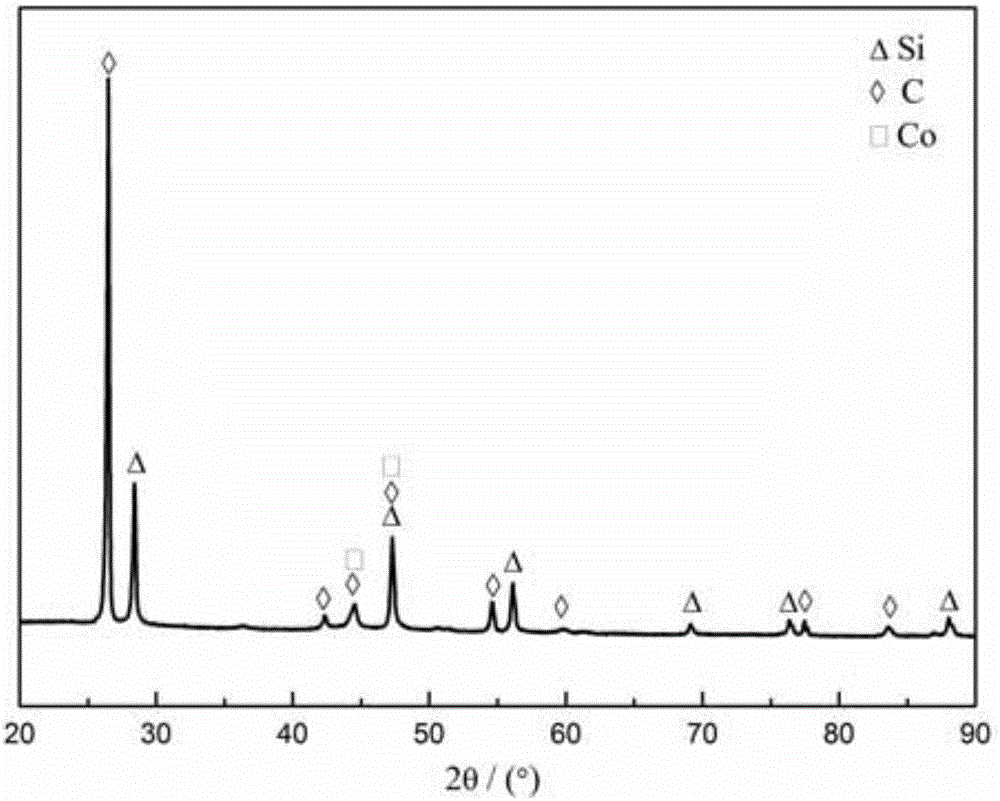

Silicon-cobalt-carbon composite material for negative electrode of lithium ion battery and preparation method of silicon-cobalt-carbon composite material

A technology of lithium ion battery and carbon composite material is applied in the field of silicon-cobalt-carbon composite material for negative electrode of lithium ion battery and its preparation field, and can solve the problems of organic solvent unfavorable to operator's health, large equipment investment, large proportion of silicon, etc. , to achieve the effect of inhibiting poor bonding strength, small investment and good cycle life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

