Preparation method and application of self-supporting ordered structure membrane electrode

An ordered structure, membrane electrode technology, applied in the direction of electrodes, circuits, fuel cells, etc., can solve the problem of high interface resistance between electrocatalysts and ion-conducting membranes, difficulty in ensuring the quality uniformity of membrane electrodes, and difficulties in reducing ion transfer resistance, etc. Problems, achieve the effect of improving the degree of interface bonding, stabilizing the interface area, and reducing the film thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

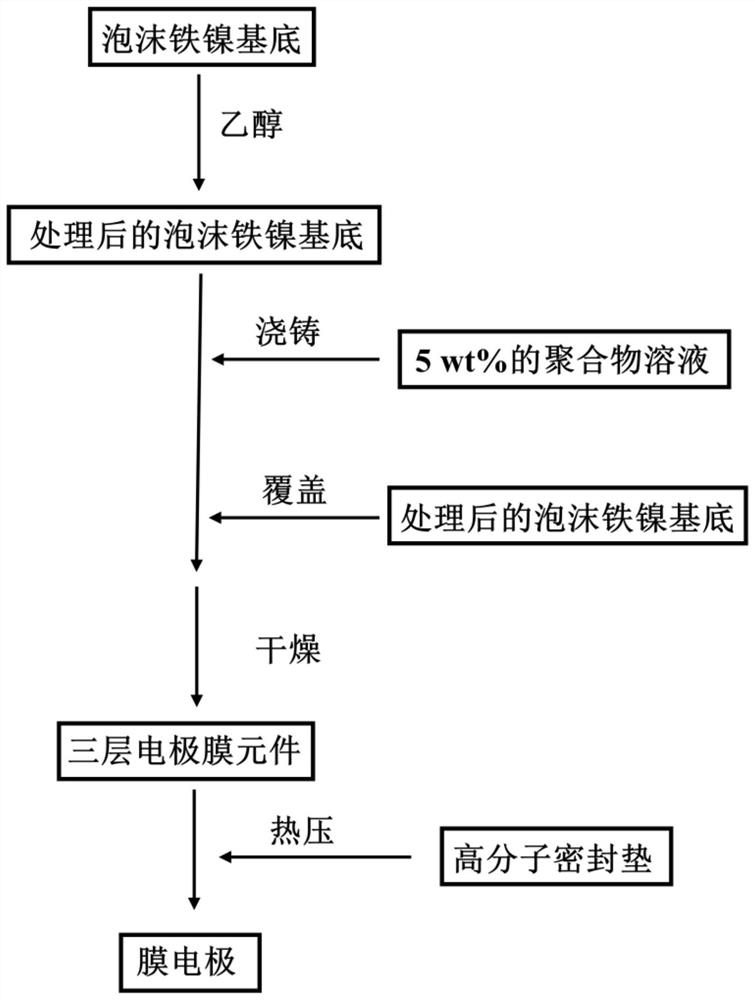

[0046] 1) use the foamed iron-nickel alloy as the catalytic electrode, which is cleaned and dried in ethanol solution;

[0047] 2) dissolving the polybenzimidazole macromolecule in N-methylpyrrolidone to make a solution with a concentration of 5% by weight;

[0048] 3) casting the polybenzimidazole solution prepared in step 2) on the surface of the foamed iron-nickel alloy treated in step 1), and spreading it on the surface of the foamed iron-nickel alloy after drooling;

[0049] 4) covering the foamed iron-nickel alloy treated in step 1) on the polybenzimidazole solution obtained in step 3), heating and drying to obtain a device in which the foamed iron-nickel alloy sandwiches a polybenzimidazole film;

[0050] 5) Using a hot pressing method to connect a polymer sealing gasket to the periphery of the device produced in step 4) to obtain a membrane electrode.

