A silicon carbon composite negative electrode material and negative electrode sheet, preparation method thereof, and lithium ion battery

A technology of silicon carbon composite material and negative electrode material, which is applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of volume expansion, electrochemical performance and cycle life to be improved, and poor cycle performance of lithium ion batteries.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

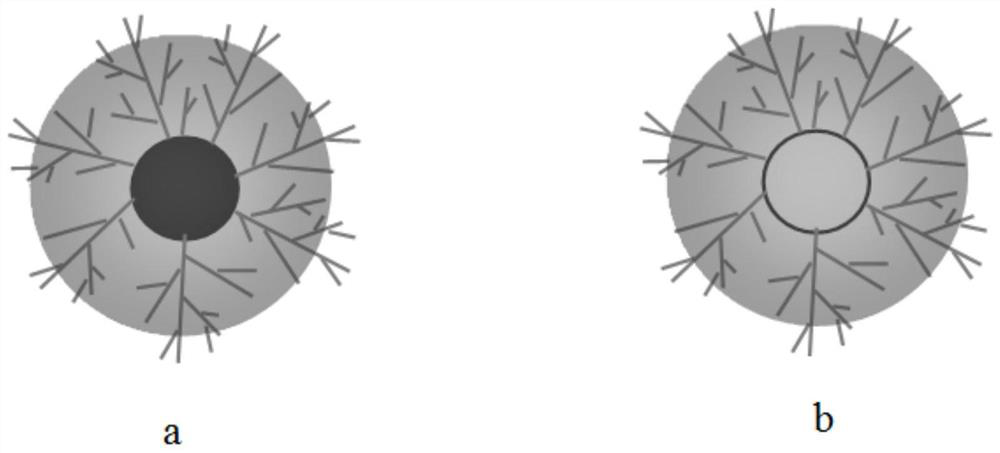

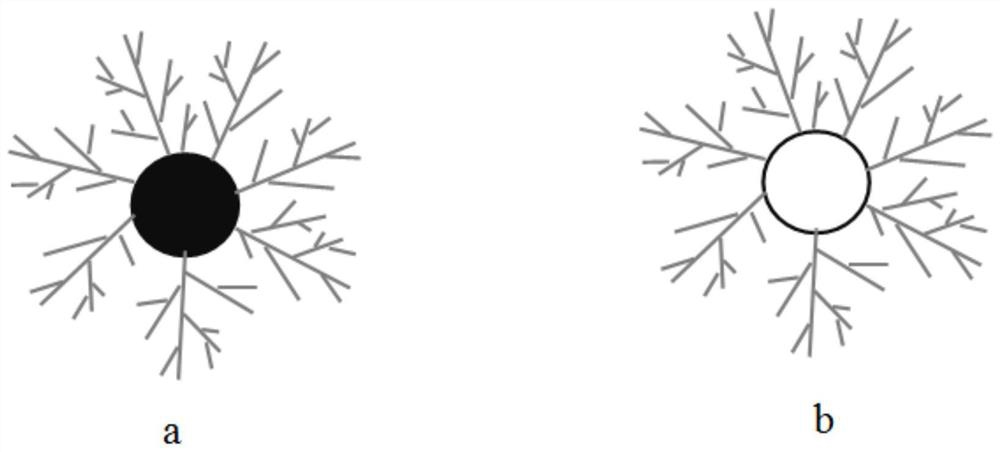

[0035] In the present invention, the carbon particulate material coated with a silica layer on the surface may be a graphite particulate material or other carbon particulate material coated with a silica layer on the surface, which can be obtained commercially, or can be obtained according to existing There are various methods to prepare. According to a specific embodiment of the present invention, the graphite particle material whose surface is coated with a silica layer is prepared according to the following method: 10 g of acid-treated graphite particles are dispersed in 80-120 mL of pH 8-13 In ammonia water, add 1-3 mL of silane coupling agent for functionalization treatment for 3-8 h, then add 80-120 mL of ethanol and dropwise add 20-40 mL of ethanol solution containing 1-5 wt% silicon precursor material III, the silicon precursor material Ⅲ is a compound that can be hydrolyzed into silica, the reaction is stirred at room temperature for 5-20 hours, the solid-liquid is se...

Embodiment 1

[0052] S1. Disperse 1 g of polystyrene balls in 100 mL of ammonia water with a pH value of 10, add 2 mL of silane coupling agent (MPS) for functionalization for 5 h, add 100 mL of ethanol, drop 30 mL of ethanol solution containing 6% TEOS, and stir at room temperature 10h, solid-liquid separation, the obtained solid product was dried at 60 °C, then heated to 600 °C and treated in an air atmosphere for 30 min to obtain hollow SiO 2 Microspheres.

[0053] The above hollow SiO 2 The microspheres were dispersed in 50mL ethanol-water mixed solution (the volume ratio of ethanol and water was 2.3:1, the same below), 1.5mL ammonia water (concentration was 5wt%, the same below) and 0.5mL ethylenediamine were added to mix well, and then added 0.5 g of 3-aminophenol, 2 mL of formaldehyde and 2 mL of ethyl silicate were vigorously stirred (150 rpm) for 5 h at 40 °C, centrifuged, and the obtained solid product was dried at 60 °C for 2 h to obtain a hollow surface with fractal structure. ...

Embodiment 2

[0057] S1. Disperse 10 g of acid-treated graphite particles in 100 mL of ammonia water with pH 8, add 2 mL of silane coupling agent (MPS) for functionalization for 5 h, add 100 mL of ethanol, and then dropwise add 30 mL of an ethanol solution containing 3wt% TEOS. Stir at room temperature for 10 h. Solid-liquid separation, and the obtained solid product is dried to obtain a graphite particle material (denoted as SiO) coated with a silica layer on the surface. 2 / C microspheres).

[0058] The above SiO 2 / C microspheres were dispersed in 50 mL of ethanol-water mixture, 2.5 mL of ammonia water and 0.5 mL of ethylenediamine were added to mix well, then 1 g of 3-aminophenol, 2 mL of formaldehyde and 4 mL of ethyl silicate were added, and vigorous stirring at 40°C (30 rpm ) reacted for 6 h, centrifuged, and the obtained solid product was dried at 60° C. for 3 h to obtain a silica / phenolic composite material with a fractal structure on the surface of the graphite core.

[0059] S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com