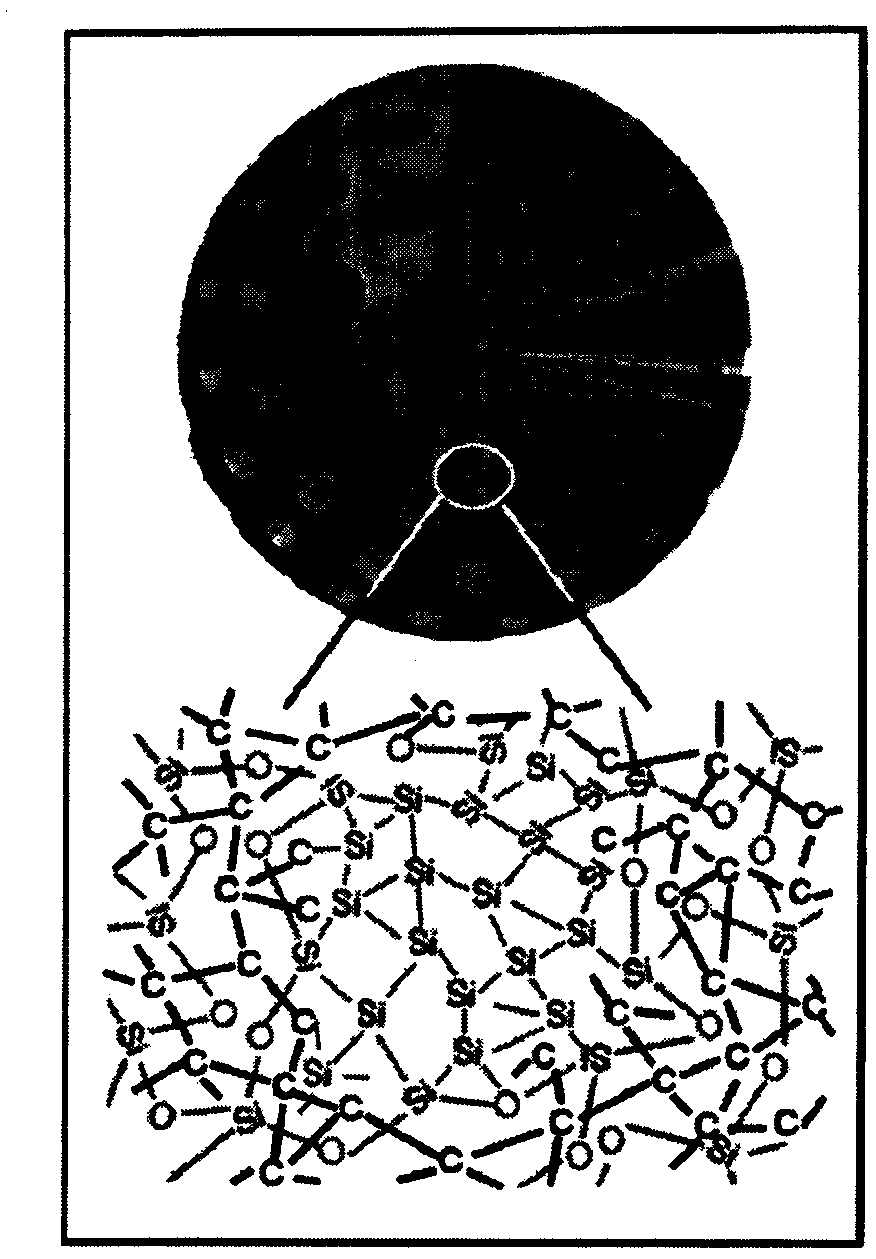

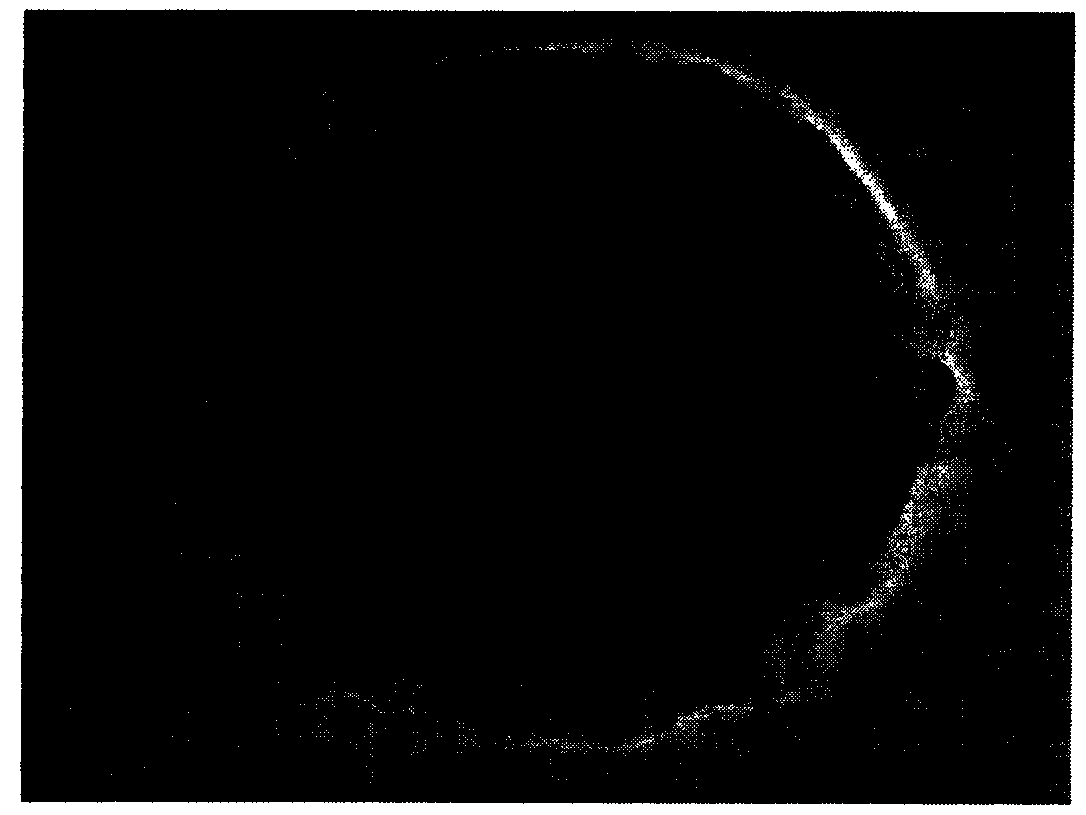

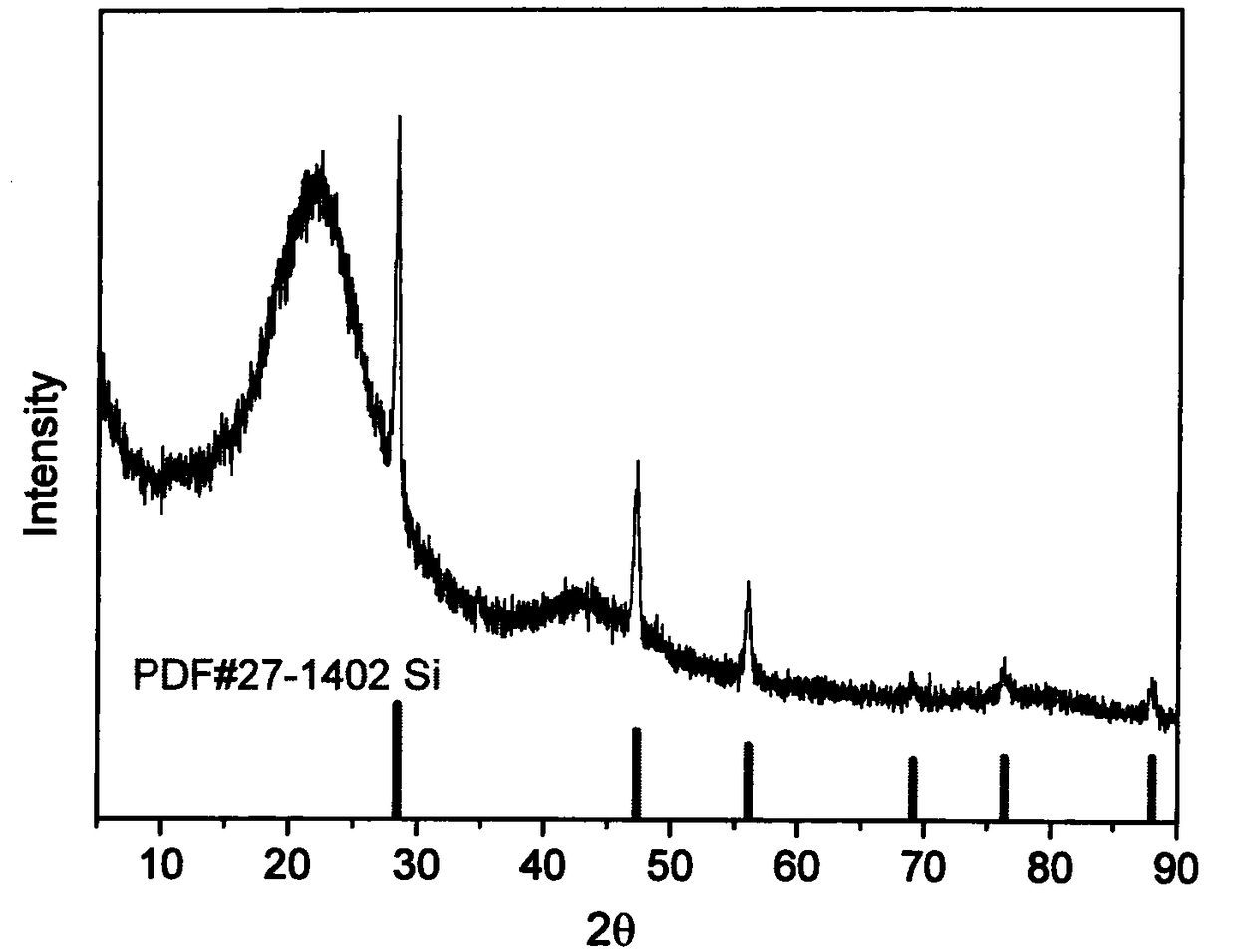

[0044] A high-performance silicon / carbon nanocomposite anode material, such as figure 1 As shown, it includes nano-spherical particles with a diameter of 100-200 nm having mesoporous channels with a pore size of 2-10 nm, and the interior of the spherical particles and / or the mesoporous channels are filled with elemental silicon particles. The size of the silicon particles is less than 10nm.

[0045] The preparation method of the high-performance silicon / carbon nanocomposite negative electrode material is:

[0046] Prepare mesoporous silicone nanoparticles. The preparation method of the mesoporous silicone nanoparticles is: mix 280mL deionized water, 120mL ethanol, and 2mL concentrated ammonia water, add 600mgCTAB, and stir for 1-3h, wherein the mechanical stirring speed is 400 Turn per minute, select the temperature at 25 degrees, then add 0.5mL 1,4-bis(triethoxysilyl)benzene (BTEB), stir overnight to obtain a uniformly dispersed suspension, centrifuge, and select the centrif...

