Ultrasonic film-rolling machine for wave lithium ion battery pole pieces

A lithium-ion battery, ultrasonic technology, applied in battery electrodes, electrode rolling/calendering, electrode manufacturing, etc., can solve problems such as uneven deformation of the surface layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

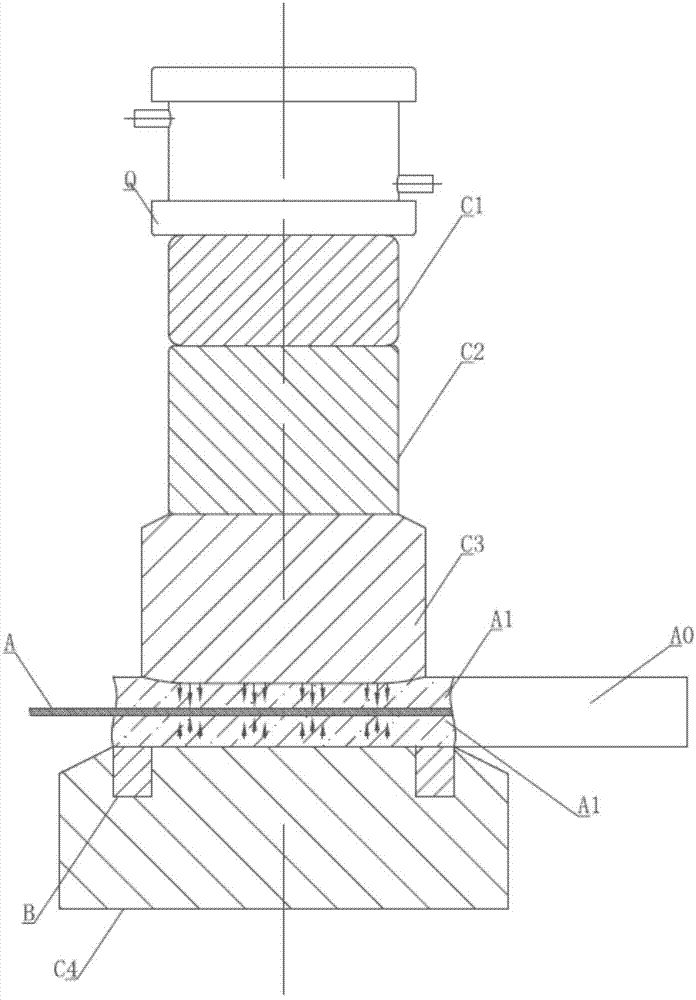

[0070] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

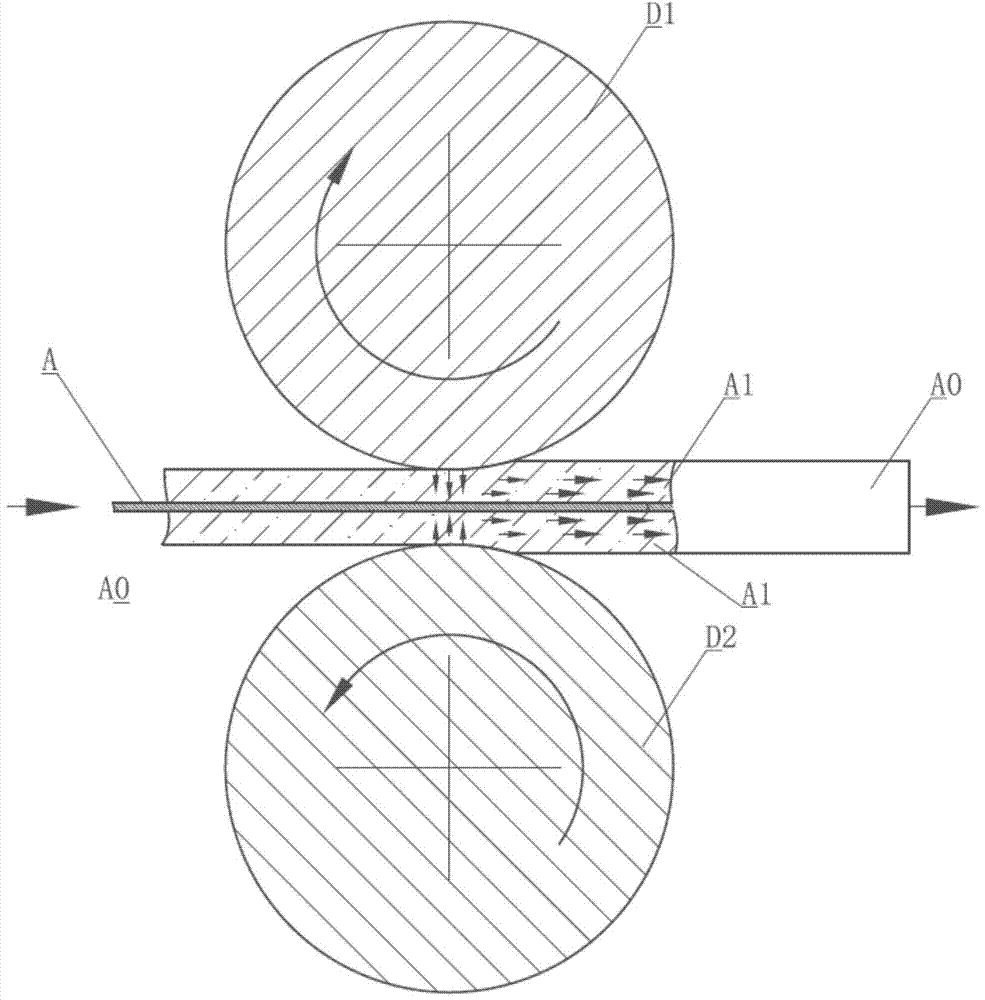

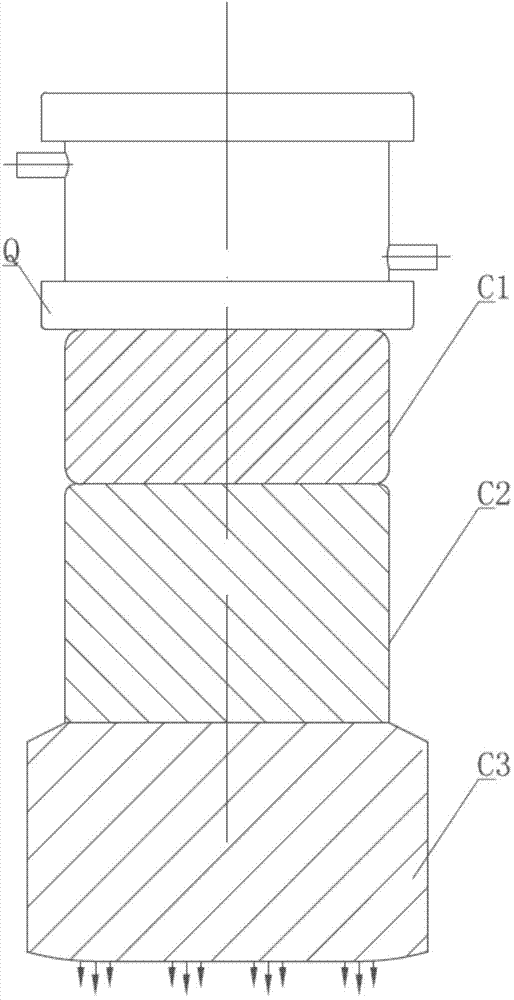

[0071] The lithium-ion battery pole piece ultrasonic film rolling machine of the present invention is composed of an unwinding motor, an ultrasonic rolling assembly, a winding motor, and an anvil. The unwinding motor and the winding motor are respectively located on the left and right sides of the ultrasonic rolling assembly, and the anvil Arranged under the rolling film pressure head of the ultrasonic rolling component.

[0072] The ultrasonic rolling assembly converts electrical energy into mechanical vibration energy through an ultrasonic transducer. The working vibration waves of ultrasonic transducers include longitudinal waves and transverse waves. When the vibration direction is perpendicular to the propagation direction, it is called transverse wave; when the vibration direction is consistent with the propagation direction, it is called...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com