A silicon-based composite negative electrode material, a preparation method thereof and an energy storage device

A technology of silicon-based material and negative electrode material, applied in the direction of negative electrode, hybrid capacitor, hybrid capacitor electrode, etc., can solve the problems of poor cycle performance, failure, pulverization, etc., and achieve long cycle life, high capacity, and ensure integrity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] Correspondingly, as figure 2 As shown, the embodiment of the present invention provides a method for preparing the above-mentioned silicon-based composite negative electrode material, and the specific steps include:

[0038] S10, taking a silicon-based material, and growing a two-dimensional quinone aldehyde covalent organic framework material in situ on the surface of the silicon-based material to form a first coating layer;

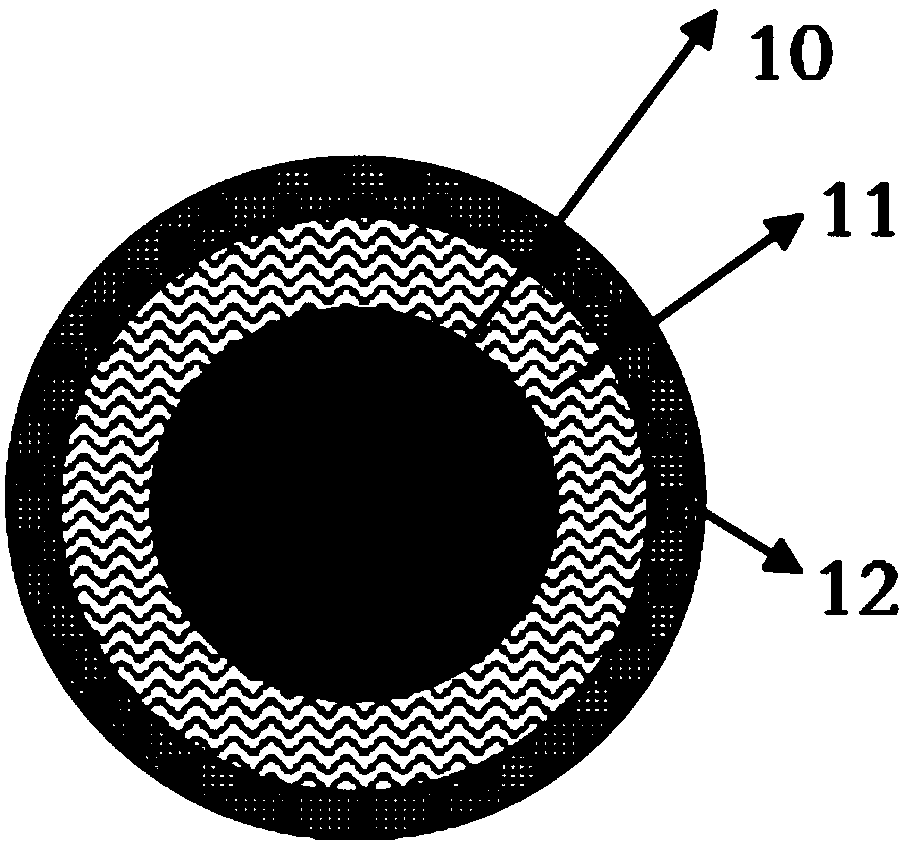

[0039] S20. Coating a fast-conducting ion material on the surface of the first coating layer to form a second coating layer, that is, to obtain a silicon-based composite negative electrode material, the silicon-based composite negative electrode material includes a silicon-based material core and is coated on the A cladding layer on the surface of the silicon-based material inner core, the cladding layer includes the first cladding layer arranged on the surface of the silicon-based material inner core and the second cladding layer arranged on th...

Embodiment 1

[0052] This example provides a method for preparing a silicon-based composite negative electrode material (Si@DAAQ-TFP@LATP), and a method for assembling Si@DAAQ-TFP@LATP as a negative electrode of a lithium-ion battery into a lithium secondary battery:

[0053] S10, Preparation of Si@DAAQ-TFP

[0054] Dissolve commercial nano-silicon with a median particle size of 100nm and DAAQ and TFP with a stoichiometric ratio of 1:1 in a mixed solvent composed of N,N-dimethylacetamide and mesitylene to obtain a mixed solution. Under sealed conditions, react the mixed solution at 80°C-140°C for 1d-7d, after cooling to room temperature, centrifuge the obtained material to obtain a solid, and use N,N-dimethylformamide (DMF) first and then use The solid was washed with acetone and dried to obtain DAAQ-TFP-coated nano-silicon, that is, Si@DAAQ-TFP.

[0055] S20, Preparation of Si@DAAQ-TFP@LATP

[0056] Add 10g Si@DAAQ-TFP into 100mL deionized water, after ultrasonic dispersion, add lithium ...

Embodiment 2

[0060] This example provides a method for preparing a silicon-based composite negative electrode material (SiO@DABQ-TFP@LLZO), using SiO@DABQ-TFP@LLZO as a negative electrode material for a lithium-ion battery, and assembling it into a secondary battery:

[0061] S10, Preparation of SiO@DABQ-TFP

[0062] SiO with a particle size of 1 μm-10 μm and 2,5-diamino-1,4-dihydroxybenzene (DABH) and TFP with a stoichiometric ratio of 7:2 were dissolved in N,N-dimethylacetamide and homogenized In a mixed solvent composed of trimethylbenzene, the mixed solution was obtained, and the mixed solution was reacted at 85°C-120°C for 1d-7d under the condition of anaerobic sealing, and after cooling to room temperature, the obtained material was centrifuged to obtain a solid, and first The solid was washed with N,N-dimethylformamide (DMF) followed by THF, and dried to obtain the SiO@DABH-TFP material. Then, SiO@DABH-TFP was gradually added to triethylamine to obtain a suspension. The suspension ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com