Embodiment 2

[0054] A high-performance silicon / carbon nanocomposite negative electrode material, comprising nano-spherical particles with a diameter of 100-200nm and mesoporous channels with a pore size of 2-10nm, the interior of the spherical particles and / or the mesoporous channels are filled with elemental silicon particles. The size of the silicon particles is less than 10nm.

[0055] The preparation method of the high-performance silicon / carbon nanocomposite negative electrode material is:

[0056] Prepare mesoporous silicone nanoparticles. The preparation method of the mesoporous silicone nanoparticles is: mix 280mL deionized water, 120mL ethanol, and 2mL concentrated ammonia water, add 800mgCTAB, and stir for 1-3h, wherein the mechanical stirring speed is 400 Turn per minute, select the temperature at 25 degrees, then add 1mL of 1,2-bis(triethoxysilyl)ethane (BTEE), stir overnight to obtain a uniformly dispersed suspension, centrifuge, and select the centrifuge speed at 9000 rpm / m...

Embodiment 3

[0062] A high-performance silicon / carbon nanocomposite negative electrode material, comprising nano-spherical particles with a diameter of 100-200nm and mesoporous channels with a pore size of 2-10nm, the interior of the spherical particles and / or the mesoporous channels are filled with elemental silicon particles. The size of the silicon particles is less than 10nm.

[0063] The preparation method of the high-performance silicon / carbon nanocomposite negative electrode material is:

[0064] Prepare mesoporous silicone nanoparticles. The preparation method of the mesoporous silicone nanoparticles is: mix 280mL deionized water, 150mL ethanol, and 2mL concentrated ammonia water, add 800mgCTAB, and stir for 1-3h, wherein the mechanical stirring speed is 400 RPM, temperature selection 25 degrees, then add 0.5mL 1,4-bis(triethoxysilyl)benzene (BTEB) and 0.5mL tetraethyl orthosilicate, stir overnight to obtain a uniformly dispersed suspension, centrifuge For separation, the rotation...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com