Lithium ion battery cathode material carbon microsphere and preparation method thereof

A technology for lithium ion batteries and negative electrode materials, which is applied in battery electrodes, carbon preparation/purification, circuits, etc., can solve the problems of poor cycle performance and rate performance, low energy density of carbon microspheres, and easy agglomeration of carbon microspheres. Achieve the effect of improved rate performance, suitable for large-scale mass production, and high uniformity of morphology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] At room temperature, add 0.1 g of glucose (2 g / L) and 0.009 g of ferrocene (0.001 mol / L) to 50 ml of acetone, and sonicate until the ferrocene is completely dissolved. Then the solution is added to a solvothermal reaction kettle, put into an oven with a temperature of 180°C, and last for 20 hours; the obtained material is filtered, and washed repeatedly with ethanol ultrasonic waves to obtain a black-gray precipitate; the black-gray precipitate is heated at 80°C Drying at 550° C. under nitrogen atmosphere for 5 hours, and heat treatment at 550° C. for 2 hours; cooling in the furnace, and grinding the heat-treated material to obtain the carbon microsphere material of the present invention.

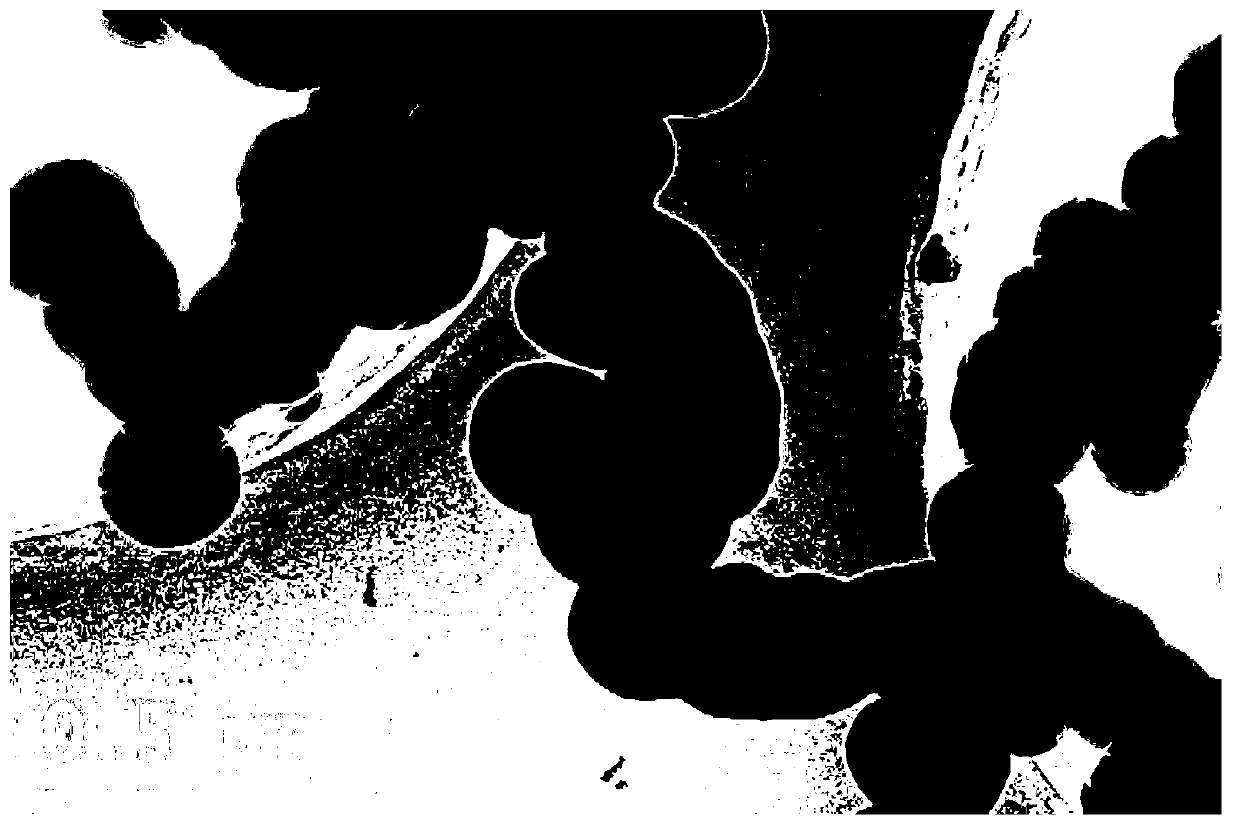

[0027] Obtained carbon microsphere material is carried out transmission electron microscope observation, the result is as follows figure 1 shown. from figure 1 It can be seen from the figure that the obtained carbon microsphere material has smooth surface, uniform shape, uniform pa...

Embodiment 2

[0030] At room temperature, add 2.0g sucrose (10g / L) and 0.076g cobalt dicene (0.002mol / L) to 200ml ethanol, and sonicate until the cobalt dicene is completely dissolved. Then the solution is added into a solvothermal reaction kettle, put into an oven with a temperature of 200°C, and last for 10 hours; the obtained material is filtered, and washed repeatedly with acetone ultrasonic waves to obtain a black-gray precipitate; the black-gray precipitate is heated at 120°C Drying for 2 hours, and then in argon atmosphere, heat treatment at 450 ° C for 10 hours; cooling with the furnace, grinding the heat-treated material to obtain the carbon microsphere material of the present invention.

Embodiment 3

[0032] At room temperature, in 500ml of acetone, add 25g of phenolic resin (50g / L) and 0.283g of nickelocene (0.003mol / L), sonicate until the nickelocene is completely dissolved. Then the solution is added into the solvothermal reaction kettle, put into an oven with a temperature of 220° C., and continue for 15 hours; the obtained material is filtered, and ultrasonically washed repeatedly with deionized water to obtain a black-gray precipitate; the black-gray precipitate is in Dry at 100°C for 2.5 hours, then heat-treat in a nitrogen atmosphere at 530°C for 4 hours; cool in the furnace, and grind the heat-treated material to obtain the carbon microsphere material of the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com