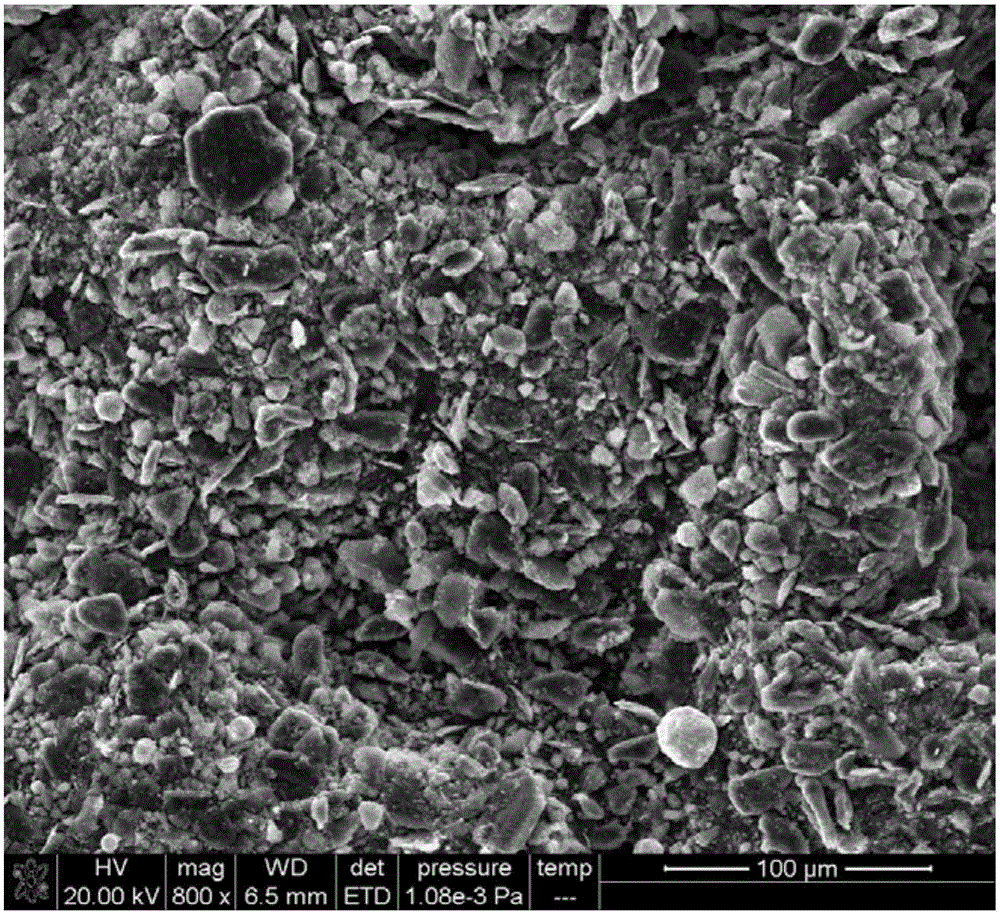

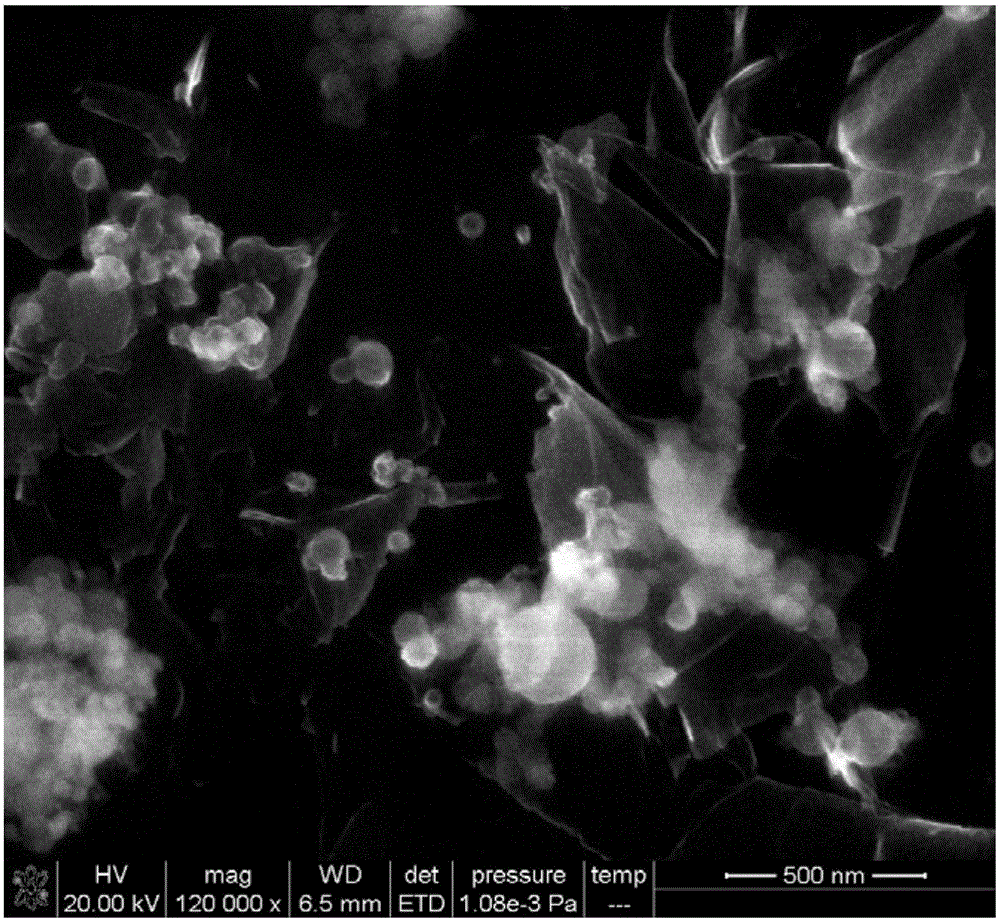

Embodiment 1

[0028] Formula: 2.91g of nano-silica powder (average particle diameter of 80nm), 2.91g of cobalt nitrate hexahydrate, 4.02g of citric acid monohydrate, and 8.73g of graphite powder (average particle diameter of 17um).

[0029] 1) Take the nano-silica powder of the recipe amount and add it to 30g deionized water, adopt 1200W power ultrasonic dispersion, and use ice-water mixture to cool at the same time, prevent the dispersion liquid from overheating, and obtain the nano-silica powder dispersion liquid;

[0030] 2) Add 10 g of deionized water to cobalt nitrate hexahydrate in the formula amount and stir to dissolve, then add it into the nano-silica powder dispersion, and mix evenly to obtain a mixed solution A;

[0031] 3) Add 10 g of deionized water to the citric acid monohydrate of the formula amount and stir to dissolve, then add it into the mixed solution A, and mix evenly to obtain the mixed solution B;

[0032] 4) Add the graphite powder of the formula amount into the mixe...

Embodiment 2

[0041] Formula: 1.455g of nano-silica powder (average particle size: 50nm), 2.91g of cobalt nitrate hexahydrate, 4.02g of citric acid monohydrate, and 8.73g of graphite powder (average particle size: 17um).

[0042] 1) Take 1.455g of nano-silica powder and add it to 50g of deionized water, and use 800W power for ultrasonic dispersion, while cooling with an ice-water mixture to prevent the dispersion from overheating, and obtain a nano-silica powder dispersion;