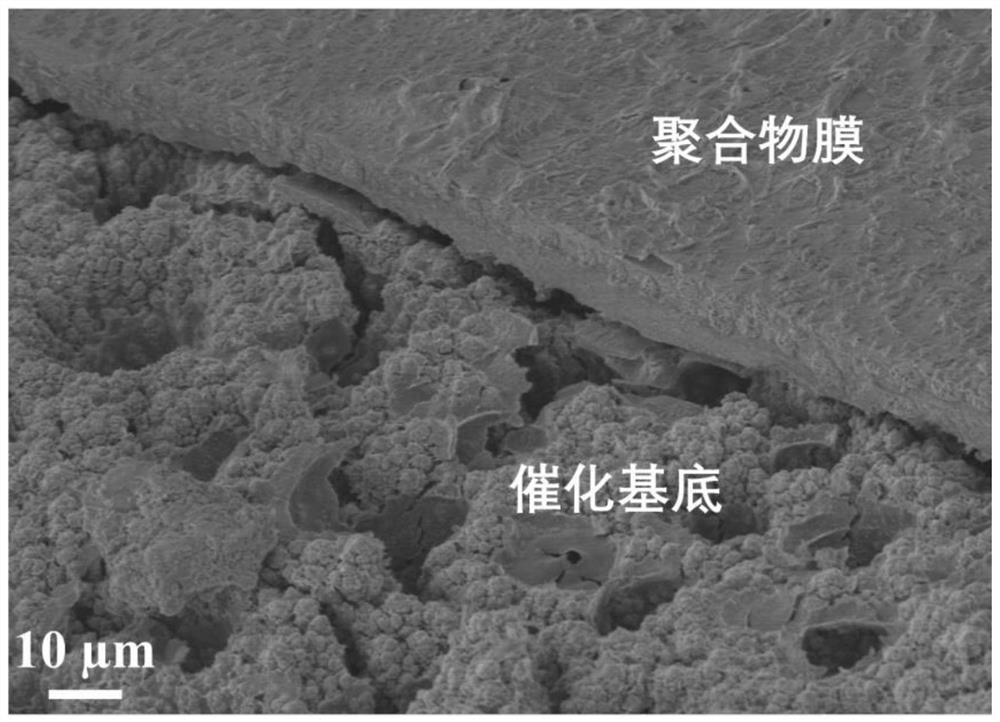

[0051] From figure 2 It can be clearly seen from the electron microscope image that the interface between the memb...

Embodiment 2

[0057] 1) use the foamed iron-nickel alloy as the catalytic electrode, which is cleaned and dried in ethanol solution;

[0058] 2) Using ethanol as a solvent, prepare a perfluorosulfonic acid resin solution with a concentration of 5% by weight, and cast it on the surface of the foamed iron-nickel alloy treated in step 1), and spread it on the foamed iron-nickel alloy after drooling surface;

[0059] 3) covering the foamed iron-nickel alloy treated in step 1) on the perfluorosulfonic acid resin solution obtained in step 2), heating and drying to obtain a device with a perfluorosulfonic acid resin film sandwiched between the foamed iron-nickel alloy;

[0060] 4) Using a hot pressing method to connect a polymer sealing gasket to the periphery of the device produced in step 3) to obtain a membrane electrode.

[0061] In kind such as image 3 As shown, the surface of the membrane electrode is smooth and flat, and the edge of the perfluorosulfonic acid resin solution is transparen...

Embodiment 3

[0063] 1) use the foamed iron-nickel alloy as the catalytic electrode, which is cleaned and dried in ethanol solution;

[0064] 2) dissolving the polyvinylidene fluoride polymer in dimethyl sulfoxide to prepare a polymer solution with a concentration of 5% by weight;

[0065] 3) spraying the polyvinylidene fluoride solution prepared in step 2) on the surface of the foamed iron-nickel alloy treated in step 1);

[0066] 4) covering the foamed iron-nickel alloy treated in step 1) on the polyvinylidene fluoride solution obtained in step 3), heating and drying to obtain a device with a polyvinylidene fluoride film sandwiched in the middle of the foamed iron-nickel alloy;

[0067] 5) Using a hot pressing method to connect a polymer sealing gasket to the periphery of the device produced in step 4) to obtain a membrane electrode.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com