Nano silicon/carbon composite material, preparation method and lithium ion battery containing nano silicon/carbon composite material as negative electrode material

A carbon composite material and nano-silicon technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as large expansion, poor material bonding force, and uneven coating of carbon-coated silicon.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

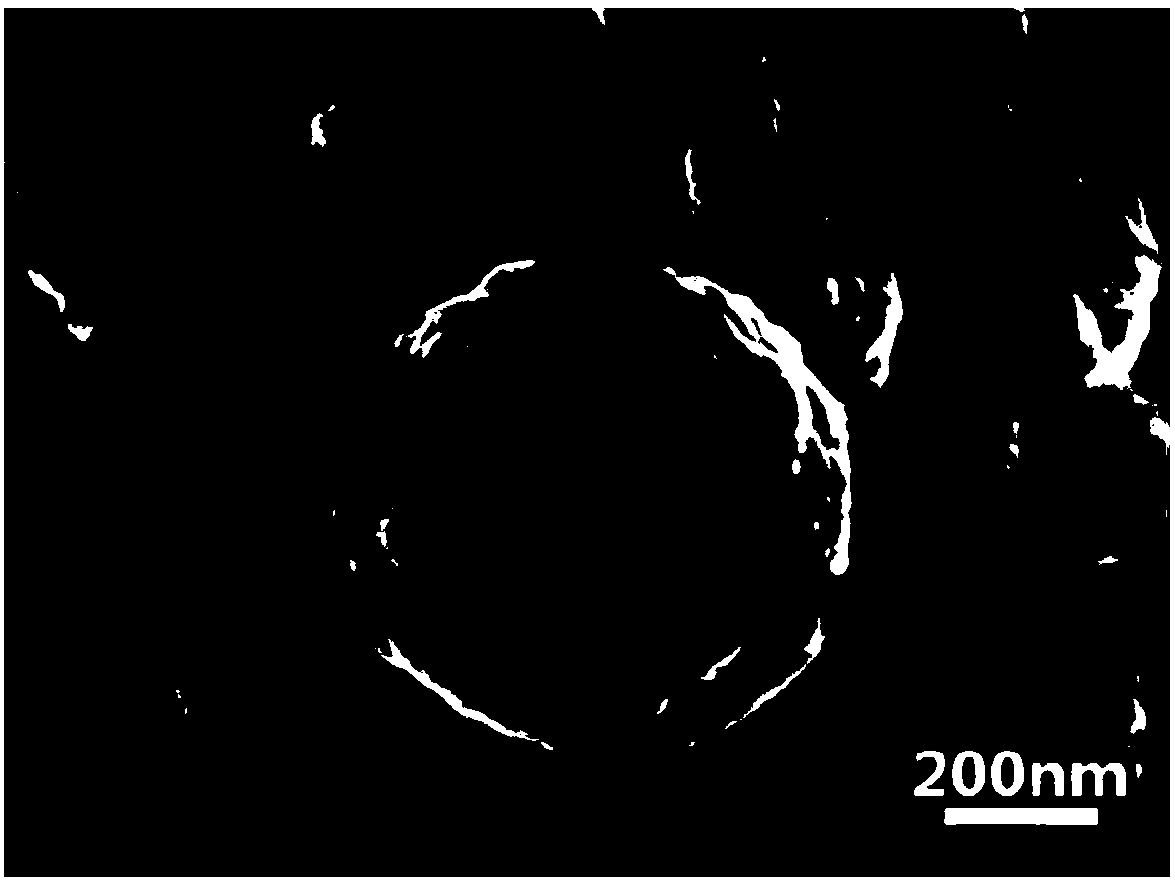

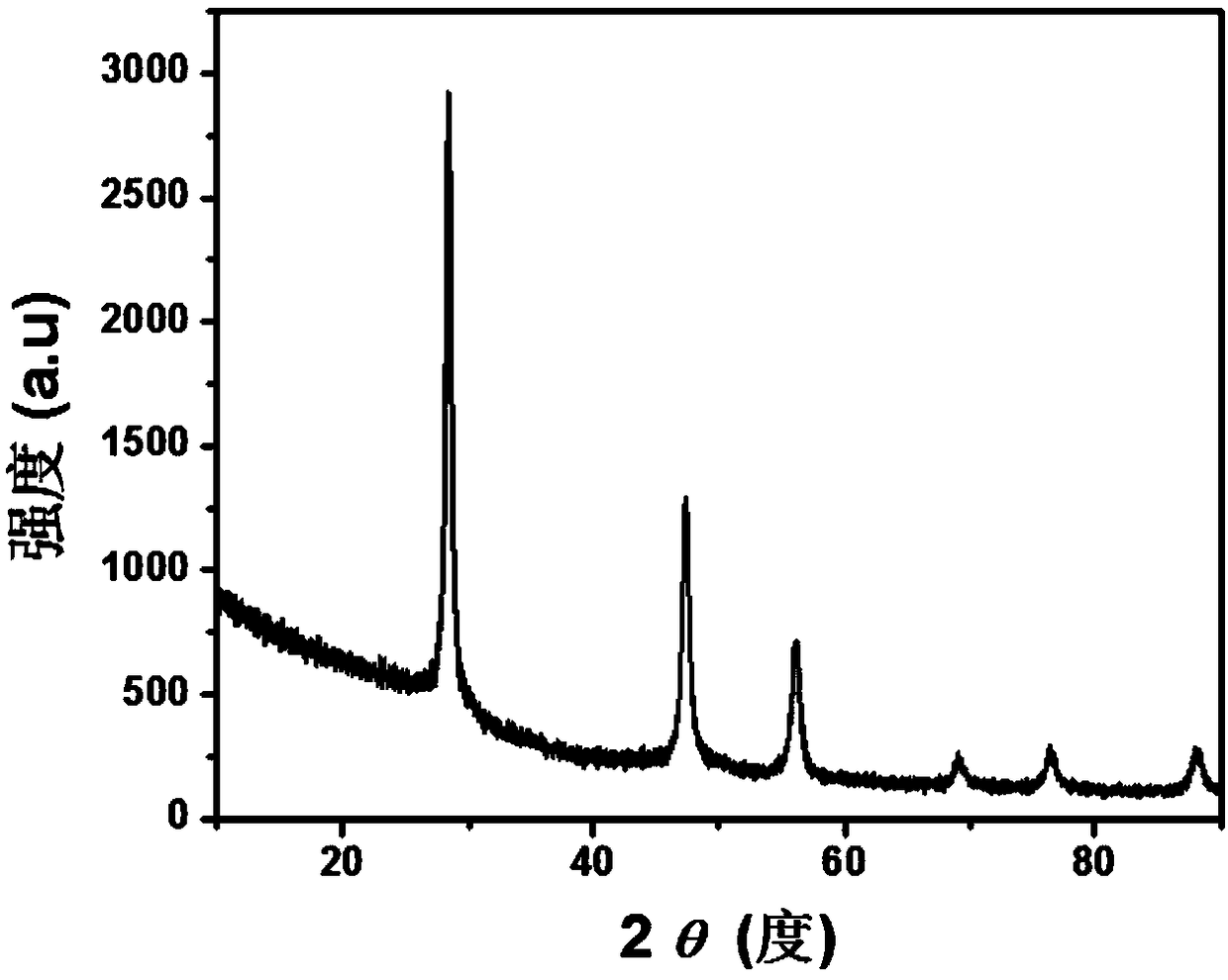

[0078] (1) 0.5 g of nano-silicon with a median particle size of 50 nm, 0.025 g of vinyl triethoxy silane, and 0.1 g of 1,3-butadiene are sequentially added to 10 ml of styrene, and the mixture is uniformly stirred to obtain a mixture.

[0079] (2) Add 80ml of distilled water, 0.25g of sodium lauryl sulfate, 0.06g of isohexadecane and 0.02g of ammonium persulfate to the above mixture and stir to obtain an emulsion. The emulsion is homogenized by a high-pressure homogenizer. After melting, transfer to a 200ml three-necked flask equipped with reflux condenser, magnetic stirrer, thermometer and nitrogen passage to raise the temperature to 85°C, react for 2h-3h, cool to complete the reaction.

