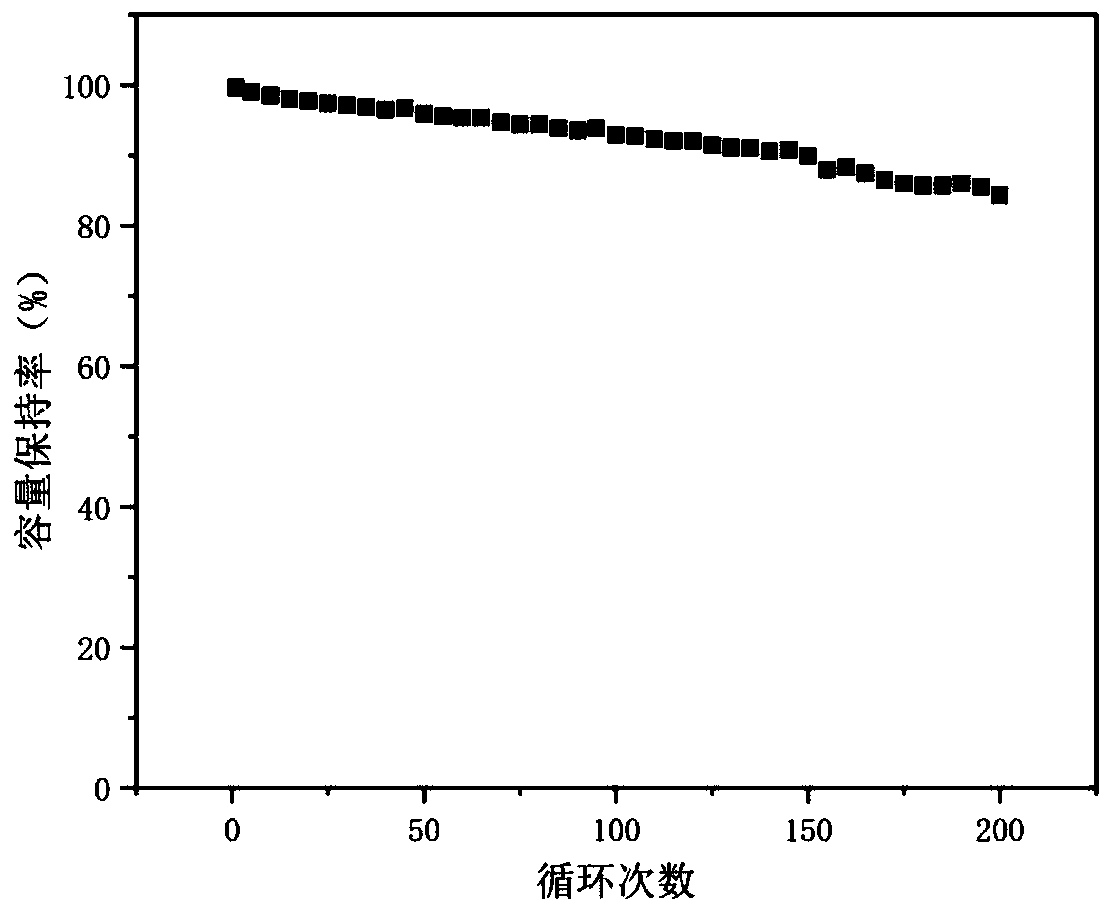

TiO2 (B) negative electrode material as well as preparation method and application thereof

A technology of negative electrode material and titanium source, applied in the field of TiO2 negative electrode material and its preparation, can solve the problems of limited practical application, high production cost, complicated process, etc., and achieve the effects of good application value, low cost and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A kind of TiO 2 (B) the preparation method of negative electrode material, comprises the following steps:

[0039] S1. Mix 50mL of ethylene glycol with 2mL of tetrabutyl titanate, heat to reflux, add 3mL of water, stir for 30min, cool, add 150mL of acetone dropwise, stir for 30min, and obtain a white precipitate, wherein the speed of dropping acetone is 1mL / min, the heating and refluxing temperature is 200°C, and the heating and refluxing time is 1h;

[0040] S2. Wash the white precipitate described in S1 with ethanol and deionized water, dry it in vacuum, and calcinate to obtain the negative electrode material, wherein the drying temperature is 70° C., and the drying time is 12 hours. Calcination adopts segmental calcination, and the segmental Calcination includes the following steps:

[0041] S21. The calcination temperature in the front stage is 150°C, the heating rate is 5°C / min, and the holding time is 3h;

[0042] S22. The calcining temperature in the second s...

Embodiment 2~4

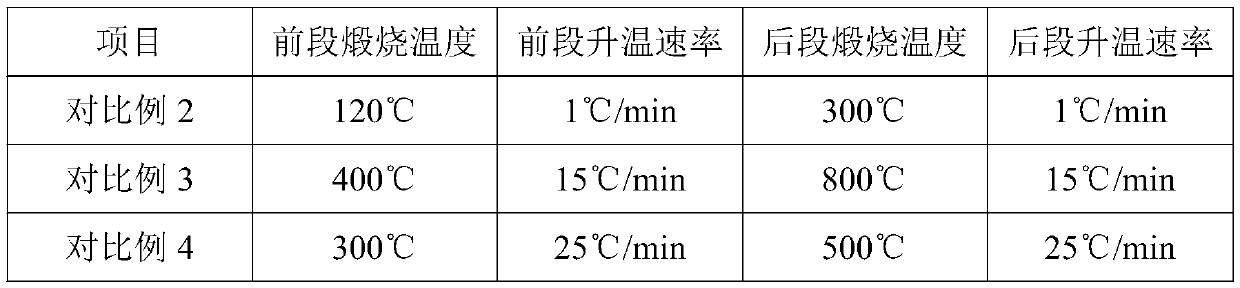

[0044] A kind of TiO 2 (B) The preparation method of the negative electrode material is basically the same as in Example 1, and the differences are shown in Table 1.

[0045] Table 1

[0046] project Pre-calcination temperature Front heating rate Post-calcination temperature Rear heating rate Example 2 100℃ 5℃ / min 400℃ 15℃ / min Example 3 200℃ 15℃ / min 700℃ 20℃ / min Example 4 300℃ 20℃ / min 500℃ 20℃ / min

Embodiment 5

[0048] A kind of TiO 2 (B) The preparation method of the negative electrode material is basically the same as that of Example 1, the difference being that the rate of dropping acetone in S1 is 30 mL / min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

| retention rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com