[0043] 2) adding the cobalt nitrate hexahydrate of the formula amount into the nano-silicon powder dispersion, stirring and dissolving to obtain the mixed solution A;

[0044] 3) Add the citric acid monohydrate of the formula amount into the mixed solution A, stir and dissolve to obtain the mixed solution B;

[0045] 4) Add the graphite powder of the formula amount into the mixed solution B and stir and mix evenly to obtain the mixed solution C;

[0046] 5) adjusting the pH=3 of the mixed solution C with ammonia water...

Embodiment 3

[0052] Formula: 2.91g of nano silicon powder (average particle size: 50nm), 4.365g of cobalt sulfate heptahydrate, 6.52g of citric acid monohydrate, 29.1g of graphite powder (average particle size: 17um).

[0053] 1) Take the nano-silica powder of the formula amount and add it to 50g deionized water, adopt 1000W power ultrasonic dispersion, and use ice-water mixture to cool at the same time, prevent the dispersion liquid from overheating, and obtain the nano-silica powder dispersion liquid;

[0054] 2) adding the cobalt nitrate hexahydrate of the formula amount into the nano-silicon powder dispersion, stirring and dissolving to obtain the mixed solution A;

[0055] 3) Add the citric acid in the formula amount into the mixed solution A, stir and dissolve to obtain the mixed solution B;

[0056] 4) Add the graphite powder of the formula amount into the mixed solution B and stir and mix evenly to obtain the mixed solution C;

[0057] 5) adjusting the pH=5 of the mixed solution C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com