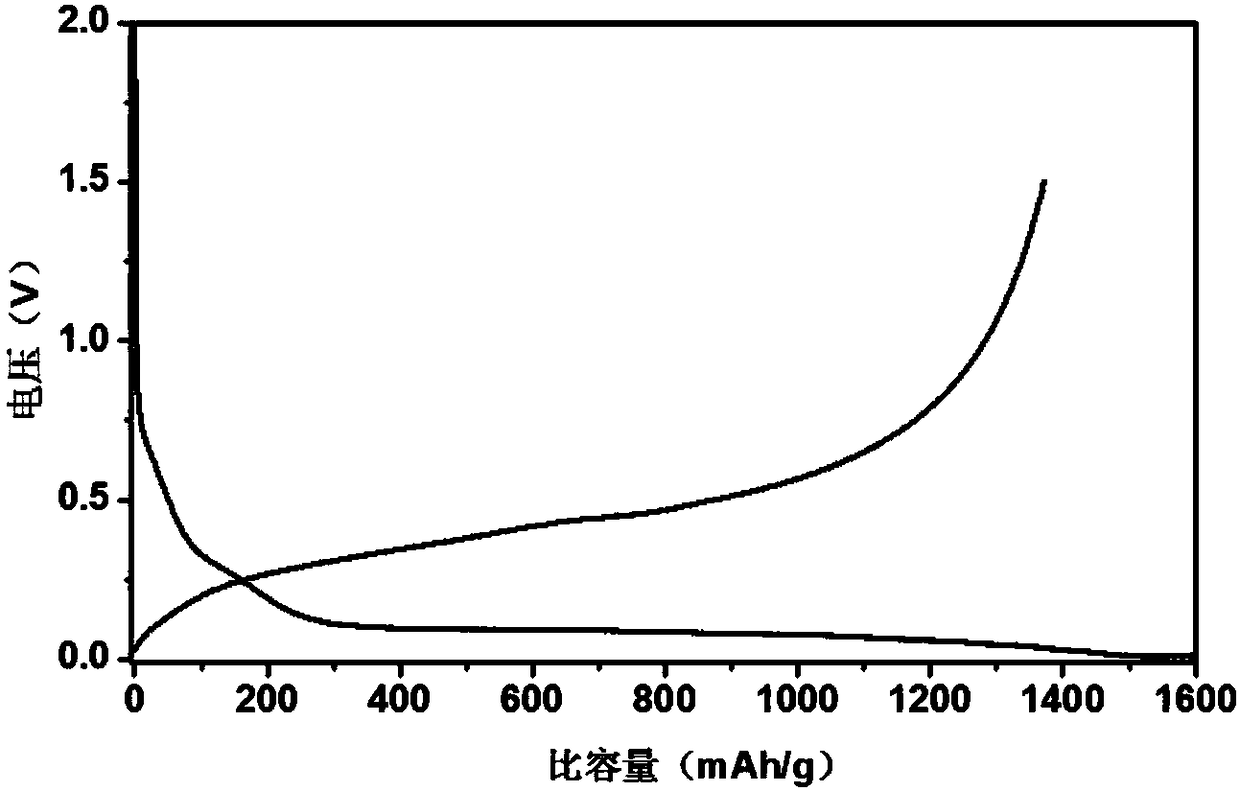

[0080] (3) After demulsification, washing and drying of the resulting emulsion, a powdery solid is obtained. Finally, the powder is prevented from being heated in a graphite crucible at 2.0°C / min to 1000°C under a nitrogen atmosphere, kept for 3h, and naturally cooled to room temperature. The hig...

Embodiment 2

[0086] (1) 0.4g of nano-silicon with a median particle size of 50nm, 0.025g of vinyltriethoxysilane, and 0.1g of 1,3-butadiene were sequentially added to 15ml of styrene, and stirred to obtain a mixture.

[0087] (2) Add 80ml of distilled water, 0.25g of sodium lauryl sulfate, 0.06g of isohexadecane and 0.02g of ammonium persulfate to the above mixture and stir to obtain an emulsion. The emulsion is homogenized by a high-pressure homogenizer Then, transfer to a 200ml three-necked flask equipped with a reflux condenser, a magnetic stirrer, a thermometer and a nitrogen passage, and raise the temperature to 85°C. After reacting for 2h-3h, cool to complete the reaction.

[0088] (3) After demulsification, washing and drying of the resulting emulsion, a powdery solid is obtained. Finally, the powder is prevented from being heated in a graphite crucible at 2.0°C / min to 1000°C under a nitrogen atmosphere, kept for 3h, and naturally cooled to room temperature. The high-temperature product ...

Embodiment 3

[0090] The preparation method is the same as that of Example 1, the difference is: the mass of commercial nano silicon is changed to 0.6 g, the volume of styrene is changed to 8 ml, and the obtained test results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Median particle size | aaaaa | aaaaa |

| Median particle size | aaaaa | aaaaa |

| Median particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com