Silicon carbon composite material for lithium ion battery and preparation method thereof

A technology of silicon-carbon composite materials and lithium-ion batteries, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of large layer spacing, complex and cumbersome preparation process, and difficulty in industrial production, and achieve mild reaction conditions and easy preparation The process is simple and the effect of improving cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] 1. Calculated according to the mass ratio, that is, the ratio of single-wall carbon tube: surfactant: solvent is 1:2:1000, disperse 0.02g single-wall carbon tube and 0.04g CMC into 20ml water, mix and stir for 2 hours, then add 0.15 g of silicon oxide powder and 2.85 g of graphite powder were transferred to a ball mill jar, rotated at high speed for 3 hours, and then dried to obtain a precursor.

[0029] The obtained precursor was heated to 600 °C at a rate of 2 °C / min in an argon atmosphere and kept at a constant temperature for 4 hours, and then naturally cooled to room temperature to obtain a single-walled carbon tube composite silicon-carbon material SWCNT / SiC.

[0030] 2. Performance analysis

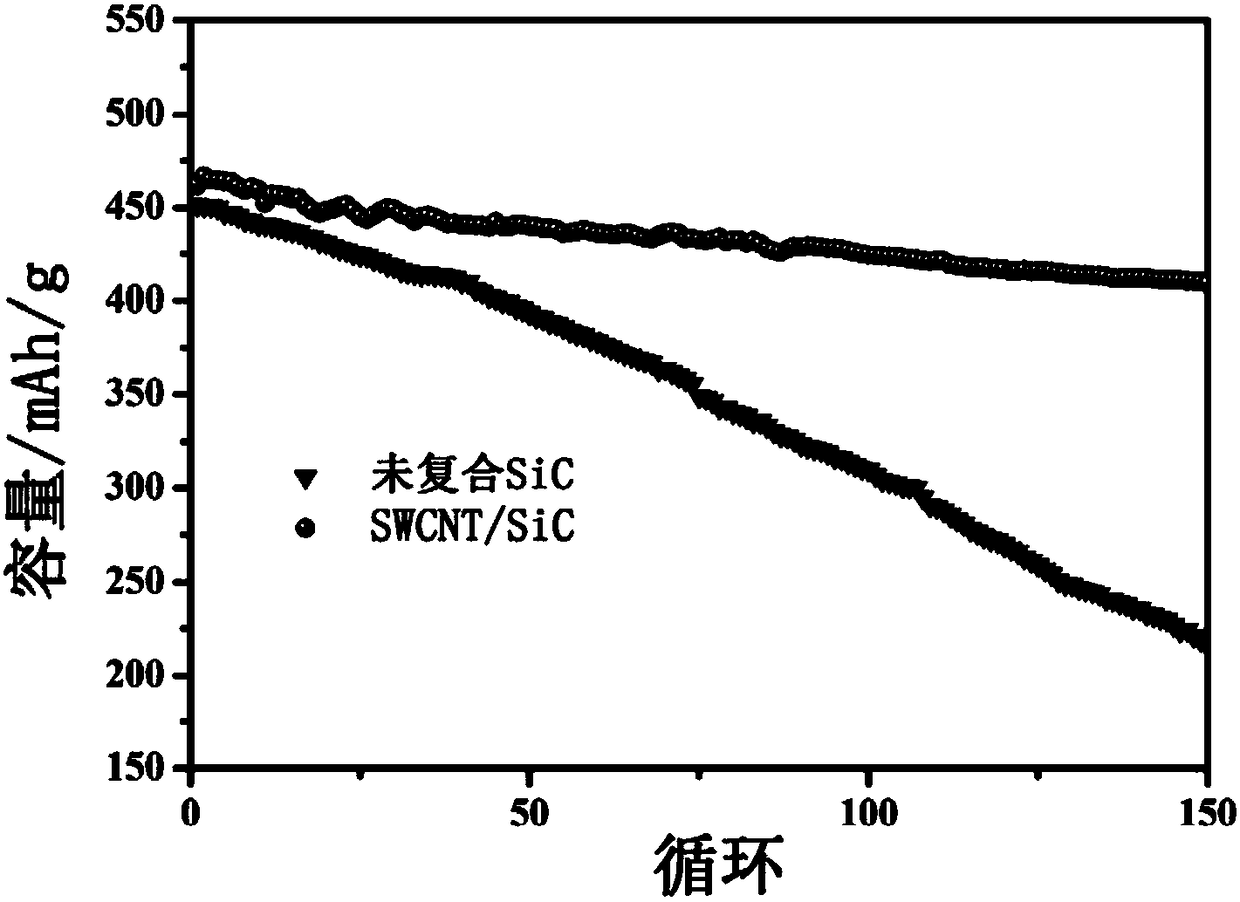

[0031] Such as figure 1 As shown, the lithium-ion battery negative electrode composite material SWCNT / SiC (wherein the proportion of silicon oxide is 5%) obtained in Example 1, that is, the single-walled carbon tube composite silicon-carbon negative electrode material has v...

Embodiment 2

[0034] Calculated by mass ratio, that is, the ratio of single-walled carbon tubes:surfactant:solvent is 1:1.5:1500, disperse 0.02g single-walled carbon tubes and 0.03g PVP into 30ml ethanol, mix and stir for 3 hours, then add 0.25g The silicon oxide powder and 4.75g graphite powder were transferred to a ball mill jar, rotated at a high speed for 4 hours, and then dried to obtain a precursor.

[0035] The obtained precursor was heated up to 500°C at a rate of 4°C / min in an argon atmosphere and kept at a constant temperature for 5 hours, and then naturally cooled to room temperature to obtain a single-walled carbon tube composite silicon-carbon material.

Embodiment 3

[0037] Calculated by mass ratio, that is, the ratio of multi-walled carbon tubes:surfactant:solvent is 1:1:1200, disperse 0.02g of multi-walled carbon tubes and 0.02g of CMC into 24ml of water, mix and stir for 2h, add 0.3g of oxidation The silica powder and 2.7g graphite powder were transferred to a ball mill jar, rotated at a high speed for 4 hours, and then dried to obtain a precursor.

[0038] The obtained precursor was heated to 550°C at a rate of 3°C / min in a helium atmosphere and kept at a constant temperature for 6 hours, and then naturally cooled to room temperature to obtain a multi-walled carbon tube composite silicon-carbon material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com