Preparation method of copper-coated porous silicon composite material and composite electrode for lithium ion battery

A composite material, porous silicon technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of volume expansion of electrode materials, and achieve the effect of improving electrical conductivity, high reversible capacity and capacity retention rate, and high reversible capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

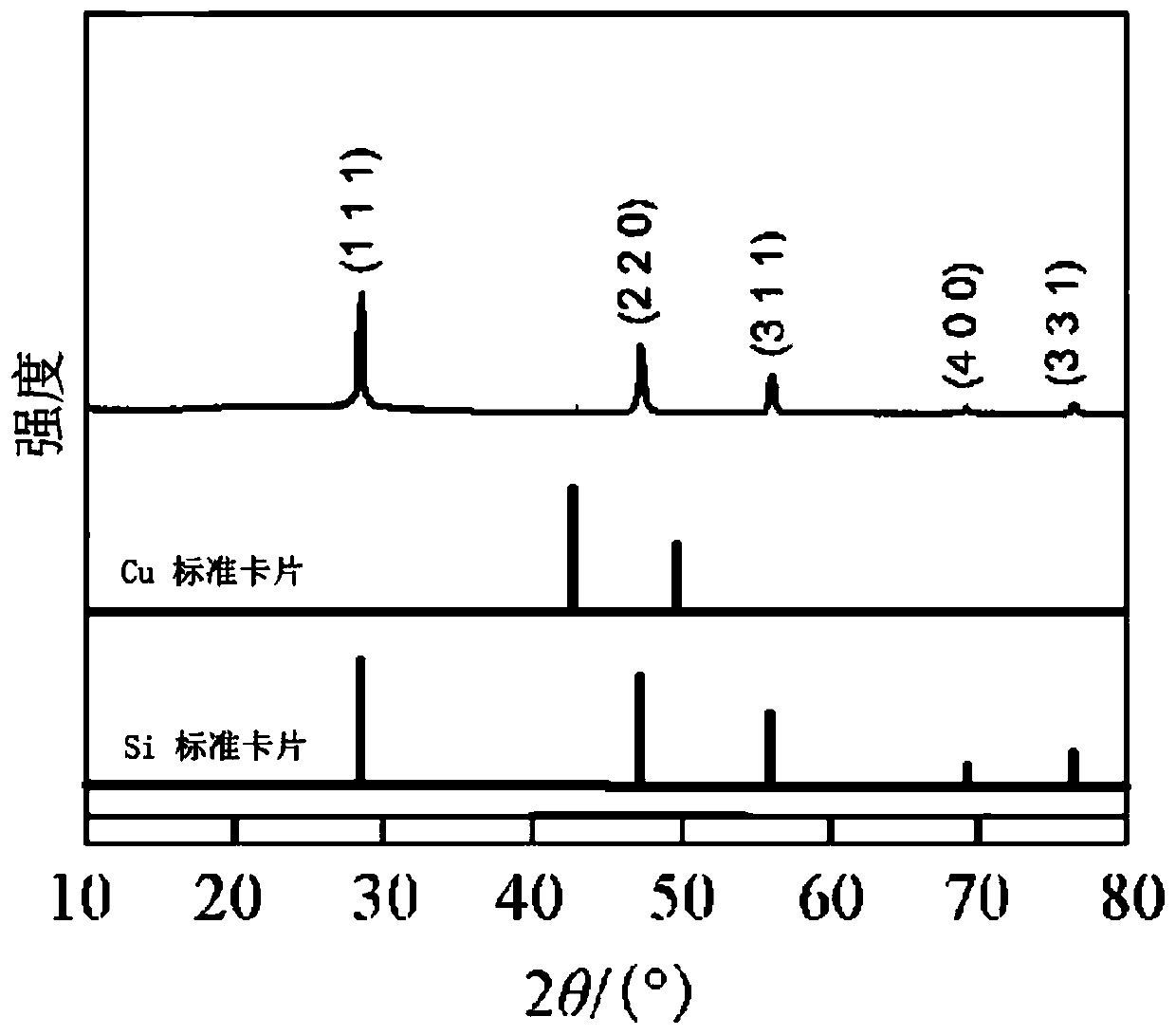

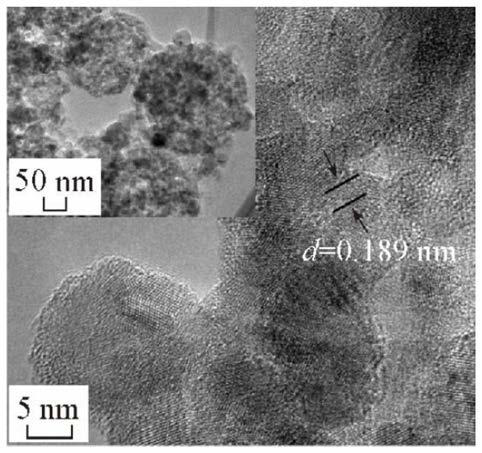

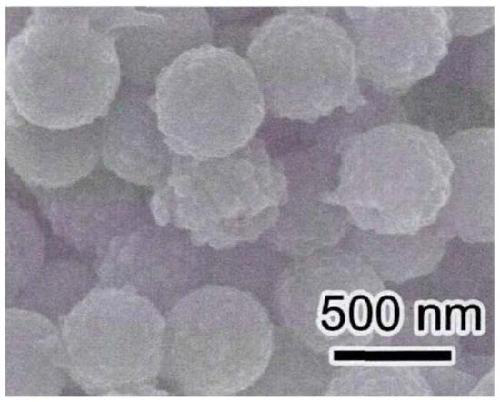

[0025] As introduced in the background art, solving the volume expansion of silicon materials during charging and discharging is an urgent problem in this field. The inventors of the present invention have conducted research on the above-mentioned problems and proposed a method for preparing a copper-coated porous silicon composite material, which includes the following steps: S1, preparing a precursor comprising silicon dioxide and copper oxide; S2, using magnesia thermal reduction The precursor is treated to reduce silica and copper oxide to form a porous silicon and copper cladding layer.

[0026] Using the above-mentioned preparation method of the present invention, the generation of SEI film can be effectively suppressed by coating copper on the porous silicon surface, and the conductivity of the above-mentioned composite material can be improved at the same time, so that it can be used as an electrode material to obtain higher first-time reversible capacity and Coulomb e...

Embodiment 1

[0041] The preparation method of the copper-coated porous silicon composite material provided in this embodiment comprises the following steps:

[0042] In a 100mL beaker, a certain amount of SiO 2 Mix with 50ml deionized water and ultrasonically disperse for 30min. According to the initial molar ratio of Si / Cu of 10:1, add a certain amount of 0.5mol / L CuSO drop by drop 4 ·5H 2 O solution, stir for 1 hour to mix the solution evenly, then add 8mol / L ammonia water drop by drop, a light blue basic copper sulfate precipitate is formed, continue to add ammonia water until the precipitate is completely dissolved, and a dark blue copper ammonia complex is formed. solution of ions. Weigh a certain amount of NaOH according to the Cu / Na molar ratio of 1:3, dissolve NaOH in 30mL of absolute ethanol, add it dropwise to the reaction system, stir at room temperature for 2h, then place it in a water bath at 30°C for 24h . After the reaction, it was filtered with suction, washed repeated...

Embodiment 2

[0045] The difference between the preparation method provided by this embodiment and Example 1 is:

[0046] Add CuSO dropwise at an initial Si / Cu molar ratio of 20:1 4 ·5H 2 O solution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com